† Corresponding author. E-mail:

The defects and electrical properties in Al-implanted 4H-SiC after activation annealing (1600 °C–1800 °C) are investigated. High temperature annealing can reduce the ion implantation-induced damage effectively, but it may induce extended defects as well, which are investigated by using Rutherford backscattering spectroscopy (RBS/C), secondary ion mass spectroscopy (SIMS), and transmission electron microscopy (TEM) analyses. According to the ratio of the channeled intensity to the random intensity in the region just below the surface scattering peak (Xmin) and RBS/C analysis results, the ion implantation-induced surface damages can be effectively reduced by annealing at temperatures higher than 1700 °C, while the defects near the bottom of the ion-implanted layer cannot be completely annealed out by high temperature and long time annealing process, which is also demonstrated by SIMS and TEM analyses. Referring to the defect model and TEM analyses, an optimized annealing condition can be achieved through balancing the generation and elimination of carbon vacancies in the ion implanted layers. Furthermore, the electrical and surface properties are also analyzed, and the hole concentration, mobility, and resistivity are obtained through the Hall effect. The optimized activation annealing conditions of 1800 °C/5 min are achieved, under which the lower defects and acceptable electrical properties are obtained.

Semiconductor material, SiC, is attractive for the applications in high power, high temperature, high frequency, and high reliability device due to its exceptional properties.[1–8] P-type doping of 4H-SiC using ion implantation and high temperature activation annealing is the key process in the fabrication of SiC devices.[2,3] Compared with boron (B), aluminum (Al) has a shallow acceptor level and a strong tendency to occupy atomic sites in the silicon (Si) sublattice, which makes Al+ ion implantation more suitable for the production of heavily doped layers.[9–14] However, a great challenge exists in the effective doping of Al, because high energy of Al ion implantation inevitably produces defects and lattice disorder. Although redistribution of the implanted dopants and partial ion-induced damages can be reduced by high temperature implantation followed by high temperature annealing, not all the damages could be annealed out by higher temperature annealing, such as residual damages (distortion of lattice, vacancies and interstitials) and extended defects, because of dynamic defect recovery and generation in the activation annealing process.[13–26] And it was reported that the formation of extended defects in the implanted layers and the interfacial dislocations of the ion-implanted layer can occur in the annealing process.[15,20,23] Such high residual damages and extended defects of the implanted layers will greatly affect the electrical performance and reliability of SiC device, such as the mobility in MOSFETs and leakage current in PIN diodes. How to suppress the generation and distribution of these defects is still an open issue in the study of this subject. Therefore, a clearer understanding of the recovery, formation and distribution of the defects in the Al-implanted layers during the implantation and annealing processing is beneficial to obtaining the better electrical properties in Al-implanted 4H-SiC through optimization of activation annealing conditions.

In this paper, the defects and electrical properties in Al-implanted 4H-SiC after high-temperature activation annealing (1600 °C–1800 °C) are investigated. The ion implantation-induced damages and the extended defects after the annealing process are investigated by using Rutherford backscattering spectroscopy (RBS/C), secondary ion mass spectroscopy (SIMS), transmission electron microscopy (TEM) analyses. The optimized activation annealing conditions are achieved, under which the lower defects and acceptable electrical properties are achieved and demonstrated by the Hall effect measurement.

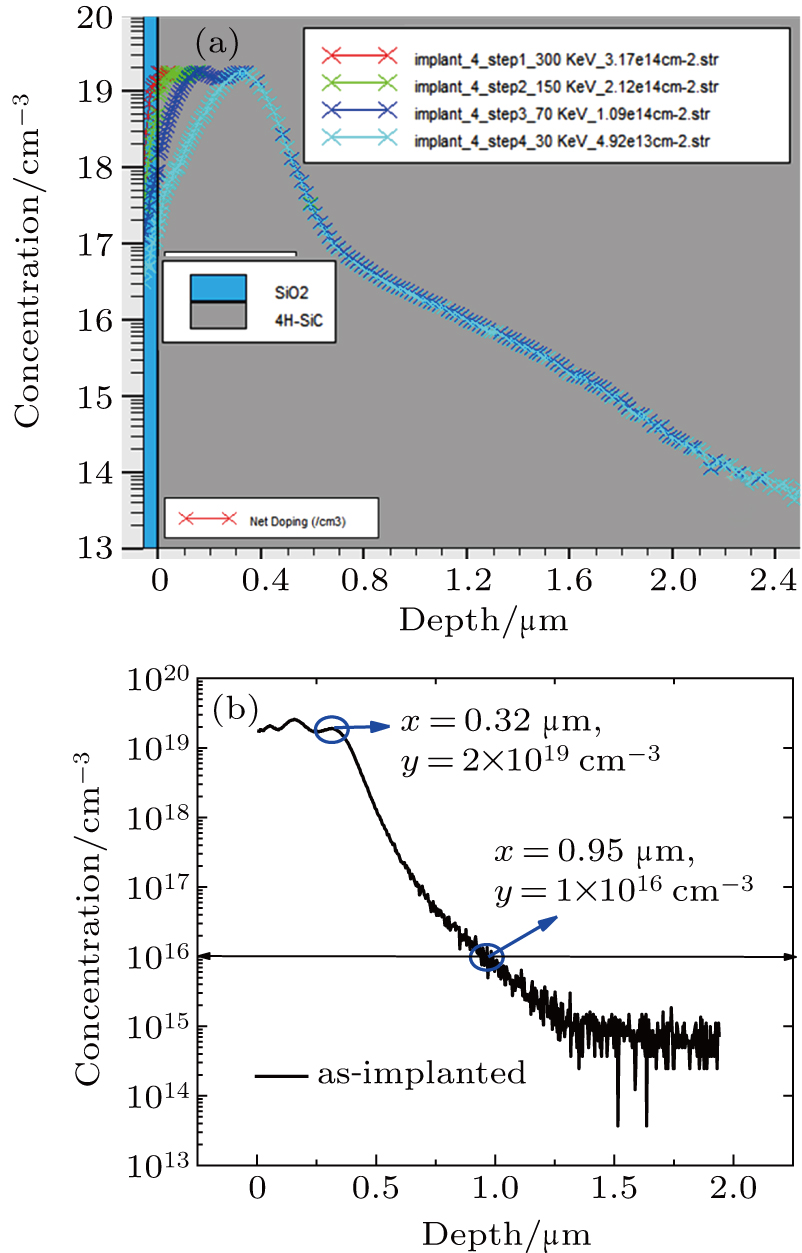

Multiple-energy Al implantations were performed on n-type, 4° off the (0001) oriented 4H-SiC epilayer at a doping concentration of 1×1016 cm−3. Hot implantation (500 °C) was used to hinder amorphization and improve the quality of crystalline in Al-implanted 4H-SiC. As seen from Fig.

Post-implantation annealing was processed at 1600 °C–1800 °C with a protective carbon capping layer. Effects on Al ion implantation on n-type 4H-SiC followed by annealing at various temperatures was studied by using RBS/C, SIMS, TEM, and atomic force microscope (AFM) analyses. Transmission line model (TLM) and Hall effect measurements are also conducted to analyze the electrical properties.

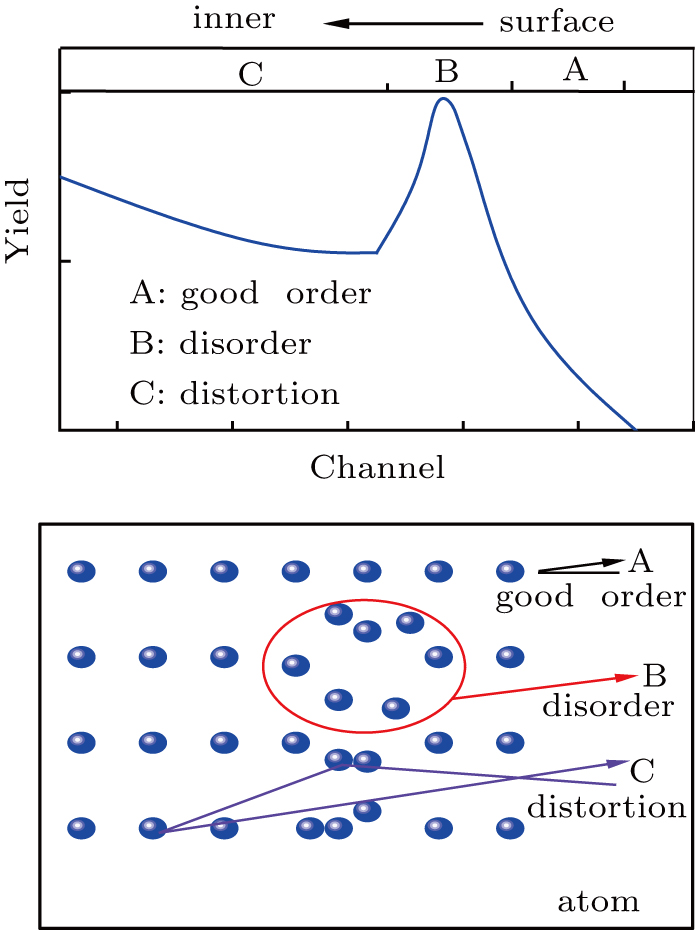

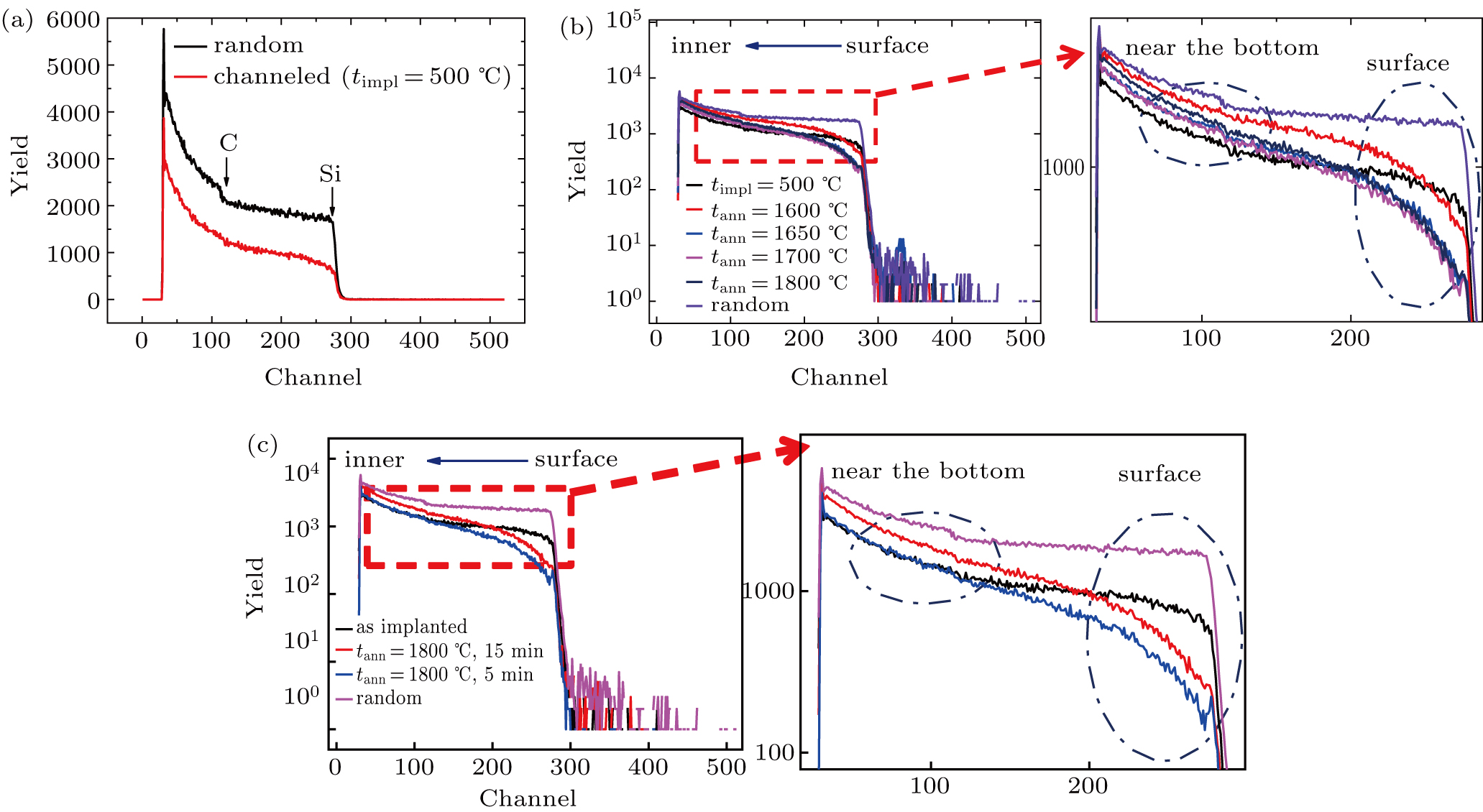

As one of the most common surface analytical techniques, Rutherford backscattering spectrometry along a low index crystallographic direction or channel (RBS/C) is sensitive to very small atomic displacements from the crystalline lattice sites. The RBS/C interaction yield is strongly influenced by the crystal disorder and crystal orientation, which makes the technique unique for the analysis of ion implantation damage in single-crystal films and wafers. As shown in Fig.

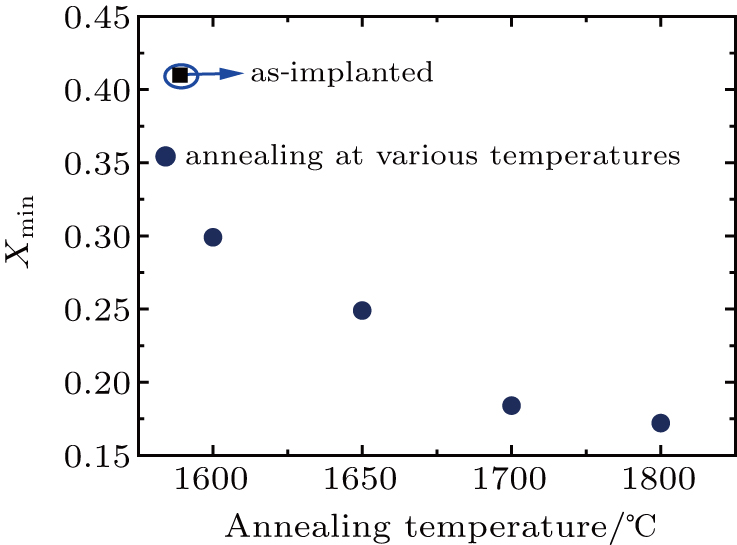

The Xmin refers to the ratio of the channeled intensity to the random intensity in the region just below the surface scattering peak. It yields information about the crystallinity in the near surface of the sample (the first 3 nm–15 nm in depth), which is related to the surface damage, contamination and the existence of oxides. Figure

| Fig. 3. Variation of Xmin (160° detector ) with temperature of implanted samples before and after activation annealing for 15 min. |

From Figs.

| Fig. 4. Overlays of implanted samples (a) before and (b) after activation annealing at various temperatures for 15 min and (c) at 1800 °C and different annealing times. |

In the amplified regions on the right in Figs.

In order to reduce the defects both near the surface and bottom of the ion-implanted layer in high temperature annealing process, the annealing is carried under the conditions of 1800 °C for 5 min and 15 min. It is shown in the amplified region on the right in Fig.

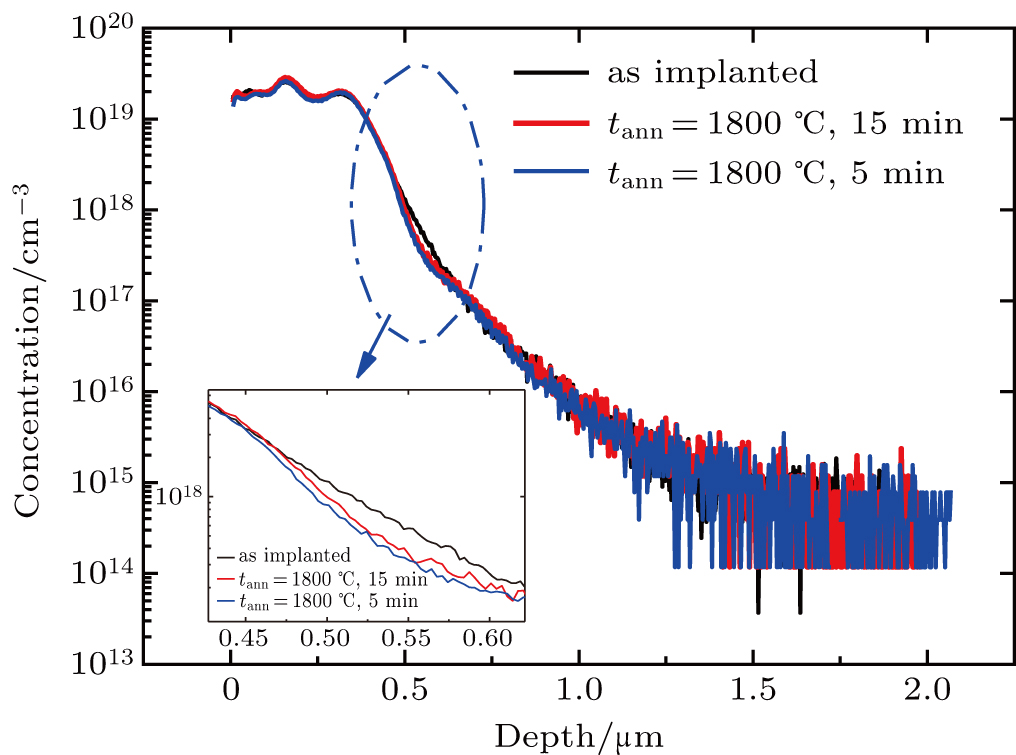

In Fig.

| Fig. 5. Profiles of implanted atoms before and after annealing at 1800 °C, 15 min/5 min by SIMS after removing protective carbon capping layer and 60-nm-thick sacrificial oxidation SiO2 layer. |

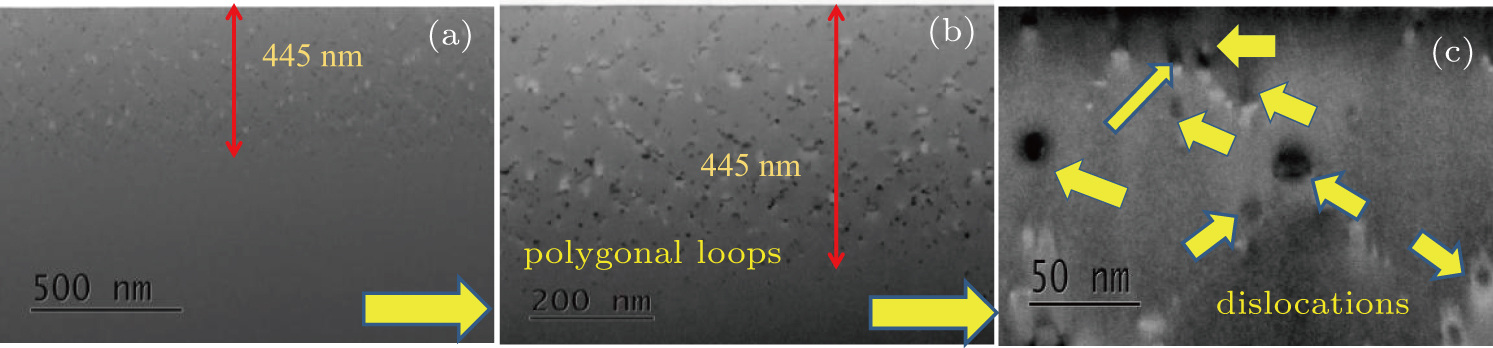

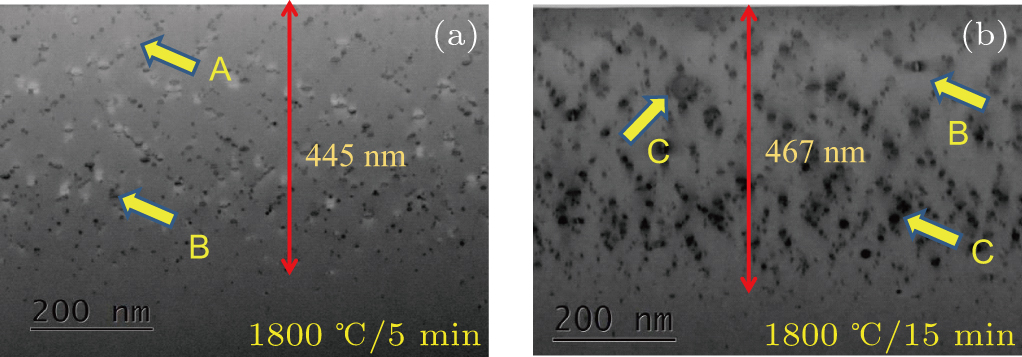

From the above results of the RBS-C technique, we find quite a low level of the residual disorders and extended defects in the implanted and annealed SiC layers. As a complement to RBS/C, cross section samples in the implanted region are prepared. And the lattice structure of the implanted layer and the annealed layerare also measured with TEM, which is equipped with an FEI Talos F200 transmission electron microscope at 200 kV. The samples for TEM are cross-sectioned, prepared by focused ion beam (FIB).

Figure

| Fig. 6. Cross-sectional micrograph in Al-implanted region by (a) 1800 °C/5 min annealing and (b) 1800 °C/15 min annealing. |

To obtain the mechanisms responsible for the formation and elimination of extended defects, according to the previous defect theory,[15,21–23] the defect model in Al-implanted 4H-SiC layer is also investigated. The high temperature activation annealing is the process of replacing the implanted Al atoms with Si. During the activation annealing, most of dopants are activated, and the ion-induced damages are recovered because of the recrystallization of the annealed samples. As seen from Fig.

As seen from Table

| Table 1.

Values obtained by Hall-effect and TLM measurements for p-type 4H-SiC samples at room temperature (RT). . |

Furthermore, the surface roughness values of Al-implanted samples before and after activation annealing at various temperatures are measured by AFM. We use the 5-point average of the large area implantation and activation annealing sample. The results in Table

| Table 2.

Average surface roughness values of Al-implanted 4H-SiC followed by annealing at various temperatures. . |

The defects and electrical properties in Al-implanted 4H-SiC after activation annealing (1600 °C–1800 °C) are investigated. High temperature annealing can reduce the ion implantation-induced damage effectively, but it may induce extended defects at the same time. How to suppress the generation and distribution of the defects is very critical. According to Xmin and RBS/C analysis, the ion implantation-induced surface damage could be effectively reduced by annealing at temperatures higher than 1700 °C, demonstrating that the damage near the surface region is greatly affected by annealing temperature. However, the effect of annealing temperature on the suppression of the defects near the bottom region is not obvious. The longer thermal annealing time (such as 15 min) may induce new extended defects near the bottom of the ion-implanted layers, which is mainly due to dynamic defect recovery and generation in the activation annealing process. Therefore, the annealing time is another key factor influencing the generation of extended defects.

From the RBS/C, SIMS, TEM, and defect model analysis, two sources of the residual defects are existent in the ion-implanted layer after annealing: one is the defects generated in ion implantation process, which cannot be completely annealed out by high temperature annealing process, and the other is the extended defects induced during activation annealing, especially for the longer activation annealing time. It can be inferred that the generation and elimination density of extended defects in the ion implanted devices are closely related to annealing conditions. The surface roughness values of all the samples after annealing are not obviously deteriorated due to the existence of an effective protective carbon capping layer. The optimized activation annealing conditions of 1800 °C/5 min are achieved, and thus the lower defects (near the surface and bottom region) and acceptable electrical properties are obtained, which are conducive to the application of numerous SiC-based devices.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] |