† Corresponding author. E-mail:

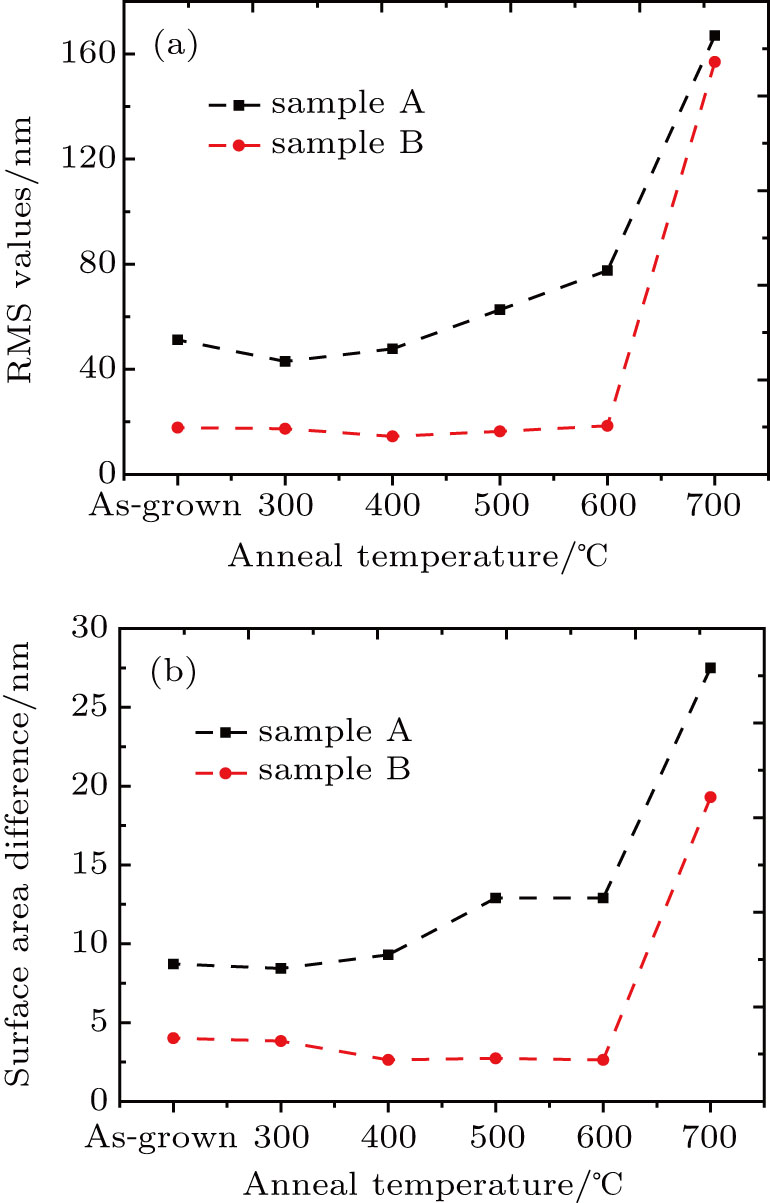

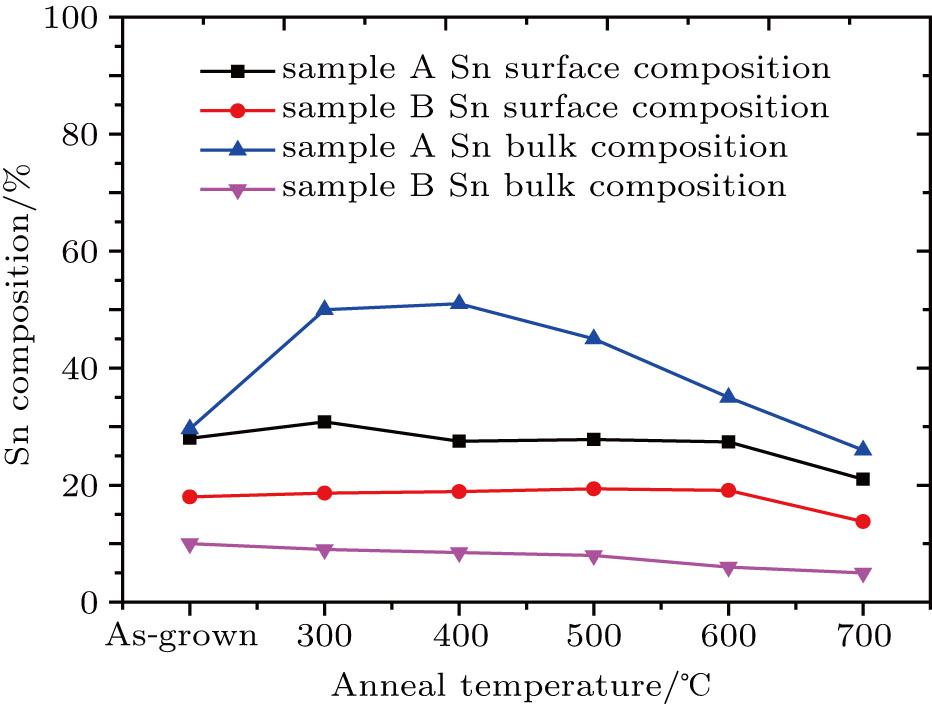

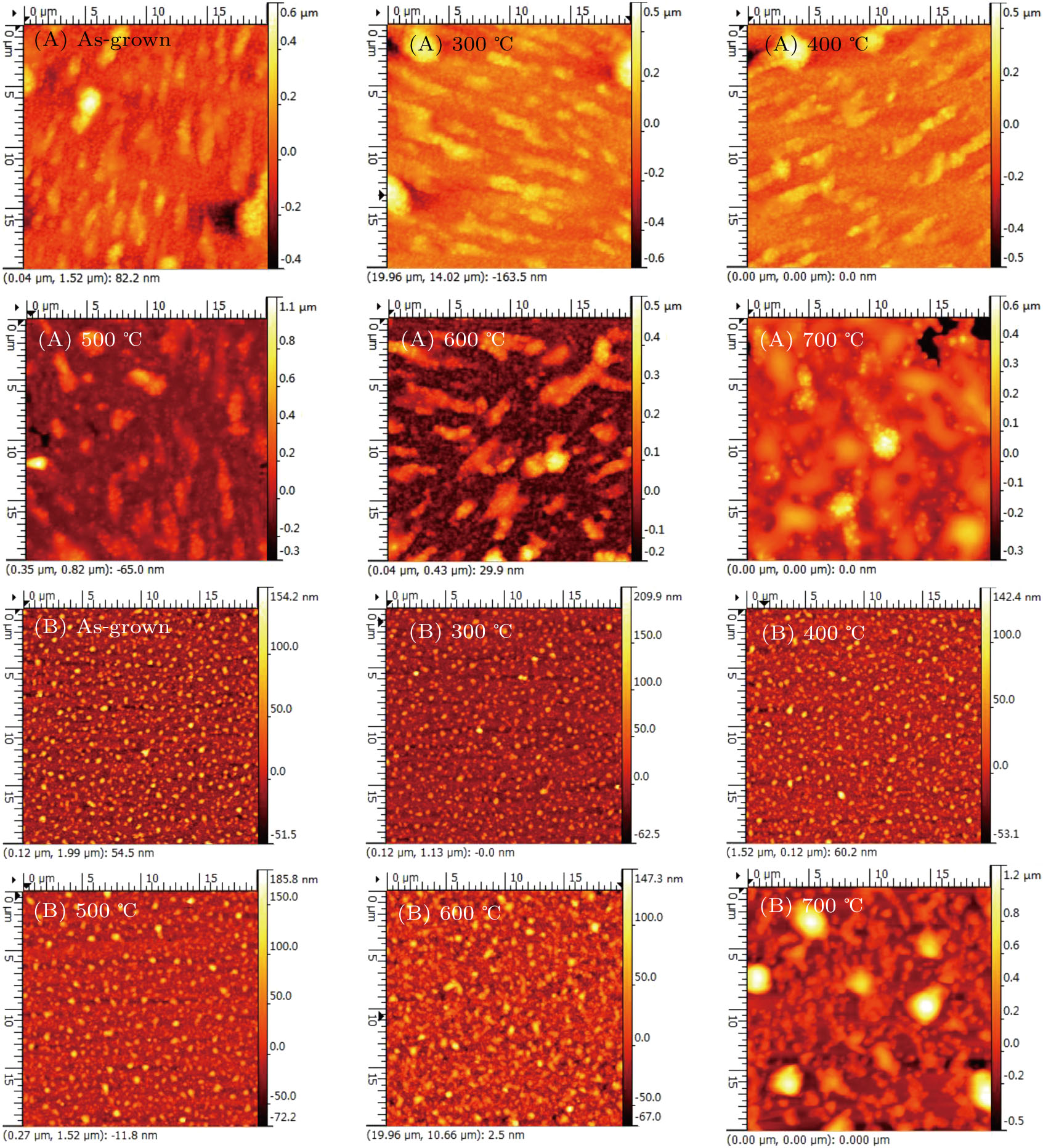

Germanium-tin films with rather high Sn content (28.04% and 29.61%) are deposited directly on Si (100) and Si (111) substrates by magnetron sputtering. The mechanism of the effect of rapid thermal annealing on the Sn surface segregation of Ge1 −xSnx films is investigated by x-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM). The x-ray diffraction (XRD) is also performed to determine the crystallinities of the Ge1−xSnx films. The experimental results indicate that root mean square (RMS) values of the annealed samples are comparatively small and have no noticeable changes for the as-grown sample when annealing temperature is below 400 °C. The diameter of the Sn three-dimensional (3D) island becomes larger than that of an as-grown sample when the annealing temperature is 700 °C. In addition, the Sn surface composition decreases when annealing temperature ranges from 400 °C to 700 °C. However, Sn bulk compositions in samples A and B are kept almost unchanged when the annealing temperature is below 600 °C. The present investigation demonstrates that the crystallinity of Ge1−xSnx/Si (111) has no obvious advantage over that of Ge1−xSnx/Si (100) and the selection of Si (111) substrate is an effective method to improve the surface morphologies of Ge1−xSnx films. We also find that more severe Sn surface segregation occurs in the Ge1−xSnx/Si (111) sample during annealing than in the Ge1−xSnx/Si (100) sample.

Germanium-tin (Ge1−xSnx) alloys are of great research interest due to the fact that their bandgap structures can be tuned by varying the Sn content, which are essential for Si-based monolithic optoelectronic.[1–5] Both the theoretical and experimental studies have shown that Ge, an indirect-gap semiconductor, can be transferred into a direct-gap semiconductor with Sn content up to 6% or 10%. Such alloys have higher carrier mobility than Ge, which makes it suitable to serve as channel material for metal oxide semiconductor (MOS) devices[6–11] and tunnel field-effect transistors (TEFT).[12,13] Besides, Ge1−xSnx-based optoelectronic devices are compatible with the traditional Si CMOS process. Numerous growth methods, such as chemical vapor deposition (CVD),[14–16] molecular beam epitaxy (MBE),[17–19] solid phase epitaxy (SPE),[20] and pulsed laser deposition (PLD)[21] have been employed to grow Ge1−xSnx films. Compared with other growth methods, magnetron sputtering is one of the low-cost methods to deposit thin-film material. The greatest advantage of the magnetron sputtering is that the deposition rate and growth temperature can be regulated separately, which leads to the depositions of Ge1−xSnx films at a reasonable growth rate at a growth temperature as low as 150 °C. In addition, Ge target and Sn target are much safer than poisonous gas precursors, such as GeH4, Ge2H6, SnD4 or SnCl4.

Several groups have grown Ge1−xSnx alloys by magnetron sputtering. Tsukamoto et al. have presented crystalline Ge1−xSnx films on Si (100) substrates by magnetron sputtering at high growth temperature and high deposition rate.[22] Zheng et al. have reported Ge1−xSnx p-i-n photodetectors with Ge1−xSnx film deposited by magnetron sputtering.[23]

Meanwhile, there are several challenges in fabricating Ge1−xSnx films mainly due to the very low solid solubility (less than 1% of Sn in Ge) and the large lattice mismatch between Sn and Ge (approximately 15%), which makes it hard to grow Ge1−xSnx films with low defect density. What is more, Sn has a low surface energy compared with Si and Ge, which leads to Sn segregating from the surface of Ge1−xSnx alloy during epitaxial growth and thermal annealing. At a high Sn composition, the Sn surface composition of the film becomes heterogeneous due to the fact that Sn tends to segregate from the surface of the film, which is harmful for the performance of the device. Good knowledge of the mechanism of the effects of post-annealing on the crystallinity and Sn surface segregation of Ge1−xSnx films is essential for fabricating the high-crystallinity Ge1−xSnx films. Therefore, it is urgently needed to fabricate Ge1−xSnx films with high Sn content and no Sn segregation.Tsukamoto et al. have investigated the Sn surface segregation with low Sn content during MBE epitaxial growth.[24] Sn migration control at high temperature due to high deposition speed was discussed.[25] The thermal stability of Ge1−xSnx films during annealing has also been reported.[26–29] Among these researches, Sn surface segregations of high-Sn- content Ge1−xSnx films on Si (100) and Si (111) have not been extensively investigated in detail.

In this study, we prepare Ge1−xSnx films on Si (100) and Si (111) substrates with Sn content up to 28.04% and 29.61%, followed by post-annealing at the temperature ranging from 300 °C to 700 °C. The effects of thermal rapid annealing on the Sn surface segregation of Ge1−xSnx films on Si (100) and Si (111) are investigated in detail. Several characterization methods are employed to discuss the crystallinities and Sn surface segregations of Ge1−xSnx films, including x-ray diffraction (XRD), atomic force microscopy (AFM), and x-ray photoelectron spectroscopy (XPS).

The Ge1−xSnx thin films were deposited directly on 4-inch n-type Si substrates by magnetron sputtering with using high-purity Ge target (99.999% purity, 50.8 mm diameter) and Sn target (99.999% purity, 50.8 mm diameter). The distance between the targets and substrates was about 150 mm. Prior to depositing the thin films, Si (100) and Si (111) substrates were cleaned sequentially by acetone, ethanol and immersed in a 1:10 = HF:H2O for 1 min to remove the native oxides from the Si substrate. Finally, the substrates were rinsed in deionized water and dried by pure N2. After loading them into the growth chamber, the chamber was pumped down to

To improve the crystallinities of the films, the 4-inch (1 inch = 2.54 cm) Si substrates along with the Ge1−xSnx films were cut into pieces for different thermal annealing temperatures ranging from 300 °C to 700 °C for 30 s in the RTP150. Pure N2 was chosen as the annealing atmosphere to avoid any effect originating from O2. The as-grown Sn mole fractions of samples were approximately 28.04% and 29.61%, respectively, as determined by XPS. In order to verify the effects of post-annealing on the crystallinity and Sn surface segregation of Ge1−xSnx films grown on Si substrates, AFM images and XRD scans were conducted.

Information about crystal orientation, Ge1−xSnx layer thickness, annealing temperature, FWHM (°), Raman peak shift

| Table 1.

Crystal orientations, values of Ge1−xSnx layer thickness (nm), annealing temperature, FWHM (°), Raman peak shift |

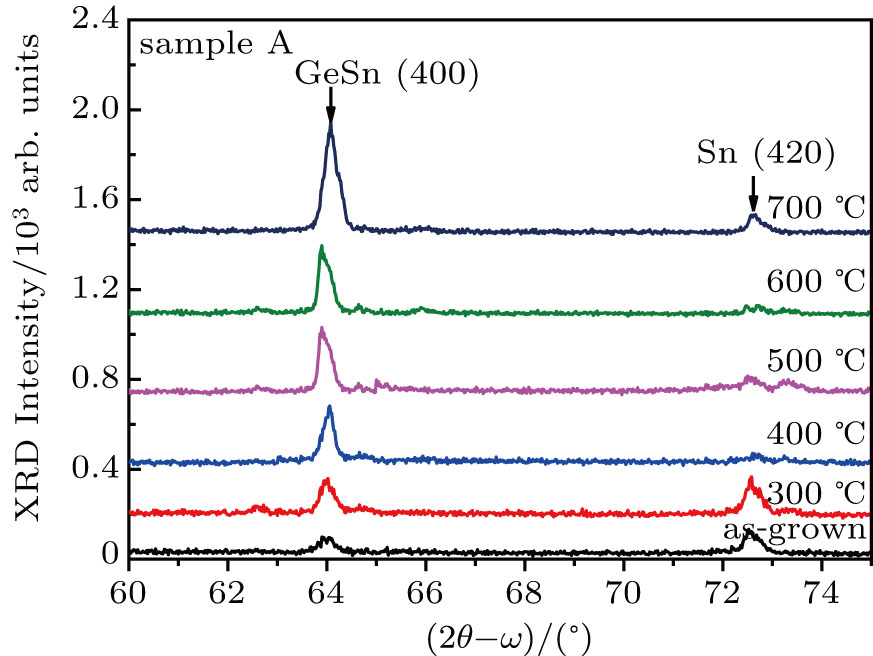

The XRD measurements of the Ge1−xSnx thin films with high Sn compositions are performed to investigate the effects of the post-annealing on the crystallinity of the Ge1−xSnx films. The XRD curves of sample A annealed at various temperatures are shown in Fig.

| Fig. 2. (color online) XRD patterns of the crystalline Ge1−xSnx/Si (111) film after RTA at 300 °C, 400 °C, 500 °C, 600 °C, and 700 °C for 30 s. |

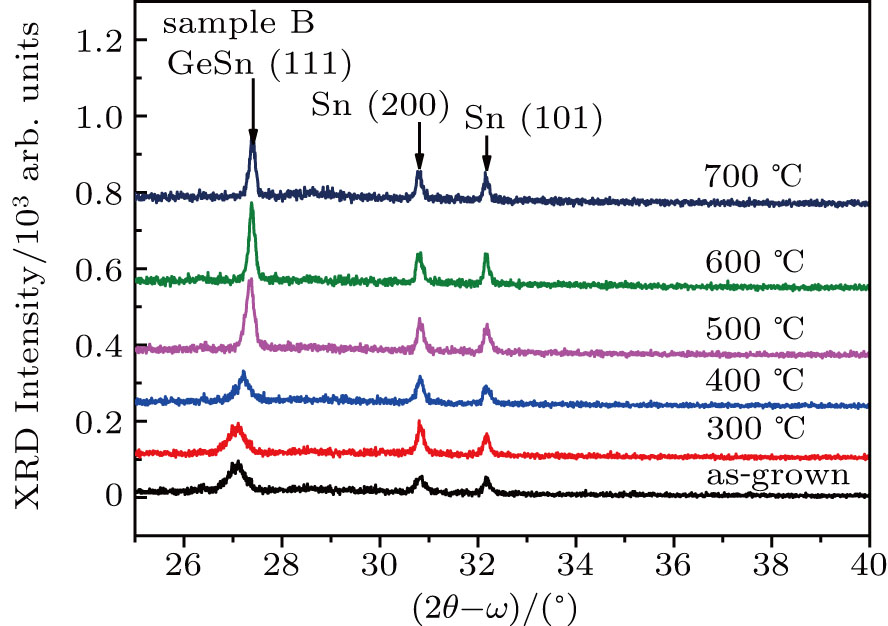

The XRD curves of the sample B annealed at various temperatures are shown in Fig.

| Fig. 3. (color online) XRD patterns of the crystalline Ge1−xSnx/Si (111) film after RTA at 300 °C, 400 °C, 500 °C, 600 °C, and 700 °C for 30 s. |

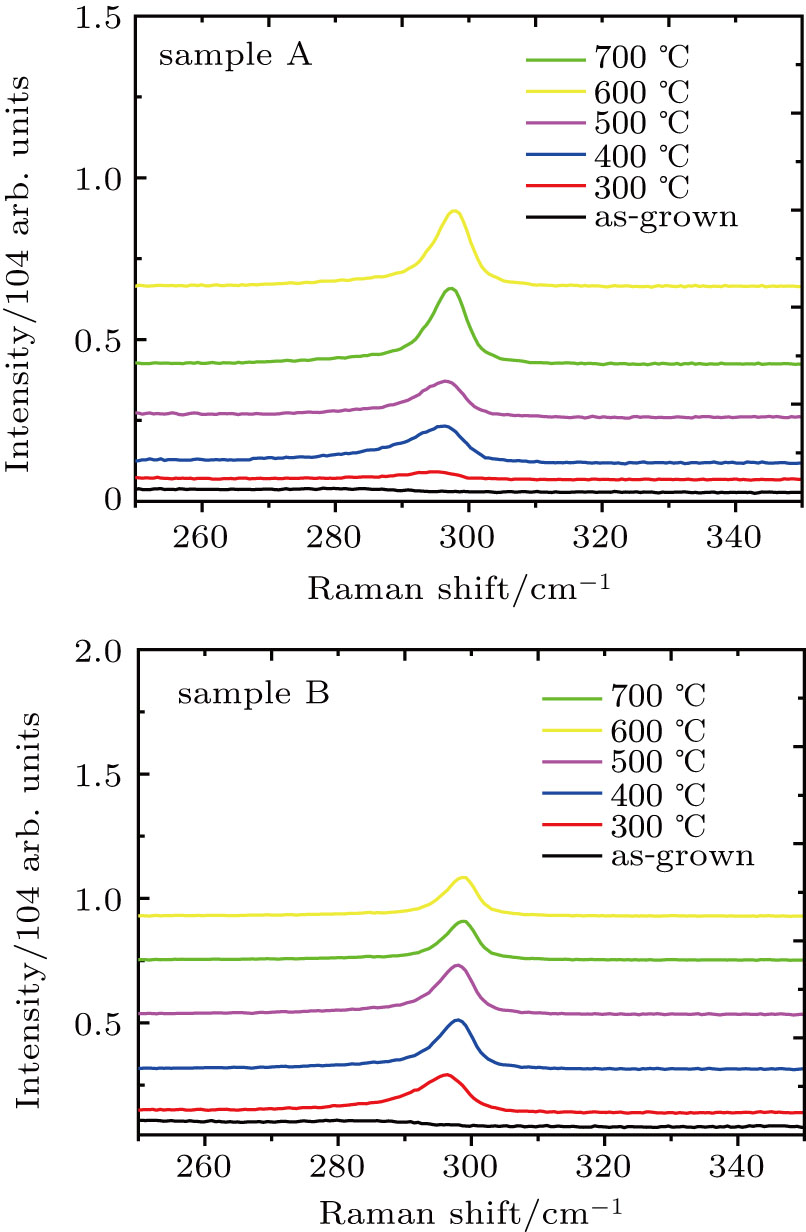

| Fig. 4. (color online) Raman spectra of sample A and B annealed at the temperatures ranging from 300 °C–700 °C. |

The peak shift compared with Ge–Ge Raman peak (300 cm−1) from bulk Ge can be calculated from the following equation[30–32]

As the thickness of GeSn layer is far beyond the critical thickness,[32] the Sn composition can be calculated from Eqs. (

Thus, Sn bulk composition of the Ge1−xSnx film can be obtained from

The effects of post-annealing on the surface morphology and Sn surface composition are identified by AFM and XPS, respectively.

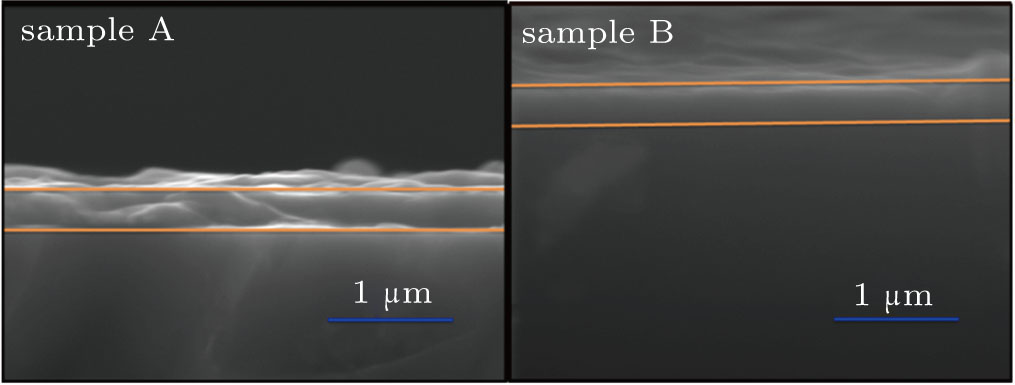

Typical

| Fig. 5. (color online) AFM surface scans (

|

Figure

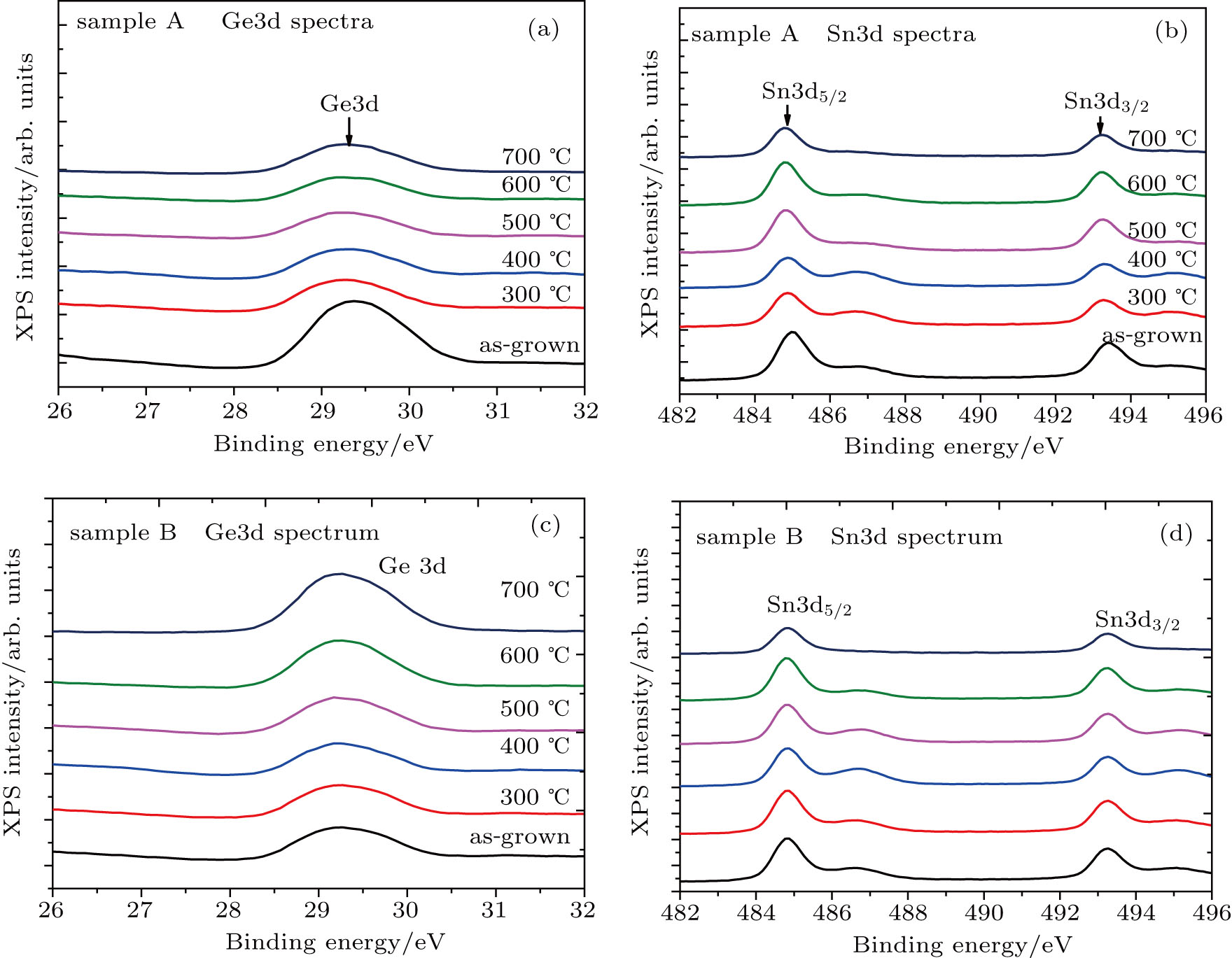

Therefore, it can be assumed that the Sn surface composition of the film will increase at a higher annealing temperature. In order to further verify this assumption, extensive XPS measurement is carried out and it is a more quantized method to determine the changes of near surface composition in the thin films. Monochromatic carbon (C) is used to calibrate the position of binding energy. In order to remove any contaminants from the surfaces of the Ge1−xSnx layers, all the samples are placed into a K-Alpha XPS system after being etched for 30 s. The XPS spectra of Ge3d and Sn3d before and after being annealed at different temperatures are plotted in Fig.

Contrary to what we assumed, the Sn surface compositions of the films decrease with annealing temperature increasing when the annealing temperature is above 300 °C. For sample A annealed at 400 °C, 500 °C, and 600 °C, Sn surface compositions are 27.5%, 27.8%, and 27.6% (Fig.

In this work, crystalline Ge1−xSnx films are grown on Si (100) and Si (111) substrate under 150 °C by magnetron sputtering. The XRD scans are performed to determine the crystallinities of Ge1−xSnx/Si (111) and Ge1−xSnx/Si (100). It is concluded that the crystallinity of Ge1−xSnx/Si (111) has no obvious advantage over that of Ge1−xSnx/Si (100). The thermal stability of the surface morphology of Ge1−xSnx/Si (111) is better than that of Ge1−xSnx/Si (100) and Sn surface composition decreases when annealing temperatures range from 400 °C to 700 °C. A higher annealing temperature may contribute to the formation of Sn desorption. However, Sn bulk compositions in samples A and B are kept almost unchanged when the annealing temperature is below 600 °C. Furthermore, more severe Sn surface segregation occurs in the Ge1−xSnx/Si (111) sample during annealing than in the Ge1−xSnx/Si (100) sample. These results reveal that an increasing annealing temperature causes Sn to form clusters and contributes to the Sn atoms moving to the surface of Ge1−xSnx thin film. Restricting the Sn atoms moving to the surface can restrain the Sn surface segregation.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] |