† Corresponding author. E-mail:

‡ Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61204091, 61404177, 51402366, and U1201254) and the Science and Technology Planning Project of Guangdong Province, China (Grant No. 2015B010132006).

In this study, the high performance of InGaN/GaN multiple quantum well light-emitting diodes (LEDs) with Al-doped ZnO (AZO) transparent conductive layers (TCLs) has been demonstrated. The AZO-TCLs were fabricated on the n+-InGaN contact layer by metal organic chemical vapor deposition (MOCVD) using H2O as an oxidizer at temperatures as low as 400 °C without any post-deposition annealing. It shows a high transparency (98%), low resistivity (510−4 Ω·cm), and an epitaxial-like excellent interface on p-GaN with an n+-InGaN contact layer. A forward voltage of 2.82 V @ 20 mA was obtained. Most importantly, the power efficiencies can be markedly improved by 53.8%@20 mA current injection and 39.6%@350 mA current injection compared with conventional LEDs with indium tin oxide TCL (LED-III), and by 28.8%@20 mA current injection and 4.92%@350 mA current injection compared with LEDs with AZO-TCL prepared by MOCVD using O2 as an oxidizer (LED-II), respectively. The results indicate that the AZO-TCL grown by MOCVD using H2O as an oxidizer is a promising TCL for a low-cost and high-efficiency GaN-based LED application.

ZnO-based transparent conductive layers (TCLs) have been widely investigated to replace indium tin oxide (ITO) in high-efficiency GaN-based light-emitting diodes (LEDs).[1–5] In our previous work,[6] metal organic chemical vapor deposition (MOCVD) proved to be a good method to grow ZnO-based TCLs for GaN-based LEDs application. As reported in literature,[6] the GaN-based LEDs with the MOCVD growing Al-doped ZnO (AZO)-TCL showed an ultra-low forward voltage of 2.86 V (@20 mA) and an epitaxial-like excellent interface between the AZO-TCL and n+-InGaN contact layer. However, these ZnO-TCLs were grown by MOCVD using high-purity O2 as an oxidizer at temperatures as high as 550 °C. In addition, to obtain high transparency ZnO-TCL, the O2 was overflowed with a diethyl zinc (DEZn) precursor with a molar ratio of 458:1. This would eventually lead to the high cost of GaN-based LEDs. To solve these problems, water is proposed as a cost free oxidizer to replace the high-purity O2. Generally, the film growth temperature of MOCVD is mainly determined by the cracking efficiency of reactors. Because the cracking efficiency of water (H2O) with the low energy bond of H–O (464 kJ/mol) is higher than that of oxygen (O–O bond energy of 498 kJ/mol), using H2O instead of O2 as an oxidizer is expected to reduce the ZnO-TCL growth temperature.[7,8] This would eventually also reduce the cost of the GaN-based LEDs. In previous studies, as the front or back contacts of a solar cell, low-cost boron doped zinc oxide (ZnO:B) films have been prepared by low-pressure chemical vapor deposition (LPCVD) using H2O as an oxidizer with typical resistivity of 1.0×10−3–2.0×10−3 Ω·cm.[9–11] As far as we know, ZnO-based TCLs grown by MOCVD using H2O as an oxidizer have not been explored for GaN-based LED applications.

In this study, AZO-TCLs were grown on p-GaN with an n+-InGaN contact layer by MOCVD at 400 °C using H2O as an oxidizer. The low-cost and high-efficiency GaN-based LEDs with these AZO-TCLs are demonstrated.

In this study, InGaN/GaN multiple quantum well (MQW) LED structures were grown on c-plane sapphire substrate by MOCVD. The InGaN/GaN MQW LED structure with an emission wavelength of 450 nm consists of a Si-doped n-GaN layer, fifteen pairs of In0.3Ga0.7N/GaN MQW active layers (with a well of 6.5–6.8 nm and a barrier of 4.7–5.1 nm), a Mg-doped p-GaN layer, and a 3-nm-thick Si-doped n+-InGaN contact layer with a carrier concentration of 3 × 1020 cm−3. An AZO-TCL with a thickness of 200 nm was prepared on the top of the contact layer by S. C. Tech. MOCVD system. As Zn, Al, O precursors and carrier gases, DEZn, trimethyl aluminum (TMAl), water (H2O), and argon (Ar) were used. The chamber pressure was 6 Torr. The reaction temperature was as low as 400 °C. This AZO film was labeled H2O-AZO. The top-emitting LED chips were fabricated with a size of 250 × 760 μm2. The H2O-AZO-TCLs were partially etched in a diluted hydrochloric acid (HCl) solution, and the n-GaN layers were exposed by inductively coupled plasma (ICP) dry etching using BCl3/Cl2/Ar gas sources. Finally, a Cr/Ag (20/200 nm) bi-layer was deposited by electron beam (EB) evaporation serving as p- and n-electrodes. The device was labeled LED-I. In comparison, LED-II and LED-III were fabricated with the same InGaN/GaN MQW LED structure, simultaneously. The TCL of LED-II is an AZO-TCL grown by MOCVD using O2 as an oxidizer at a temperatures of 550 °C, which is labeled as O2-AZO. The growth condition of the O2-AZO was described in detail in literature.[6] The TCL of LED-III is a conventional ITO, which is prepared by EB evaporation at a temperature of 280 °C, followed by rapid thermal annealing at 500 °C. The current–voltage (I–V) and light output power (LOP) characteristics of the LEDs were measured by Agilent B1500A Semiconductor Device Analyzer and Fit Tech IPT6000 LED chip/wafer probing and testing system. The contact resistance of the TCLs on p-GaN with the n+-InGaN contact layer was evaluated by the circular transmission line model (CTLM).

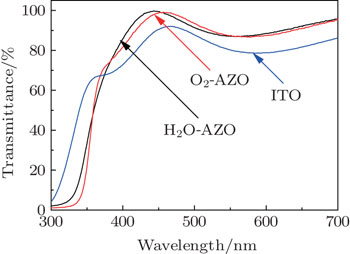

The transmission spectra with a wavelength range from 300 to 700 nm were measured and shown in Fig.

| Table 1. Mobility, carrier concentration, resistivity of various TCLs measured by the van der Pauw Hall effect measurement. . |

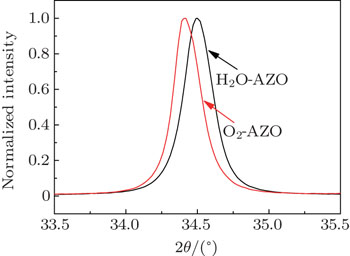

In order to understand the origin of the improved conductive properties of the H2O-AZO-TCL, the 2θ to ω x-ray diffraction (XRD) pattern was used to analyze the crystalline structure of both AZO-TCLs grown on the sapphire substrate. As shown in Fig.

| Fig. 2. The 2θ to ω XRD patterns of ZnO (0002) peaks of H2O-AZO- and O2-AZO-TCLs deposited on sapphire substrates. |

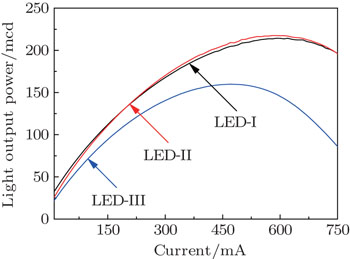

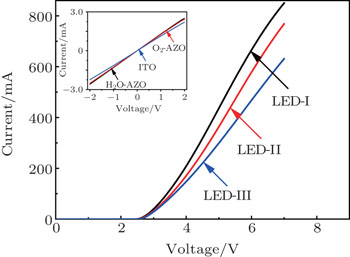

The current–voltage (I–V) characteristics of the LEDs with various TCLs were demonstrated. As shown in Fig.

| Fig. 3. I–V characteristics of LEDs with various TCLs. The inset shows the I–V characteristics of H2O-AZO-, O2-AZO-, and ITO-TCLs contacts on p-GaN with n+-InGaN contact layer. |

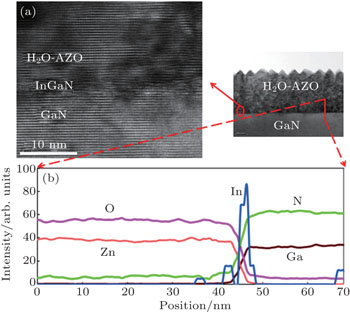

| Fig. 4. Cross-sectional HRTEM image (a) and the major element EDX line scan analysis spectra (b) of the H2O-AZO-TCL/n+-InGaN/p-GaN interface. |

Figure

In conclusion, an AZO-TCL with high conductivity and high transparence was grown by MOCVD using H2O as an oxidizer at temperatures as low as 400 °C. It was used as TCLs in InGaN/GaN MQW LEDs. Compared with LEDs with O2-AZO-TCL and ITO-TCL, the LEDs with H2O-AZO-TCL exhibit a low Vf and a high power efficiency. In addition to the epitaxial-like interface between the H2O-AZO-TCL and the p-GaN with n+-InGaN contact tunneling layer, these results could be attributed to the lower bulk resistivity of H2O-AZO-TCL. Considering the low cost of H2O-AZO-TCL, the AZO-TCL grown by MOCVD using H2O as an oxidizer will make a great contribution to the production of low-cost and high-efficiency GaN-based LEDs.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 |