† Corresponding author. E-mail:

Project supported by the National Basic Research Program of China (Grant No. 2013CB632103), the National Key Technology Support Program of China (Grant No. 2015BAF24B01), the Natural Science Foundation of Fujian Province of China (Grant No. 2016J05147), the Key Sci-Tech Research and Development Platform of Fujian Province, China (Grant No. 2014H2002), the Provincial University Foundation of Fujian Province, China (Grant No. JK2013030), the Educational Youth Key Foundation of Fujian Province, China (Grant No. JA13210), and the Scientific Research Fund of Fujian University of Technology, China (Grant No. GY-Z14073).

The properties of n-Ge epilayer deposited on Si substrate with in-situ doping technology in a cold-wall ultrahigh vacuum chemical vapor deposition (UHVCVD) system are investigated. The growth temperature of ∼500 °C is optimal for the n-Ge growth in our equipment with a phosphorus concentration of ∼1018 cm−3. In the n-Ge epilayer, the depth profile of phosphorus concentration is box-shaped and the tensile strain of 0.12% confirmed by x-ray diffraction measurement is introduced which results in the red shift of the photoluminescence. The enhancements of photoluminescence intensity with the increase of the doping concentration are observed, which is consistent with the modeling of the spontaneous emission spectrum for direct transition of Ge. The results are of significance for guiding the growth of n-Ge epilayer with in-situ doping technology.

Germanium (Ge) has the potential to be engineered to become a direct band gap material for an on-chip integrated light source due to the fact that its direct-to-indirect band separation is only 140 meV at room temperature.[1–3] Until now, three key methods to tune the Ge band structure to a direct or quasi-direct band gap material are still under research: the first one is heavily n-type doping Ge,[4,5] the second one is biaxial tensile strained Ge,[6,7] and the last one is germanium-tin (Ge1 − xSnx) alloy.[8–10] With heavily n-type doping in Ge, the indirect L valleys are filled by the extrinsic electrons thermally activated from the n-type donors, and there is a higher possibility for the excess electrons to thermally occupy the Γ valley of the conduction band, contributing to the direct gap light emission.[11] Therefore, doping in Ge, especially n-type doping, will play a significant role in improving the efficient radiative recombination of Ge at the Γ point.

To date, there have been many schemes to realize the heavily n-type doping Ge and improve the light emission efficiency. As is well known, ion implantation is an efficient technique to increase doping concentration in Ge. However, interstitial point defects which can damage the Ge structure by adding extra optical losses are also created through implantation.[12] The in-situ doping technology, which is natural to dope the Ge film during the epitaxy, is another way to achieve heavily n-type doping Ge without any implantation-related damage compared with the implanted Ge films. It avoids deep in-diffusions of dopants and provides fairly shallow junctions while offering high electrically activated concentrations at low processing temperatures.[13–16] However, many challenges, including difficulty in finding the suitable n-type dopant with high solubility and low diffusivity, and difficulty in preparing the heavily n-type doping Ge with high crystal quality, also need to be solved to achieve heavily n-type doping Ge by the in-situ doping technology.

In this paper, the detailed properties of n-Ge epilayer on Si substrate, prepared with in-situ doping technology in UHVCVD, are presented including the optimal growth temperature, depth profiles of phosphorus concentration, surface morphologies, strain status, and photoluminescence.

Several phosphorus in-situ doped Ge epilayers on Si substrate are prepared in a cold-wall UHVCVD, with a base pressure of 5 × 10−8 Pa. A reflection high-energy electron diffraction (RHEED) apparatus is equipped to monitor in situ and in real time the Ge growth mode in the growth chamber. Pure Si2H6 and GeH4 are used as the sources of Si and Ge, respectively. Phosphine (PH3) diluted at 0.5% in H2 is used for n-type doping.

The silicon substrates are treated with standard RCA (Radio Corporation of American) cleaning, and then they are baked in the growth chamber to de-oxidized at 850 °C for 30 min. After that, a 300-nm-thick Si buffer layer is grown at 750 °C, followed by a 520-nm Ge virtue substrate (VS) grown at 600 °C with a low-temperature self-patterned Ge coalescence island template. Then about 400-nm phosphorus layers doped Ge with various doping concentrations are grown at 450 °C, 500 °C, and 630 °C for 2 hours by controlling the ratio of PH3 gas flow to GeH4 gas flow in the growth chamber. More details of the growth conditions can be found elsewhere.[17,18]

The doping concentrations of the samples are estimated by the four-point probe method and confirmed by secondary ion mass spectrometry (SIMS). The surface morphologies of the samples are analyzed by atomic force microscopy (AFM) in a tapping mode. The double crystal x-ray diffraction (XRD) is employed to evaluate the strain status and crystal quality of the samples. The photoluminescence (PL) is measured at room temperature using an Ar+ laser emitting at 488 nm to characterize the optical properties of the samples.

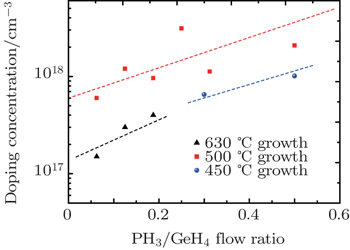

As is well known, in-situ doping is a complicated process that may be affected by many parameters such as the gas flow, the growth temperature and the base pressure in the growth chamber. In order to optimize the growth of n-Ge, the doping concentrations in n-Ge epilayers grown with various PH3-to-GeH4 gas flow ratios at growth temperatures of 450 °C, 500 °C, and 630 °C are studied, and the results are shown in Fig.

| Fig. 1. Plots of doping concentration in n-Ge epilayers versus PH3-to-GeH4 flow ratio at growth temperatures of 450 °C, 500 °C, and 630 °C. |

It is worthy to be noted that the effect of growth temperature on n-Ge epilayers can be different in different growth systems. The doping concentration decreases as temperature increases from 3.6 × 1020 cm−3 at 400 °C down to 1019 cm−3 at 750 °C in reduced pressure chemical vapor deposition (RPCVD), which is reported in Ref. [14]. Also, in the hot-wall UHVCVD, the doping levels in Ge films decrease at both high temperatures and low temperatures as reported in Refs. [5] and [19], and the growth temperature of ∼650 °C is optimal for a maximal doping concentration of 1 × 1019 cm−3. However, only ∼1018 cm−3 n-type doping concentration at a growth temperature of ∼500 °C has been achieved by in-situ doping technology in our cold-wall UHVCVD system. It may be due to the cold-wall system, which means that additional cooling applied to the chamber wall can affect the desired pressure during the growth.

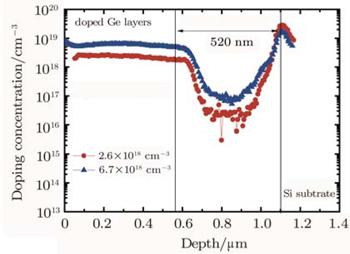

The typical SIMS depth profiles of the n-Ge epilayers on Si substrate with doping concentration of 2.6 × 1018 cm−3 and 6.7 × 1018 cm−3 are shown in Fig.

| Fig. 2. Typical SIMS depth profiles of the n-Ge epilayers on Si substrate with doping concentrations of 2.6 × 1018 cm−3 and 6.7 × 1018 cm−3, respectively. |

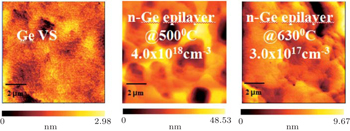

The variations in roughness with growth temperature are shown in Fig.

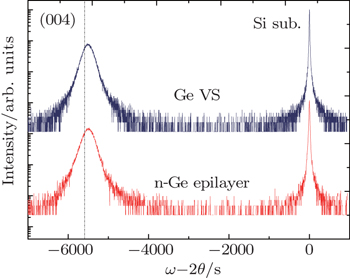

Double crystal x-ray diffraction (XRD) is performed on the n-Ge epilayer in order to examine the crystal quality and strain status. The typical ω–2θ symmetric (0 0 4) XRD scan of the n-Ge epilayer and Ge VS are shown in Fig.

| Fig. 4. Typical ω–2θ symmetric (0 0 4) XRD scans of the n-Ge epilayer and Ge VS. The straight dotted line indicates the theoretical peak position of bulk Ge. |

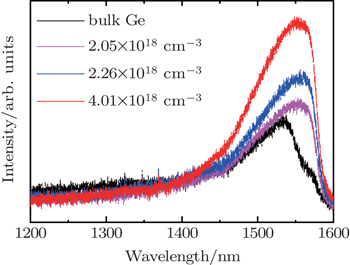

Room temperature photoluminescence of the n-Ge epilayers are measured with an InGaAs detector array cooled by liquid nitrogen. As shown in Fig.

| Fig. 5. Room temperature photoluminescences of the n-Ge epilayers and bulk Ge for various doping concentrations. |

A shift of the band gap in the n-Ge epilayer maybe lies in two aspects: band gap narrowing effect due to doping in the n-Ge film[23] and tensile strain in n-Ge epilayer.[6] For the former one, a significant band gap narrowing effect will occur in the degenerately n-doped Ge film, that is, doping level will be higher than 1 × 1019 cm−3.[21] To our samples, the quasi-Fermi levels are under the L-band, which indicates that a red-shift in the photoluminescence spectrum of the film does not result from the band gap narrowing. For the latter, the XRD curve indicates that the tensile strain in the n-Ge epilayer is about 0.12%, corresponding to the reduction of 17.5 meV in the direct band gap of Ge, which is matched with the red shift of 15 meV in the PL curve of n-Ge epilayer. It indicates that the red shift of photoluminescence comes from the tensile strain in the n-Ge epilayer.

On the other hand, PL intensity of the sample is enhanced with n-type doping concentration increasing as shown in Fig.

| Fig. 6. Simulation of the spontaneous emission spectra of the direct band transition in Ge for various doping concentrations. |

The spontaneous emission spectrum for direct transition Rsp can be expressed as

Here, τr is the radiative lifetime (10−10 s);[24] hv is the direct band absorption coefficient of Ge;

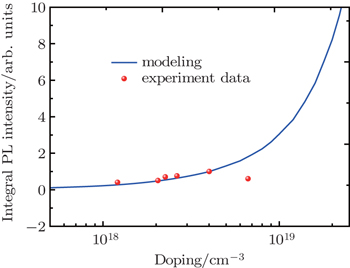

The enhancement of integral PL intensities (from modeling and experimentally measuring data) with the increase of the doping concentration is shown in Fig.

In this study, we exhibit the properties of n-Ge epilayer on Si substrate with in-situ doping technology in UHVCVD. The growth temperature of ∼500 °C seems to be an optimum temperature for growing the n-Ge epilayer in our system with a phosphorus concentration of ∼1018 cm−3. SIMS depth profiles of the n-Ge epilayer indicate that the distribution of dopant is box-like. XRD curves show that the tensile strain of the n-Ge epilayer is the same as that of Ge VS, which indicates that the doping does not contribute to releasing or increasing the strain in the growth of n-Ge epilayers. The tensile strain dominantly contributes to the red shift of the PL in the n-Ge epilayers. The simulation of spontaneous emission spectrum of the direct band transition in Ge shows that the PL intensity increases with the increase of doping concentration in the n-Ge epilayer, which is consistent with the experimental data. The studies will enable efficient application of Ge-based devices.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 |