† Corresponding author. E-mail:

‡ Corresponding author.

Project supported by the National Natural Science Foundation of China (Grant No. 61178018) and the Ph.D. Funding Support Program of Education Ministry of China (Grant No. 20110185110007).

Modulation caused by surface/subsurface contaminants is one of the important factors for laser-induced damage of fused silica. In this work, a three-dimensional finite-difference time-domain (3D-FDTD) method is employed to simulate the electric field intensity distribution in the vicinity of particulate contaminants on fused silica surface. The simulated results reveal that the contaminant on both the input and output surfaces plays an important role in the electric field modulation of the incident laser. The influences of the shape, size, embedded depth, dielectric constant ( ε r ), and the number of contaminant particles on the electric field distribution are discussed in detail. Meanwhile, the corresponding physical mechanism is analyzed theoretically.

High-peak power lasers have been developed in many fields, including laser-driven inertial confinement fusion (ICF) experiments, material properties at extreme conditions, and laser micromachining. Thousands of optical components including fused silica glass are needed in high-peak power laser systems. [ 1 ] In particular, they serve as lenses, mirrors, vacuum windows, debris shields, etc., for large laser facilities such as National Ignition Facility (NIF) in USA, [ 2 ] Laser MegaJoule (LMJ) in France, [ 3 ] and SG-III laser facility in China. [ 4 ] However, surface/subsurface contaminations of the optical components are inevitable during the assembling and operating processes. Those particles are difficult to remove completely from the optical surface because of the strong adhesion forces for tiny particulates, especially submicron ones. [ 5 , 6 ] Actually, the laser-induced damage in optics due to contaminations has become a major obstacle for its applications. Due to absorption, scattering, and modulation of the contaminants, contamination-enhanced laser-induced optical damage (C-LID) has been proved to be a significant factor in reducing the laser reliability and lifetime. [ 7 ] Furthermore, contaminations will restrict the energy delivered to the target and increase the running cost of the laser systems, particularly at 355 nm. For this reason, it is useful to establish a C-LID model about laser modulation to aid understanding of the damage mechanisms.

The laser-induced damage involves intrinsic and extrinsic damage. The intrinsic damage of the optical material caused by intense laser pulse has been widely studied. [ 8 – 10 ] In most cases, the damage mechanism is usually attributed to multi-photon ionization, avalanche ionization, and joule heating. The extrinsic damage means the damage of the optical material mainly caused by other factors such as surface contamination, stress, etc. C-LID is an extrinsic damage and there have been some reports about its damage behaviors and mechanisms. For strong absorption contaminants such as metallic particles, the damage threshold is often determined by the thermal stress induced by the heating of the contaminant in the laser beam. The absorbing particles in glass have been studied in detail both experimentally and theoretically. [ 11 – 14 ] For non-absorbable or weak absorption contaminants, light intensity modulation caused by the surface contaminants plays an important role for laser-induced damage. Génin et al. studied the light intensity distribution behind an obscuration by using Fresnel diffraction theory. The results showed that the intensity modulation is as a function of particle size (10–150 μm), shape and of the distance from the particle. [ 15 ] Mainguy et al. studied the propagation of high-power laser beams when interacting with environmental pollution particles by using CEA-DAM MIRÓ beam propagation code, and concluded that the highest intensification factor is up to about 9 in the downstream propagation for the circular phase particles in the cases of ∼ Φ 150 μm at 3 ω laser and ∼ Φ 400 μm at 1 ω laser. [ 16 ] Previous studies mainly focused on light intensity modulations from the particles with size of about dozens to hundreds of microns. However, little work has contributed to the electric field modulation with the scale ranging from sub-micrometric to micrometric particles. However, a large number of micron even smaller particles exist in the high-peak power laser facilities. [ 17 ]

In this work, the light intensity modulation caused by submicron to micron contamination particles on the input/output surface is numerically calculated with three-dimensional finite difference time domain (3D-FDTD) method. The effect of the shape, size, dielectric constant ( ε r ), and the number of particles on the electric field distribution is simulated and discussed.

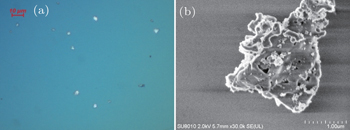

According to the morphology of particulate contaminants on the surface of fused silica observed by an optical microscope and scanning electron microscopy (SEM) (Fig.

| Fig. 1. The morphology of the particulate contaminant observed by (a) optical microscope and (b) scanning electron microscopy. |

In general, FDTD method is well applied to calculate the electric field for a scale of wavelength-level. Therefore, this method is appropriate to calculate the electric field caused by the particulate contaminant with a size ranging from submicron to a few microns, and the calculated results are reliable for tiny particles. In this work, Maxwell’s equations are solved by 3D-FDTD method to calculate the electric field intensity distribution in the vicinity of the contaminant. [ 18 ] For simulation, the wavelength of the incidence laser is λ = 355 nm. The simulation region is rectangular gridded with a uniform grid δ = λ /12 = 29.6 nm, and the domain size is 160 δ × 160 δ × 215 δ . The perfectly matched layer (PML) absorbing-boundary condition is utilized in this paper, which is a lossy medium with ultralow reflectance over a broad spectrum and large angles of incidence. [ 18 , 19 ] The thickness of the PML is 21 δ , which is applicable for the total field region. In addition, the 355-nm laser with an amplitude of 1.0 V/m is loaded along the z axis, and the transverse magnetic (TM) wave is considered in this work. The relative dielectric constants of fused silica, air, and the contaminant are 2.25, 1.0, and ε r = 3.8 (besides the relative dielectric constant in Section 3.3), respectively.

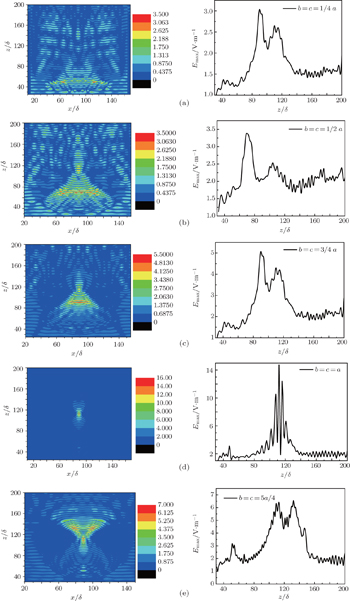

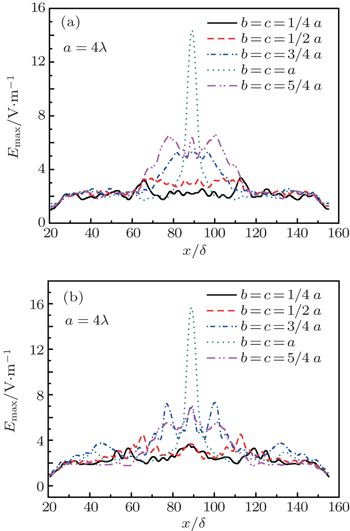

In this section, the influence of the flattening of the ellipsoid on the electric field ∣ E ∣ distribution is investigated. The ratio of the semi-axis along y direction to the semi-axis along x direction ( b / a ) is defined as the flattening of the ellipsoid. In order to ensure b / a is the only influencing factor, other parameters should be fixed. The semi-axis of the ellipsoid along x direction is set as a = 4 λ , while b and c change from 1 λ to 5 λ , and the embedded depth is set as h = 0, i.e., the whole particle lies on the surface.

Figures

| Fig. 5. Peak electric field E max distribution along x direction for different flattening of ellipsoid for the particle (a) on the input surface and (b) on the output surface. |

The simulation also reveals that the influences of the contaminant on fused silica optics are different for particles on the input surface and output surface. For the input surface contamination, the maximum electric field appears in the surface or the subsurface of fused silica, as shown in Fig.

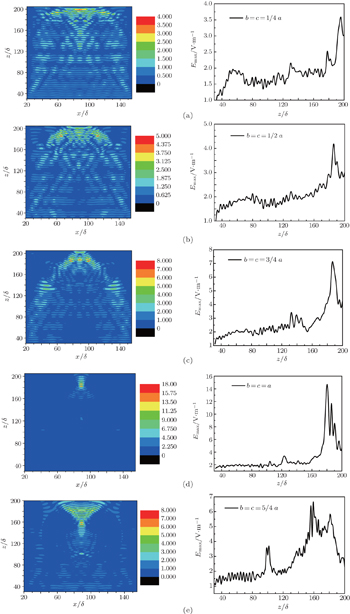

In order to investigate the influence of particle size on the electric field intensity modulation of the incident laser, we calculated the electric field distribution for the spherical particle with a radius changing from 1 λ to 5 λ for three cases: (i) the whole particle lies on the surface ( h = 0), (ii) half of the particle is embedded in the surface ( h = r ), and (iii) the whole particle is embedded in the surface ( h = 2 r ).

Figure

In general, various contaminants, e.g., dust, aerosol, metal flakes, cloth threads, etc., exist on the surface of fused silica. Hence, the relative dielectric constant ε r of these contaminants is different. In order to understand the influences of different contaminants on the electric field modulation, it is necessary to discuss the relation between laser modulation and ε r of particulate contaminants.

Figure

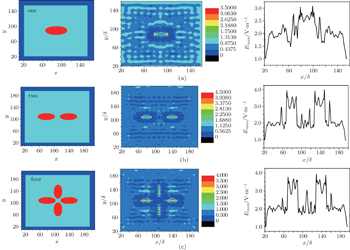

In the actual optical subsurface, a number of particles probably exist in a given domain, so it is necessary to discuss the modulation of the electric field multiple for particles. In this section, we will discuss the influences of one, two, and four particles on the modulation. Here, we just discuss particles on the input surface. All particles are the same ellipsoid, the long semi-axis of the ellipsoid is a = 2 λ , and the short semi-axis of the ellipsoid is b = c = λ . The distance d between two adjacent particles is λ .

Figure

In summary, the electric field intensity modulation to the incident laser by surface contaminants on fused silica depends on the particle parameters, including the shape, size, embedded depth, dielectric constant ( ε r ), and the number of particulate contaminants. In addition, the modulation on fused silica for particles on the input surface is higher than that on the output surface at the same contamination conditions. In this work, we just considered ellipsoid particles and spherical particles. Actually, the surface contaminants have different shapes and morphologies. The local electric field is usually enhanced by the irregular regions. [ 23 – 25 ] However, since the high local field caused by the irregular regions is usually not in fused silica but in particle, it has little effects on the distribution of total electric field intensity in fused silica.

The influence of particulate contaminate on the electric field intensity modulation for different parameters is simulated with 3D-FDTD method. Several conclusions are obtained as follows.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 |