† Corresponding author. E-mail:

Project supported by the President Foundation of the China Academy of Engineering Physics (Grant No. YZJJLX2018003) and the National Natural Science Foundation of China (Grant No. 21601168).

The effects of 400 keV helium ion irradiation dose and temperature on the microstructure of the Ti3SiC2 ceramic were systematically investigated by grazing incidence x-ray diffraction, scanning electron microscopy, and transmission electron microscopy. The helium irradiation experiments were performed at both room temperature (RT) and 500 °C with a fluence up to 2.0 ×1017 He+/cm2 that resulted in a maximum damage of 9.6 displacements per atom. Our results demonstrate that He irradiations produce a large number of nanometer defects in Ti3SiC2 lattice and then cause the dissociation of Ti3SiC2 to TiC nano-grains with the increasing He fluence. Irradiation induced cell volume swelling of Ti3SiC2 at RT is slightly higher than that at 500 °C, suggesting that Ti3SiC2 is more suitable for use in a high temperature environment. The temperature dependence of cell parameter evolution and the aggregation of He bubbles in Ti3SiC2 are different from those in Ti3AlC2. The formation of defects and He bubbles at the projected depth would induce the degradation of mechanical performance.

The layered carbides and nitrides, MAX phase ceramics,[1–3] have received much attention since Nowotny first synthesized a large number of carbides.[4] The MAX ceramic is generally written as

Several MAX ceramics have been synthesized or theoretically predicted.[5] Among them, Ti3SiC2[3,9,15,18,19,21–23] and Ti3AlC2[11,13,14,24,25] are representative materials in the MAX phase and have been suggested for the next generation nuclear reactor applications thanks to their advantages of thermal/mechanical properties at high temperature and radiation damage resistance. The irradiation effects on Ti3SiC2 and Ti3AlC2 subjected to helium[3,12–14,18,19,21,25] and heavy ion[15,16,22,23,26–28] irradiations have been intensively investigated. Spherical He bubbles were formed in Ti3SiC2 after He irradiation up to 1.0 ×1018 He+/cm2 at room temperature (RT).[14] Tallman et al.[6,9] studied the neutron radiation effect in several polycrystalline MAX phases, including samples of Ti3AlC2, Ti2AlC, Ti3SiC2, and Ti2AlN. The results showed that the lattice distortion occurred and the dislocation loops formed in the samples of Ti3SiC2. Zhang et al.[3] found that the high temperature He irradiation and post-annealing offered a path for the recovery of irradiation damages in Ti3SiC2. Song et al.[19] studied the migration and clustering of He atoms in Ti3SiC2 based on the theoretical calculation. Zhang et al.[18] revealed the microstructure changes of Ti3SiC2 from damage Ti3SiC2, damaged TiC precipitation to crystal TiC phase formation due to He irradiation up to 1.0 ×1017 He+/cm2. Pang et al.[29] illustrated that the structure distortion in Ti3AlC2 after combined Fe and He ions irradiation was more serious than that by single Fe-ion irradiation. Flem et al.[7] performed the in-situ study of 92 MeV Xe ion irradiation damage on Ti3(Si,Al)C2 materials by using an transmission electron microscope (TEM) to elucidate the deformation mechanism at a very small scale. Different energies of Au and Xe heavy ions irradiations were conducted to the Ti3SiC2 material for the purpose of separation of the effects of nuclear interactions from those of electronic ones.[17,22]

It was proposed that irradiation would induce substantial crystal structure defects[7,15,28] and cell volume expansion,[26,28] as well as the dissociation of MAX to TiC,[6,12] which contributed to the volumetric swelling of the MAX phases.[30] Usually, the amorphization of nuclear materials would lead to degraded corrosion resistance and the materials become brittle,[31,32] so the transformation of MAX phases from crystalline to amorphous under irradiation was considered to inevitably contribute to the degradation of the mechanical property. Up to now, the previous studies suggested that the MAX phases have not been completely amorphized even the irradiation dose up to 116.9 dpa.[23] The remarkable irradiation resistance of MAX ceramics was suggested to be ascribed to the A layer atoms offering the space to accommodate point defects.[9,10] Besides, Shen et al.[23] proposed that the Xe+ irradiation induced TiC nanograins enhanced the irradiation tolerance of Ti3SiC2 ceramic because the formation of nanograins provided a higher density of boundaries.[14] Helium irradiation caused the lattice expansion of Ti3SiC2 at a low irradiation dose and induced the phase transformation from Ti3SiC2 to crystal TiC phase.[18] Wang et al.[8] directly observed the mixing of Ti and Al atoms under Au ion bombardment at atomistic-scale resolution, as well as the formation of fcc-(Ti3Al)C2 phases.

Although the effects of ion irradiation on Ti3SiC2 have been reported before by Nappé et al.,[27] Whittle et al.,[16] Zhang et al.,[15] Shen et al.,[23] and Zhang et al.[3,18] A systematic TEM investigation of the He irradiation damage with respect to fluence and temperature is still necessary to understand the evolution and mechanism of He bubbles in Ti3SiC2 lattice. In this work, the Ti3SiC2 bulk samples are irradiated with 400 keV He+ ions at both RT and 500 °C. The irradiation induced damages are characterization by grazing incidence x-ray diffraction (GIXRD) and TEM. The irradiation induced defects are accurately obtained by comparing the microstructure in the irradiated area with that in the un-irradiated area from the same Ti3SiC2 grain. The correlations between the irradiation damage and dose and temperature are analyzed and discussed.

The Ti3SiC2 bulk samples used in this study were synthesized by a hot pressing method.[23,25] The Ti (99%, 200 mesh), Si (99%, 300 mesh), and graphite (99%, 200 mesh) powders with a molar ratio of 3:1.2:2 were weighted and used as the starting materials for synthesizing Ti3SiC2 ceramic. The Ti, Si, and C powders were dry mixed in a resin jar, followed by ball milling for 12 h, and then sieved. The mixture powders were put into a graphite die and uniaxially pressed at 5 MPa, and then heated to a desired temperature of 1550 °C and hold for 1 h under an Ar atmosphere. The as-obtained bulk sample was finally cooled down to RT and pressed for 5 min. The bulk specimens used for irradiation and characterization have a size of 5 mm (L) ×5 mm (W) ×3 mm (T), and were prepared by cutting into pieces using a diamond saw and mechanically polishing to remove the surface contamination.

The He irradiation experiments were performed at Michigan Ion Beam Laboratory in University of Michigan. The ion implantation energy was set at 400 keV with the sample normal direction, which would result in a projected range of 1330 nm that was calculated by SRIM code.[33,34] The SRIM code was also used to simulate the He irradiation induced damage and He concentrations in the Ti3SiC2 matrix and the used displacement energies were 25 eV, 25 eV, and 28 eV for Ti, Si, and C,[12,35] respectively. The helium fluence was in a range from 0.5 ×1017 He+/cm2 to 2.0 ×1017 He+/cm2, and the helium flux was set at 0.78 ×1014 He+/(cm2

| Table 1.

The detailed conditions for helium irradiation and the induced damages at the projected depth of 1330 nm in the as-implanted sample based on the SRIM calculation. . |

After irradiation, the cross-sectional TEM specimens with thickness of around 100 nm were prepared by a focused ion beam (FIB) lift-out technique in a Helios 650 Nanolab workstation.[36] The detailed FIB procedures for the TEM sample preparation could be found elsewhere.[36] Due to the extreme thin irradiation surface layer, the structures of the irradiated samples were examined by GIXRD using an X’pert PRO MPD with a Cu

An SEM image of surface morphology of pristine Ti3SiC2 sample is shown in Fig.

| Fig. 2. (a) SEM image of Ti3SiC2 before irradiation. EDS mapping of (b) Ti and (c) Si elements from the area shown in (a). (d) XRD pattern acquired from Ti3SiC2 before irradiation. |

The SAED pattern obtained in TEM analysis confirms the crystal structure of the Ti3SiC2 sample. A TEM lamellar of the pristine sample across the interface between Ti3SiC2 grains and impurity phases was prepared by an FIB lift-out method. Figure

Figure

| Fig. 4. SEM images of Ti3SiC2 specimens after He irradiation up to 2.0 ×1017 He+/cm2 at (a)–(c) RT or (d)–(f) 500 °C. |

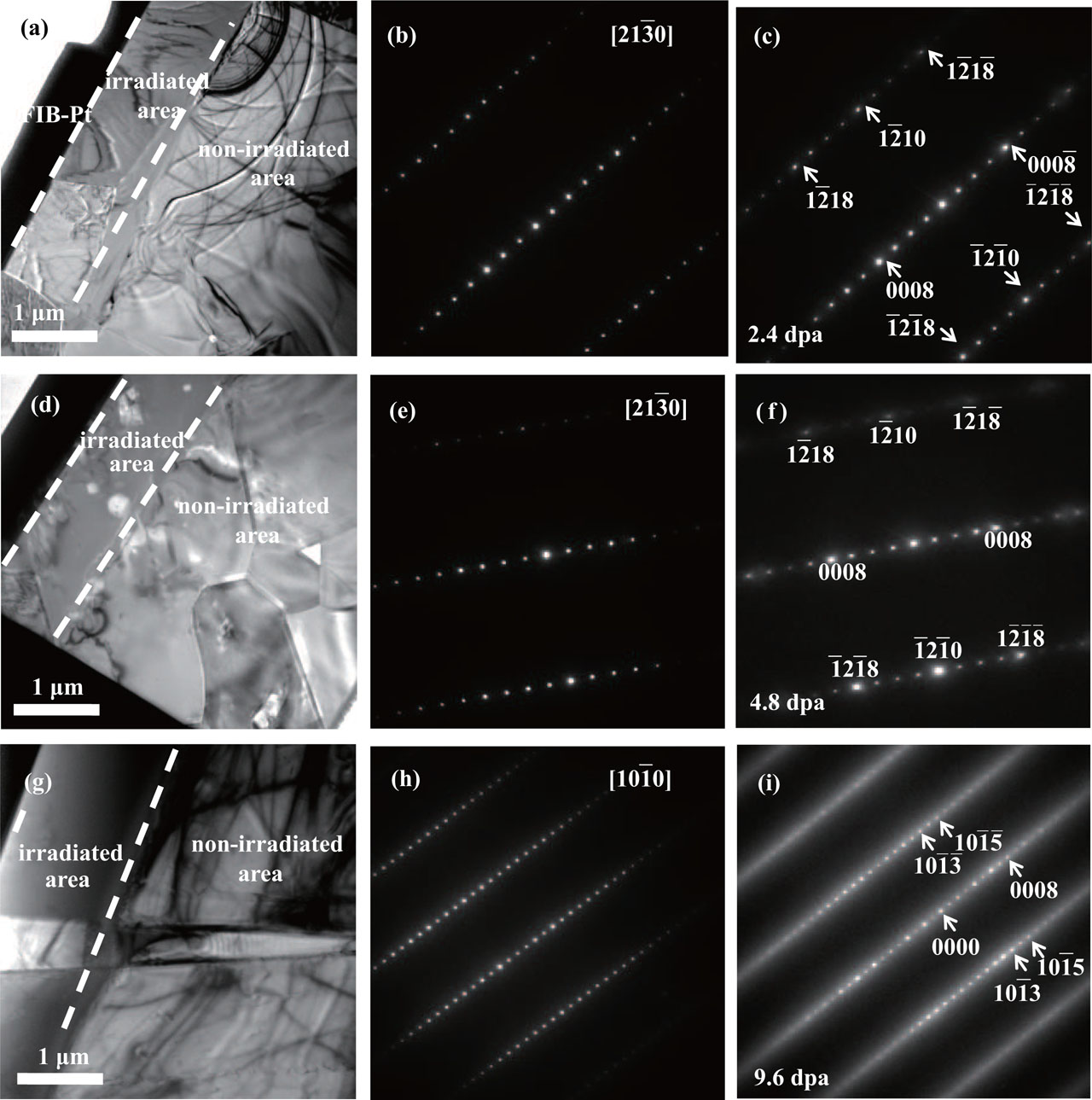

Figure

At RT, for the LT2.4 specimen, the SAED patterns from the irradiated and non-irradiated areas in Fig.

Figure

| Fig. 7. BF image of LT9.6 specimen in which a lot of He bubbles formed at the projected depth. The inset shows the SAED pattern taken from this area. |

At 500 °C, for the HT2.4 specimen, the SAED patterns taken from the non-irradiated and irradiated areas are shown in Figs.

Figure

| Fig. 8. GIXRD patterns of Ti3SiC2 specimens after He irradiation at (b) RT and (a) 500 °C with fluence increasing from 0.5 ×1017 He+/cm2 to 2.0 ×1017 He+/cm2. |

| Table 2.

The Ti3SiC2 crystal structure parameters, a-LP, c-LP, and cell volume, calculated from the GIXRD patterns (Fig. |

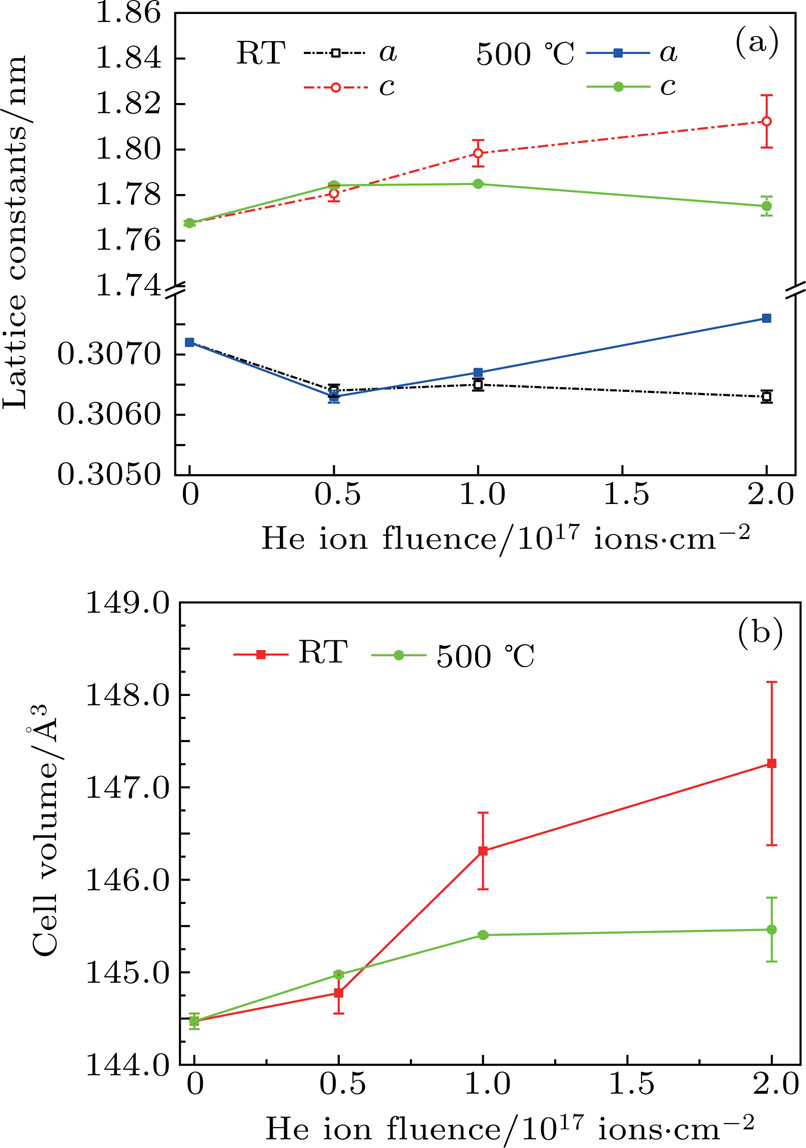

At RT, a slight reduction of a-LP and an obvious expansion of c-LP, leading to the volume expansion of 0.74%, are observed after irradiated to 2.4 dpa, as shown in Fig.

| Fig. 9. (a) The a-LP, c-LP and (b) cell volume of Ti3SiC2 change as a function of irradiation temperature and fluence. |

At 500 °C, the reduction of a-LP and the expansion of c-LP are 0.29% and 0.94%, respectively. However, with the dose increasing from 2.4 dpa to 9.6 dpa, a-LP starts to expand to 0.13%, while the expansion of c-LP drops from 0.94% to 0.42%, indicating that the Ti3SiC2 cell starts to recover with the higher He fluence. This phenomenon is contrary to the result from the RT irradiation. The FWHMs of the (10

The SAED results demonstrate that the dissociation of Ti3SiC2 to TiC phase occurred after He irradiation, which has been reported by Tallman et al.[9] Shen et al.[23,25] demonstrated that the Xe and He ion irradiation would induced the formation of TiC nanograins in Ti3SiC2 and Ti3AlC2 ceramics. The precipitation of TiC nanograins would be beneficial for improving the irradiation resistance of MAX ceramics. The dissociation of Ti3SiC2 has been well explained by theoretical calculations that the bonding between Ti and Si is relatively weaker than Ti–C bonds, which can induce the removal of the Si layer leaving the TiC unperturbed.[14] Zhang et al.[3] found that He bubble aggregation in Si layer at high temperature provided a path for Si loss and the formation of TiC nanograins. The mechanism of the formation of fcc-TiC phase has been clearly understood in atomistic scale by Wang et al.[8] Under Au ion irradiation, the Al atoms would left their original sites and enter the TiC lattice to randomly replace the Ti atoms and to form the metastable γ -(Ti3Al)C2 and the fcc-(Ti3Al)C2 phases.[8] Therefore, the fcc phase product formed during the dissociation of Ti3SiC2 phase should be ascribed to the formation of fcc-(Ti3Si)C2 while the Si atoms enter the TiC lattice and occupy the Ti sites.

At both RT and 500 °C, the SAED and GIXRD results revealed the volume swelling after He irradiation, which could be easily understood that the He bubbles aggregating at the Si layer induce the c-LP expansion and volume expansion.[13,14] In comparison, the volume expansion of Ti3SiC2 increases remarkably with the increasing He fluence at RT, while it shows a slight increase at 500 °C. This may imply the different mechanisms of He atoms diffusion in the Ti3SiC2 lattice. It is well-known that the Si layer, having larger lattice space, represents nano-scale interfaces that function as natural sinks for He atoms and defects.[9,30] The presence of Si layer is responsible for the outstanding irradiation resistance of Ti3SiC2 phase. Therefore, it is easily understood that the He bubbles grow along the c-plane with the post-irradiation and induce the c-LP expansion at RT and 500 °C.

The mechanism of He bubble aggregation is proposed to interpret the different changing tendencies of Ti3SiC2 cell parameters irradiated at RT and 500 °C. Figure

In contrast, the He bubbles exhibited different diffusion and aggregation mechanism at 500 °C. Once the defects formed in the TiC lattice, they would play an important role as natural sinks for He atoms. Song et al.[21] found that the He atoms could be trapped by vacancies in the C layer based on the first-principles calculation. For fcc-TiC, the {111} plane is the habit plane with lower formation energy of defect. The implanted He atoms tend to incorporated into the {111} planes.[40] As shown in Fig.

In comparison to Ti3AlC2,[36] Ti3SiC2 exhibited a better irradiation resistance that was conforming to the results of Tallman et al.[11] and Shen et al.[23] The most important reasons should be ascribed to the absence of surface exfoliation and smaller volume expansion in Ti3SiC2 after He irradiation. It seems that the temperature dependence of cell parameters in Ti3SiC2 under He irradiation was different from that in Ti3AlC2,[23] which has been well explained by the different migration and aggregation of He atoms in Ti3SiC2 and Ti3AlC2. The detailed investigation of He atom diffusion and defect evolution at an atomistic scale is still preferred for understanding the different irradiation effects in Ti3SiC2 and Ti3AlC2. Meanwhile, the Ti3SiC2 ceramic should be more suitable for using at high temperature environment due to the high annihilation of the irradiation defects.[9,18,19,21]

The He irradiation damage on Ti3SiC2 with different He fluence and irradiation temperature was systematically investigated by GIXRD, SEM, EDS, and SAED techniques. Helium irradiation of 2.0 ×1017 He+/cm2 fluence causes a maximal damage of 9.6 dpa at the projected depth. At both RT and 500 °C, the results show that He irradiations produce a large number of defects in the Ti3SiC2 lattice, which evolve to the dissociation of Ti3SiC2 to TiC with the increasing He fluence. At RT, the cell volume swelling of Ti3SiC2 increases continuously with the He fluence, indicating the accumulation of He bubbles on the Si layers. In comparison, the volume of Ti3SiC2 shows a slight swelling during irradiation at 500 °C, while the a-LP starts to expand at higher He fluence. This suggests that the He bubbles prefer to migrate into the TiC lattice rather than the Si layer at higher temperature. It is evident that the changing tendency of the cell parameter and the He bubble aggregation in Ti3SiC2 is significantly different from that in Ti3AlC2. It is proposed that Ti3SiC2 is more suitable for use in a high temperature environment and exhibits better irradiation resistance than Ti3AlC2.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] |