† Corresponding author. E-mail:

We investigate the magnesium (Mg) incorporation efficiencies in MgxZn1−xO films on c-plane Zn-face ZnO substrates by using metalorganic chemical vapor deposition (MOCVD) technique. In order to deposit high quality MgxZn1−xO films, atomically smooth epi-ready surfaces of the hydrothermal grown ZnO substrates are achieved by thermal annealing in O2 atmosphere and characterized by atomic force microscope (AFM). The AFM, scanning electron microscope (SEM), and x-ray diffraction (XRD) studies demonstrate that the MgxZn1−xO films each have flat surface and hexagonal wurtzite structure without phase segregation at up to Mg content of 34.4%. The effects of the growth parameters including substrate temperature, reactor pressure and VI/II ratio on Mg content in the films are investigated by XRD analysis based on Vegard’s law, and confirmed by photo-luminescence spectra and x-ray photoelectron spectroscopy as well. It is indicated that high substrate temperature, low reactor pressure, and high VI/II ratio are good for obtaining high Mg content.

ZnO and its base ternary alloys are promising candidates for optoelectronic applications in the ultraviolet region, owing to their direct wide bandgaps and large exciton binding energies. By incorporating magnesium (Mg) into the ZnO matrix, the energy bandgaps of MgxZn1−xO alloys can be adjusted from 3.3 eV to 7.8 eV.[1] Hence MgxZn1−xO alloy is considered as a suitable material for energy engineering in ZnO-based low-dimensional optoelectronic devices. There have been numerous reports on MgxZn1−xO/ZnO heterostructure devices, including single heterostructure ultraviolet light-emitting diodes[2] metal–semiconductor–metal solar-blind photodetectors,[3] field-effect transistors,[4] etc.

However, the growth of MgxZn1−xO is complicated for the different stable structures of ZnO (wurtzite) and MgO (rocksalt). Poor crystalline quality and phase separation are thus problems that have to be resolved.[5] Besides, large lattice-mismatch between the commonly used substrates and films and low Mg incorporation efficiency in the MgxZn1−xO films are also important factors responsible for deteriorating the crystalline quality. According to the phase diagrams of ZnO–MgO binary systems, the thermodynamic solid solubility of MgO in a ZnO matrix is normally less than 4%.[5] Nevertheless, previous studies have shown that single wurtzite structure MgxZn1−xO films can be acquired with significant Mg compositions up to 33%∼49%.[1,6,7] The large variation of incorporation efficiency in MgxZn1−xO alloys might be attributed to the non-thermal equivalent natures of different techniques and growth conditions. Therefore, it is necessary to understand the effects of the growth parameters on Mg incorporation efficiency in MgxZn1−xO thin films.

Several methods have been employed to grow MgxZn1−xO alloys, including pulsed laser deposition (PLD),[8] magnetron sputtering,[3,9] molecular beam epitaxy (MBE),[4,10] and metalorganic chemical vapor deposition (MOCVD).[11,12] Among these methods, MOCVD is a promising technique for industrial applications due to its advantages of high growth rate, large-area deposition, and good thickness and composition uniformity.

It is reasonable that closely lattice-matched substrates are favorable for the epitaxial growth of the films. Therefore, the quality of wurtzite structure MgxZn1−xO films can be improved by using ZnO single crystal as substrate without a buffer layer, owing to their naturally matched lattice. The MgxZn1 −xO is crucial for serving as a barrier layer or quantum wells in ZnO/MgxZn1−xO heterostructures, and high quality of MgxZn1−xO films would promote the performance of the device.[2] High quality MgxZn1−xO films grown on ZnO single crystal also were proved to be important for fabricating superior solar-blind photodetectors.[3] Although ZnO single crystal substrates are already commercially available and some research has been dedicated to the homoexpitaxial growth of ZnO films on them,[13] the systematical study of MgxZn1−xO film growth on ZnO substrates is very important but still lacking. This can be attributed to various factors, such as high cost-level of device-grade ZnO substrates, immature surface treatment technique, and highly variable quality of crystal structure. We have reported the hydrothermal growth of ZnO single crystals with new mineralizers and low-cost liners. A large-sized ZnO single crystal whose x-ray θ–rocking curve has a full width at half maximum (FWHM) of 36 arcsec for (002) reflection and a room temperature electron mobility of 239 cm2/V·s has been obtained.[14] In this study, we report on the epitaxial growth of MgxZn1−xO films on Zn-face of ZnO substrates by MOCVD. Growth parameter dependence of the Mg incorporation efficiency in the films is systematically discussed.

The MgxZn1−xO thin films investigated in this study were deposited by a vertical and resistively heated MOCVD on c-plane ZnO substrates grown by the hydrothermal method. The ZnO substrates were 10 mm×10 mm×0.5 mm in size. Before being sent to the reactor, they were chemo-mechanically polished followed by thermal annealing in O2 atmosphere. For the preparation details as well as structural and optical properties of the ZnO substrates, the readers can refer to Ref. [14]. Biscyclopentadienyl-magnesium (Cp2Mg), diethyl-zinc (DEZn) and oxygen (O2, 7N) were used as the precursors for Mg, Zn, and O, respectively. Ultra-high purity N2 (9N) was used as the carrier gas. In order to prevent the gas phase reactions, O2 and metal–organic sources were introduced separately into the reactor and just mixed below the susceptor. The flow rates of Cp2Mg and DEZn were fixed at 2800 sccm and 25 sccm respectively, resulting in a Cp2Mg/DEZn ratio of 2:1. The O2 flow rate was varied between 60 sccm and 200 sccm to regulate the VI/II ratio (the molar flow ratio of O2/(Cp2Mg+DEZn)). Process pressure in the reactor was varied from 10 Torr to 250 Torr (1 Torr = 1.33322×102 Pa). The substrate temperature ranged from 380 °C to 460 °C. The susceptor rotating speed was 1000 rpm. All the films were deposited for one hour.

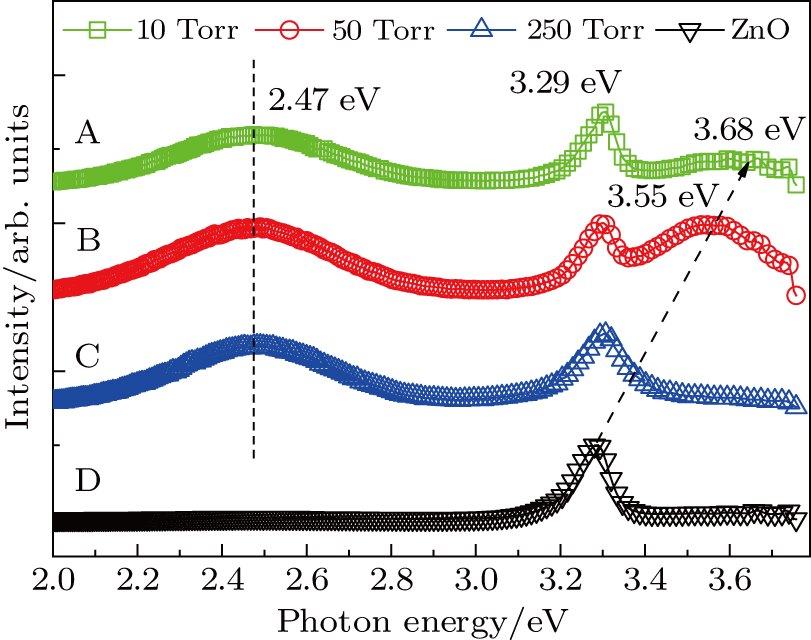

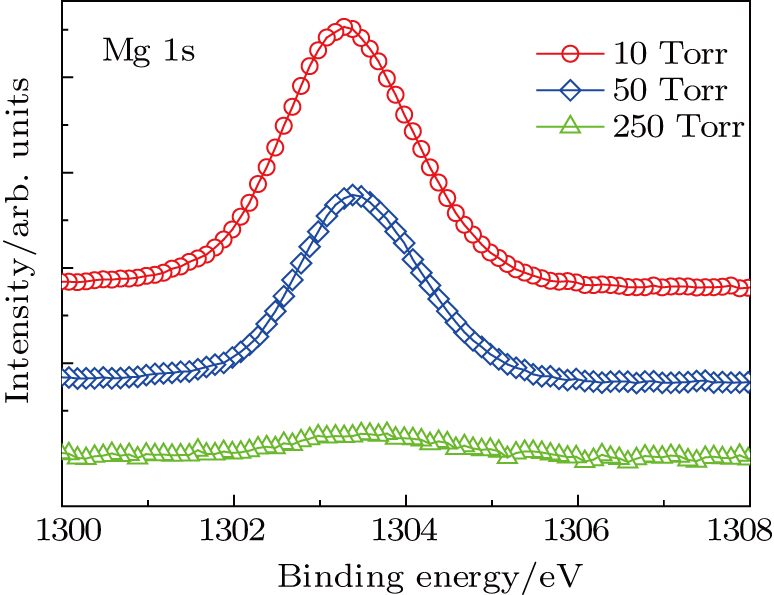

The surface morphologies of ZnO substrates and MgxZn1−xO films were investigated using atomic force microscope (AFM) and scanning electron microscope (SEM). The structure properties of MgxZn1−xO films were analyzed by x-ray diffraction (XRD) in θ–2θ geometry using PANalytical X’ Pert PRO with Cu Kα source. The Vegard’s law has been verified to be a good model for MgxZn1−xO alloys due to the similar size of Zn ion (0.60 Å) to that of Mg ion (0.57 Å).[6,15–17] Mg content in MgxZn1−xO films was determined by the calculation of c-axis lattice parameter following the Vegard’s law. Photo-luminescence (PL) spectra were obtained at room temperature by using a He–Cd laser (325 nm) as the excitation light source. X-ray photoelectron spectroscopy (XPS) was also applied to MgxZn1−xO films to study the change of Mg content.

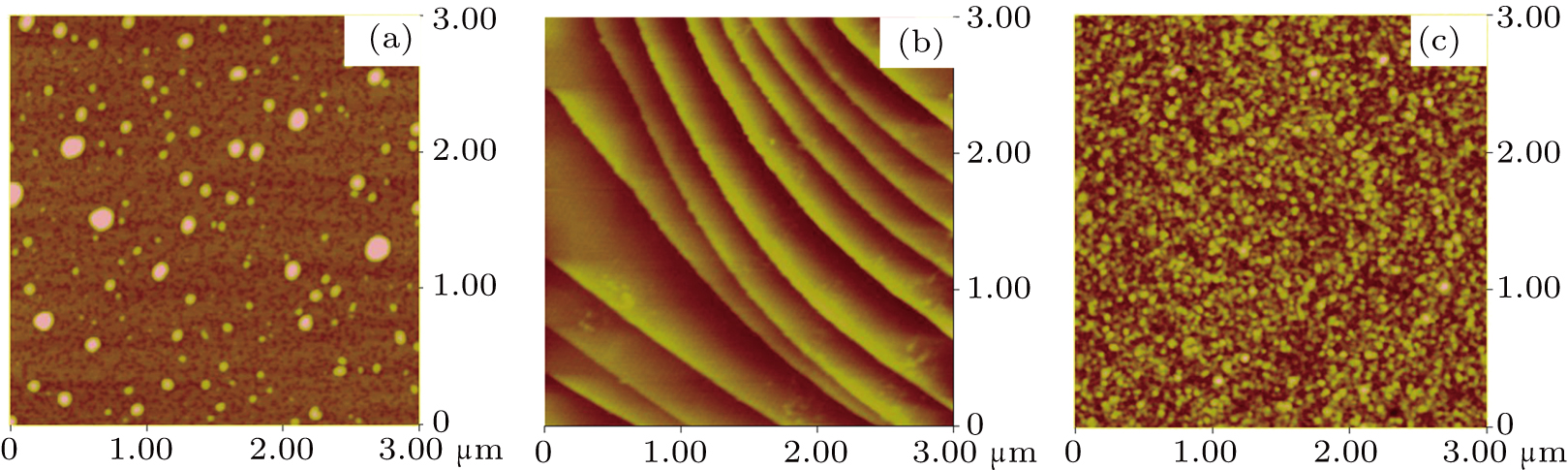

It has been shown that the surface of ZnO substrate plays a crucial role in the quality of the epitaxial growth of thin film.[18] Various treatment methods for ZnO substrates including thermal annealing, wet-chemical etching and plasma treatment have been proposed to obtain an atomically flat surface.[19–21] In this study, thermal annealing technique is employed for chemo-mechanically polished ZnO substrates. Many uniformly sized islands on a smooth surface can be seen in the AFM image of as-polished ZnO substrate (Fig.

| Fig. 1. (color online) Atomic force microscopy images of (a) the as-polished and (b) as-annealed ZnO substrate, and (c) MgxZn1−xO film grown on the annealed ZnO substrate. |

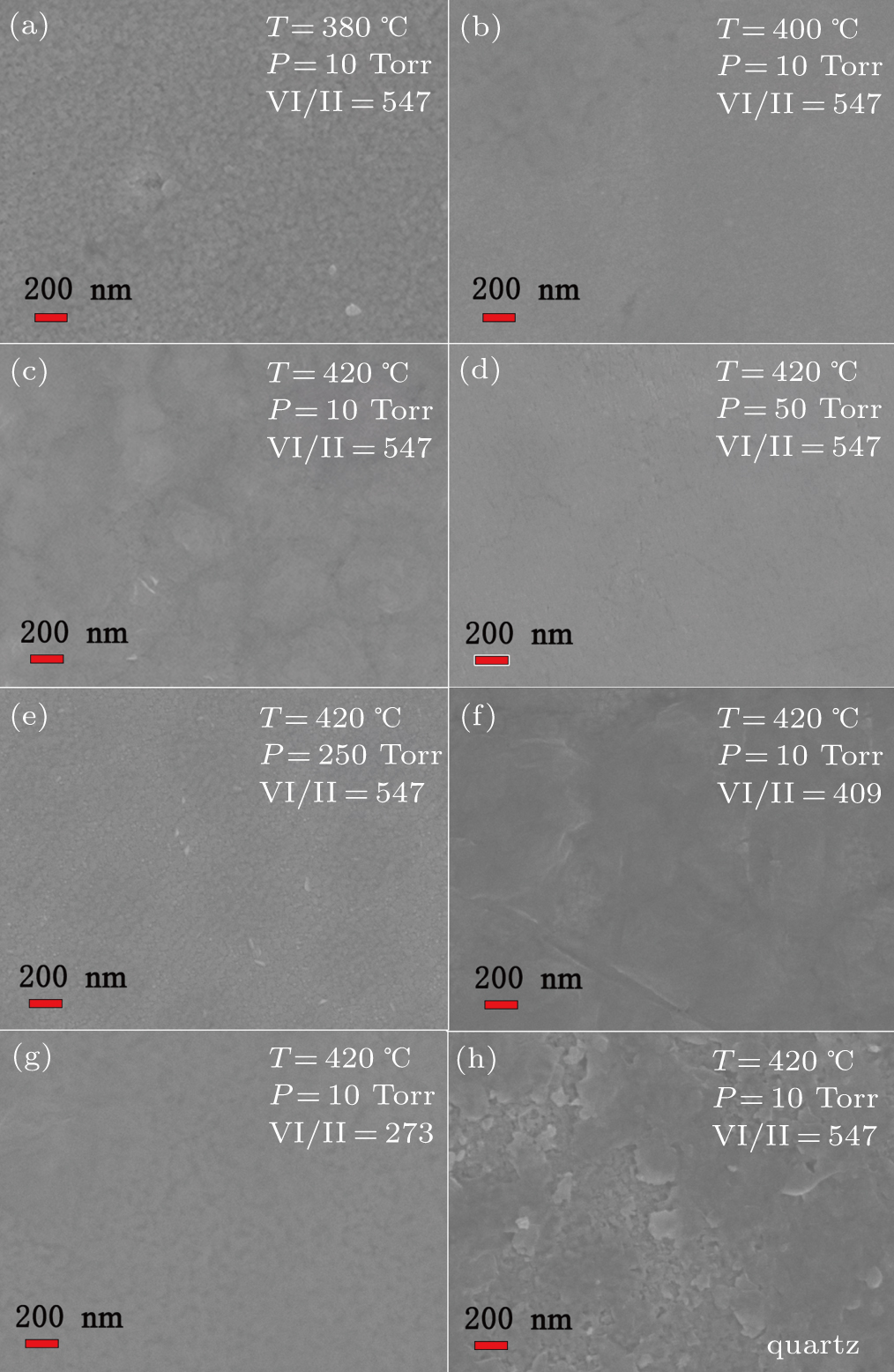

The SEM images of MgxZn1−xO films grown on ZnO substrates at various growth parameters are shown in Figs.

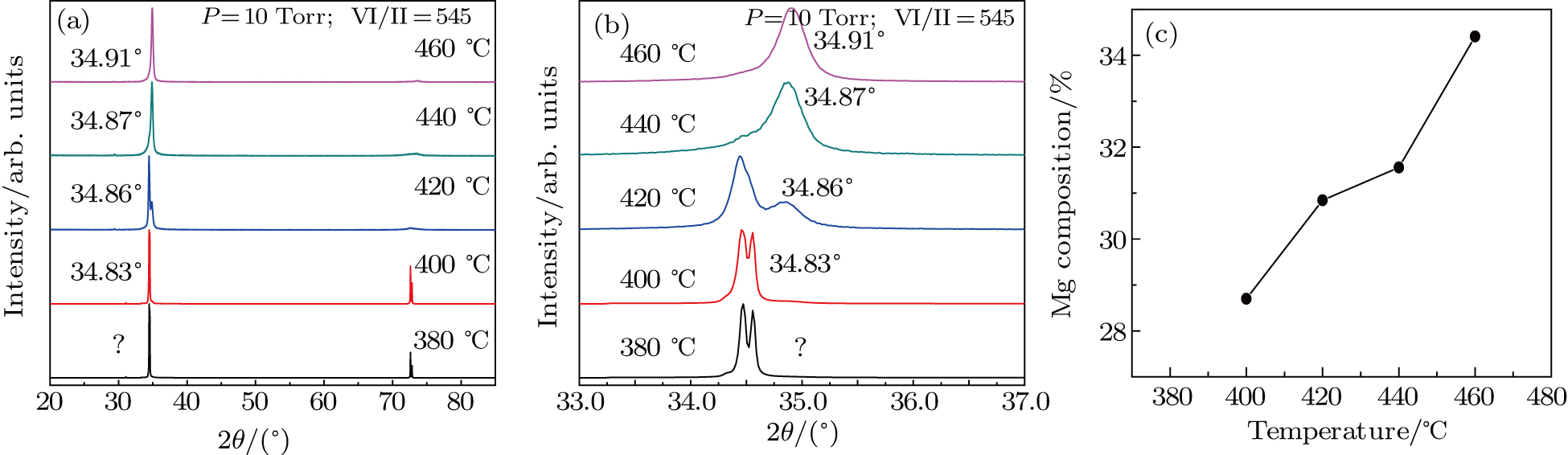

The effects of growth parameters on the incorporation of Mg component are discussed below. We first investigate Mg incorporation efficiencies in MgxZn1−xO films at various growth temperatures (from 380 °C to 460 °C), while the reactor pressure and the VI/II ratio are kept at 10 Torr and 545, respectively. XRD patterns of the samples are shown in Fig.

Since the film is thick enough and exceeds its critical thickness value, the strain in the film is assumed to be completely relaxed. Following Vegard’s law, we determine Mg content according to the relationship c = 5.2029 − 0.0020 x that is deduced from Fig.

| Table 1.

Calculated results of the effect of the substrate temperature. . |

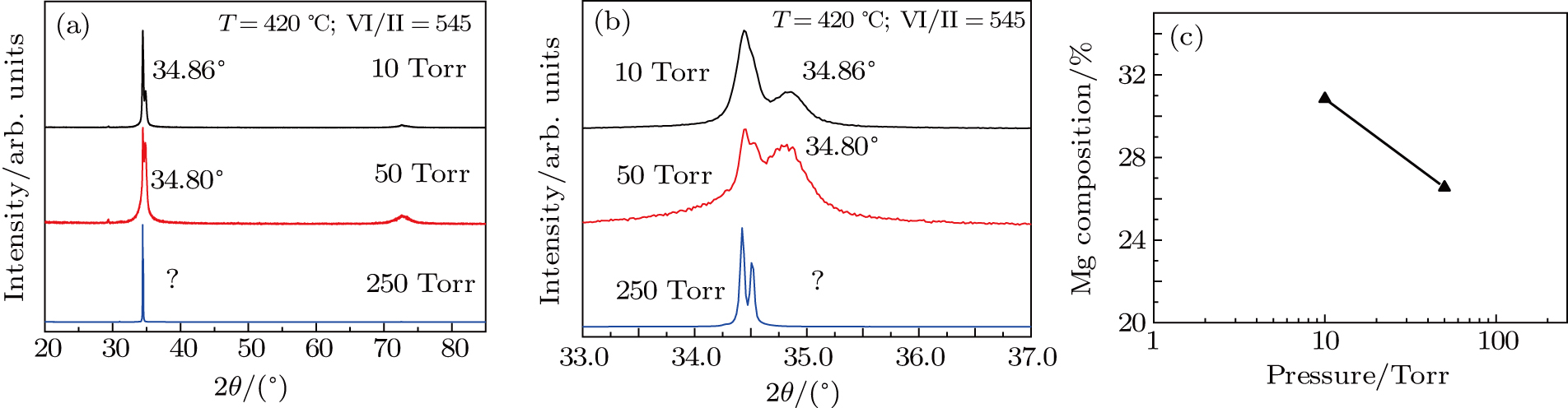

Figures

| Table 2.

Calculated results of the effect of the reactor pressure. . |

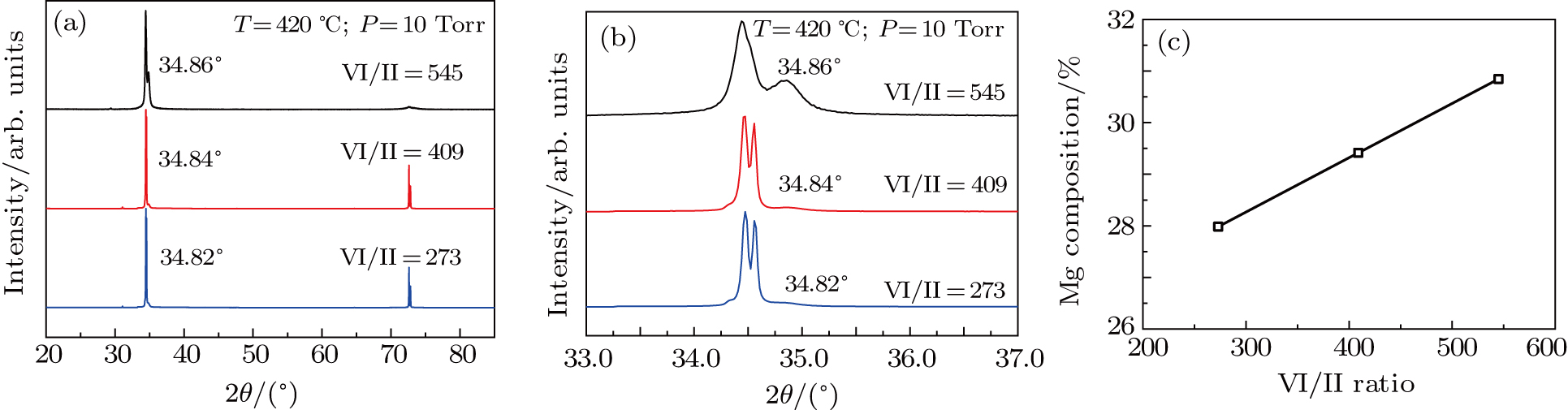

As shown in Figs.

| Table 3.

Calculated results of the effect of the VI/II ratio. . |

To further verify the above results, PL and XPS measurements are performed on the samples under different reactor pressures. Figure

Figure

In this work, single hexagonal phase MgxZn1−xO films with various values of Mg content are synthesized by MOCVD on c-plane Zn-face ZnO substrates. AFM images and SEM images demonstrate that MgxZn1−xO films each with flat surface can be obtained on appropriately thermally treated substrates. Systematical XRD, PL, XPS analyses reveal that high substrate temperature, low reactor pressure, and high VI/II ratio are needed to enhance the Mg incorporation efficiency in MgxZn1−xO films.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] |