† Corresponding author. E-mail:

Project supported by the National High Technology Research and Development Program of China (Grant No. 2014AA032608), the National Natural Science Foundation of China (Grant No. 61404101), and the China Postdoctoral Science Foundation (Grant No. 2014M562415).

We have investigated the factors affecting the current spreading length (CSL) in GaN-based light-emitting diodes (LEDs) by deriving theoretical expressions and performing simulations with APSYS. For mesa-structure LEDs, the effects of both indium tin oxide (ITO) and n-GaN are taken into account for the first time, and a new Q factor is introduced to explain the effects of different current flow paths on the CSL. The calculations and simulations show that the CSL can be enhanced by increasing the thickness of the ITO layer and resistivity of the n-GaN layer, or by reducing the resistivity of the ITO layer and thickness of the n-GaN layer. The results provide theoretical support for calculating the CSL clearly and directly. For vertical-structure LEDs, the effects of resistivity and thickness of the CSL on the internal quantum efficiency (IQE) have been analyzed. The theoretical expression relating current density and the parameters (resistivity and thickness) of the CSL is obtained, and the results are then verified by simulation. The IQE under different current injection conditions is discussed. The effects of CSL resistivity play a key role at high current injection, and there is an optimal thickness for the largest IQE only at a low current injection.

Current spreading is an important issue in many light-emitting diode (LED) materials,[1–4] particularly in materials that possess low conductivity.[5] For mesa-structure LEDs, current spreading in the top p-type layer is very weak, owing to the high resistivity of the p-type top cladding layer. This problem has been avoided by a current-spreading layer that spreads the current under the top electrode to regions not covered by the opaque top electrode. Usually, indium tin oxide (ITO) is employed as the p-type current-spreading layer above the p-GaN layer.[6,7] Many studies have analyzed the effects of ITO on current spreading.[8–15] There are also some studies on the effects of the resistivity and thickness of n-GaN on the current spreading length (CSL).[16,17] In this work, the effects of both ITO and n-GaN are taken into account, and a new Q factor is introduced to explain the effects of different current flow paths on CSL.

Vertical-structure LEDs, in comparison to mesa-structure LEDs, have smaller series resistance and better heat dissipation, which can achieve higher current density.[18] It is desirable to maintain high internal quantum efficiency (IQE) even at high current density level, since high IQE is a key factor to promote LED applications and energy saving. However, the current crowding effect starts to impede IQE improvement more significantly under high current injection, among other droop factors.[19] To address this issue, current-spreading layers have been predominantly employed in the top-emitting LED epi-structures. There are many such experimental or simulation-based studies in the literature to date.[20–26] The CSLs with low resistivity are superior to those with high resistivity, and the current spreading capability of thick CSLs is better than that of thin ones. Moreover, there is an optimal CSL thickness corresponding an IQE peak at low current density.[27,28] However, the current-density-dependent behavior of the fundamental parameters of the CSL as well as their impact on IQE in the high current density regime have not so far been well studied and differentiated in the literature. This requires a direct inquiry into the theoretical relationship between, for example, CSL resistivity/thickness and chip-IQE. In this work, we investigated the effect of CSL on the IQE of vertical-structure, GaN-based LEDs, by varying the basic physical properties, such as resistivity and layer thickness, of CSLs.

The current spreading path and equivalent circuit of the common mesa-structure LED are shown in Fig.

Using Ohm’s law, we obtain

Shown in Fig.

The same way, if we only consider path B (i.e., the effect of the n-GaN layer), the CSL can be expressed as

In fact, path A and B are present in both, and considering the effects of both, the CSL can be integrated as

Under different conditions, the proportions of paths A and B are not equal; we thus introduce a Q factor, defined as:

Figure

For calculation of IQE at different resistivity and thickness of the CSLs, from Fig.

| Fig. 2. (a) Schematic model of a vertical LED chip with a stripe-shaped n-metal. (b) Schematic illustration of current spreading in structure with linear stripe contact. |

The current spreading length (LS) is proportional to the thickness t, and inversely proportional to the resistivity ρ. Thus, k can be defined as

We define c0 = LS1/W, where LS1 is the current spreading length at 300 K in the condition of J0 = 100 mA/mm2, ρ0 = 1 × 10−4 Ω·cm, t0 = 5 μm, and W = 2 μm. From above, an expression for J is obtained as

The simulation structure is shown in Fig.

The effect of n-GaN on current spreading has been simulated, the results of which are shown in Figs.

Firstly, the effect of ITO on current spreading is investigated. Figure

| Fig. 3. Two-dimensional distribution of current density (a) without ITO layer and (b) with ITO layer. |

To verify the effect of resistivity and thickness of ITO layer on the CSL, we consider Figs.

A detailed explanation considering the Q factor is as follows. An increase in resistivity (ρn) results in an increase in the equivalent resistance (path B in Fig.

From the analysis, the theoretical explanation of the effects of the n-GaN layer has been perfected by the introduction of the Q factor.

The parameters of Fig.

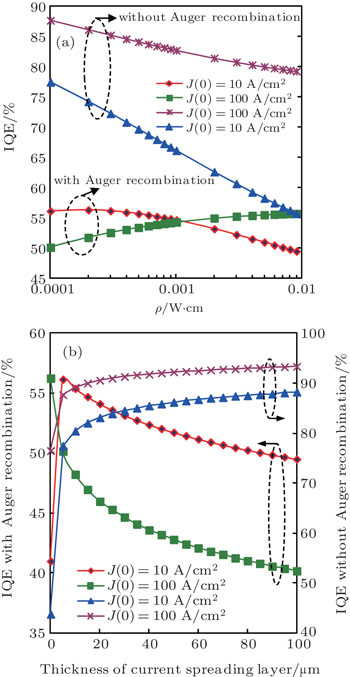

It has been reported that Auger nonradiative recombination plays a major role in the efficiency drop of MQW LEDs at high current density.[25] When the Auger recombination term is not considered, i.e., C = 0 in the ABC model, taking B = 2 × 10−11 cm3·s−1 (at 300 K)[30] and substituting Eq. (

Auger recombination is further considered at 300 K, taking C = 2 × 10−30 cm6·s−1,[30] with the obtained results shown in Fig.

Equation (

In order to further verify the effect of the CSL on IQE in the device (there are defects and dislocations in the device, i.e., considering the electronic leakage), the software APSYS is used to simulate. The simulation results are shown in Fig.

From Fig.

We have investigated the effect factors of CSL in mesa-structure LEDs. The effect of current spreading can be strengthened by increasing the thickness or reducing the resistivity of the ITO layer. A Q factor has been introduced for studying the effect of the n-GaN layer on current spreading, the value of which can be reduced by increasing resistivity or decreasing the thickness of n-GaN, thereby enhancing the CSL. Finally, the theoretical expressions are verified by using APSYS simulation software. The results of this work provide theoretical support for calculating the CSL of different mesa-structure LEDs more clearly and directly.

Moreover, the theoretical relationship between current density and the parameters (resistivity and thickness) of the CSL is obtained for the vertical GaN-based LEDs. IQE is discussed for different current injection conditions, which increases with the decrease of CSL resistivity and the increase of CSL thickness only in the low current density region. Through calculation with and without Auger recombination, IQE increases steadily and the efficiency droop is reduced with increasing of resistivity of CSL at high current injection; therefore, the effects of CSL resistivity play a key role. Only at low current injection, there is an optimal thickness for the maximal IQE, when the effects of thickness play a dominant role.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 | |

| 30 | |

| 31 | |

| 32 | |

| 33 | |

| 34 | |

| 35 |