Project supported by the National Key Research and Development Program of China (Grant No. 2016YFB0400603) and the National Natural Science Foundation of China (Grant No. 61335004).

Project supported by the National Key Research and Development Program of China (Grant No. 2016YFB0400603) and the National Natural Science Foundation of China (Grant No. 61335004).

† Corresponding author. E-mail:

Project supported by the National Key Research and Development Program of China (Grant No. 2016YFB0400603) and the National Natural Science Foundation of China (Grant No. 61335004).

Silver nanowire (AgNW) networks have been demonstrated to exhibit superior transparent and conductive performance over that of indium-doped tin oxide (ITO) and have been proposed to replace ITO, which is currently widely used in optoelectronic devices despite the scarcity of indium on Earth. In this paper, the current spreading and enhanced transmittance induced by AgNWs, which are two important factors influencing the light output power, were analyzed. The enhanced transmittance was studied by finite-difference time-domain simulation and verified by cathodoluminescence measurements. The enhancement ratio of the light output power decreased as the GaP layer thickness increased, with enhancement ratio values of 79%, 52%, and 15% for GaP layer thicknesses of 0.5 μm, 1 μm, and 8 μm, respectively, when an AgNW network was included in AlGaInP light-emitting diodes. This was because of the decreased current distribution tunability of the AgNW network with the increase of the GaP layer thickness. The large enhancement of the light output power was caused by the AgNWs increasing carrier spread out of the electrode and the enhanced transmittance induced by the plasmonic AgNWs. Further decreasing the sheet resistance of AgNW networks could raise their light output power enhancement ratio.

AlGaInP light-emitting diodes (LEDs) are widely applied in traffic signals and backlighting units for liquid crystal displays.[1,2] Indium-doped tin oxide (ITO) is commonly used as the transparent conductive layer on the top of LED structures to spread the carriers away from the opaque electrodes to enhance the quantum efficiency and avoid current crowding under the electrodes.[3] However, the scarcity of indium on Earth is causing the price of ITO to soar, thus raising the cost of LED chips.[4,5] Recently, commercially percolated silver nanowire (AgNW) networks have received much attention because they demonstrate promising transparent conductive performance originating from their low inter-wire junction resistance and low absorption loss.[6] The transmittance and sheet resistance of AgNW networks, which are two figures of merit to evaluate transparent conductive performance, reached ∼ 93.5% at 550 nm and ∼ 21.1 Ω/sq, respectively, when used as a skin-like pressure sensor.[7] A purified AgNW film could further improve the transmittance to 97.5% while keeping the sheet resistance below 70 Ω/sq.[8] AgNW networks can improve the optical performance when applied to optoelectronic devices. For example, the external quantum efficiency of AlGaInP LEDs was improved by 80%–100% when an AgNW network was used as a transparent conductive layer.[9,10] The efficiency of an organic solar cell containing an AgNW network electrode was demonstrated to be 1.45 times higher than that using an ITO electrode.[11] The efficiency enhancement was attributed to the current spreading and the charge injection. The electrical and optical performances of LEDs are interrelated. However, the joint electrical and optical effects of AgNW networks on the light output power of LEDs have not yet been studied. There is still much research that needs to be conducted before ITO can be replaced with AgNW networks in commercial optoelectronic devices, such as LEDs.

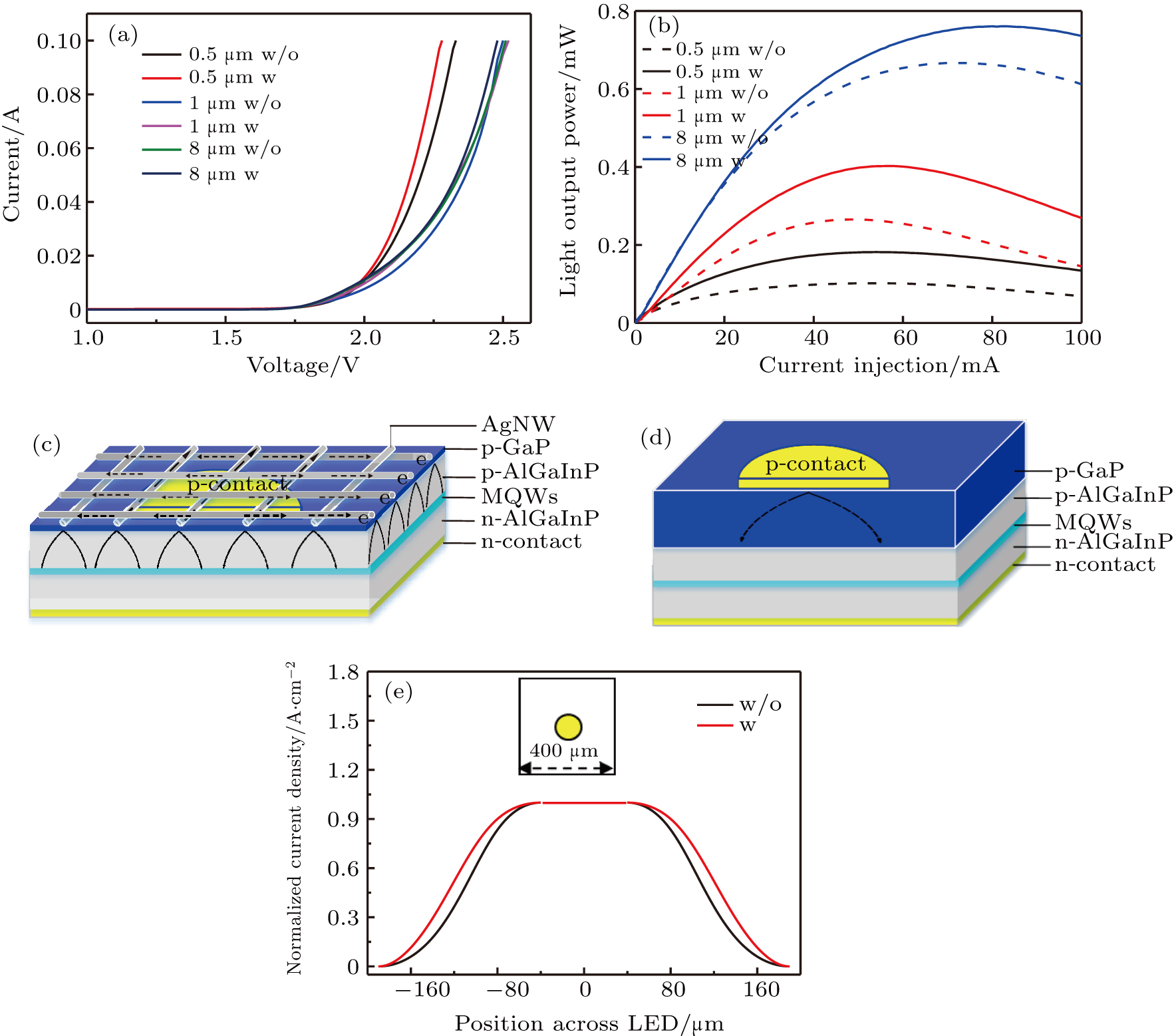

In this paper, the mechanism of the optical transmittance enhancement of AgNWs induced by surface plasmons (SPs), which is one of the important factors affecting the light output power of LEDs, is studied in detail. For AlGaInP LEDs with GaP layer thicknesses of 0.5 μm, 1 μm, and 8 μm, the maximum light output power increases by about 79%, 52%, and 15%, respectively, upon substitution of ITO with AgNWs. We examine the reason why the enhancement ratio of the light output power of AlGaInP LEDs decreases with the increase of the GaP thickness.

AlGaInP LEDs were grown on n-GaAs substrates by metal–organic chemical vapor deposition. Fifteen pairs of Al0.6Ga0.4As/AlAs layers with distributed Bragg reflectors were grown on a 100-nm-thick GaAs buffer layer. The active region was composed of 800-nm-thick 60-period (Al0.5Ga0.5)0.5In0.5P/(Al0.1Ga0.9)0.5In0.5P multiple quantum wells (MQWs), which were sandwiched in p- and n-(Al0.7Ga0.3)0.5In0.5P cladding layers for electron and hole confinement. To study the current spreading effect of the AgNW network, three thicknesses of the Mg-doped p-GaP window layer were used in this work, which were 0.5 μm, 1 μm, and 8 μm, with a doping density of 5 × 1018 cm−3. Au (50 nm)/BeAu (150 nm)/Au (200 nm) with a diameter of 100 μm was first deposited and then patterned by wet etching as the p-type electrode. After the LED wafer was lapped down to around 200 μm, AuGeNi (50 nm)/Au (300 nm) was deposited as the n-type electrode. The wafer was annealed in nitrogen at 430 °C for 30 s. Then AgNW solution with a concentration of 0.5 mg/mL or 1.5 mg/mL was spin coated at 270 rpm on the LED surface to provide a uniform distribution and then stuck on the LED surface through the van der Waals force. Each LED with an AgNW film was put on a hot plate at 200 °C for 10 min to lower the nanowirenanowire contact resistance. Each LED wafer was scribed into chips (300 μm × 300 μm), and then were packaged. The light output power and electroluminescent spectrum were carried out by integrating sphere (Ocean Optics USB 2000+), and the current–voltage (I–V) curves were measured by Keithley 4200.

Figures

The high transmittance of the AgNW network, because of the absorption behavior of Ag, could be considered to originate from the exposed area. We count the number of Ag-NWs in the SEM images in Figs.

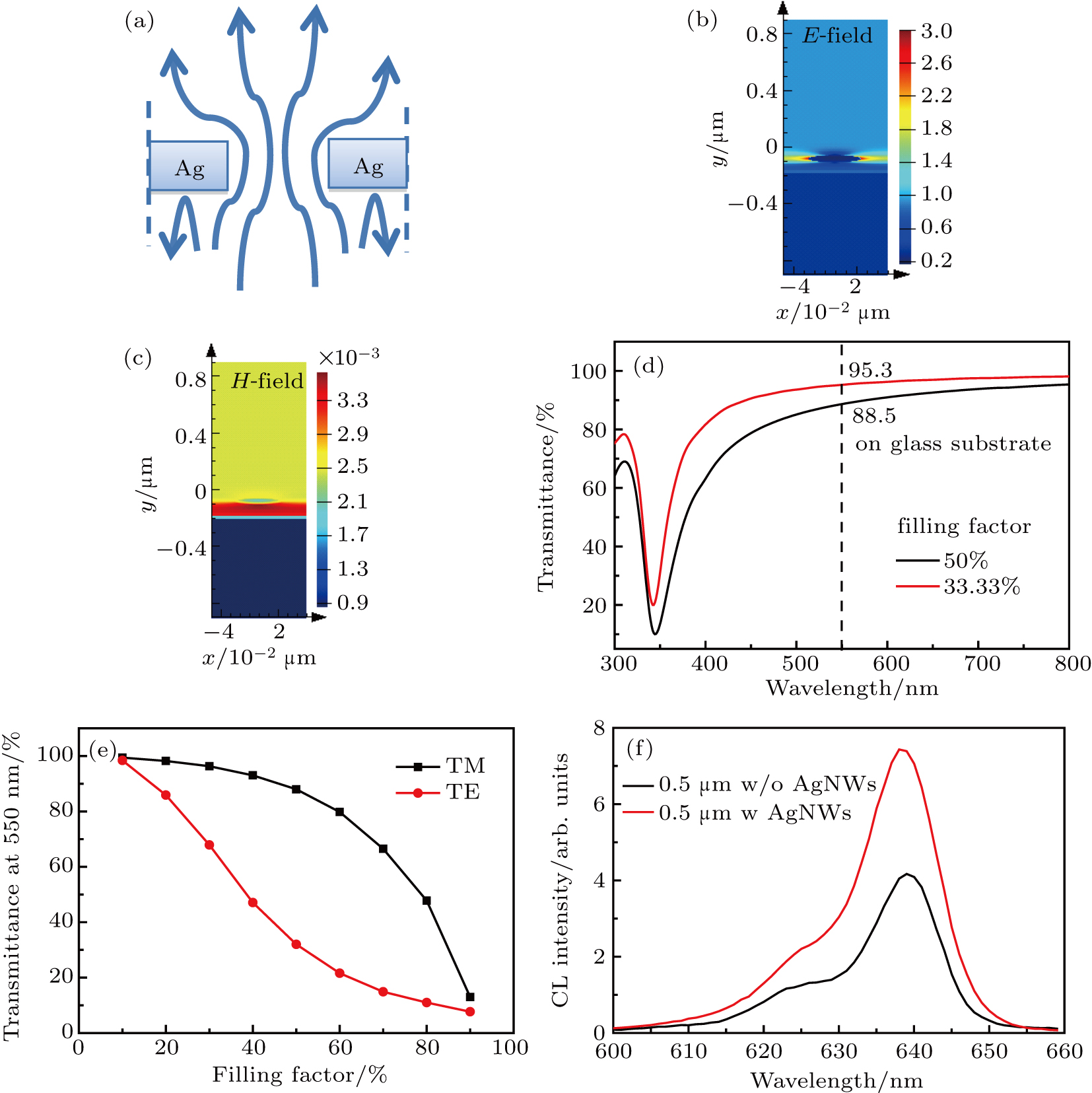

To ensure accurate analysis of the light transmission, the electric and magnetic field distribution of a one-period AgNW structure by a normal incident transverse magnetic (TM) polarized plane wave at 550 nm is calculated by finite-difference time-domain (FDTD) simulation for an AgNW filling factor of 50% on a glass substrate, as presented in Figs.

Cathodoluminescence (CL) measurements were carried out to confirm the plasmonic transmittance enhancement of the AgNW network. The carriers in the MQWs were uniform, which were excited by a continuous wave (CW) electron beam (e-beam).[16] The measurement system was a spatially resolved CL spectroscope (Gatan Mono 3+) combined with a field-emission environmental scanning electron microscope (ESEM). The ESEM-CL system allowed the observation and measurement of nanostructures with a spatial resolution of 1.2 nm and spectral precision of 0.66 nm. The experimental conditions of the ESEM and the CL spectrometer included an accelerating voltage of 20 kV, an e-beam current of 0.1 nA to 10 nA, a working distance of 12.6 mm, and a photomultiplier tube (PMT) detector with a grating of 1200 l/mm. The detection wavelength of the PMT detector ranged between 200 nm and 930 nm. Figure

Figure

The enhancement of transmittance induced by the SPs of AgNWs should be the same for all the samples with different GaP layer thicknesses, which indicates that the increase of the light output power should also be the same. However, the electrical properties of the AgNW network and GaP window layer determine the current distribution as well as the light emission profile of the LEDs. Figures

Light generated outside the electrode can be enhanced by the plasmonic AgNWs, which indicates that the more the current spreads out, the more the light transmittance is enhanced. For the LED with a 0.5-μm-thick GaP layer, the highest increase ratio of light output power of 79% is mainly attributed to the increased lateral current spreading and then the plasma-enhanced transmittance. Meanwhile, for the LED with an 8-μm-thick GaP layer, the enhancement of light output power by the AgNWs is the smallest among all the LEDs. This is because the AgNWs have little effect on the lateral current spreading in this case, so only a portion of the optical field outside the electrode on the LED surface has the chance to obtain the enhanced transmittance.

The light output power of AlGaInP LEDs with AgNWs as a transparent conductive layer for current spreading was examined. It was found that the increase of the ratio of light output power of AlGaInP LEDs with and without AgNWs decreased with the increase of GaP layer thickness, which was attributed to the decreased tunability of the additional current spreading caused by the AgNW network. When the sheet resistance of the GaP layer was lower than that of AgNW networks, which are connected in parallel, the current spreading path changed from AgNWs to GaP. The output light increase of about 79% obtained for the thin GaP layer was mainly attributed to the current spreading induced by the AgNWs and then their SP-enhanced transmittance effect. The optimized results show that large power enhancement and well contact can be obtained both by using this new technology, in which better carrier transportation and light transmittance are achieved at the same time.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] |