† Corresponding author. E-mail:

We fabricated TiN coplanar waveguides using standard lithography techniques followed by ICP etch. In order to achieve high quality factor, we investigated the film growth by choosing different deposition conditions for various substrates. Quality factors of waveguide resonators were measured at 20 mK in both high and low microwave power limits. An inner quality factor of several million was achieved at high power limit for a predominantly (200)-oriented TiN film which was grown on HF cleaned silicon wafer. A quality factor of larger than one million was achieved at high power limit for TiN film grown on sapphire.

The recent progresses on superconducting quantum computation suggest that superconducting quantum circuits are promising approaches to realize scalable quantum computation.[1–5] Currently, the most common circuitry design for manipulating and reading the superconducting qubits is a circuit QED system, which consists of a superconducting qubit coupled with coplanar waveguides (CPW) or 3D cavities.[6–9] The coplanar waveguides are crucial parts for qubit manipulation and measurement. In addition, the coplanar waveguides also serve as couplers to couple different qubits together.[1, 10] Therefore, the property of coplanar waveguide has a great influence on the performance of qubit.[11] It is found that high quality factor, which means low loss, is a preliminary for long resonant lifetimes and better resolved frequencies, leading to a longer qubit decoherence time and higher signal-to-noise ratio for qubit measurement.[12]

The essential issues that affect quality factor of CPW include the electric resistance, the quality of the film, the participation ratio,[13] and the substrate. Since superconducting materials below the critical temperature exhibit zero electric resistance, Al, Nb, and Re are widely used to fabricate high quality factor CPW in superconducting quantum circuits. The typical value of the quality factor of these CPW is about

In order to further increase the quality factor of CPW, people have tried to minimize the TLSs in the materials. It is found that nitrides are very stable even against oxidation.[12] Superconducting coplanar waveguide based on nitrides has shown very high quality factor in high power regime. Recently, several groups have reported CPWs of high quality factors made of TiN and NbTiN, respectively.[17, 18] However, voltage bias and deep etching are used in these processes, increasing the unwanted variation of the fabrication. Moreover, the toxicity of HMDS the Delft group used to clean substrate makes the process more dangerous. Here, we simplify the procedures by using standard lithography techniques followed by ICP etch. We investigate the optimal deposition conditions for TiN film. An inner quality factor of several million is achieved at high power limit for a predominantly (200)-oriented TiN film which is grown on HF cleaned silicon wafer. A quality factor of larger than one million is achieved for TiN film grown on sapphire at high power limit. These figures of merit are comparable to those reported in previous processes.

By using reactive DC sputtering system, we deposit TiN films onto both high resistivity (> 10 k

The quality of the film is one of the important issues to the quality factor of CPW. At first, we investigate the influence of HF cleaning on the growth of TiN film. Two groups of TiN films are sputter-deposited onto silicon substrate with and without HF cleaning. The nitrogen gas flow was set at either 6 or 8 sccm while the argon gas flow was always 12 sccm. Total gas pressure is kept at 0.4 Pa and the substrates are preheated to 500 °C before deposition. XRD results of these TiN films are shown in Fig.

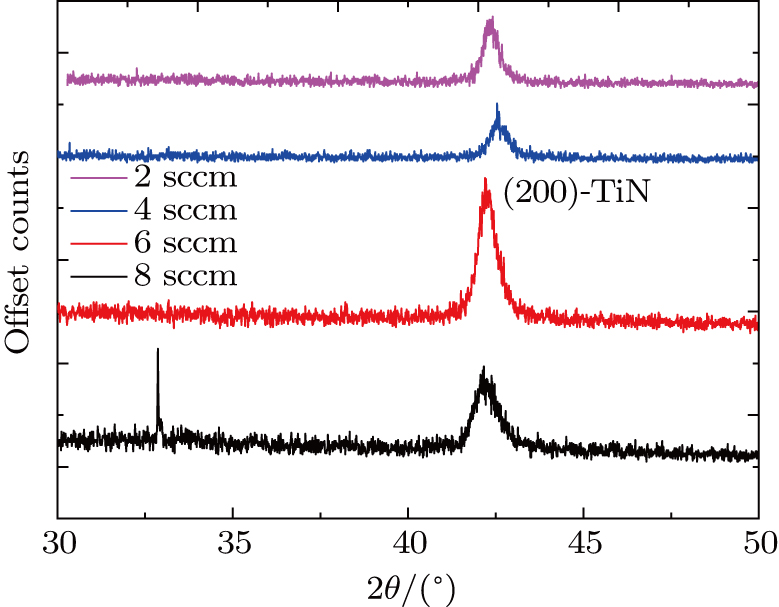

Since we used reactive DC sputter method, the nitrogen gas percentage may have an influence on the growth of TiN films. We change the nitrogen gas flow (2, 4, 6, 8 sccm) while keeping the argon gas flow at 12 sccm and total pressure at 0.4 Pa. All the silicon substrates are cleaned by HF solution before being loaded to sputter chamber and are heated to 500 °C before deposition. From the XRD results, we can know that all the four films exhibit (200)-TiN growth priority and no (111)-TiN characteristic peak can be seen. From the height and FWHM of the peaks, we can consider nitrogen gas flow of 6 sccm as an optimum condition for (200)-TiN to grow.

We also investigate the effect of the total pressure on the film. Shown in Fig.

Besides investigating the crystallization of TiN films, we also measure the flatness of the film surface. AFM scans of TiN films grown in different nitrogen gas flow are shown in Fig.

To summarize the optimum TiN film growth condition, we find that HF cleaning has a positive effect on the growth of (200)-TiN film on silicon substrate. The high nitrogen to argon ratio limit might not be the best choice. A lower total pressure and medium nitrogen gas percentage can result in a good TiN film with only (200) orientation.

It is find that the quality factor of the CPW relies on the loss of the substrate. In order to decrease the loss of CPW, people have broadly used sapphire instead of silicon as substrates in superconducting quantum circuits.[20, 21] We use sapphire substrate for comparison. Similar to that of the silicon substrate, we sputter the TiN film on a sapphire at 500 °C, 0.4 Pa total pressure, 6 sccm nitrogen flow, and 12 sccm argon flow. The XRD spectrum of TiN film on sapphire is shown in Fig.

| Fig. 5. XRD result of TiN film grown on sapphire. (111)-TiN peak at 2θ around 37.5° and (200)-TiN peak at 2θ around 43° are both present. |

Using standard lithography technique followed by ICP SF

|

A full transmission curve of waveguide resonators fabricated on TiN film which grown on silicon substrate is shown in Fig.

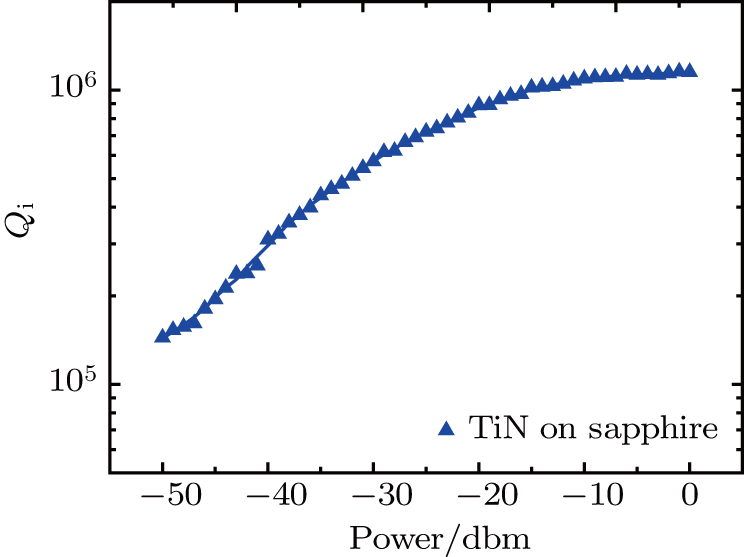

Usually, the quality factor of CPW depends on the input power. We measure the quality factor versus the input power of one TiN waveguide resonator in Fig.

In conclusion, we have investigated TiN films grown in different conditions, i.e., with/without HF cleaning, nitrogen to argon gas flow ratio, total pressure, silicon/sapphire substrate. XRD and AFM are utilized to characterize the crystallization and surface topography respectively. Generally, (200)-TiN has been successfully obtained on silicon substrate both with and without HF cleaning. They have shown a high quality factor at multi-photon level. TiN film on sapphire is a mixture of (111)-TiN and (200)-TiN. However, it still shows a low loss at both multi and single photon limit. These high quality factor CPWs are promising for sustaining a long coherence life time of quantum states.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] |