† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61308092 and 61505209).

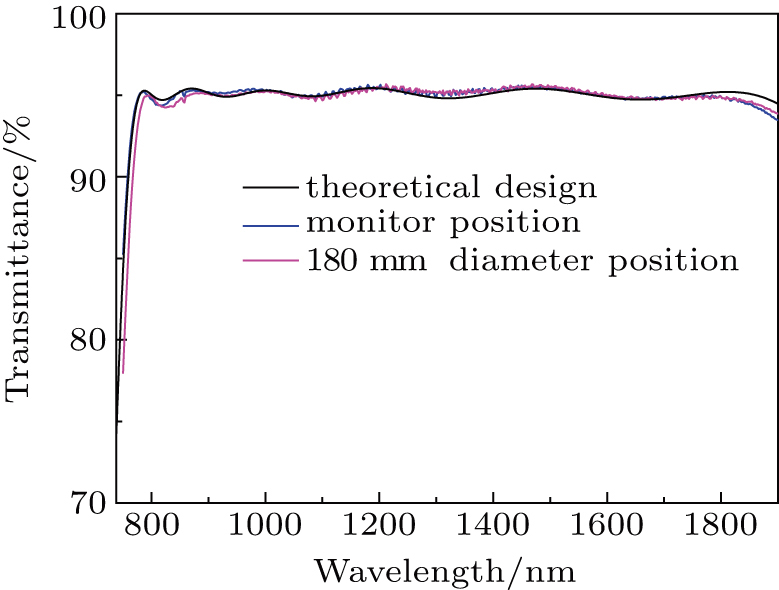

Multi-layer optical coatings with complex spectrum requirements, such as multi-band pass filters, notch filters, and ultra-broadband antireflection coating, which usually contain very thin layers and sensitive layers, are difficult to be fabricated using a quartz crystal monitoring method or a single wavelength optical monitoring system (SWLOMS). In this paper, a broadband antireflection (AR) coating applied in the wavelength range from 800 nm to 1800 nm was designed and deposited by ion beam sputtering (IBS). Ta2O5 and SiO2 were chosen as high and low refractive index coating materials, respectively. The optimized coating structure contains 9 non-quarter-wave (QW) layers totally with ultra-thin layers and sensitive layers in this coating stack. In order to obtain high transmittance, it is very important to realize the thickness accurate control on these thin layers and sensitive layers. A broadband optical monitoring mixed with time monitoring strategy was successfully used to control the layer thickness during the deposition process. At last, the measured transmittance of AR coating is quite close to the theoretical value. A 0.6% variation in short wavelength edge across the central 180 mm diameter is demonstrated. A spectrum shift of less than 0.5% for 2 continuous runs is also presented.

Optical coatings with complex spectrum requirements, such as multi-band pass filters, notch filters, and ultra-broadband antireflection (AR) coatings[1,2] with ultra-thin and sensitive layers, are very difficult to be controlled accurately by a quartz crystal monitoring method[3] or a single wavelength optical monitoring system (SWLOMS)[4] due to their intrinsic defects and limitations.[5–9] To surpass the limitation of these methods, great efforts have been made on improving the broadband optical monitoring (BBOM) technique for decades. The BBOM is an available method and has many advantages, such as error self-compensation, higher monitor precision, adaptation to non-quarter-wave, and sensitive film deposition. The transmission spectrum of the coating during the deposition process can be acquired in-situ using a charge coupled detector (CCD) spectrometer,[10] which is equipped in the deposition chamber. The machine-installed software fits the acquired spectrum immediately, based on which the deposition process is terminated when the value of merit function meets the target. However, ultra-thin layers can hardly be monitored only by using BBOM due to small value change in transmittance at monitored layers. Thus, time monitoring is preferable because of the stable deposition rate of IBS.

In this paper, a broadband AR coating applied in the wavelength range from 800 nm to 1800 nm was designed and then deposited by IBS. Ta2O5 and SiO2 were chosen as high and low refraction coating materials, respectively.[11] The optimized structure contains 9 non-quarter-wave layers totally with ultra-thin layers and sensitive layers. In order to obtain high transmittance, the most important thing is to realize the thickness accurate control of these thin layers and sensitive layers. A broadband optical monitoring mixed with time monitoring strategy was successfully used to control the layers thickness during the deposition process.

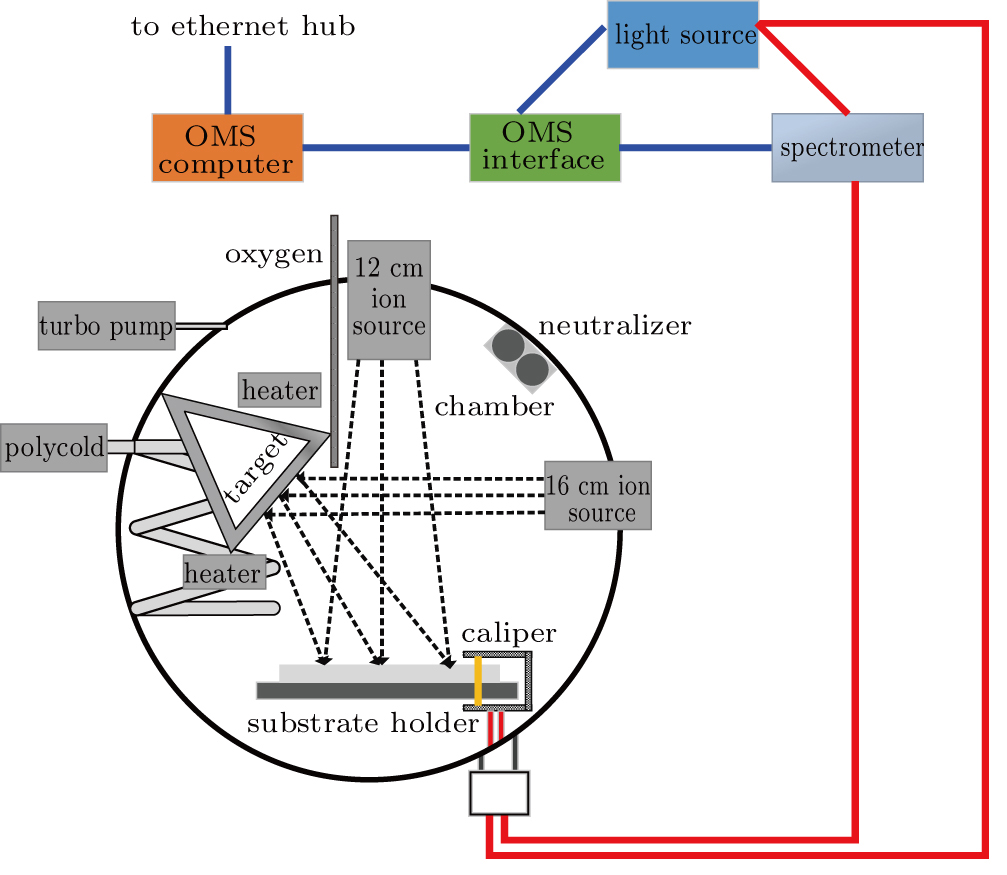

The broadband AR coating was fabricated by dual ion beam sputtering (DIBS),[12–15] as shown in Fig.

Optilayer was employed to design broadband AR coatings in the range from 800 nm to 1800 nm. The refractive indices of Ta2O5 and SiO2 are shown in Fig.

|

| Fig. 2. (color online) Refractive indices of materials. Red line represents the Ta2O5 layer and blue line represents the SiO2 layer. |

The average transmittance of the optimized design coating is more than 99.5% (without considering reflection of backside) in the wavelength range from 800 nm to 1800 nm. The initial design was based on a standard quarter-wave stack which contained 9 layers and provided enough optimizable variables to realize high transmittance (99.5%). However, it is difficult to avoid introducing ultra-thin layers when the film design is optimized. The theoretical transmission spectrum without considering backside reflection and the stack structure of the final optimized design coating are shown in Figs.

The optical monitoring software provides a superior solution for optical end point detection of optical multi-layer coatings produced by the Spector-HT system. The Quest OMS contains a variety of algorithms for controlling quarter-wave and non-quarter-wave coatings, using in-situ measurements of the transmission spectrum of the monitoring witness. The operator-friendly software offers fully automatic operation incorporating real time[16] and historical deposition analysis capabilities. Many control schemes are employed to control the layer thickness, such as average rate (range) module, initial optical rate module, quarter-wave scaling end point module, and transmission fit module. The transmission fit module contains three fitting strategies, which are introduced to monitor the optical film deposition process as candidates, i.e., Control to Thickness, Single Wavelength, and Control to Spectrum.

In this paper, the BBOM system is employed to control the layer thickness. The BBOM system is a real time method related parameters (e.g., deposition rate and refractive index) calculated by fitting the real time measured transmission spectrum by a well-known matrix method to calculate a stop time prediction that most closely matches the target thickness for this layer. It contains a variety of algorithms for controlling quarter-wave and non-quarter-wave coatings, using in-situ measurements of the transmission spectrum of the monitoring witness. When the BBOM is used, the transmission spectrum of each layer in-situ measured by broadband optical monitoring system is fitted, the real time refractive index and deposition rate can be obtained. Then the stop time is calculated based on the chosen thickness. The deposition time is determined by

|

Figure

From Fig.

As a comparison, two monitoring methods were given for this broadband AR coating. Table

| Table 1. The monitoring strategy of each layer. . |

The broadband optical monitoring system uses intermittent transmission monitoring through the center of one of the planets. Only a small part of a planet can be monitored during the deposition. In order to obtain large aperture optical components with the same performance as the monitoring witness, uniformity is a truly important factor, which can directly affect optical and mechanical performance of high precision optical coatings. It is necessary to control the coating thickness distribution over the coated substrates. A static mask and a rotary accurate mask were designed and introduced to realize accurately layer thickness control during deposition. Generally, the static mask is used for uniformity coarse adjustment to limit the variation in the short wavelength edge to a small range and it should never be modified again after generation. The rotary accurate mask can be generated and reshaped using many times iteration for several consecutive runs until the variation in the short wavelength edge is small enough and meets the requirement. Figure

Figure

Repeatability, which can never be ignored in batch production, is also an important performance factor for an optical film coater. Thus, experiments for 2 continuous runs were executed. Figure

In this paper, broadband AR coatings in the range from 800 nm to 1800 nm were designed by Optilayer and deposited by IBS. Broadband optical monitoring mixed with time monitoring was employed to monitor the layer thickness during the deposition process. Results show that broadband AR coatings can be successfully fabricated by IBS using BBOM and time monitoring strategy during the deposition process. A 0.6% variation in the short wavelength edge across the central 180 mm diameter is demonstrated. A wavelength shift of less than 0.5% for 2 continuous runs is also presented.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] |