† Corresponding author. E-mail:

‡ Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61404098, 61176070, and 61274079), the Doctoral Fund of Ministry of Education of China (Grant Nos. 20110203110010 and 20130203120017), the National Key Basic Research Program of China (Grant No. 2015CB759600), and the Key Specific Projects of Ministry of Education of China (Grant No. 625010101).

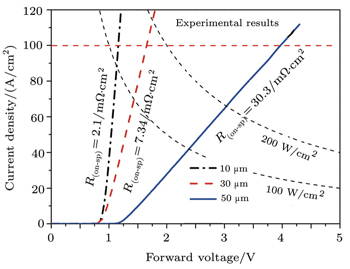

In this paper, 1.2 kV, 3.3 kV, and 5.0 kV class 4H–SiC power Schottky barrier diodes (SBDs) are fabricated with three N-type drift layer thickness values of 10 μm, 30 μm, and 50 μm, respectively. The avalanche breakdown capabilities, static and transient characteristics of the fabricated devices are measured in detail and compared with the theoretical predictions. It is found that the experimental results match well with the theoretical calculation results and are very close to the 4H–SiC theoretical limit line. The best achieved breakdown voltages (BVs) of the diodes on the 10 μm, 30 μm, and 50 μm epilayers are 1400 V, 3320 V, and 5200 V, respectively. Differential specific-on resistances (Ron−sp) are 2.1 mΩ ·cm2, 7.34 mΩ·cm2, and 30.3 mΩ·cm2, respectively.

Silicon carbide (SiC) is one of the most promising wide band gap semiconductors for high power, high frequency, and high temperature electronic applications.[1–7] In particular, it can lead to a drastic reduction in size and weight of the power electronic system. The commercial availability of 4-inch (1 inch = 2.54 cm) wafer of 4H–SiC and the continuing efforts in scaling up SiC substrates by a number of companies are creating the basis for an emerging SiC power electronic industry.[8–15] The 4H–SiC Schottky barrier diode (SBD) as one of the major unipolar devices, is expected to replace the Si bipolar rectifier in a range from 600 V to 6500 V in the future due to its fast switching speed and low switching power dissipation. One of the typical applications of SiC SBDs is to serve as a fast diode employed in a power-factor-correction circuit of switching mode power supply.[16–19] Because of the negligibly small reverse recovery time of SiC Schottky barrier diode, the switching loss can be dramatically reduced and the switching frequency can be increased, leading to the downsizing of passive components. Since the first 1-kV SiC Schottky barrier diode with a low specific on resistance was demonstrated in 1993,[20,21] sustained efforts have been made to develop the SiC power Schottky barrier diode device technology and many 4H–SiC high voltage Schottky barrier diode devices have been demonstrated.[7–12,16,19,22] In the present paper, we report our newly developed high performance 1.2 kV, 3.3 kV, and 5.0 kV class 4H–SiC The first epitaxial layer sample (No .1) has a thickness of Schottky barrier diodes. 10 μm and a doping amount of 6.7 × 1015·cm−3. The second epitaxial layer sample (No. 2) has a thickness of 30 μm and a doping amount of 2.1 × 1015·cm−3. The third epitaxial layer sample (No. 3) has a thickness of 50 μm and a doping amount of 1.1 × 1015·cm−3. The Ti (for No. 1 and No. 2) and Ni (for No. 3) are employed as the Schottky contact metal.

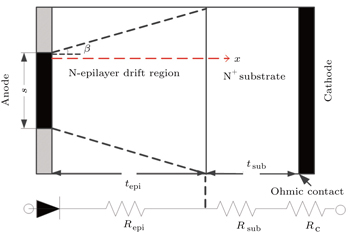

Figure

| Fig. 1. Simplified cross-sections of the fabricated and simulated 4H–SiC SBD structure (a) and fabrication process flow (b). |

The fabrication process starts from a standard cleaning process, after which the native oxide was stripped in dilute hydrofluoric (HF) acid. Next, aluminum (Al) was ion implanted to form the multiple floating guard rings (MFGR) termination. The Al implanted epitaxial layers were annealed at 1700 °C for 30 min to electrically activate Al ions. A graphite film was used to suppress degradation in the electrical properties of SBDs by activation annealing. The graphite film was removed by oxidation at 1100 °C for 1 h after the activation annealing, followed by surface passivation with plasma enhanced chemical vapor deposition (PECVD) oxide. Then, Ni was sputtered on the back cathode region. The Ohmic contact annealing was carried out at 1000 °C for 5 min by using a rapid thermal processing (RTP) system. Ti or Ni film was also deposited and patterned to form the front Schottky contact. After ohmic and Schottky contact formation, about 4-μm Al was sputtered to form a thick overlay metal on the anode and cathode separately to improve the voltage and current distribution. Finally, a thick polyimide was coated as the last passivation layer. The active area size of fabricated devices were all 4 mm2.

| Table 1. Thickness values and doping concentrations of 4H-SiC epilayer employed for SBD fabrication. . |

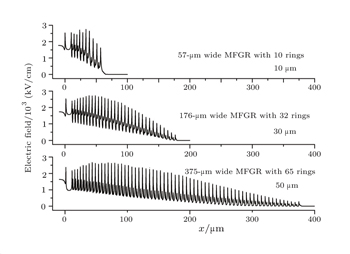

To achieve a nearly ideal breakdown voltage of the fabricated 4H–SiC SBD, the MFGR junction termination structure was adopted, designed and optimized with an ISE-DESSIS simulator. To achieve the nearly ideal breakdown voltage, the key is to optimize the MFGR width (w) and space (s). The objective of the MFGR is to reduce the electric field at the edge of Schottky contact and make the electric field distribution more uniform through the termination region. The obtained optimum designs for the 4H–SiC SBDs have 57 μm-wide MFGR with 10 rings (epitaxial thickness: 10 μm), 176 μm-wide MFGR with 32 rings (epitaxial thickness: 30 μm), and 375 μm-wide MFGR with 65 rings (epitaxial thickness: 50 μm), respectively. Figure

Figure

| Fig. 3. Forward current density–voltage characteristics of SiC SBDs fabricated with wafers No. 1–No. 3 having different epitaxial thickness values (10 μm, 30 μm, and 50 μm). |

Owing to the current flow with the lateral effect in the epitaxial layer of power SBD device, the active area is larger than the anode area. Therefore, the forward conduction of 4H–SiC SBD can be a model as shown in Fig.

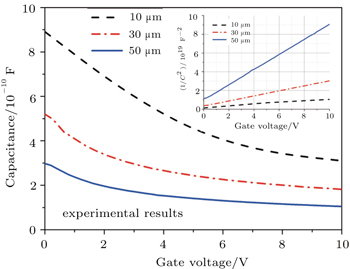

The reverse blocking characteristics of fabricated 4H–SiC SBDs based on epitaxial layers with different thickness values are in Fig.

| Fig. 6. Reverse leakage current density characteristics (JR–V) of the fabricated 4H–SiC SBDs based on epitaxial layers with different thickness values. |

The dc blocking characteristic test is done in a probe station that is capable of testing the case of up to 10 kV. It can be seen that a sharp avalanche behavior is observed at reverse voltages of 1.4 kV (epitaxial thickness: 10 μm), 3.32 kV (epitaxial thickness: 30 μm), and 5.2 kV (epitaxial thickness: 50 μm), respectively. Figure

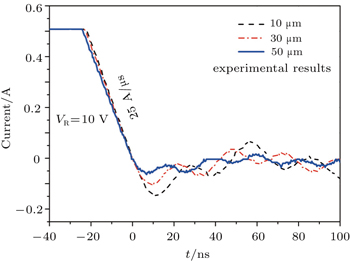

The reverse recovery transients of the 1.2-kV, 3.0-kV, and 5.0-kV 4H–SiC SBDs at room temperature are shown in Fig.

| Fig. 7. Reverse recovery transient characteristics of the fabricated 4H-SiC SBDs at room temperature. |

| Table 2. Reverse recovery characteristics of the fabricated 4H–SiC SBDs at room temperature. . |

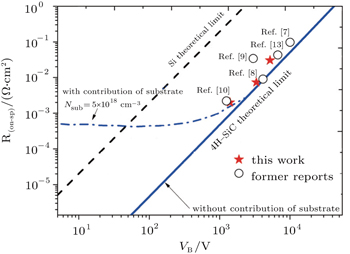

Figure

For the unipolar power device such as Schottky diode, there is a tradeoff between specific on-resistance and breakdown voltage. For a certain rated breakdown voltage (BV), the ideal on-resistance of the device depends on the dielectric constant, the carrier mobility, and the critical electric field of semiconductor material. The on-resistance can be expressed as follows:

High-performance 4H–SiC power SBDs with three N-type drift layer thickness values of 10 μm, 30 μm, and 50 μm are designed and fabricated in this paper. The presented devices show excellent avalanche breakdown capabilities, static characteristics, and reverse recovery transients. The performances of the fabricated devices are very close to the 4H–SiC theoretical limit line. We successfully obtain a 4H–SiC SBD fabricated on a 30-μm thick 2.1 × 1015 cm−3 nitrogen-doped epilayer with a breakdown voltage of 3.32 kV and a differential specific-on resistance (Ron−sp) of 7.34 mΩ· cm2, achieving a best

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 |