† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. U1832190, 61501364, U1537211, and 11705142).

The phenomenon of secondary electron emission is of considerable interest in areas such as particle accelerators and on-board radio frequency (RF) components. Total secondary electron yield (TSEY) is a parameter that is frequently used to describe the secondary electron emission capability of a material. It has been widely recognized that the TSEY vs. primary electron energy curve has a single-hump shape. However, the TSEY–energy curve with a double-hump shape was also observed experimentally—this anomaly still lacks explanation. In this work, we explain this anomaly with the help of a millimetre-scale (mm-scale) silver pillar array fabricated by three-dimensional (3D) printing technology. The TSEY–energy curve of this pillar array as well as its flat counterpart is obtained using sample current method. The measurement results show that for the considered primary electron energy (40–1500 eV), the pillar array can obviously suppress TSEY, and its TSEY–energy curve has an obvious double-hump shape. Through Monte Carlo simulations and electron beam spot size measurements, we successfully attribute the double-hump effect to the dependence of electron beam spot size on the primary electron energy. The observations of this work may be of help in determining the TSEY of roughened surface with characteristic surface structures comparable to electron beam spot size. It also experimentally confirms the TSEY suppression effect of pillar arrays.

Secondary electron emission is of particular interest to various applications, including but not limited to accelerator,[1,2] high power microwave components on satellite,[3,4] and electric propulsion.[5] Total secondary electron yield (TSEY), which is frequently used to characterize the secondary electron emission capability of a material, refers to the average emitted electrons per incident primary electron. Generally speaking, TSEY is determined by the outermost surface of the target material. When primary electron energy is no more than a number of keV, the thickness of surface layer responsible for secondary electron emission is just a number of nanometers. For applications such as electron cloud suppression of particle accelerators, TSEY suppression is favored. Various surface treatment methods have been studied for this purpose, such as carbon coating,[6] TiN coating,[7] plasma bombardment,[8] vacuum pyrolyzing,[9] and surface roughening.[10–18] For example, millimeter-scale structures such as triangular and rectangular groove have been studied both theoretically and experimentally. However, secondary electron emission suppression capability of pillar array has only been studied theoretically in Ref. [16] without any experimental verification.

It is well-known that TSEY depends on several parameters, such as incident energy and angle[14] of primary electron, temperature,[19] and contaminations.[8] It is also widely known that typical yield–energy curve is of a single-hump shape.[20] What is more, if expressed in reduced form, the yield–energy curve for various materials can be described by a universal curve.[20] However, based on both our own experiences on TSEY measurement and data presented in published work,[19,21] it was found that the yield–energy curve may be of a double-hump shape. As shown in Fig.

| Fig. 1. The TSEY–energy curve showing an abnormal double-hump shape (reproduced from Refs. [19] and [22]). Wang et al. fabricated roughened surface with silver plated aluminum plates using laser etch technique, while Mata et al. reported secondary electron emission properties of polished and unpolished aluminum samples. |

In this work, taking advantage of three-dimensional (3D) printing technology (i.e., selective laser sintering technology), a silver millimeter-scale pillar array is fabricated with the expectation to answer the two questions mentioned above. Through Monte Carlo simulations and TSEY measurements, we verify that pillar array is efficient for electron emission suppression, and an energy-dependent electron beam size results in a double-hump shape yield–energy curve.

A schematic view of the fabricated pillar array is shown in Fig.

The measured TSEYs of both flat surface and pillar array surface are shown in Fig.

Considering the theoretical work presented in Ref. [16], experimental observations shown in Fig.

First, to demonstrate the TSEY suppression effect, we set up our simulation as follows: the electron beam spot size is set as 15 mm and the pillar array has a size of 15 × 15. The diameter, height, and interval of the pillar are the same as those used in Fig.

The second and third observations mentioned earlier can be explained by considering the dependence of electron beam spot size on the primary electron energy. Due to the working principle of electron gun, its spot size may change with primary electron energy. Generally, the exact relation between spot size and primary electron energy usually depends on the detailed design of electron gun and its working condition. Although it may be possible to ensure consistent spot size by adjusting the setup parameters of the electron gun, for the measurement system used in this work, the spot size changes with primary electron energy from sub-millimeter to a number of millimeters. It is obvious that the following two cases will have different TSEYs. Case 1: all the primary electrons impact with the top of the pillar. Case 2: all the primary electrons impact with the bottom substrate on which pillars stand. These two extreme cases are possible if the electron beam spot is small enough. For the first case, its TSEY will be close to the TSEY of flat surface. For the latter case, its TSEY will be much lower due to the shadowing effect. More generally, for a predefined electron beam spot size and radiation position, it is very possible that the primary electrons radiate both the pillar top and the bottom substrate. Then, the TSEY in this situation will be determined by the combined effect of cases 1 and 2. Therefore, to explain the measurement results shown in Fig.

There are many measurement methods for electron beam spot size, such as Refs. [23] and [24]. Considering the available setup, we adopt the following method to estimate the size of the electron beam spot, as shown schematically in Fig.

To demonstrate how to extract electron beam spot size, we conduct some Monte Carlo simulations using a similar method in Ref. [12]. A typical dependence of TSEY on the radiation location is shown in Fig.

To further demonstrate how the detector dimensions and electron beam spot size influence the observed TSEY, we conduct Monte Carlo simulations using parameters for copper presented in Ref. [1] and primary electron energy of 300 eV for the detector mentioned above and for spot size ranging from 0.05 mm to 8 mm. The movement step is set as 0.25 mm. The obtained results are shown in Fig.

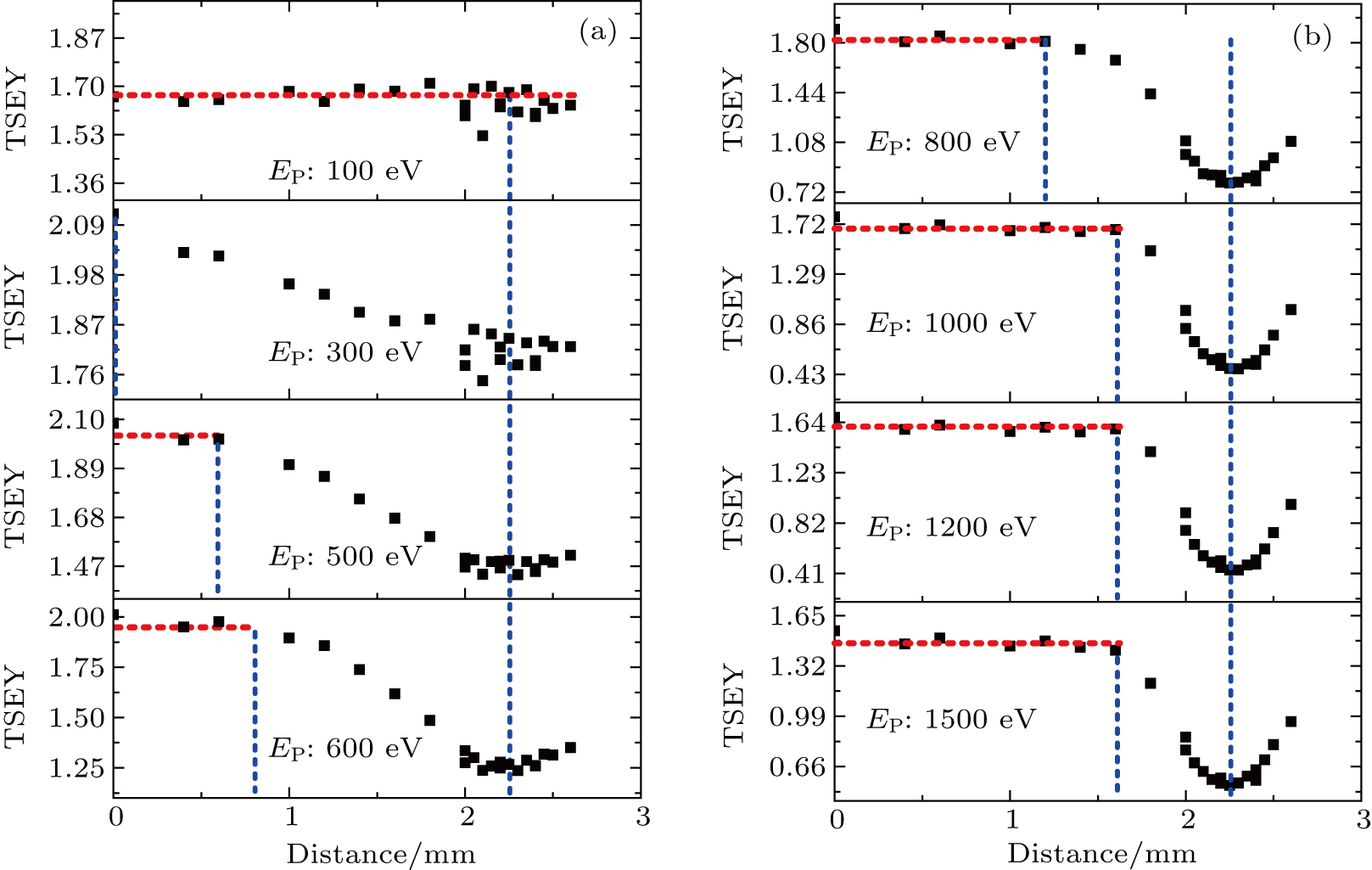

The experimental results of electron beam spot size are shown in Fig.

| Fig. 8. The dependence of measured TSEY on radiation position for various primary electron energies. |

To provide a more intuitional physical interpretation of the experimental results, in addition to the Monte Carlo simulation presented above, we also adopt a simple model, as shown in Fig.

We use the following procedure to evaluate the TSEY of the pillar array surface shown in Fig.

The calculation results are shown in Fig.

In summary, we have analyzed the abnormal double-hump TSEY–energy curve both theoretically and experimentally. The 3D printed mm-scale pillar array, which shows both TSEY suppression effect and double-hump effect, is used for experimental verification. Monte Carlo simulations and simplified model are used to interpret observations. It is found that the double-hump effect is induced by the dependence of electron beam size on the primary electron energy; namely, the spot size decreases with the primary electron energy. Thus, one should care about the electron beam spot size when characterizing the TSEY of a material, especially for the case where the electron beam spot size is comparable to the characteristic structure of the surface.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] |