† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61574110, 61334002, and 61474091) and the National Key Technology Research and Development Program of the Ministry of Science and Technology of China (Grant No. 2015AA016801).

In this paper, the enhancement-mode AlGaN/GaN HEMT combined with the low damage recessed-gate etching and the optimized oxygen plasma treatment was fabricated. Scanning electron microscope/energy dispersive spectrometer (SEM/EDS) method and x-ray photoelectron spectroscopy (XPS) method were used to confirm the formation of oxides. Based on the experimental results, the obtained enhancement-mode HEMT exhibited a threshold voltage of 0.5 V, a high peak transconductance of 210 mS/mm, and a maximum drain current of 610 mA/mm at the gate bias of 4 V. Meanwhile, the on/off current ratio of enhancement-mode HEMT was as high as 108, drain induced barrier lowering (DIBL) was as low as 5 mV/V, and subthreshold swing (SS) of 80 mV/decade was obtained. Compared with the conventional HEMT, the Schottky reverse current of enhancement-mode HEMT was three orders of magnitude lower, and the off-state breakdown voltage of which was higher. In addition, a power gain cutoff frequency (fmax) of the enhancement-mode HEMT was larger than that of the conventional one.

Since GaN materials have high electron saturation velocities and high breakdown electric fields, AlGaN/GaN high electron mobility transistors (HEMTs) are widely used in the field of high frequency and high power.[1,2] In order to meet the AlGaN/GaN HEMT applications in the field of radio frequency (RF) switch circuits and digital circuits, enhancement-mode AlGaN/GaN HEMTs become an important choice. There are many methods to fabricate enhancement-mode AlGaN/GaN HEMTs, of which the recessed-gate structure is proved to be a feasible way. Enhancement-mode HEMTs using recessed-gate structure usually have the following several methods: the first method is an etching groove under the gate region only using dry etching.[3] This method is simple, but the etching depth is significant, so the damage induced by etching is severe and the Schottky leakage current will increase. The second way is an etching groove using dry etching to make the barrier layer thickness minimized or be completely etched, then a better quality dielectric layer is grown above the gate region.[4,5] This method can obtain a large threshold voltage, and a small Schottky reverse leakage current. However, this method is more difficult to precisely control the etching depths, and the etching damage in the channel will be introduced with a thin barrier layer. Meanwhile, the quality of interface between barrier layer and gate dielectric is difficult to be guaranteed. The third one is using wet etching to form the groove under the gate region, and then a better quality dielectric layer is grown above the gate region.[6] Using this way, the etching depth can be precisely controlled, but the process is time consuming and the lateral extension under the gate region cannot be ignored.

In this paper, enhancement-mode AlGaN/GaN HEMTs combined with the low damage recessed-gate structure and optimized oxygen plasma treatment were fabricated. By using this method, the AlGaN barrier layer was less etched and the distance between gate and channel was large enough to avoid the etching damage in the channel by etching. Oxygen plasma treatment can make part of the AlGaN barrier layer be oxidized, which can form the simple metal–insulator–semiconductor (MIS) structure. Scanning electron microscope/energy dispersive spectrometer (SEM/EDS) and x-ray photoelectron spectroscopy (XPS) were used to confirm the formation of oxides. This process is relatively simple. The enhancement-mode HEMT with this method exhibits high performance in the terms of direct current (DC) and RF.

The AlGaN/GaN material wafer was grown on sapphire substrate by metal–organic chemical vapor deposition. The epitaxial layers consist of (from the substrate to the surface): 400-μm sapphire, 2-μm non-doped GaN layer, and 18-nm Al0.25Ga0.75N barrier layer. The room temperature Hall measurements of the structure yield an electron sheet density of 9.2 × 1012 cm− 2 and an electron mobility of 1800 cm2·V−1·s−1.

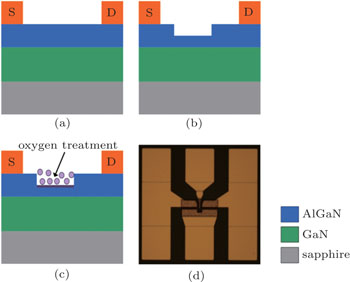

The fabrication processes started with ohmic contacts formed by an alloyed Ti/Al/Ni/Au metal stack annealed at 830 °C for 30 s, and then the mesa was formed by using Cl2 plasma dry etching in an inductively coupled plasma (ICP) system. After SiN deposition of 60 nm on the surface by plasma enhanced chemical vapor deposition, the SiN above the gate region was etched by the ICP system. Then the wafer was divided into three regions: A, B, and C. There was no treatment on region A. Region B was only treated by Cl2 plasma in the ICP system, during which the etch rate was 0.14 nm/s and the etching depth was 7 nm. Region C was not only treated by Cl2 plasma in the ICP system, and then region C was treated by O2 plasma in the ICP system. The ICP coil power was 100 W, the reflected RF power was 30 W, and the treatment time was 60 s. The gate electrode of the whole wafer was formed by the Ni/Au (30 nm/200 nm) E-beam evaporation and liftoff. The gate length of 1.2 μm, and source drain spacing of 3 μm were set in the three types of devices. The Keithley 4200 semiconductor parameter analyzer and Agilent E8363B vector network analyzer were used to measure the device parameters. The regions A, B, and C for three types of devices were named samples A, B, and C, respectively. The cross-sectional schematics of these three types of post gated HEMTs and an electron-microscope image of enhancement-mode HEMT are shown in Fig.

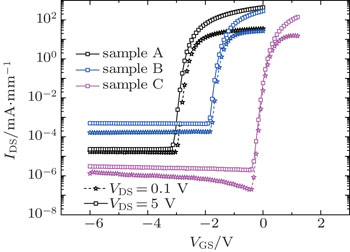

Figure

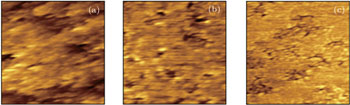

Figure

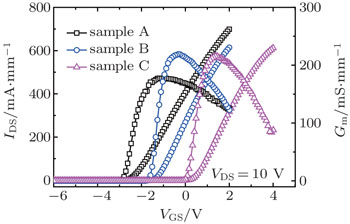

It can be seen that the channel current of sample C at VGS − Vth = 2 V is 410 mA/mm and that of sample B at VGS − Vth = 2 V is 420 mA/mm. It indicates that under the same gate drive voltage, two-dimensional electron gas (2DEG) concentration under the gate region after oxygen plasma treatment is not significantly changed, the current has little degradation. The peak transconductance of sample A is 177 mS/mm and that of sample B is 218 mS/mm. The higher peak transconductance of recess-gate HEMTs is related with the fact that the AlGaN barrier layer is thin under the gate region. Sample C shows the peak transconductance of 215 mS/mm, which indicates that the ability of gate control of HEMTs by oxygen plasma treatment is not significantly degraded.

Saito et al.[8] have studied the influence of the etching depth of recessed-gate on AlGaN/GaN HEMT characteristics. The relationship between the threshold voltage and AlGaN barrier layer thickness under the gate region can be expressed as

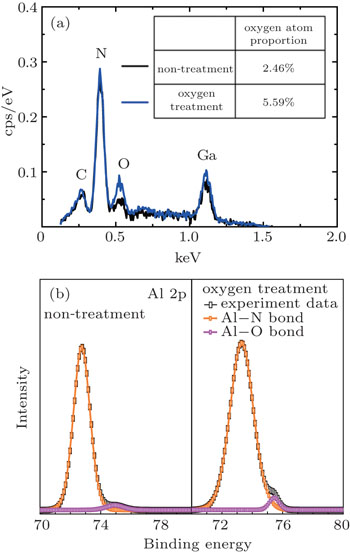

In order to study the mechanism for threshold voltage variations by oxygen plasma treatment, the SEM/EDS and XPS methods are used. The SEM/EDS method can be used to analyse the surface element changes, and XPS can scan and measure the chemical structure within 8 nm depth. Two specimens are obtained, one specimen has no treatment, and the other one is treated by oxygen plasma in the ICP system. The ICP coil power is 100 W, the RF power is 30 W, and the treatment time is 60 s. As shown in Fig.

| Fig. 5. The SEM/EDS acquisition rate and XPS results for two specimens (a) EDS data and (b) Al 2p core-level spectra. |

Figure

When the device is biased at different drain voltage, the threshold voltage will drift due to the drain induced barrier lowering (DIBL) effect and the short channel effect. The rate of change of threshold voltage drift and drain-source voltage is usually used to measure the short channel effect.[10] It can be seen from Fig.

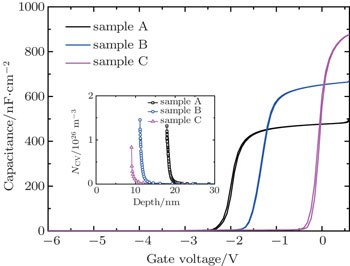

In order to study the influence of recessed gate etching and oxygen plasma treatment on the interface state, double sweep C–V curves at 100 kHz frequency of three samples are tested, as shown in Fig.

Figure

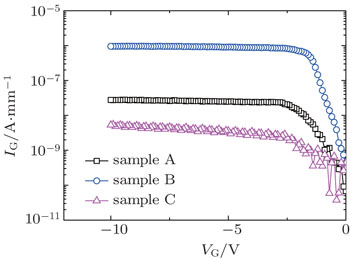

On the one hand, oxygen plasma treatment can make the Al composition in the AlGaN barrier layer reduce, and the electrons density below the gate is also decreased. On the other hand, the MIS layer can increase the barrier height that can suppress the probability of direct tunneling, and the oxygen plasma treatment does not introduce significant surface states. Therefore, the probability of trap-assisted tunneling is not possible, and the Schottky reverse leakage current by oxygen plasma treatment is suppressed.

Figure

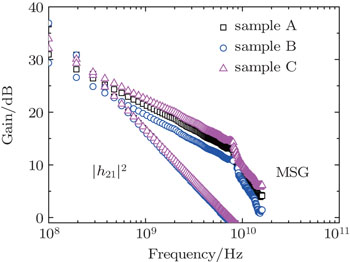

The on-wafer RF performance of three samples with LG = 1.2 μm is characterized from 100 MHz to 16 GHz. The current gain cutoff frequency (fT) is given by the extrapolation of |h21|2 with a − 20 dB/dec slope. The current gain and maximum stable gain (MSG) of three samples are derived from measured S parameters as a function of frequency, as shown in Fig.

In summary, high performance enhancement-mode AlGaN/GaN HEMTs have been fabricated. This method combines the low damage recessed-gate structure and optimized oxygen plasma treatment. The increment of RMS is no more than 0.3 nm indicating the low damage of recess-gate through AFM test. SEM/EDS method and XPS method are used to confirm the formation of oxides. The obtained enhancement-mode HEMTs exhibit threshold voltage of 0.5 V, high peak transconductance of 210 mS/mm, and maximum drain current of 610 mA/mm at a gate bias of 4 V. Meanwhile, the on/off current ratio of enhancement-mode HEMTs is as high as 108, DIBL is as low as 5 mV/V, and SS of 80 mV/decade is obtained. Compared with the conventional HEMTs, the Schottky reverse current of enhancement-mode HEMTs is three orders of magnitude lower and the off-state breakdown voltage of which is higher. In addition, fmax of enhancement-mode HEMTs is larger than that of the conventional one. The results indicate that the low damage recessed-gate structure combined with the optimized oxygen plasma treatment can be a favorable way to fabricate the enhancement-mode HEMTs.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 |