† Corresponding author. E-mail:

‡ Corresponding author. E-mail:

Project supported by the National Basic Research Program of China (Grant Nos. 2013CB933604), the National Natural Science Foundation of China (Grant No. 51572290), and the Fund from the Chinese Academy of Sciences (Grant Nos. 1731300500015 and XDB07030100).

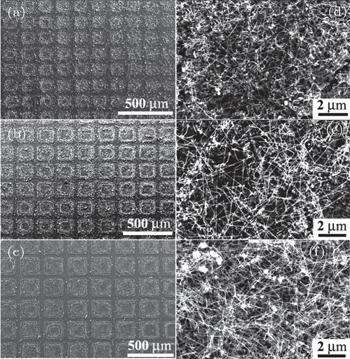

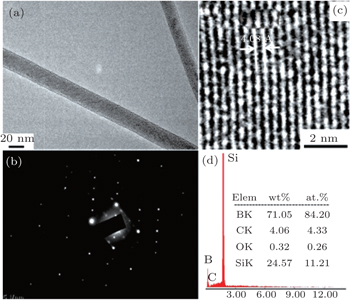

Large-area patterned films of boron nanowires (BNWs) are fabricated at various densities by chemical vapor deposition (CVD). Different widths of unit-cell of Mo masks are used as templates. The widths of unit-cell of Mo masks are 100 μm, 150 μm, and 200 μm, respectively. The distance between unit cells is 50 μm. The BNWs have an average diameter of about 20 nm and lengths of 10 μm–20 μm. High-resolution transmission electron microscopy analysis shows that each nanowire has a β-tetragonal structure with good crystallization. Field emission measurements of the BNW films show that their turn-on electric fields decrease with width of unit-cell increasing.

For flat-panel field emission display devices, the pattern growth of cold cathodes based on quasi-one-dimensional nanoscale materials is becoming increasingly important because patterning can dramatically improve field emission (FE) properties and increase the FE enhancement factor by reducing screening effects between units of nanomaterials.[1,2] Boron bonds through a unique three-center two-electron bond make it possible to form the B12 icosahedron structural unit.[3] Therefore, boron possesses chemical stability and many desirable physical properties, such as low density, high melting point, and hardness comparable to diamond.[4,5] Moreover, it has a large tensile strength and high Young's modulus and a negative high-temperature electrical resistivity. Boron one-dimensional (1D) nanostructure, as a cold cathode material, has exhibited superior FE performances.[6]

The morphology of a boron nanostructured cold material, such as aspect ratio and density, can affect its FE properties. Therefore, preparation of patterned boron 1D nanostructure is important for improving the FE behavior.[7,8] In recent decades, various patterned 1D nanostructures have been fabricated by different means.[9–13] The patterned 1D nanostructures have also shown superior field emission properties. Compared with random-growth 1D nanostructured film, patterned structure has a lower turn-on field and threshold field. These results indicate that the FE property is significantly improved. In our group, patterned boron nanostructures have been synthesized by self-assembly of magnetic catalyst nanoparticles and a pre-manipulation to pattern the catalyst with a grid template serving as a mask.[14,15] In this present work, we use different widths of unit-cell of Mo masks as templates to tune the patterned distribution densities of boron nanowires. The results of field emission measurements of patterned BNWs with different unit-cell sizes indicate that their turn-on electric field decreases with increasing the width of unit-cell in the patterning.

Boron powder (with purity 99.99%), B2O3 (99.99%), and carbon powder (99.9%) were purchased from Beijing Sinopharm Chemical Reagent Co. Argon (99.9%) and H2/Ar (H2, 10 vol%) were purchased from Beijing Praxair Application Gas Co., Ltd. Boron powder, B2O3, and carbon powder with mass ratio of 4:2:1 were mixed together as precursors.

The patterned BNWs were fabricated by the template method used in our previous reports.[15,16] A detailed description is as follows: different widths of unit-cell of Mo masks (100, 150, and 200 μm) were fixed on the surfaces of Si (111) wafers; then, 100-μL Fe3O4 hexane solution (20 mg/mL) was dropped on the Mo mask, coating the Si substructure and heated at 100 °C for 60 min; finally, the Mo mask was removed from the surface of the Si substrate, uncovering the patterned catalyst substrate. We used chemical vapor deposition (CVD) to grow patterned BNWs. The Si wafer patterned with Fe3O4 catalyst nanoparticles was placed in an alumina boat, lying in front of the precursors. Then, the alumina boat was transferred into a quartz tube in a horizontal tube furnace. After the system was pumped below 10 Pa, 50 sccm (standard cubic centimeters per minute) H2/Ar mixed gas (10%, volume ratio %) was introduced and system pressure was changed to 1 × 102 Pa. Then the furnace was heated to 1150 °C at a rate of 8 °C/min and the system pressure was maintained at 1 × 104 Pa. The reaction was allowed to continue for 2 h at this temperature. The furnace was cooled down to room temperature at a rate of 8 °C/min. Brown–black products were found on the Si substrate.

The morphology and the structure of the BNWs were characterized by field emission scanning electron microscopy (FE-SEM: SFEG, FEI Corp), transmission electron microscopy (TEM: Tecnai-20, Philips Corp.), and high resolution transmission electron microscopy (HRTEM: Tecnai F20, FEI Corp.), respectively. Measurements of the field emission (FE) properties of patterned BNWs were performed on a high vacuum FE analysis system (4 × 10− 5 Pa).

Figure

Further structure characterizations of BNWs are performed by transmission electron microscopy (TEM), high-resolution transmission electron microscopy (HRTEM), and selected area electron diffraction (SAED). Figure

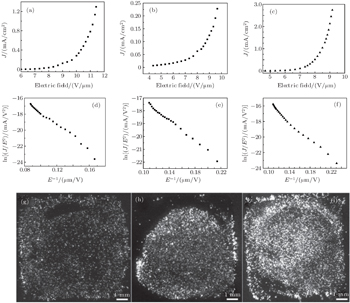

The field emission (FE) properties of different morphologies of boron nanostructures have been investigated by many groups. They have exhibited good FE behavior. In the present work, we measure the FE properties of boron nanowires patterned prepared on the different-width unit-cells. The FE measurements are carried out at room temperature in a vacuum with a base pressure of 3 × 10−5 Pa–4 × 10− 5 Pa. Each BNW sample respectively serves as a cathode, and a molybdenum probe (1 mm in diameter) is used as an anode. During our experiments the anode-cathode distance was fixed to be 300 μm. Table

| Table 1. Values of Eto and Ethr of patterned BNWs prepared on the different-width of unit-cells. . |

The relationship curves of patterned BNWs prepared on the different-width unit-cells between current density J and applied field E are shown in Fig.

The Fowler–Nordheim (FN) curves of patterned BNWs prepared on the different-width unit-cell are plotted in Figs.

In order to evaluate the uniformity of field emission for each sample, we measure their brightness distribution. Figures

In order to reduce the screening effect of boron nanowires, we prepare the boron nanowires (BNWs) by using different-width unit-cells. The widths and the numbers of the unit cells for these three Mo templates are quite different as summarized in Table

The BNW sample using Mo mask with a 200-μm-wide unit-cell has the largest number of emitters on the Si substrate with the same area, which leads to the fact that it has the lowest turn-on and threshold field. It can be illustrated as follows. From Table

| Table 2. Comparisons of structure parameters among three BNW patterns using Mo masks with different-width unit-cells. . |

Figure

Now a question arises: why can the 100-μm-wide unit cell not produce such a good aspect ratio nor uniformity like the 200-μm unit cell. The reason of uniformity and aspect ratio of nanowires affected by the unit-cell size can be derived from the preparation process of the patterned catalysts. In experiment, we use Fe3O4 nanoparticles (NPs) hexane solution to drop on the surface of the Mo mask to pattern the catalyst NPs. In this process, the soakage between the hollow region of the Mo mask and the catalyst NPs solution is insufficient due to the effect of the surface tensile force in the small space sizes of 100 μm and 150 μm unit. It might result in non-uniform distribution of NPs catalysts after removing the hexane solvent. Some parts of the surface of unit-cell are not covered by catalyst NPs. The concentrations of catalyst NPs decrease in the 100 μm and 150 μm unit. Therefore, they affect the growth of nanowires, which leads to the relative non-uniformity and reduction of length of nanowires (Figs.

Large-area films of boron nanowires (BNWs) patterned with different-width unit-cells (100, 150, and 200 μm) are fabricated using the Mo mask as templates by the chemical vapor deposition (CVD) method. The BNWs have an average diameter of about 20 nm and lengths of 10 μm–20 μm. The high-resolution transmission electron microscopy and select area electron diffraction results show that the boron nanocones have a β-tetragonal structure with good crystallization. Field emission measurements of BNW films patterned with different-width unit-cells show that their turn-on and threshold electric field decrease with increasing the width of unit-cell. The results indicate that the patterned growth method is also applicable to optimizing the FE properties of other field emitter nanostructures.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 |