† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61205032, 61475061, 61405070, 61177027, 61275033, and 61261130586) and the Science and Technology Development Plan of Jilin Province, China (Grant No. 20140519006JH).

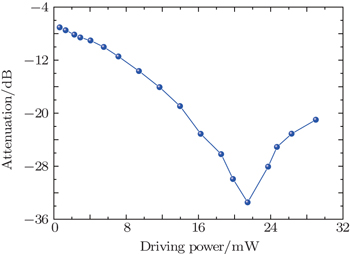

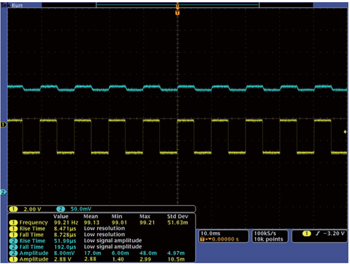

Visible light variable optical attenuators (VOA) are essential devices in the application of channel power regulation and equalization in wavelength-division multiplexing cross-connect nodes in plastic optical fiber (POF) transmission systems. In this paper, a polymer/silica hybrid waveguide thermo–optic attenuator based on multimode interference (MMI) coupler is designed and fabricated to operate at 650 nm. The single-mode transmission condition, MMI coupler, and transition taper dimensions are optimized through the beam propagation method. Thermal analysis based on material properties provides the optimized heater placement angle. The fabricated VOA presents an attenuation of 26.5 dB with a 21-mW electrical input power at 650 nm. The rise time and fall time are 51.99 and 192 μs, respectively. The time–stability measurement results prove its working reliability.

In the near future, high data rate networks over Gb/s are urgently needed for the application of multimedia technology in automobiles, automation, and at home in a large scale.[1] Compared with single-mode glass optical fiber that has been widely used in trunk lines for long-distance communications, polymethyl methacrylate (PMMA) polymer optical fiber or plastic optical fiber (POF) with a large core diameter and step-index (SI) profile has merits of low-cost, robustness to mechanical stress and immunity to electromagnetic interference, which make it a good candidate for home internet connections and automotive applications.[2,3] Recently, wavelength-division multiplexing (WDM) technology together with the progress of laser diodes and optimized receiver fabrication, became an effective way to increase the capacity of the visible light transmission in POF systems.[4–6] In addition, the signal amplification device with a gain of 14 dB at 650 nm has also been reported.[7] All these works provided good potentials of WDM data transmission for POF systems.

Variable optical attenuators (VOA) are essential devices in applications of gain control of optical amplifiers, channel power regulation and equalization in WDM cross-connect nodes and transmission systems.[8] Characteristics of fast response, wide attenuation range, and low insertion loss are crucial to the performance of VOA. Different approaches have been reported to implement a VOA.[9–12] Although many of them can provide desirable performances and reliability, polymer-based waveguide VOA offers a specific advantage in providing good compatibility with POF system. In addition, the polymer has a thermo–optic coefficient that is one order of magnitude larger than that of inorganic materials, such as silica.[8] Low-cost, easy fabrication, good optical and mechanical properties, and being compatible with different substrates allow the low-cost, large-scale integration of polymer VOA with a wide range of photonics components on a single chip.[13] TO controlled whole polymer VOA can be implemented by bent waveguide,[14] straight channel,[15] or interference coupler structures.[16] However, they either suffers precise dimension control and environment requirement, or long response time induced performance declining.

In this work, a multi-mode interference (MMI) coupler in the form of polymer/silica hybrid waveguide structure is proposed. Compared with whole polymer VOAs,[14–16] the adoption of silica with a high thermal conductivity as bottom cladding can overcome the deficiency of low thermal diffusion of polymer bottom-cladding, which is favorable to accelerating the relaxation of heat in the waveguide and improving time response performance. The adoption of MMI coupler improves the fabrication tolerance of dimension departures from the design ones. Besides, the polymer SU-8 cannot only provide a low optical absorption at 650 nm, but also a high TO coefficient that is good to decrease the absorption loss and power consumption. Here, waveguide dimensions are optimized by beam propagation method (BPM). Device performances of attenuation, power consumption, temporal response, as well as time stability are confirmed according to the applied voltage control.

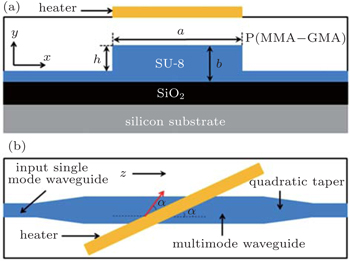

The proposed VOA consists of a pair of input/output single-mode waveguides connected to the tapered transition sections, a multimode waveguide coupler, and an electrode heater that is aligned at an angle of α to the MMI coupler above the upper-cladding, as shown in Fig.

| Fig. 1. Schematic diagram of (a) cross-sectional view, and (b) top view of designed 650-nm optical attenuator. |

Multiple-layer waveguide configurations, including the thickness, shape, and refractive indices of polymers, need to be tailored to fulfill single-mode propagation confinement. In this paper, the designed attenuator based on polymer/silica waveguide was supported by a silicon wafer, which facilitates heat flow. Poly(methyl-methacrylate-glycidly-methacrylate) (P(MMA–GMA)) synthesized by ourselves and commercial polymer SU-8 were used as the upper-cladding and core material, respectively, due to their stable chemical properties.[17,18] A thin silica layer on the silicon substrate was chosen to be the bottom-cladding to quicken the response. To enhance the thermal field modulation, the upper-cladding between the metal heater and core layer was chosen to be 2 μm, which was thick enough to restrain the metal induced optical loss.

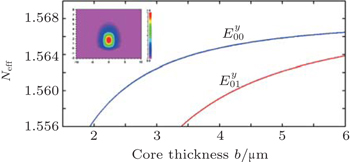

A rib waveguide architecture with desired mode shape was supposed to be used in this design. The relationship between the core thickness b and the effective refractive index Neff of the rib waveguide at a wavelength of 650 nm based on the effective index method (EIM) is shown in Fig.

The MMI coupler plays a key role in the operation of the attenuator. The working principle of MMI coupler is based on the self-imaging effect that an interference pattern consisting of a single or multi-fold reproduction of the input field appears periodically when sufficient modes are excited along the MMI region. The input power can be coupled to the output single-mode waveguide with low insertion loss through the propagation of higher-order modes besides the fundamental mode.[19,20] It is well known from the MMI self-imaging theory that N-fold images of the input field are obtained at distances

However, these equations and conclusions are based on the assumption that the core and cladding materials have a high refractive index contrast, under which conditions the optical penetration depth is very small so that the effective width of the multimode waveguide We can be considered to be the geometrical dimension Wmmi. In this design, the refractive index of the core material SU-8 is 1.568, while cladding materials of P(MMA–GMA) and SiO2 are 1.51 and 1.46, respectively. This low refractive index contrast will inevitably lead to a deeper penetration of mode field into claddings, which results in errors between We and Wmmi. As a result, the calculated Lπ based on We = Wmmi does not precisely accord with the practical conditions. Therefore, BPM method is employed for the optimization of MMI coupler dimensions. Mode coupling and power propagation damping in the MMI region will also happen. Therefore, the length of MMI coupler needs to be optimized with defined width and architecture. As shown in Fig.

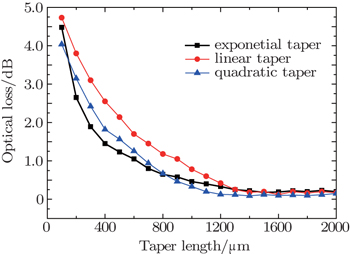

The transition waveguide should ensure that the first-order mode could propagate adiabatically with no transforming to higher-order or radiated modes, which means that the fundamental mode should maintain most power after propagating a certain distance. A general consensus on tapered waveguides is that if a taper is made long enough, and has a gradual enough taper slope, the loss will be very low. Therefore, the conversion loss from the input single-mode waveguide and MMI waveguide would be minimized by a proper design of the transition waveguide structure. The mode adapter with a gradual tapering shape of parabolic, linear, or exponential tapers are commonly used. Although an adequate slow taper can provide adiabatic changes in optical mode profiles, compact adapters designed optimally are indispensable in a high-density optical circuit. In this design, linear, exponential, and quadratic laterally tapered waveguides as a transition section between the single-mode input/output waveguide and the MMI coupler are analyzed to restrain the scattering loss and accordingly increase the power collection of divided modes. Since the widths for a given taper along the propagation direction are different from each other, the accumulated losses can be compared as a function of propagation length, and a region can be found after which the taper loss is acceptable for this VOA application.

When the length of MMI coupler is fixed at 4050 μm and the output tapered waveguide adopts the same dimensions as the input one, a comparison of the optical loss changing with the variation of tapered waveguide length is shown in Fig.

Thermal characteristics of the attenuator, including thermal diffusion and steady-state response evaluation, can be studied by solving the following heat transfer Fourier’s equation in transient condition with constant thermal conductivity:[22]

| Table 1. Material parameters used in thermal calculations. . |

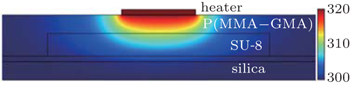

When a certain driving power is applied to the heater, the calculated steady state of heat distribution across the section of VOA waveguide is shown in Fig.

Thermal analysis allows evaluation of the power consumption by analyzing the power dissipation per unit length that is required to get a certain temperature difference.[23] It is reasonable to demonstrate that this power is proportional to the thermal conductivity

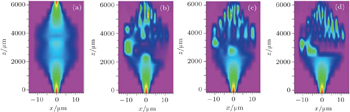

| Fig. 7. Schematic of non-attenuation (a) and maximum attenuations when heaters are placed at α angles of 1˚ (b), 1.5˚ (c), and 2˚ (d) with respect to the mode propagation direction. |

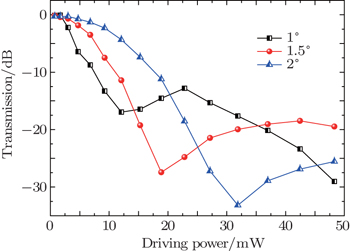

Considering the thermal field distribution across the waveguide and its modulating behavior, the heater is placed with an optimized angle α = 1.5˚ on the top cladding, which is a compromise between the power consumption and attenuation range. The fluctuation of power consumption in Fig.

Firstly, a layer of 3-μm-thick silica was formed on the silicon substrate by thermal oxidation method as the bottom-cladding. A layer of 3-μm-thick SU-8 (Microchem Co., USA) was spin-coated over the bottom-cladding at 3500 rpm and baked for 10 min at 65 ˚C, 20 min at 90 ˚C to evaporate the solvent, respectively. After being UV cured by a mercury (Newport Co., 10 mW/cm2 at 365 nm) lamp for 30 s, it was hard baked at 95 ˚C for 30 min. Then, the SU-8 cross-linked sufficiently, exhibiting excellent chemical and thermal stability. The photoresist BP212 (Kempur Microelectronics Inc., China) was spin-coated on a thermal deposited metal mask and patterned by UV photolithography machine (ABM Co. Inc., USA) to define VOA waveguide patterns. After that, inductively coupled plasma (ICP) etching was carried out in oxygen atmosphere to form the ridge waveguide. Afterwards, P(MMA–GMA) was spin-coated on the SU-8 core layer at 2500 rpm and subsequently baked at 120 ˚C for 2.5 h to remove the solvent. This upper-cladding can improve the efficiency of guided mode index modulation and decrease the roughness of the film surface after ICP processing. Finally, a layer of 600-nm Al film was thermally evaporated and patterned with UV photolithography. Wet etching was adopted to form a heater aligned on the upper-cladding. Before the measurement, the sample device was sliced by a wafer dicing machine DAD-3220 (DISCO Co. Inc, Japan) to reduce fiber-coupling-induced optical loss. The optical microscope image of Fig.

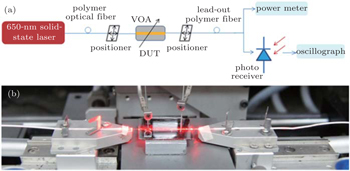

The measurement setup of transmission and switching performances for the fabricated thermal VOA is shown in Fig.

| Fig. 9. (a) Measurement setup of transmission and switching performances for VOA, (b) photo of VOA under test with fiber alignment system. |

The measured attenuation characteristics at a wavelength of 650 nm are shown in Fig.

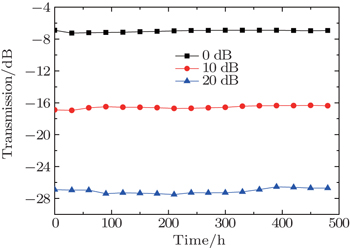

The intrinsic volume relaxation of polymers might affect the optical performance of an interference-based attenuator during its service life. Moreover, the large thermo–optic coefficient of polymer material makes this attenuator possibly to be temperature-dependent. Therefore, the device working stability is tested under different attenuation levels within 480 h, as shown in Fig.

As mentioned before, the time response is measured by an oscilloscope DPO4104B (Tektronix Inc., USA) through collecting the output optical power with a polymer fiber, which is connected to an optical power meter. Here, the rise time and fall time are defined as the time that the detected optical power increases from 10% to 90% or decreases from 90% to 10% of its peak value, respectively. When a 100-Hz square waveform drive current is applied to the heater, the measured optical rise time and fall time are 51.99 and 192 μs, respectively, as shown in Fig.

Comparing performances of reported attenuators based on TO effect,[14–16] polymeric VOA has the lowest power consumption of less than 10 mW, however, the longest response time. Since the thermal conductivity of silica is six times larger than that of polymers, the generated heat will transmit to the silicon substrate more quickly than using the polymer as the bottom-cladding. Hence, this attenuator costs less time to realize heat diffusion, and the response time is shorter than that of the whole polymeric VOA. However, compared to silica as the bottom-cladding, all polymer waveguide configurations can reduce the power consumption due to the relatively small thermal conductivity. Therefore, a tradeoff between the power consumption and response time needs to be balanced and it is desirable to adopt a complex waveguide configuration to realize a desired device response. Besides, the small device dimensions of less than 1 mm in length and 24 μm in width features compactness, and the resulting low insertion loss of 6.8 dB provides good potential of this VOA for planar lightwave chip applications.

In this paper, a 650-nm visible-light attenuator based on polymer/silica hybrid waveguide is designed and experimentally demonstrated. The mode propagation condition and transition waveguide are optimized through EIM and BPM methods. Thermal analysis provides the optimal metal heater angle. The attenuation characteristics are numerically investigated. Experimental characterization of the fabricated device presents an attenuation of 26.5 dB with 21-mW electrical input power at 650 nm. Fast response (rise time and fall time are 51.99 μs and 192 μs, respectively) is observed due to the adoption of silica bottom-cladding with relatively large thermal conductivity. In addition, the measured working stability proves this device can satisfy the reliability requirements for telecom components.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 |