† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61306017, 61334002, 61474086, and 11435010) and the Young Scientists Fund of the National Natural Science Foundation of China (Grant No. 61306017).

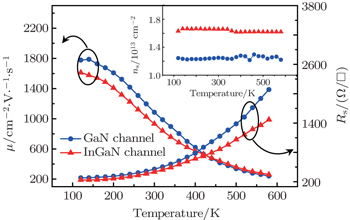

Pulsed metal organic chemical vapor deposition is introduced into the growth of InGaN channel heterostructure for improving material qualities and transport properties. High-resolution transmission electron microscopy imaging shows the phase separation free InGaN channel with smooth and abrupt interface. A very high two-dimensional electron gas density of approximately 1.85 × 10 13 cm −2 is obtained due to the superior carrier confinement. In addition, the Hall mobility reaches 967 cm 2 /V·s, owing to the suppression of interface roughness scattering. Furthermore, temperature-dependent Hall measurement results show that InGaN channel heterostructure possesses a steady two-dimensional electron gas density over the tested temperature range, and has superior transport properties at elevated temperatures compared with the traditional GaN channel heterostructure. The gratifying results imply that InGaN channel heterostructure grown by pulsed metal organic chemical vapor deposition is a promising candidate for microwave power devices.

The application of AlGaN/GaN heterostructures in fabricating high electron mobility transistors (HEMTs) has received much attention since 1993 because of their outstanding electrical properties. [ 1 – 3 ] So far the studies have entered into a more mature stage, and the research effort is shifting to the higher frequency microwave power device. [ 4 ] However, there are still some limitations of the GaN-based HEMTs, such as the low-frequency 1/ f noise and the RF-current collapse, which are attributed to the inferior confinement of the highdensity two-dimensional electron gas (2DEG) in channel. [ 5 ] To address this limitation and spatially confine the channel electrons, InGaN channel is proposed as a substitute for the traditional GaN channel. In comparison with GaN, InGaN channel has a narrower band gap and forms a deeper quantum well with a wide band gap barrier. [ 6 , 7 ] On the other hand, due to the large electron affinity of InN (5.8 eV), [ 8 ] the In- GaN channel forms a large discontinuity of conduction band at the interface between InGaN channel and GaN buffer layers. Hence the employment of the InGaN channel effectively increases the carrier confinement in the channel layer. As a consequence, the InGaN channel heterostructure shows better performances in suppressing the 1/ f noise [ 9 ] and RF-current collapse [ 5 , 10 ] than the GaN channel. [ 11 ] In addition, the InGaN channel is theoretically superior to the conventional GaN channel in such aspects as the higher saturation velocity and sheet carrier density attainable, [ 12 ] which are beneficial to the improvement of 2DEG mobility and density. [ 13 ] Furthermore, according to the previous research, HEMT with InGaN channel operates well in suppressing the virtual gate effect. [ 14 ] Therefore, InGaN channel heterostructures have a great potential in fabricating microwave power devices.

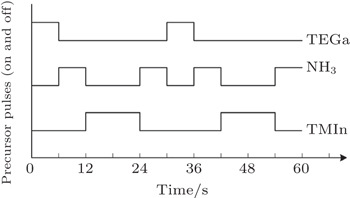

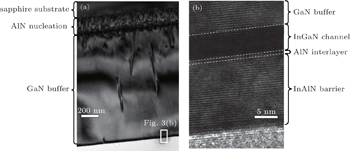

Some achievements have been obtained in demonstrating the outstanding properties of InGaN channel heterostructures and devices. [ 15 – 18 ] However, from the epitaxial point of view, it is still a challenge to obtain high-quality InGaN channel according to the state-of-the-art epitaxial technology. The main issues are the phase separation [ 19 ] and composition inhomogeneity, resulting from unfavorable thermodynamic reactions. In this paper, pulsed metal organic chemical vapor deposition (PMOCVD) is used to grow InGaN channel, and satisfactory material qualities and heterostructure properties are obtained. The microstructure of InAlN/InGaN heterostructure grown by PMOCVD is detected by high-resolution transmission electron microscopy (HR-TEM). The HR-TEM image shows the phase-separation-free InGaN channel with smooth and abrupt interface, indicating the superiority of PMOCVD and well-controlled growth technology in our experiments. Besides, according to the fact that little attention has been paid to the transport properties of InGaN channel heterostructures at high temperature, temperature-dependent Hall measurement is also carried out, and the results show the InGaN channel heterostructure is superior compared with the conventional GaN channel heterostructure at elevated temperatures.

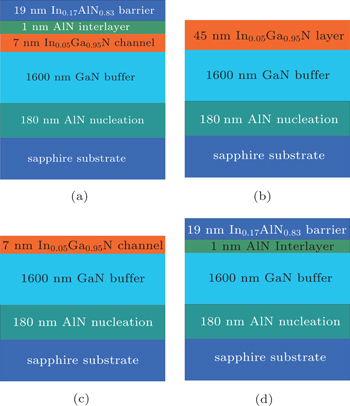

The samples investigated in this paper were grown on the two-inch c -plane sapphire substrates in a home-made vertical low pressure metal organic chemical vapor deposition (MOCVD) system. The sectional view of the InAlN/InGaN heterostructure sample is shown in Fig.

| Fig. 1. Epilayer structures for (a) InAlN/InGaN heterostructure, (b) 45-nm InGaN layer, (c) 7-nm InGaN channel layer, (d) InAlN/GaN heterostructure grown by (pulsed) MOCVD. |

Figure

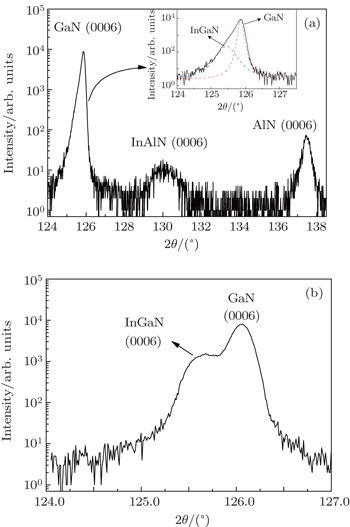

The typical high-resolution x-ray diffraction (HR-XRD) ω −2 θ scan of the InAlN/InGaN heterostructure from the symmetric (0 0 0 6) reflection is shown in Fig.

| Fig. 4. High-resolution XRD triple-axis (0 0 0 6) ω –2 θ scans of (a) InAlN/InGaN heterostructure and (b) 45-nm InGaN film on GaN buffer. |

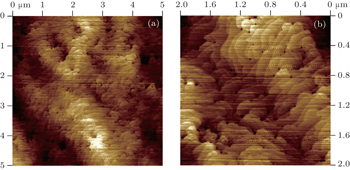

According to the previous studies, interface roughness scattering in InGaN channel heterostructures is more serious than those in conventional GaN channel samples, [ 25 ] which is the most acute issue that impedes the improvement of 2DEG mobility. In addition, interface roughness scattering becomes even more serious at room temperature. [ 26 , 27 ] Therefore, for improving the 2DEG mobility, it is of great importance to make a smooth interface in InGaN channel heterostructure. In order to detect the interface morphology between the InGaN channel and barrier layers in a straightforward way, an additional sample as shown Fig.

| Fig. 5. AFM images of surface morphology of InGaN channel with scan areas of (a) 5 × 5 and (b) 2 × 2 μm 2 . |

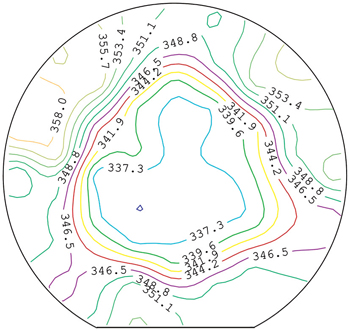

We first measure the transport properties of InAlN/InGaN heterostructure by room temperature (RT) Hall measurement. The 2DEG density reaches 1.85 × 10 13 cm −2 with an electron mobility of 967 cm 2 /V·s. Sheet resistance and resistance uniformity of the two-inch wafer are also measured by the contactless eddy current sheet resistivity mapping. As shown in Fig.

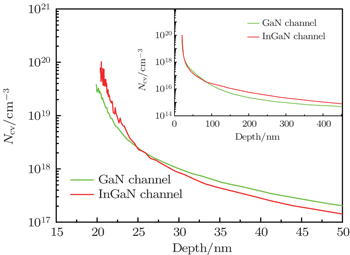

For additional electrical information, such as the sheet carrier concentration and 2DEG confined position, capacitance–voltage (CV) profiling technique is applied and operated at room temperature with a test frequency of 100 kHz and an Hg probe with a contact area of 600 μm 2 . For contrast, the result of conventional InAlN/GaN heterostructure as shown in Fig.

In order to meet the needs of different applications, HEMTs should operate steadily and reliably in a wide temperature range. The transport performances of InGaN channel heterostructures at low temperature and room temperature have been demonstrated. [ 22 , 23 , 26 ] For the further investigation of the 2DEG transport properties of InAlN/InGaN heterostructures in a wider temperature range, extended temperature-dependent (120–580 K) Hall measurement, conducted on a 1 cm × 1 cm sample in van der Pauw geometry using four indium dots as Ohmic contacts, is carried out. For contrast, the results of traditional InAlN/GaN heterostructure over the same temperature range are also shown. Figure

| Fig. 7. Profiles of the carrier concentration as a function of the depth for InAlN/InGaN and InAlN/GaN heterostructures, measured by CV method. |

In this work, PMOCVD is used to grow high-quality InGaN channel heterostructure, which is proven to be rewarding to the improvement of InGaN material quality, and further to the transport properties of heterostructure. The microstructure and satisfactory transport properties in this paper indicate that InGaN channel heterostructure grown by PMOCVD is a promising candidate for microwave power devices.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 |