† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 61471301), Natural Science Basic Research Program of Shaanxi, China (Grant No. 2017JQ5083), and PhD Research Startup Foundation of Xi’an University of Science and Technology, China (Grant No. 2017QDJ044).

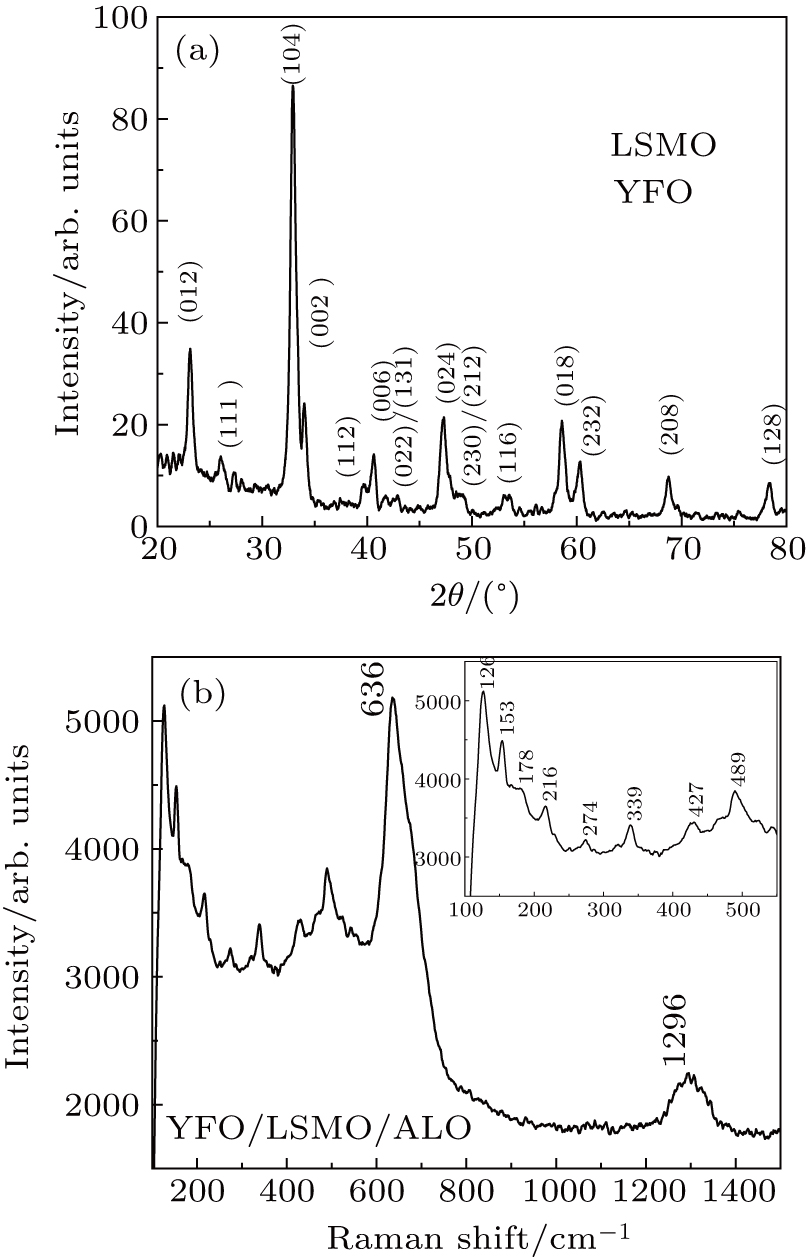

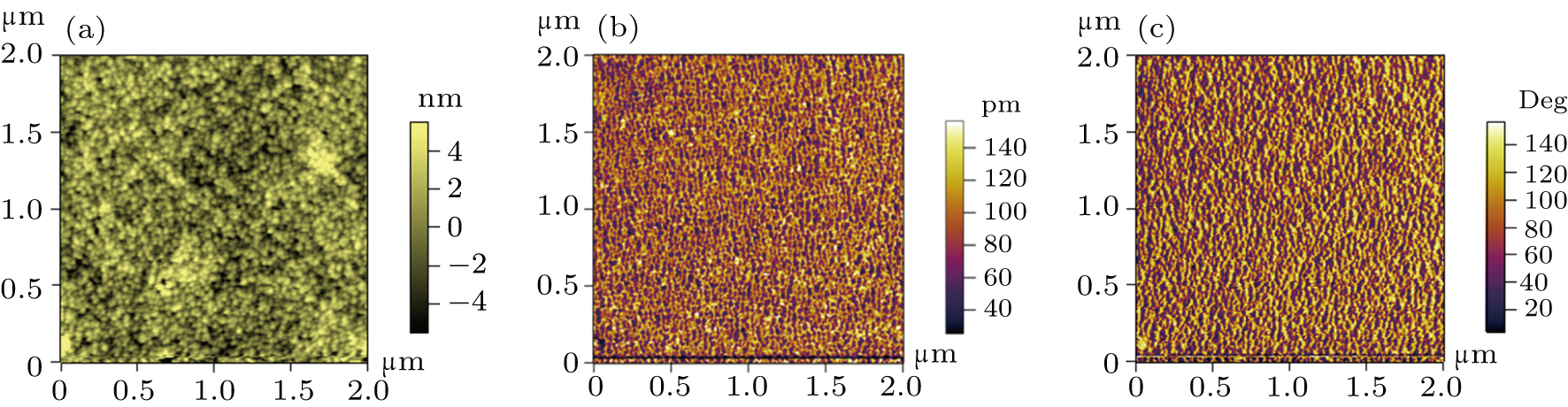

Orthorhombic YFeO3 thin film was prepared on La0.67Sr0.33MnO3/LaAlO3 substrate by a sol–gel spin-coating method. The structures of the YFeO3/La0.67Sr0.33MnO3/LaAlO3 (YFO/LSMO/LAO) sample were detected by x-ray diffraction pattern, Raman spectrometer, scanning electron microscopy, and atomic force microscope. The local ferroelectric polarization switching properties of the orthorhombic YFO film were confirmed by piezoresponse force microscopy (PFM) for the first time. The results show that the YFO film deposited on LSMO/LAO possesses orthorhombic structure, with ultra-fine crystal grains and flat surface. The leakage current of the YFO film is 8.39 × 10−4 A⋅cm−2 at 2 V, with its leakage mechanism found to be an ohmic behavior. PFM measurements indicate that the YFO film reveals weak ferroelectricity at room temperature and the local switching behavior of ferroelectric domains has been identified. By local poling experiment, polarization reversal in the orthorhombic YFO film at room temperature was further observed.

Multiferroics providing both ferroelectric and ferromagnetic (or antiferromagnetic) properties are well known for their intriguing physical origin and potential applications in sensor, actuation, and ferroelectric memory.[1–3] Meanwhile, they are promising materials in multiple-state memories, electric-field-controlled ferromagnetic resonance devices, and transducers with magnetically modulated piezoelectricity due to the magnetoelectric effect.[4–6] However, this kind of material is very rare as its two contrasting order parameters of ferroelectricity and magnetism turn out to be mutually exclusive.[4] Therefore, seeking new functional materials having multiferroic properties and exploring physical mechanism have been hot topics in the field of physics and material sciences.

Recently, RFeO3 system was considered as a new type of multiferroics, regardless of the orthorhombic perovskite structure[7,8] or the hexagonal structure.[9,10] Orthoferrites (RFeO3 with an orthorhombic perovskite structure) have been studied on the good magnetic, optical, and thermal properties for decades. There was hardly any report on the electric properties until the existence of ferroelectricity in the orthoferrites was testified. As a member of RFeO3 system, YFeO3 presents an orthorhombically distorted perovskite structure, with the iron ion surrounded by six oxygen atoms forming an octahedron. The presence of a Dzyaloshinskii–Moriya (DM) interaction can lead to a canting of the spin-lattice, resulting a weak ferromagnetic ordering in YFeO3.[11] It is confirmed that YFeO3 displays a transition from antiferromagnetic to paramagnetic at 655 K.[11] Although recent reports have shown the possibility of ferroelectricity in orthorhombic YFeO3,[12] it has still been a controversial topic.[13,14] Furthermore, there are few studies so far about the ferroelectric properties of orthorhombic YFeO3 film, especially for the microscopic domain structures.

In our previous work,[15] the hexagonal YFeO3 film was prepared by the sol–gel method combined with spin coating technique and its characteristics were analyzed. Here, we obtain the orthorhombic YFeO3 film successfully, only by changing the lattice-matched substrate. This work is a short report on the electrical properties of the orthorhombic YFeO3 thin film on La0.67Sr0.33MnO3/LaAlO3 substrate, where we consider the La0.67Sr0.33MnO3 film as bottom electrode. In particular, its domain structure and polarization reversal behavior are studied.

The La0.67Sr0.33MnO3 (LSMO) layer was successively deposited on LaAlO3(111) (ALO) substrate by a pulsed laser deposition (PLD) method using a KrF excimer laser, with laser wavelength of 248 nm, laser repetition rate of 4 Hz, and pulse energy density of 1.5 J/cm2. The LSMO layer was deposited and annealed in situ at 1073 K in 10.0 Pa oxygen pressure. Subsequently, YFeO3 (YFO) thin film was prepared by a conventional sol–gel spin-coating method. Details about the preparation of precursor solution can be found in Ref. [15]. The precursor solution was coated on LSMO/ALO by spin-coating process at 1500 rpm. The as-deposited film was dried in air at 453 K and the coating process was repeated to the desired thickness. The film was pyrolyzed at 723 K to remove organic residuals. Finally, the film was subject to annealing at 1223 K in air to improve its crystallinity.

The crystal structures were performed by x-ray diffraction (XRD, D/Max2550VB+/PC, Rigaku) with Cu Kα radiation, and laser Raman microscope (inVia, Renishaw, England) with the exciting source of 533 nm laser. The thicknesses were characterized by a scanning electron microscope (SEM, JSM-5800, JEOL) operated at 20 keV. The surface morphology and piezoelectric response were investigated by atomic force microscope (AFM, MFP-3D-SA, Asylum Research) equipped with dual alternating current (AC) resonance tracking Piezoresponse force microscopy (DART-PFM). All the procedures were conducted under atmosphere condition at room temperature. Conductive cantilevers AC240TM with Pt-coated tips were used. The nominal spring constants were 2 N/m with a fundamental resonance frequency of the free tip-vibration of approximately 70 kHz. Detailed description of the PFM analysis is shown below. The leakage current and ferroelectric hysteresis-loop measurements were tested with ferroelectric test systems (Precision LC, Radiant Technologies Inc) at room temperature. Here, Pt electrode was used to form ohmic contacts with LSMO and YFO, respectively.

Figures

| Fig. 1. (a) AFM image of the LSMO layer, (b) AFM image of the YFO layer, and (c) the cross-sectional SEM micrograph of the sample. |

The XRD pattern of YFO film deposited on LSMO/LAO substrate is presented in Fig.

Figure

Figure

Figure

The nanoscopic ferroelectric characteristics of the YFO film are characterized by piezoelectric force microscopy. The capacitive layer of YFO formed between the bottom electrode of LSMO and the conducting scanning probe has been measured. Figure

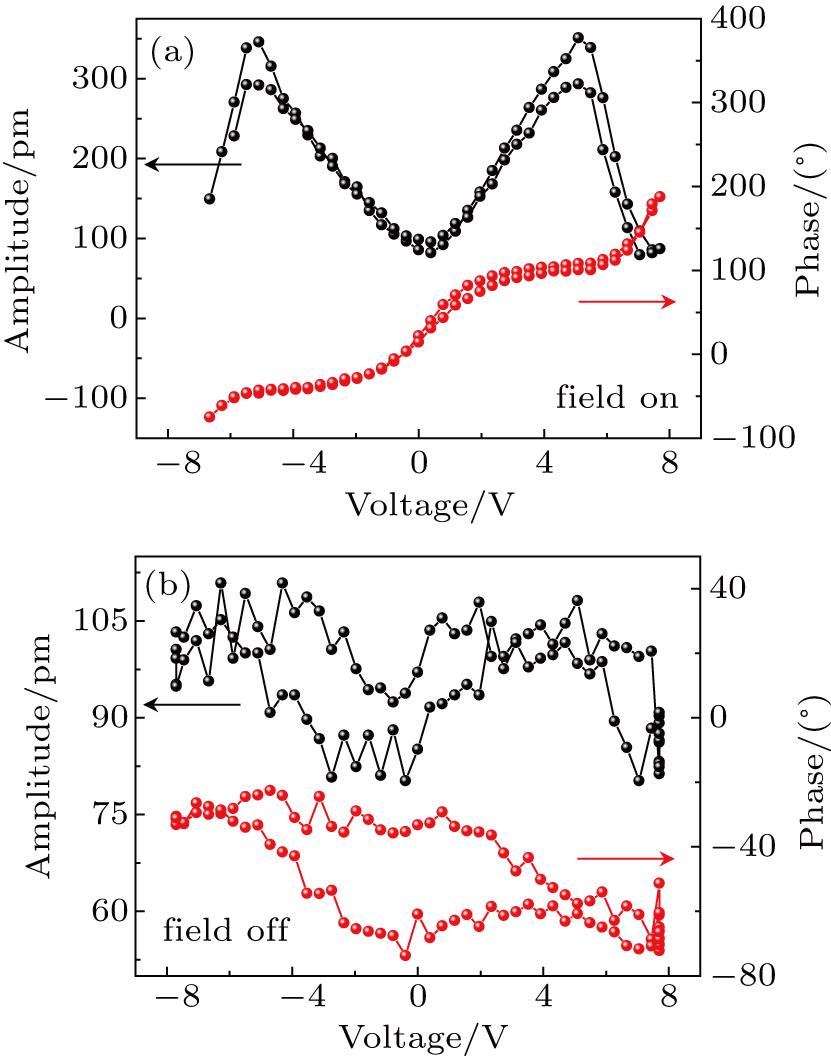

In order to get a better insight into the local switching behavior of ferroelectric domains, piezoresponse loops are recorded by placing the tip over the center of the grains and in the on-field and off-field modes, respectively. As can be seen in Fig.

| Fig. 5. PFM amplitude (black) and phase (red) loops proving the ferroelectric nature of the YFO layer sandwiched between the tip and LSMO: (a) on-field mode and (b) off-field mode. |

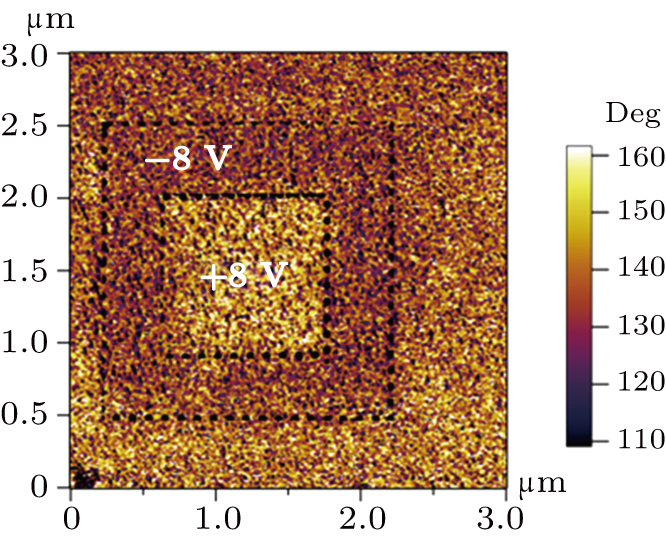

Further, local poling experiment has been performed so as to testify successful polarization switching. The sample was poled under direct current (DC) voltages with “box-in-box” writing processes. In the “box-in-box” writing processes, −8 V was applied on a 2 × 2 μm2 area, and +8 V was applied on a 1 × 1 μm2 square inside simultaneously. Figure

In summary, YFeO3 thin film with another crystal structure is prepared on LSMO/LAO substrate by a sol–gel spin-coating method. X-ray diffraction pattern and Raman spectrum reveal that the YFO film is polycrystalline orthorhombic structure. The leakage current density of the YFO film is 8.39 × 10−4 A⋅cm−2 at an applied electric field of about 148 kV/cm. Due to the large leakage current, the unsaturated P–E loop is obtained at the room temperature. PFM phase image of the YFO film reveals weak ferroelectric domain structure and its polarization can be rotated under the external field. The present work promotes the understanding of the multiferroic properties in orthorhombic YFO.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] |