† Corresponding author. E-mail:

Hot deformation is one of the primary methods for fabricating anisotropic rare earth permanent magnets. Firstly, rapidly quenched powder flakes with a nanocrystal structure are condensed into fully dense isotropic precursors using the hot-pressing process. The prepared isotropic precursors are then hot-deformed to produce high-anisotropy uniaxial bulk rare earth permanent magnets and a highly textured structure is produced via this process. The resulting magnets possess many advantages such as near-net-shape, outstanding corrosion resistance, and ultrafine-grain structure. The influence of the preparation parameters utilized in the hot-pressing and deformation processes on the magnetic properties and microstructure of the permanent magnets are systemically summarized in this report. As a near-net-shape technique, the hot deformation process has notable advantages with regard to the production of irregular shapes, especially for radially oriented ring-shaped magnets with high length-diameter ratios or thin walls. The difficulties associated with the fabrication of crack-free, homogeneous, and non-decentered ring-shaped magnets are substantially resolved through an emphasis on mold design, adjustment of deformation parameters, and application of theoretical simulation. Considering the characteristics of hot-deformed magnets which include grain shape and size, anisotropic distribution of intergranular phases, etc., investigation and improvement of the mechanical and electric properties, in addition to thermal stability, with the objective of improving the application of hot-deformed magnets or ring-shaped magnets, is of practical significance.

In the mid-1980s, Lee[1] originally reported on a method to prepare an anisotropic Nd–Fe–B magnet with ultrafine grain size by hot pressing and die-upsetting the rapidly quenched Nd–Fe–B alloy at a high temperature. Compared to the traditional sintering method, the die-upsetting process can realize a strong magnetic anisotropy without the application of an external magnetic field. It is therefore appropriate for the production of ring magnets with radial orientation. The formation of texture in this kind of Nd–Fe–B magnet, i.e., hot deformation (HD) magnet, is attributed to the anisotropy of the elastic modulus of the Nd2Fe14B grains. As shown in Fig.

| Fig. 1. Variations of elastic modulus of Nd2Fe14B along (E ∥) and perpendicular (E ⊥) to c-axis directions and their difference with temperature. The data is extracted from Ref. [2]. |

| Fig. 2. Demagnetization curves of HP and HD for the over-stoichiometric and rare-earth-lean magnets.[6] |

There are three advantages of the hot deformation process based on the conclusions of Croat et al.:[7] fewer manufacturing steps and therefore suitable for continuous mass production; net shaping or near net shaping which requires minor or no finish grinding; ideal process for producing specially shaped magnet such as arc or ring shape with radial orientation. To date, backward extruded ring magnets with radial orientation have been used in electric power steering systems and in AC servo motors. HD magnets with their ultrafine-grain structure have the potential to yield a high coercivity (H cj), and as a result, they have regained much attention. Currently, most of the investigations on hot deformed Nd–Fe–B magnets are primarily focused on the preparation technology and microstructure optimization to improve magnetic properties, especially coercivity. Moreover, the stress-induced crystallographic orientation is another critical issue pertaining to hot-deformed Nd–Fe–B magnets. Hot-pressing and hot deformation processes have prominent advantages with respect to the production of bulk nanocomposite permanent magnets, and were once considered to be candidates for the fourth generation of rare earth permanent magnets. However, the results of previous studies have indicated that texture formation is very difficult to achieve using a hot deformation process in the case of nanocomposite magnets due to the rare-earth-lean composition. By infiltrating the grain boundary of nanocomposite magnets with eutectic alloys, the capacity for deformation and texture formation are significantly improved. The orientation mechanism of diffusion-processed nanocomposite magnets has also been extensively discussed in recent years.

The preparation process including melt spinning, hot-pressing, and hot deformation significantly influences the microstructure and magnetic properties of HD magnets. As the starting material, the powders crushed from melt-spun ribbons consist of nanocrystals[8] or amorphous matrix.[9] Although melt-spun ribbons exhibit high oxidation resistance, the oxygen content of the HD magnet increases with a decrease of the size of the particles in the powders. In order to produce hot deformed magnets with better performance, the particle size of commercial melt-spun powders is generally

An isotropic precursor is obtained by hot-pressing melt-spun powders. The density variation of the precursors prepared at different HP temperatures is shown in Fig.

| Fig. 3. (a) Dependence of the density of HP precursor on HP temperature ranging from 590 °C to 710 °C and (b) demagnetization curves of HP precursors prepared at the temperatures of 630 °C, 670 °C, and 710 °C.[6] |

The fully dense precursors are deformed to be anisotropic magnets with good texture during the HD process under suitable temperature and stress.[10] The texture in HD Nd–Fe–B magnets develops because of the stress-induced preferential grain growth via a dissolution-precipitation mechanism.[14,15] Figure

Demagnetization curves of HD magnets prepared at the HD temperatures of 780–860 °C are shown in Fig.

Hot deformed magnets with deformations ranging from 30% to 80% were produced and their magnetic properties were investigated (Fig.

| Fig. 6. (a) Magnetic properties of hot deformed magnets with deformation of 30%, 52%, 64%, 70%, and 80%. (b) XRD patterns of the hot deformed magnets with deformation of 30%, 70%, and 80%.[6] |

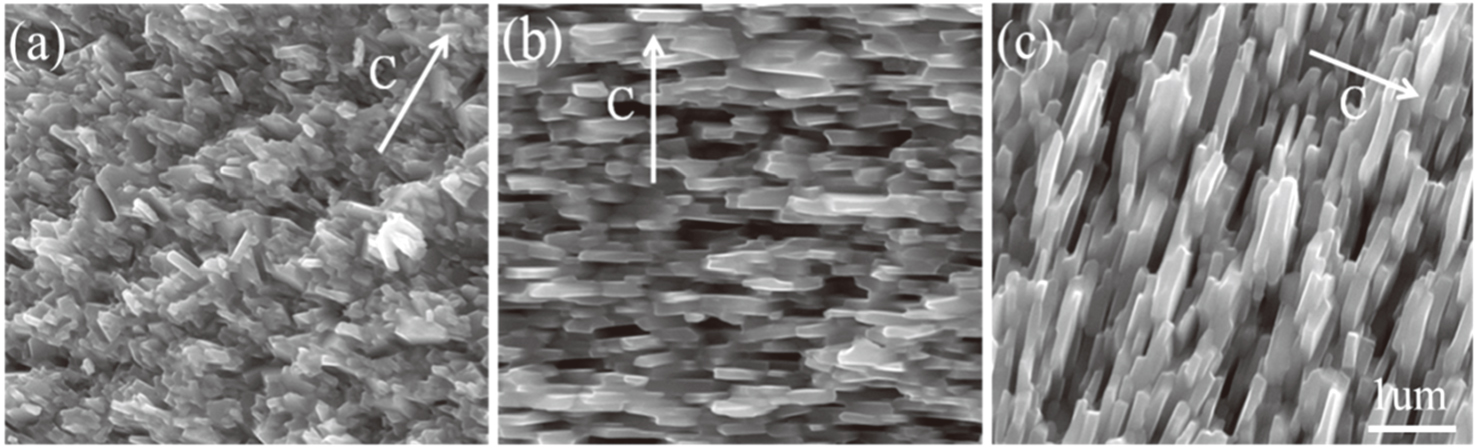

Figure

| Fig. 7. Microstructure of hot deformed magnets with deformation of (a) 30%, (b) 70%, and (c) 80%. The white arrows represent the easy magnetization direction of the c-axis that is perpendicular to the plane of the platelet grains.[6] |

The deformation speed can be evaluated with a constant strain rate

A coarse grain region and fine equiaxed grain region can be found in hot deformed magnets as shown in Figs.

Figure

| Fig. 10. (color online) Distribution of remanence (B r), coercivity (H cj) and maximum energy product ((BH)max) along axial direction of the HD magnet with deformation of (a) 37% and (b) 52%.[23] |

Hot deformed Nd–Fe–B magnets are made of multi-phase materials that consist of the Nd2Fe14B matrix phase, Nd-rich phase, and B-rich compound. Magnetic properties, especially remanence and energy product, strongly depend on the grains alignment along the c-axis direction and the content and distribution of the Nd-rich phase. In the deformation process, Nd2Fe14B grains are wetted by the liquid Nd-rich phase, which promotes the formation of platelet-shaped grains via grain slipping and rotation.[3] In addition, Nd-rich phase at grain boundaries enhances the decoupling effect of Nd2Fe14B grains and facilitates the augmentation of the coercivity. Therefore, the Nd content in a hot deformed magnet is higher than that in the Nd2Fe14B tetragonal phase. Yi et al.[4] investigated the influence of the Nd content on the microstructure and magnetic properties of hot deformed magnets with nominal composition Nd12.8+xFe75.28−xCo5.5Ga0.42B6, as shown in Figs.

| Fig. 11. Magnetic properties of the Nd12.8+xFe75.28−xCo5.5Ga0.42B6 magnets with different Nd content.[4] |

| Fig. 12. (color online) Microstructure of Nd12.8+xFe75.28−xCo5.5Ga0.42B6 magnets with (a) x = 0, (b) x=0.54, and (c) x=0.18.[4] |

It has been reported that coercivity and maximum energy product are enhanced significantly by the addition of Cu powder using dual-alloy technology.[14] Microstructure analyses indicate that the NdCu2 phase is formed in grain boundaries, which obviously improves the texture of the Cu-doped magnet due to the lower melting point of the intergranular phase. This leads to the enhancement of magnetic properties. Ma’s research[27] indicates that Nb addition leads to a notable increase in both the remanence and the coercivity because of the improvement of the c-axis texture and the refinement of the microstructure. Microstructure analysis revealed that Nb atoms are enriched at the grain boundaries and form NbFeB compounds. Li et al.[28] researched the influence of Al, MoS2, Zn, etc. on magnetic properties, and found that MoS2 and Al are effective in increasing the remanence and energy product, while Zn can increase the coercivity. Moreover, Co, Ga, Zr, V, Mo, etc. are utilized for HD magnets to tune the microstructure or improve the magnetic properties.[29–31]

In fact, SmCo5 permanent magnets can also be fabricated by hot pressing and subsequent hot deformation. In recent years, Yue[32,33] reported on hot-deformed anisotropic SmCo5 magnets with a high coercivity over 5 T. The raw powder was prepared using a ball milling technique and the result revealed that deformation levels up to 90% lead to the formation of well-aligned platelet grains. Images of the microstructure are shown in Fig.

| Fig. 13. TEM images of (a) hot pressed, (b) 70%-deformation, and (c) 90%-deformation SmCo5 magnets.[34] |

Coercivity is an intrinsic property which plays a key role in the commercial application of Nd–Fe–B magnets. However, the maximum experimental value of coercivity is only 20%–30% of the theoretical value deduced according to the S-W model.[34] Enhancement of coercivity has been a primary challenge for researchers who study Nd–Fe–B magnets. The coercivity of Nd–Fe–B magnets is sensitive to the microstructure including defects on the surface of grains, ferromagnetic grain boundary phases, and effective demagnetization factors. In order to identify an appropriate method for improving the coercivity, there has been a significant effort directed at attempting to understand the coercivity mechanism of Nd–Fe–B magnets.

Generally, there are two dominant coercivity mechanisms of Nd–Fe–B magnets: nucleation and domain wall pinning mechanisms. However, a consensus has not been achieved with regard to the dispute of the validity of the two mechanisms. In hot-deformed Nd–Fe–B magnets, a strong domain wall pinning is considered to be the primary coercivity mechanism.[35,36] Theoretically, the strength of the domain wall pinning force at the grain boundaries determines the coercivity values. The initial magnetization curves are often adopted to evaluate the magnetization behavior and coercivity mechanism. An S-shaped profile of the initial magnetization is obtained for the HD magnets, which indicates the existence of complicity in the coercivity mechanism.

The first step shows a high reversal susceptibility and relative ease of magnetization. It indicates that reversal domain wall motion dominates the magnetization behavior. In the second step, domain wall pinning at the grain boundaries is dominant. The two-step S-shaped magnetization curve indicates an inhomogeneous domain wall pinning mechanism in the HD Nd–Fe–B magnets. In addition, Volkov et al.[36] investigated the magnetic domain walls structures in hot-deformed Nd–Fe–B magnets and discussed domain wall pinning at the grain boundaries and inhomogeneous microstructures in detail. The inhomogeneous microstructures, which are grain boundary phases and different types of defects on the grain surfaces, result in the inhomogeneous domain wall pinning. An inhomogeneous domain wall pinning mechanism can be used to describe the dominant coercivity mechanism in HD Nd–Fe–B magnets. However, a nucleated micromagnetic model (

The enhancement of the coercivity has been the primary challenge for researchers. In Nd–Fe–B magnets, it has been reported that the coercivity increases with a decrease of the grain size. According to the S-W model, the maximum coercivity could be obtained as soon as the grain size is single domain size, and the coherent rotation of the magnetic moment is perfectly achieved. Due to their nanocrystalline grains, HD Nd–Fe–B magnets have a potential to achieve a high coercivity. However, the coercivity of these magnets is significantly lower than the theoretical value, even though the grain sizes are so-called nanoscale. This may be caused by ferromagnetic intergranular phases, platelet-shaped grains, surface defects, etc., which limit the enhancement of the coercivity for hot-deformed Nd–Fe–B magnets. Reversal domains would be nucleated at ferromagnetic intergranular phases and grain surface defects, followed by propagation into Nd2Fe14B grains. Moreover, the platelet-shaped grains may also be the primary cause of the relatively low coercivity which would significantly increase the effective demagnetization factor N eff.

Although many of the aforementioned disadvantages could not be avoided in HD Nd–Fe–B magnets, significant effort has been made to increase the coercivity. The coercivity enhancement mechanism is discussed in this section.

The addition of certain elements is beneficial to the enhancement of coercivity in HD Nd–Fe–B magnets.[30,37,38] It is commonly assumed that this enhancement is attributable to the modification of the grain-boundary phase by the addition of the elements. Moreover, microstructure optimization and enhancement of magnetocrystalline anisotropy are both beneficial to the increase of the coercivity. Rare earth fluorides have been utilized to produce 45 EH and 50 UH grade sintered Nd–Fe–B magnets for practical application based on their resistance to oxidation and the operational convenient of the procedure. In HD Nd–Fe–B magnets, rare earth fluorides have also been utilized in the fabrication of high coercivity magnets. Tang et al.[39] and Sawatzki et al.[40] have independently reported on the use of DyF3 compounds to produce hot compact precursors followed by hot-deformation. The substitution of Dy for a portion of Nd results in the formation of (Nd, Dy)2Fe14B, and is considered to be the main reason for the enhancement of the coercivity. However, the existence of a mass of DyFe3 compounds in the diffusion regions between adjacent ribbons leads to a large wastage of rare earth resources and a decrease in remanence. Moreover, the scarcity of heavy rare earth (HRE) elements has motivated many researchers to investigate a more effective way to increase coercivity without or with minimal use of HRE. Microstructure optimization may prove to be a more effective way to increase coercivity. In a recent study, Zheng et al.[41] discovered that the coercivity can be increased from 15.6 kOe to 17.75 kOe by introducing WC alloy with a high melting point to inhibit the growth of coarse grains. Figure

| Fig. 14. (color online) (a) BSE images and (b) the EDS elemental map of W obtained from the 1.0 WC sample. (c) and (d) BSE images of coarse grains region for the initial and 1.0 WC sample, respectively.[41] |

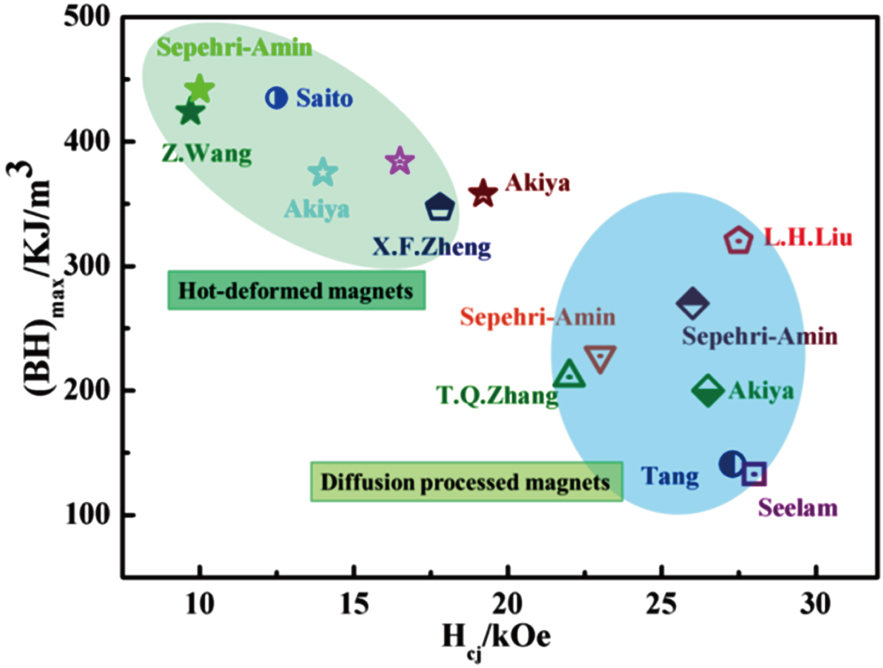

Grain refinement and the optimization of grain boundaries can eliminate ferromagnetic phases and surface defects, and are among the most effective procedures for increasing the coercivity. It is well-accepted that the coercivity of Nd–Fe–B magnets is influenced by the content of Nd-rich phases, and the coercivity increases with an increase in the content of Nd-rich phases.[13] Recently, grain boundary diffusion of rare earth eutectic alloys in nanostructure magnets has been investigated to increase coercivity. It has been shown that HDDR powders with a coercivity of 19.5 kOe can be obtained using a diffusion process based on Nd–Cu eutectic alloy.[42] The thickened grain boundary of the HDDR powders is considered to be the primary reason for the enhanced coercivity. The coercivity of melt-spun Nd–Fe–B powders was shown to be enhanced to 2.6 T due to Nd–Cu infiltration.[43] Sepehri-Amin et al. reported that the high coercivity of ultrafine-grained hot-deformed Nd–Fe–B magnets with 2.3 T is due to the formation of Nd–Cu GBDP.[44] An analysis of the element distribution proved that the ferromagnetic elements in the intergranular phases are reduced from ∼55 at.% to an undetectable level, which results in the decoupling of Nd–Fe–B grains and an increase of the coercivity.

In addition, a much higher coercivity at 2.6 T is simultaneously achieved by low-temperature grain boundary diffusion of Nd60Dy20Cu20 eutectic alloy and Pr70Cu30 alloy, respectively.[45–47] Many researchers have determined that the composition of ferromagnetic elements in intergranular phases parallel to the c-axis is substantially reduced and that a thin Dy-rich shell surrounds Nd2Fe14B grains. Based on previous investigations, an optimized composition of PrNd–Cu alloy was utilized and an HD Nd–Fe–B magnet with a higher coercivity of 2.7 T was obtained.[48] The BSE SEM images of the HD and diffusion-processed magnets are illustrated in Fig.

Based on the demagnetization profiles presented in Ref. [48], the coercivity of the surface regions is stronger than that of the center regions of the diffusion-processed magnets. Moreover, the TEM images in Ref. [48] indicate that the diffusion process is inhomogeneous, which results in magnetization behavior similar to nanocomposite magnets. Recently, one of the highest reported coercivity values of 28 kOe was achieved without HRE addition by diffusion of low melting temperature glass forming Pr60Al10Ni10Cu20 alloys.[49] The large enhancement of the coercivity is attributed to the magnetic isolation of the Nd2Fe14B grains by the Nd-rich amorphous/crystalline intergranular phase. These phases are considered to be non-magnetic. Bance et al.[50] reported that the thickness of surface defects, which are commonly considered to possess lower magnetocrystalline anisotropy, plays a critical role in the magnetization reversal process. In addition, it was found in Ref. [50] that the single-grain computed results for the angular dependence of the coercive field appear to be in good agreement with experimental results when imperfect grain alignment of real magnets is considered. Nonetheless, the enhancement of the coercivity is primarily due to the modification of grain boundaries by the infiltration process of rare earth eutectic alloys.

Figure

|

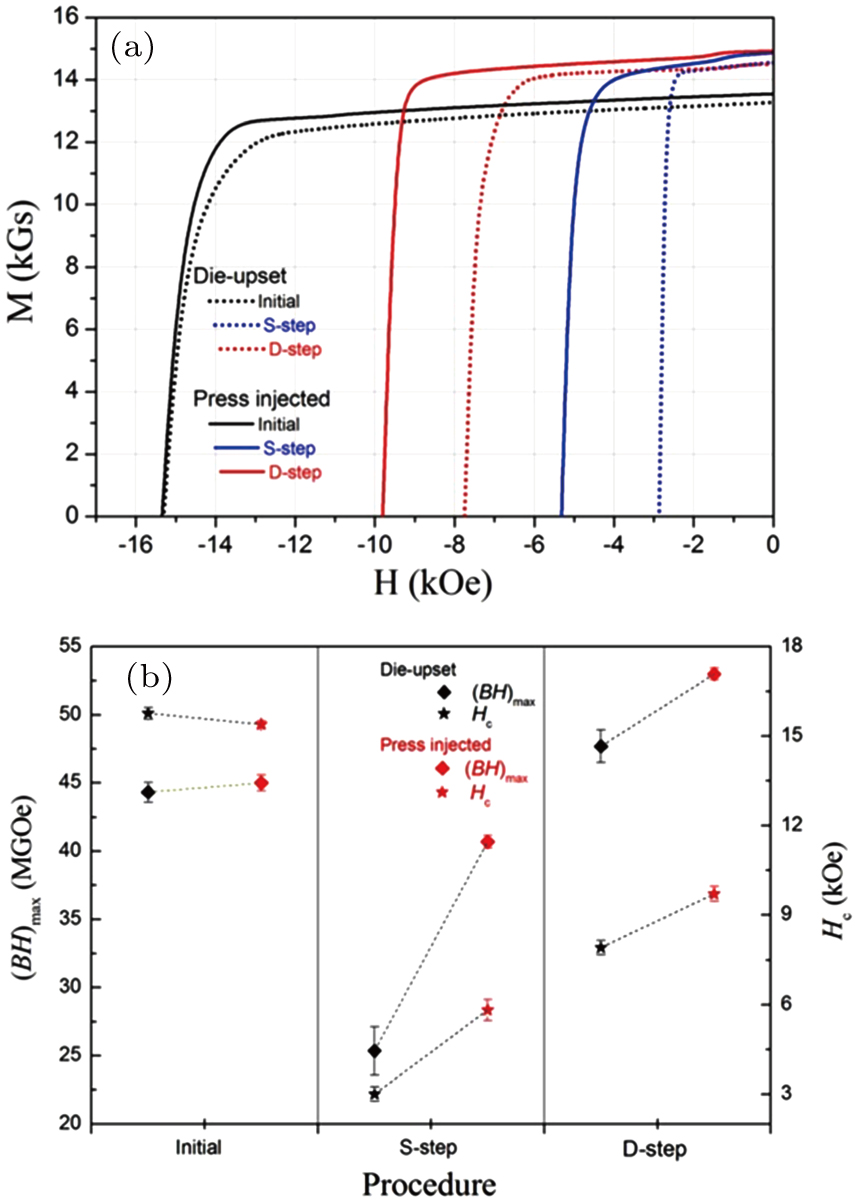

In sintered Nd–Fe–B magnets, optimized structures of (Nd, Dy)2Fe14B or (Nd, Tb)2Fe14B surrounding the Nd2Fe14B phases can be formed using GBDP to yield a dramatic increase in the coercivity without remarkable reduction in the remanence. In hot-deformed Nd–Fe–B magnets, a high coercivity may also be obtained if such a core-shell structure is achieved. Liu et al.[54] reported on a diffusion-processed HD magnet with a coercivity value of 2.75 T and a remanence value of 1.3 T using Nd62Dy20Al18 alloys as a diffusate. In this study, both the core-shell structure with a high magnetocrystalline anisotropy, and magnetic isolation decoupled by nonmagnetic intergranular phases, result in a large enhancement of the coercivity with a slight decrease of the remanence. Recently, Wang et al.[53] developed a procedure to obtain excellent comprehensive magnetic properties of HD Nd–Fe–B magnets based on Dy-Cu press injection and subsequent annealing. The demagnetization curves and magnetic properties of the hot-deformed and Dy–Cu press injected magnets at different stages of the process are shown in Fig.

| Fig. 17. (color online) (a) Demagnetization curves of the hot-deformed and Dy–Cu press injected magnets. (b) Magnetic properties of the hot-deformed and Dy–Cu press injected magnets in different stages of the procedures: initial state, S-step, and D-step annealed states.[53] |

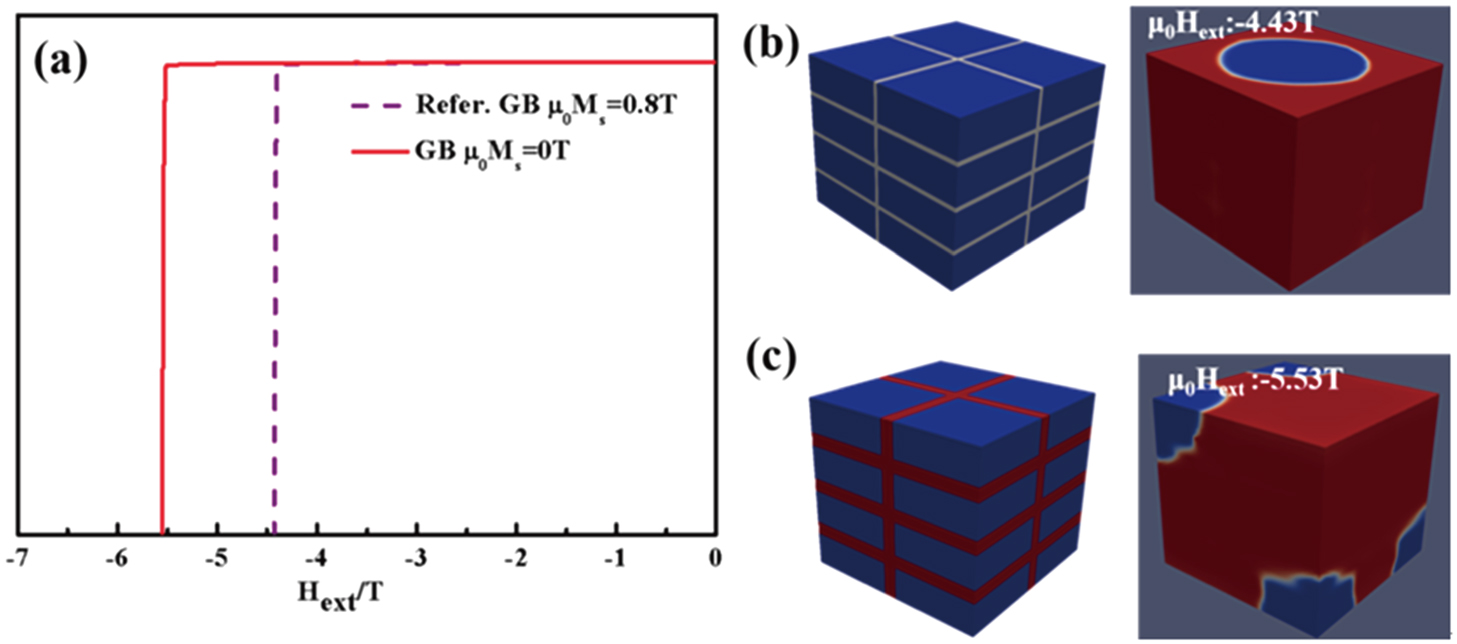

Based on the preceding discussion, the coercivity is closely related to facet defects of grains and the magnetism of the intergranular phases. A high coercivity can be obtained by modification of the grain boundaries and the intergranular phases. Sepehri-Amin et al.[44] investigated the influence of the magnetism of intergranular phases on the coercivity using a finite element model. The micromagnetic simulation result indicates that a reduction of the magnetization in the intergranular phase would effectively improve the coercivity, which is in agreement with experimental results.

Moreover, according to the S-W model, magnetic isolation by the nonferromagnetic intergranular phases is also beneficial for the enhancement of coercivity in HD Nd–Fe–B magnets. Bance et al.[50] studied the influence of defect thickness on the angle of the coercivity. The results indicate that the magnetization reversal mechanism shifts from nucleation to de-pinning with increasing defect thickness. Tang et al.[48] analyzed the magnetization behavior of the diffusion processed HD magnets and identified an S-shaped magnetization profile as shown in Fig.

| Fig. 18. (color online) Micromagnetic simulations of intergranular phases by finite element micro-magnetic simulation model (supplied from NIMTE). |

| Fig. 19. (a) Recoil loops of the diffusion processed sample; (b) field dependence of remanence and reversible susceptibility.[48] |

In summary, the coercivity has become the dominant obstacle to the widespread application of Nd–Fe–B magnets. Researchers are faced with the difficult task of achieving a high coercivity (HRE-free) without reducing the remanence. Based on the results of previous investigations, a high coercivity may be obtained by appropriate optimizations of the grain boundaries and intergranular phases. Firstly, the Nd-rich intergranular phases, which are simply considered as nonmagnetic phases, should be the key microstructure for the coercivity enhancement of Nd–Fe–B magnets. If the ferromagnetism of the intergranular phases could be weakened and the neighboring grains could be decoupled, a high coercivity would be achievable. Secondly, the core-shell structure, which could inhibit the reversal domain nucleation due to the magnetic hardness of the surfaces of the grain, may also provide an effective avenue for obtaining a high coercivity. A high coercivity without a corresponding reduction of the remanence has been achieved in thin films which have an almost ideal microstructure.[54,55] Nonetheless, this is a great challenge and it is expected that a higher coercivity than that of thin films is required.

Recently, new rare-earth permanent magnetic materials with high magnetic properties have attracted much interest due to the increasing demand for environment-friendly and energy-saving devices. However, the scarcity and high cost of rare earth (RE) limit the applications of high-performance rare-earth compounds, such as in the case of Nd–Fe–B permanent magnets. The relatively high concentration of iron (cobalt) atom of nanocomposite magnets has resulted in a reduction of the usage of RE elements, and thus makes a great contribution to the sustainable development of the RE industry. Therefore, the development of nanocomposite magnets has become one of the main avenues for easing the RE shortage. In addition to the reduced RE content, a high soft-magnetic phase fraction in nanocomposite magnets contributes to a large saturation magnetization for potentially high energy products. This implies that the exchange interaction between “soft-hard” magnetic phases can perform well if the “soft-magnetic” phase is thinner than the domain wall thickness of only 3.9 nm for the Nd2Fe14B system. The magnetostatic interaction is demonstrated to relax the strict requirements for the size of the soft-magnetic inclusions. To date, numerous soft-hard composite systems have been investigated. Currently, bonded Nd–Fe–B nanocomposite magnets fabricated by Nd–Fe–B/α-Fe magnetic powders have been widely used. However, the isotropic magnetic characterization and high concentration of nonmagnetic resin adhesive result in a substantial deterioration of the magnetic performance. The obtained maximum energy product (BH)max of the isotropic powders was lower than

The hot-pressed/hot-deformed technique has become an important branching procedure for preparing fully dense anisotropic nanocrystalline magnets. Generally, we can obtain anisotropy hot-deformed Nd–Fe–B composite magnets by several different pathways. The nanocomposite Nd–Fe–B magnets were prepared with isotropic Nd-lean magnetic powders. Compared to the Nd-rich magnetic powders, the Nd-lean magnetic powders give rise to the degradation of the deformability for the bulk material. It is difficult to realize a stress-induced crystallographic orientation in single nanocomposite Nd–Fe–B magnets. Subsequently, the co-doping technique has been widely used to improve the deformability of nanocomposite magnets, such as Nd-rich/Nd-lean[57,58] and Nd-rich/Fe(Co) systems.[59] Since low-melting RE-rich intergranular phase plays an essential role in the stress-induced solution-precipitation creep process,[15,60,61] RE-rich eutectic can be diffused into the grain boundaries to facilitate the formation of a highly textured structure.

To obtain the Nd-lean magnetic powders with rare-earth content lower than the chemical stoichiometry, the ingots with lower RE contents are usually quenched into melt-spun ribbons.[62–65] Then the nanocomposite magnets fabricated by these crystallized Nd-lean magnetic powders are obtained using the hot-pressed and hot-deformed processes. The demagnetization curves of nanocomposite Nd–Fe–B hot-deformed magnets (nominal composition Nd

| Fig. 20. Demagnetization curves of rare-earth-lean Nd–Fe–B nanocomposite magnets parallel and perpendicular to easy-magnetization direction.[62] |

| Fig. 21. (a) SEM fracture surface of hot-deformed magnets with a composition of Nd9.3Pr1Dy0.3Fe77.4Co6.1Ga0.2B5.7 (at.%). (b) TEM micrograph and SAED pattern (inset) of magnets with a composition of Nd9.3Pr1Dy0.3Fe77.4Co6.1Ga0.2B5.7 (at.%).[62] |

In amorphous systems, the crystallization control in amorphous alloys is of particular importance for the development of high-performance nanocrystalline materials. Li et al.[74] succeeded in controlling α-Fe and Nd2Fe14B crystallization processes in amorphous Nd9Fe85B6 by a combination of severe plastic deformation at room temperature and subsequent heat treatment, as shown in Fig.

| Fig. 22. TEM images and electron diffraction SAED patterns of amorphous Nd9Fe85B6 alloy (a) subjected to HPTD and subsequently annealed at 600 °C for 10 min and (b) directly annealed at 725 °C for 10 min.[67] |

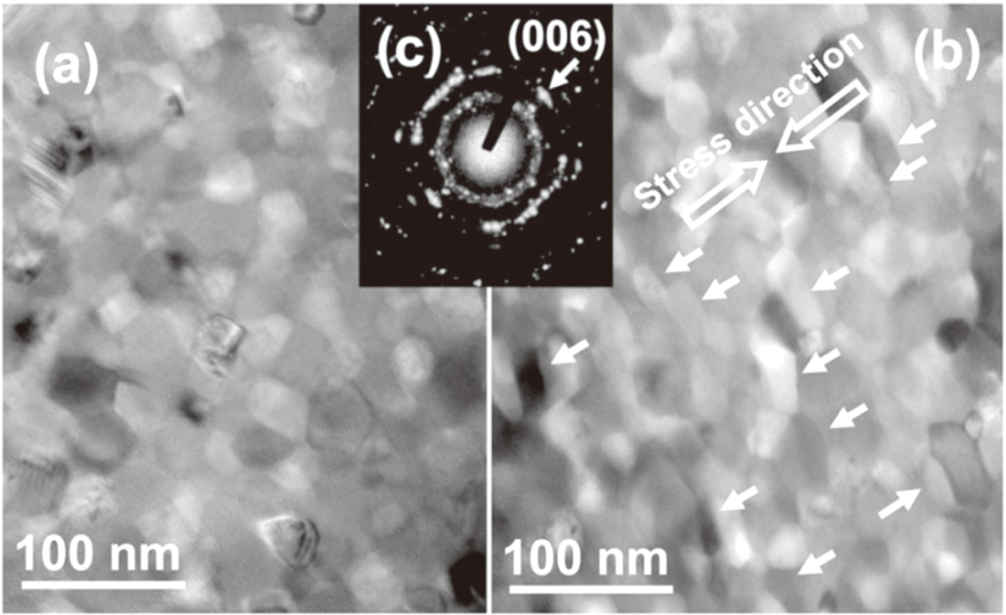

| Fig. 23. TEM bright-field images (a) perpendicular and (b) parallel to the stress direction, (c) SAED patterns of the bulk amorphous Nd9Fe85B after hot deformation.[64] |

Since Nd-lean magnetic powders exhibit poor deformability, co-doping techniques have been developed to fabricate high-performance nanocomposite magnets. For instance, Nd-rich magnetic powders are co-doped with Nd-lean magnetic powders to improve the deformability of bulk samples. Experimental results have demonstrated that the maximum energy product of co-doped magnets can be increased to

| Fig. 24. (a) SEM micrograph of Fe–Co powder particles; (b) SEM back scattered electron image of a hot-deformed composite Nd13.5Fe80Ga0.5B6/α-Fe (91.7 wt.%/8.3 wt.%) magnet.[59] |

Since the formation of texture in nanocomposite magnets is difficult, it is of importance to reveal the mechanism of texture formation in hot deformation. Prior investigations indicate that the RE-rich phase is an essential factor for the magnetʼs deformability. To investigate the deformation mechanism of rare-earth-lean nanocomposite magnets, the low-melting RE-rich eutectic alloy is added to the hot deformation process. Thus the formation of a textured structure can be controlled by adjusting the composition and concentration.

Figure

| Fig. 25. (color online) (a) BSE SEM image showing the interface of particles in the sample hot pressed at 600 °C, (b) EDS maps of elements in this area and (c) EDS line-scan across the interface region marked in (a).[69] |

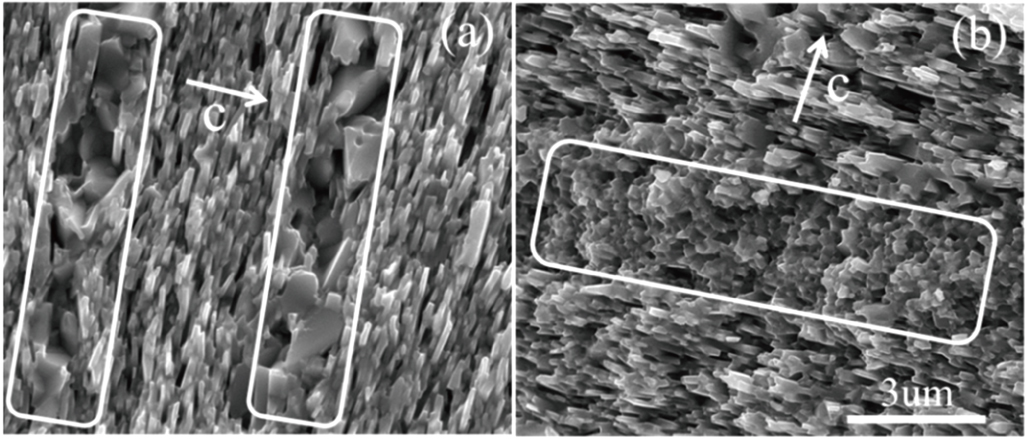

Apart from the hot-pressed process, the mechanism of microstructure evolution in eutectic-doped hot-deformed magnets was also studied. The effect of low-melting Nd-rich intergranular phases on the formation of platelet-shaped grain and textured structure is critical. Tang et al.[70] studied the effect of Nd-rich phases on texture formation in nanocomposite magnets by the diffusion of Nd–Cu eutectic. The results demonstrate that the Nd-rich intergranular phases are favorable to the anisotropy of Nd–Fe–B magnets, as shown in Fig.

| Fig. 26. Field emission SEM micrographs of hot-deformed nanocomposite magnets with various Nd–Cu alloy addition: (a) x = 0, (a) x = 4 wt.%, (c) x = 6 wt.%, and (d) x = 10 wt.%.[70] |

In addition, the crystal structures in the intergranular phases are correlated with the chemical composition (Fig.

| Fig. 27. TEM/HRTEM and fast Fourier transform images of hot-deformed nanocomposite magnets with a deformation rate of 30%.[69] |

Radially oriented Nd–Fe–B ring magnet (RM) is a special Nd–Fe–B magnet with a ring shape with the easy c-axis along the radial direction (Fig.

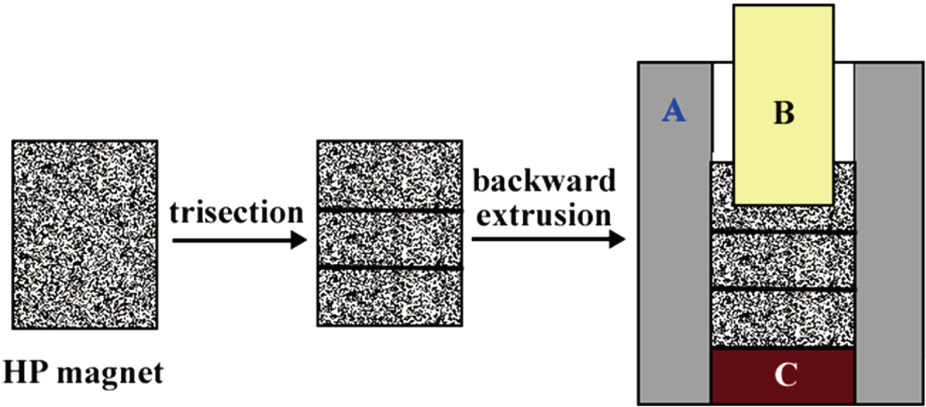

The procedure of the backward extrusion method is illustrated in Fig.

| Fig. 29. (color online) Schematic illustration of the procedure of backward extrusion method.[6] |

The HD RM has significant potential for application in brushless DC motors.[71] However, some researchers have indicated that the inhomogeneity of magnetic performance limits the application of HD RM in industry to some extent. For example, the remanence decreased quasilinearly from the inner to outer surface of backwardextruded (BE) RM along the radial direction.[20,72] In the axial direction, remanence initially increased, then decreased from the top to the bottom of the RM.[73,74] To examine the cause of this inhomogeneity, the mechanisms of texturing and material flow must be evaluated.

To date, three main mechanisms have been proposed to explain the formation of platelet Nd2Fe14B grains in the hotdeformed magnet. Li et al.[60] suggested a mechanism based on the dissolution of nonfavorably oriented crystallites in the Nd-rich phase and their reprecipitation on the crystallites, which have their c-axes oriented parallel to the stress direction. An extensive study by Grünberger et al.[20] suggested that the diffusion creep mechanism played a dominant role, which is accompanied by rheological and viscous flow. Yuri and Leonowicz[75,76] have proposed another mechanism, which considered the mechanical rotation of grains when they deformed plastically, and the alignment results from the geometric anisotropy of the crystallites. However, the subsequent evolution of these Nd2Fe14B platelets has rarely been reported because they depend greatly on the preparation strategy.

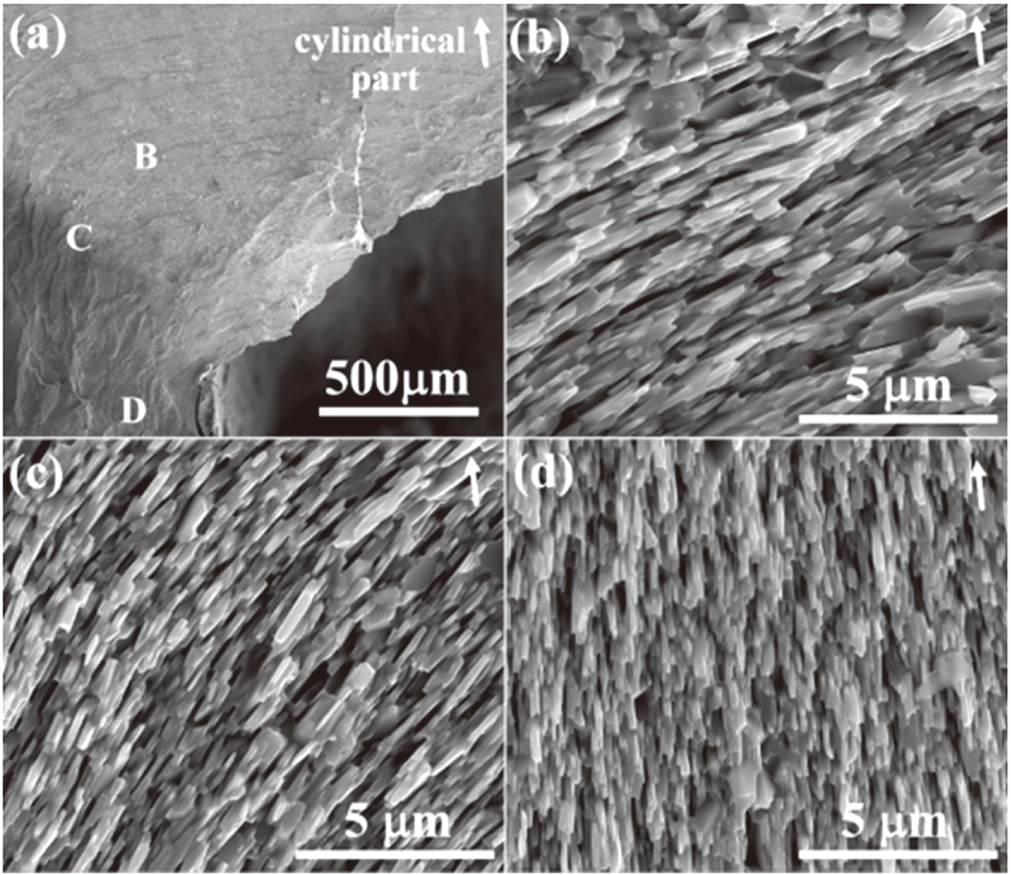

Yin et al.[5] have performed a systematic investigation of texture evolution and materials flow over a partly deformed ring magnet. This ring magnet was divided into two parts: a ring-shaped part and a cylindrical part. Their investigation revealed that the formation of the platelet-shaped grains occurred in the cylindrical part and the depth of the texture zone was limited by the bottom of the punch. Further investigations suggest that equiaxed grains are distributed in the bottom region of the cylindrical part because no material flow occurs in that region (Fig.

| Fig. 30. (color online) Schematic illustration of the texturing zone and the non-texture zone in the cylindrical part of the ring magnet prepared using the backward extrusion method.[5] |

| Fig. 31. SEM images of the region where the cylindrical part meets the ring-shaped part: (a) the image under low-magnification, (b)–(d) the high-magnification images of regions B, C, and D in (a), respectively. The white arrows represent the pressing direction.[5] |

Radially oriented RM exhibits inhomogeneity of the remanence along the axial direction.[72,77] This inhomogeneity has been ascribed to the texture difference in the axial direction.[78,79] To address this problem, Tang et al.[80] developed a pre-deformation technique. The HP magnet was initially subjected to a 52% deformation. This was followed by backward extrusion into the RM. The RM prepared using this technique exhibited a significant improvement in the homogeneity of the remanence and the coercivity along the axial direction (Fig.

| Fig. 32. (color online) (a) Magnetic performance and (b) the SEM images of the samples cut from different axial positions of the ring magnet prepared by pre-deformation and BE method. The white arrows represent the radial direction.[6] |

Apart from the improvement of the remanence homogeneity, the enhancement of the magnetic performance was another focus of the RM research. Yi et al.[4] have investigated the effect of Nd content on the remanence of RM and the Nd content of 13.34 at.% was optimized. Gutfleisch et al.[79] determined that the deformation temperature and deformation speed have a great influence on the coercivity with little effect on the remanence of the RM prepared from the HDDR powder. A large deformation rate is beneficial to the coercivity, however, the deformation temperature has an optimum value of 725 °C. The optimized deformation temperature for melt-spun powder was determined by Li et al. to be 800 °C for texture formation and 660 °C for coercivity.[81] Moreover, a deformation rate of 0.01 and deformation ratio of 70% were determined to be optimum for the best texture and remanence.

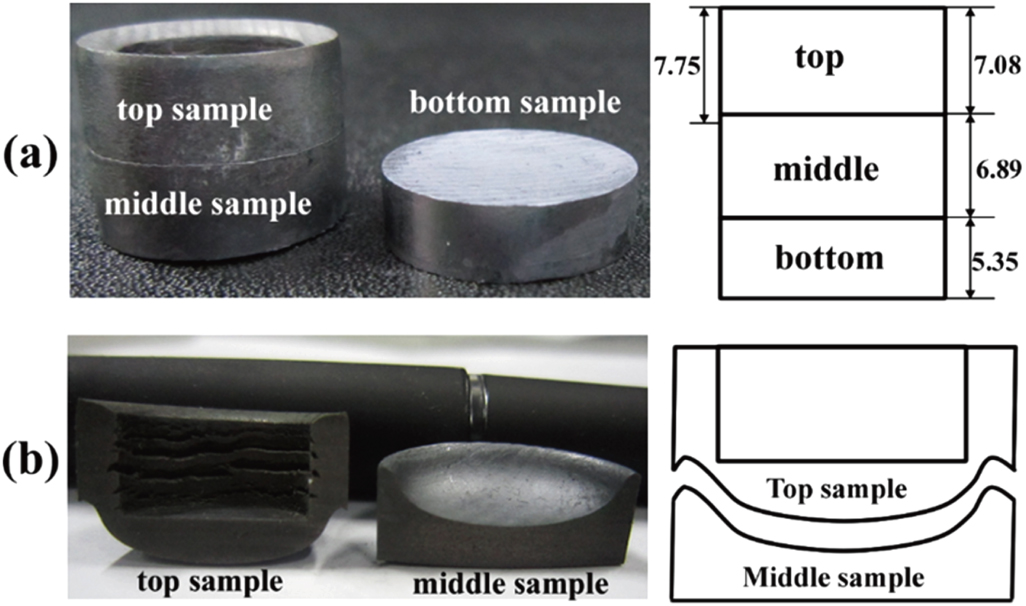

Radially oriented RM prepared by the backward extrusion method usually exhibits cracks along the tangential direction on the inside surface in the top region (Fig.

| Fig. 33. Tangential cracks in the top region of ring magnet.[6] |

| Fig. 34. Image on the vertical section of the backward-extruded ring magnet.[6] |

| Fig. 35. (color online) Schematic illustration of backward extrusion of the stacked HP magnets which were trisected from a mother HP magnet.[6] |

| Fig. 36. Photograph and schematic illustration of the bottom (a), middle (b), and top (b) samples after backward extrusion of stacked trisected hot pressing precursor. The height of the ring-shaped part is 7.75 mm.[6] |

| Fig. 37. Illustration on the three zones in cylindrical metals or alloys that were freely deformed under uniaxial pressure.[6] |

| Fig. 38. Images of the different shapes of punches and the ring magnets prepared with them: (a) half-spherical-end punch; (b) arc-shaped-end punch; (c) beveling cylinder; (d) cylinder.[6] |

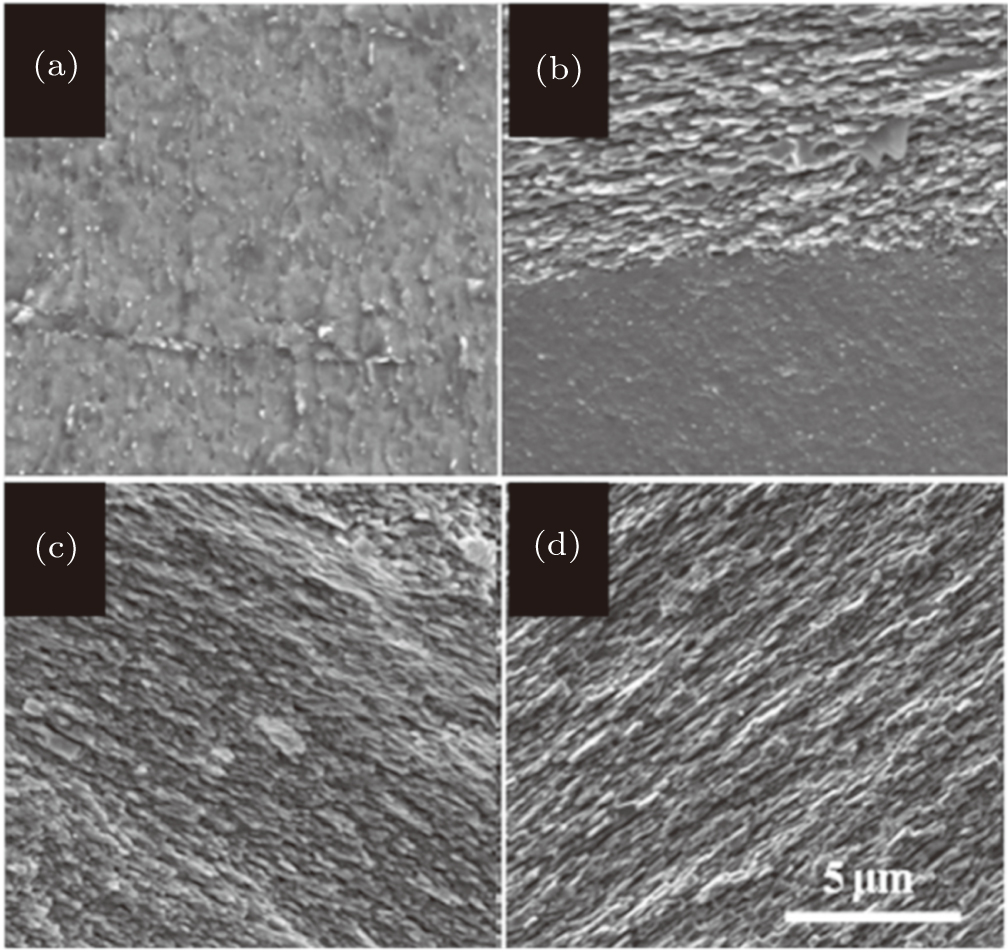

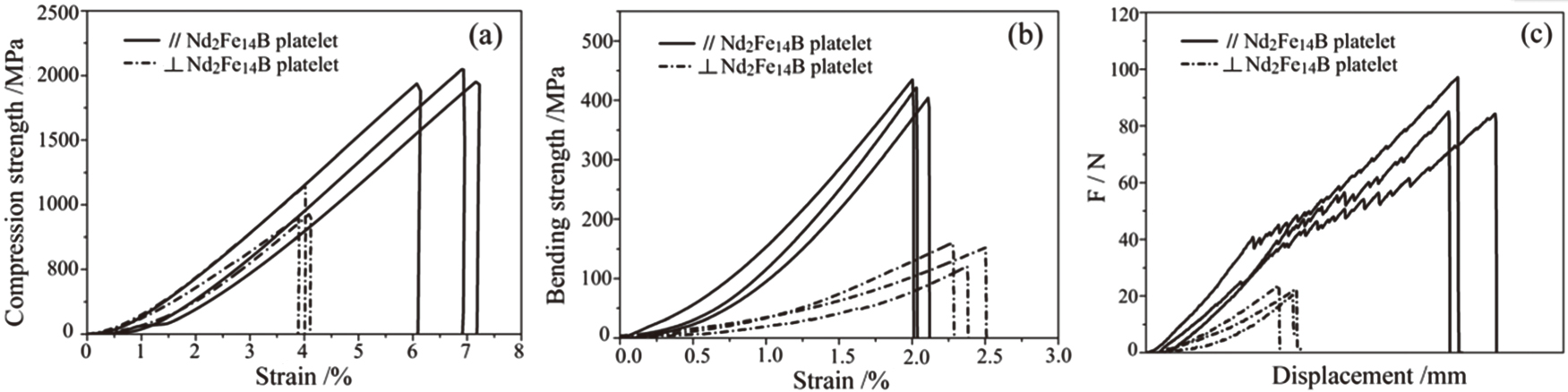

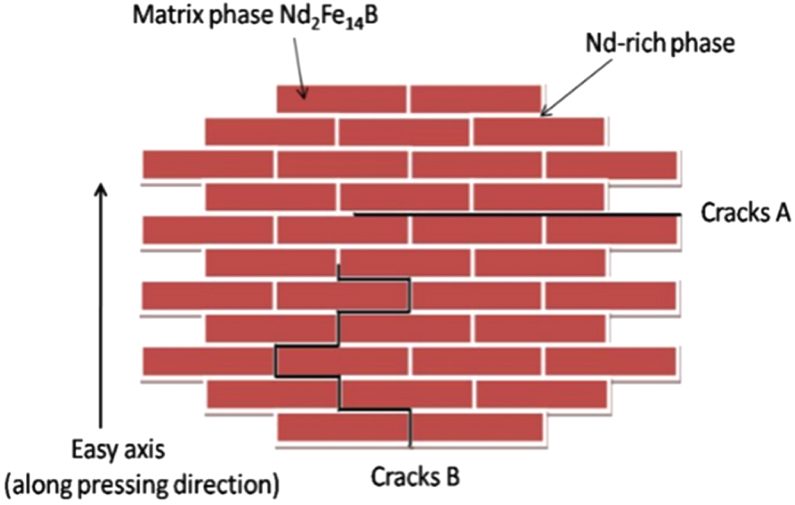

Sintered Nd–Fe–B magnets were initially reported to show an inferior fracture toughness compared to metals.[86] Their fracture toughness (K

IC) is approximately 1–2 magnitudes lower than that of metals.[87,88] This fragile characteristic shortens the life of devices and is undesirable for machinery. HD Nd–Fe–B magnets have the characteristics of both a laminated structure consisting of Nd2Fe14B platelets and anisotropic grain boundaries (GB) (Figs.

| Fig. 40. (color online) Schematic illustration of the microstructure of hot-deformed (a) and sintered (b) Nd–Fe–B magnets. |

| Fig. 41. Compression strength (a), bending strength (b), and fracture toughness (c) of HD Nd–Fe–B magnets along the directions that are parallel (dot-slash line) and vertical (straight line) to Nd2Fe14B platelets.[89] |

| Fig. 42. (color online) Sketch map of crack propagation along the grain boundary in HD magnets.[89] |

| Table 1.

Compression strength (σ

c), bending strength (σ

b), and fracture toughness (K

IC) of HD Nd–Fe–B magnet along the directions parallel ( |

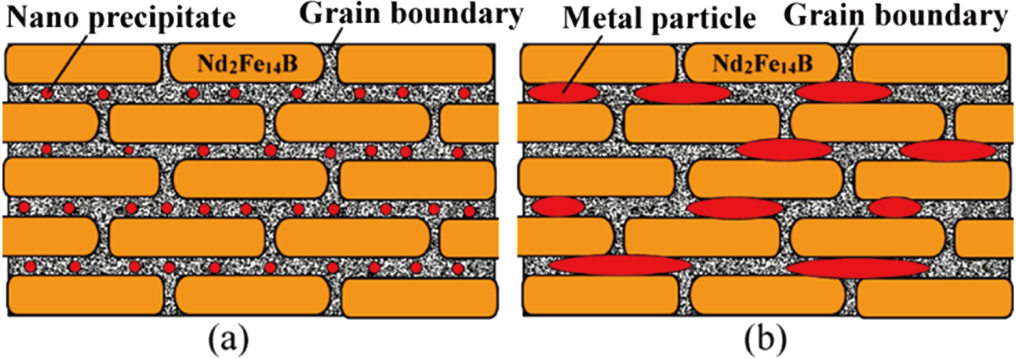

Since HD Nd–Fe–B magnets are easily cracked or broken along the GB parallel to the Nd2Fe14B platelets (GB-P), there are two methods that can be implemented to improve the toughness in this direction: the accumulative precipitation of nano-sized ductile phase and the dispersion of hard metal particles in GB-P (Fig.

In addition, other preparation parameters have been optimized to improve mechanical performance. Yi et al.[17] improved the bending strength of HD magnets by the addition of Cu powder. Ju et al.[100] tested the bending strength and toughness of these magnets using different Nd content, and discovered that the bending strength perpendicular to the Nd2Fe14B platelets increased with the increment of RE content, while a corresponding decrease was observed parallel to Nd2Fe14B platelets. Lin et al.[16] revealed the coarse grains could reduce both the compressing strength and the bending strength of HD magnets. This result is consistent with the finding that ultrafine grain is effective for improving impact toughness and bending strength.[101] Hu et al.[102,103] studied the mechanical performance of the HD magnet for different deformation rates. It was determined that both the Vickers hardness and the fracture toughness reached maximum values at a deformation rate of 40%. Hu et al.[104] also optimized the HD temperature for the Rockwell hardness and fracture toughness. Recently, Zheng et al.[105] determined that the cracks of hot-deformed Nd–Fe–B magnets are located in the ribbons boundaries comprised of non-oriented coarse grains. By suppressing the interfacial coarse grains, the mechanical properties can be effectively improved. This improvement can be ascribed to the refined grain size and reduced stress concentration.

Nd–Fe–B magnets can be utilized in the rotators of brushless motors to achieve large torques and high efficiency. Nevertheless, these magnets are good conductors and eddy current loss during rotation in an alternating electromagnetic field is expected. The eddy current cause an increase in the operating temperature of the magnet which reduces the remanence and torque. As such, suppression of the increase in temperature during the application process is favorable to the improvement of magnet stability.

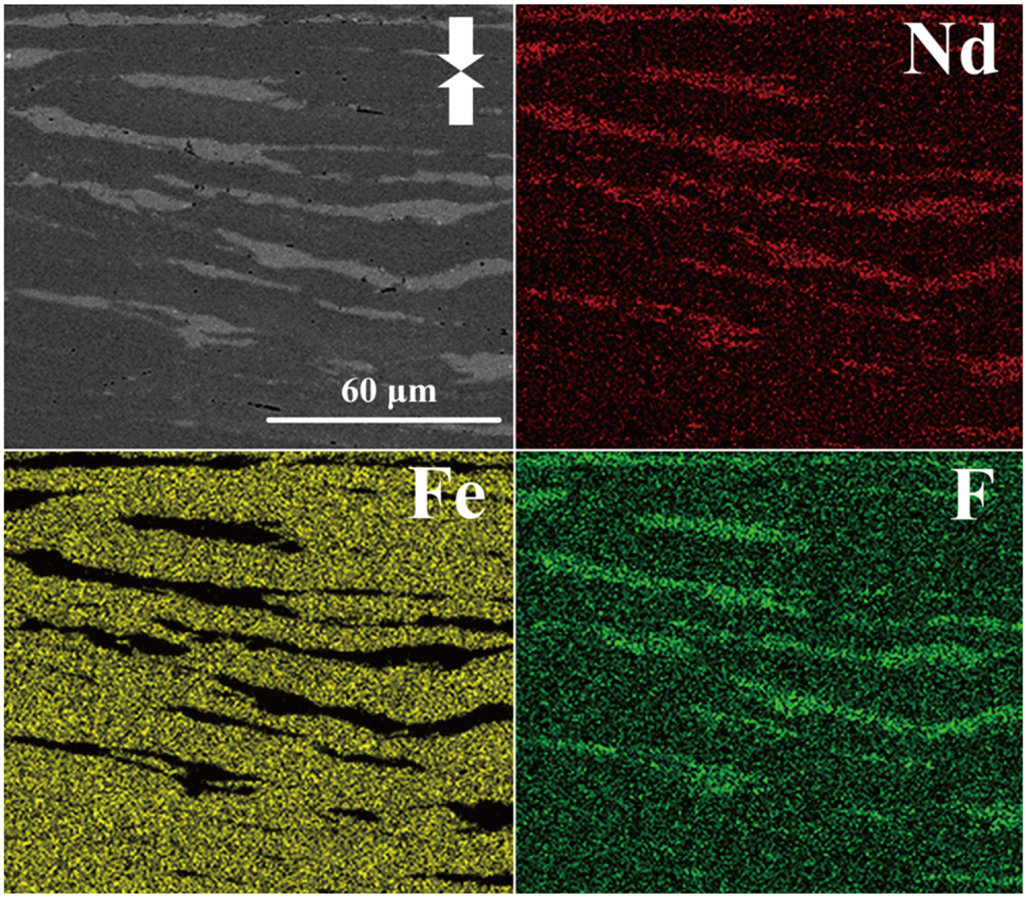

One commonly used approach is to increase the electric resistivity of Nd–Fe–B magnets. Since the grain boundary exhibits a much lower resistivity than the Nd2Fe14B phase, increasing the resistivity of the grain boundary is key. In this regard, Marinescu et al.[106] have investigated the use of fluorides including NdF3, DyF3, and CaF2. The results show that CaF2 is the most stable additive after hot deformation and brings the highest resistivity for Pr-Fe-B HD magnets. Furthermore, the coercivity of the HD magnet remained nearly constant. Zheng et al.[107,108] introduced Al2O3 and SiO2 nanoparticles into Nd–Fe–B HD magnets. Both of these nanoparticles are able to increase the resistivity, but the remanence and coercivity were observed to significantly decrease. The deterioration of magnetic performance was due to the introduction of the element oxygen and atom diffusion during the HD process. After that, Wang et al.[109] has developed a facile method in which NdF3 powder was added into Nd–Fe–B magnet in a stacking way (Fig.

| Fig. 44. (color online) Back scattered electron SEM image for Nd2Fe14B/NdF3 (2.12 wt.%) hot-deformed magnets with laminated structure and the element concentration maps for Fe, Nd, and F. Arrow is the pressure direction.[109] |

| Fig. 45. Dependence of the electrical resistivity of Nd2Fe14B/NdF3 on the percentage of NdF3.[109] |

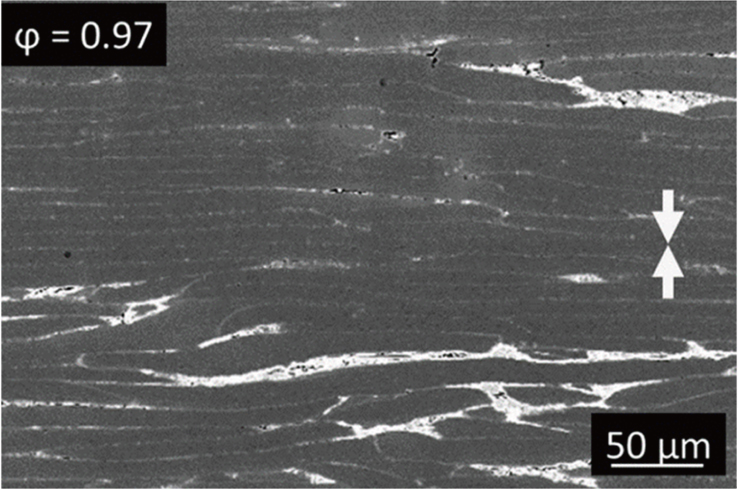

Subsequently, Zheng[110,111] reported similar works and prepared a Nd–Fe–B/CaF2 composite magnet with which the effect of CaF2 addition on the properties of the HD Nd–Fe–B magnet was investigated. Interestingly, when the mixtures were blended in ethanol, CaF2 was observed to transform from discontinuous blocks to continuous laminated structures in the composite magnet. The resistivity of the composite magnet increased with the increment of CaF2 and reached a maximum value of

In addition, Sawatzki et al.[112] also enhanced the electrical resistivity of Nd–Fe–B hot-deformed magnets via adding DyF3 powders. The DyF3 additive that is enriched at the particle boundaries forms insulating Dy–F rich inclusions, which improve the electrical resistivity of local regions (Fig.

| Fig. 46. BSE image on a polished cross-section shows the electrically insulating Dy–F rich inclusions (bright area) within the MQU-F flakes (dark areas). The white arrows indicate the pressing direction.[112] |

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] | |

| [42] | |

| [43] | |

| [44] | |

| [45] | |

| [46] | |

| [47] | |

| [48] | |

| [49] | |

| [50] | |

| [51] | |

| [52] | |

| [53] | |

| [54] | |

| [55] | |

| [56] | |

| [57] | |

| [58] | |

| [59] | |

| [60] | |

| [61] | |

| [62] | |

| [63] | |

| [64] | |

| [65] | |

| [66] | |

| [67] | |

| [68] | |

| [69] | |

| [70] | |

| [71] | |

| [72] | |

| [73] | |

| [74] | |

| [75] | |

| [76] | |

| [77] | |

| [78] | |

| [79] | |

| [80] | |

| [81] | |

| [82] | |

| [83] | |

| [84] | |

| [85] | |

| [86] | |

| [87] | |

| [88] | |

| [89] | |

| [90] | |

| [91] | |

| [92] | |

| [93] | |

| [94] | |

| [95] | |

| [96] | |

| [97] | |

| [98] | |

| [99] | |

| [100] | |

| [101] | |

| [102] | |

| [103] | |

| [104] | |

| [105] | |

| [106] | |

| [107] | |

| [108] | |

| [109] | |

| [110] | |

| [111] | |

| [112] |