Project supported by the National Key Research and Development Program of China (Grant Nos. 2016YFB0402002, 2016YFB0401803, 2017YFB0405002, 2017YFB0405003, and 2017YFB0405005), the National Natural Science Foundation of China (Grant Nos. 61574160, 61704184, and 61334005), the Strategic Priority Research Program of the Chinese Academy of Science (Grant No. XDA09020401), the Chinese Academy of Science Visiting Professorship for Senior International Scientists (Grant No. 2013T2J0048), the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20170430), and the CPSF-CAS Joint Foundation for Excellent Postdoctoral Fellows, China (Grant No. 2016LH0026).

Project supported by the National Key Research and Development Program of China (Grant Nos. 2016YFB0402002, 2016YFB0401803, 2017YFB0405002, 2017YFB0405003, and 2017YFB0405005), the National Natural Science Foundation of China (Grant Nos. 61574160, 61704184, and 61334005), the Strategic Priority Research Program of the Chinese Academy of Science (Grant No. XDA09020401), the Chinese Academy of Science Visiting Professorship for Senior International Scientists (Grant No. 2013T2J0048), the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20170430), and the CPSF-CAS Joint Foundation for Excellent Postdoctoral Fellows, China (Grant No. 2016LH0026).

† Corresponding author. E-mail:

Project supported by the National Key Research and Development Program of China (Grant Nos. 2016YFB0402002, 2016YFB0401803, 2017YFB0405002, 2017YFB0405003, and 2017YFB0405005), the National Natural Science Foundation of China (Grant Nos. 61574160, 61704184, and 61334005), the Strategic Priority Research Program of the Chinese Academy of Science (Grant No. XDA09020401), the Chinese Academy of Science Visiting Professorship for Senior International Scientists (Grant No. 2013T2J0048), the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20170430), and the CPSF-CAS Joint Foundation for Excellent Postdoctoral Fellows, China (Grant No. 2016LH0026).

Thermal characteristics of multiple laser stripes integrated into one chip is investigated theoretically in this paper. The temperature pattern of the laser diode mini-array packaged in a TO-can is analyzed and optimized to achieve a uniform temperature distribution among the laser stripes and along the cavity direction. The temperature among the laser stripes varies by more than 5 K if the stripes are equally arranged, and can be reduced to less than 0.4 K if proper arrangement is designed. For conventional submount structure, the temperature variation along the cavity direction is as high as 7 K, while for an optimized trapezoid submount structure, the temperature varies only within 0.5 K.

In recent years, high power and high wavelength stability GaN-based blue laser diodes (LDs) have drawn great attention due to their potential applications in laser display and lightening.[1–3] Instead of watt-class single stripe laser diodes, integrating multiple stripes into one single chip to constitute an LD array is an effective way to achieve high output power.[4–7] Usually, the LD chips are packaged in a TO-can to realize electrical pumping and thermal dissipation. However, for an LD array, the temperature in each stripe can vary because the stripes are not thermally independent.[8,9] Careful consideration should be taken to optimize the arrangement of the stripes to achieve a uniform temperature distribution among the stripes. Furthermore, there is an inherent disadvantage for conventional TO package. Due to the asymmetric structure of the TO-can, the heat dissipation of the area close to the rear cavity facet is more effective than that of the area close to the front cavity facet. The temperature within the chip is not uniform along the cavity direction.[10] The nonuniformity of temperature among the stripes and along the cavity direction may deteriorate the wavelength stability, output power of LDs, and the device reliability.[5,11,12]

In this paper, the thermal characteristics of a GaN-based LD mini-array (with 5 laser stripes) in a TO-9 package is analyzed by using finite element method (FEM). Based on the analysis results, the arrangement of stripes is studied and optimized numerically to enhance the temperature uniformity. The influences of different submount structures are compared, and the temperature uniformity can be significantly improved if a trapezoid AlN submount is used.

The following heat conduction equation is numerically solved for the analysis of thermal characteristics of the GaN based LD mini-array in a TO-9 package.

|

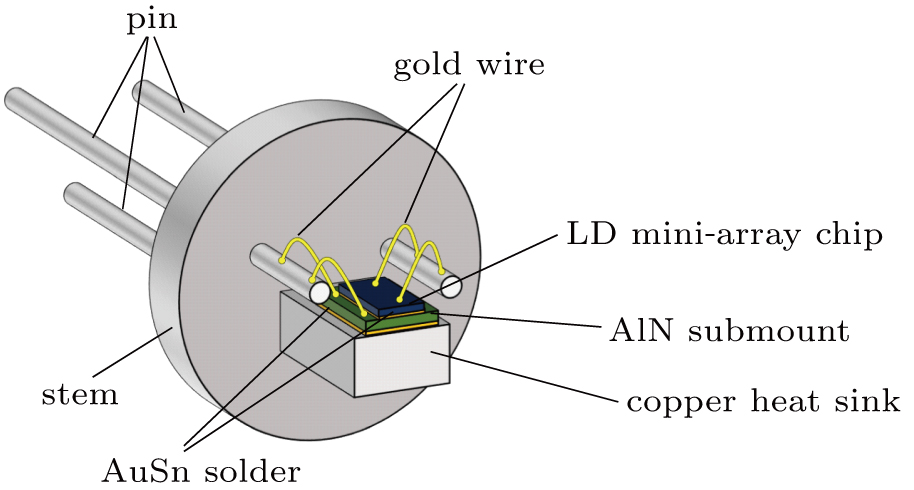

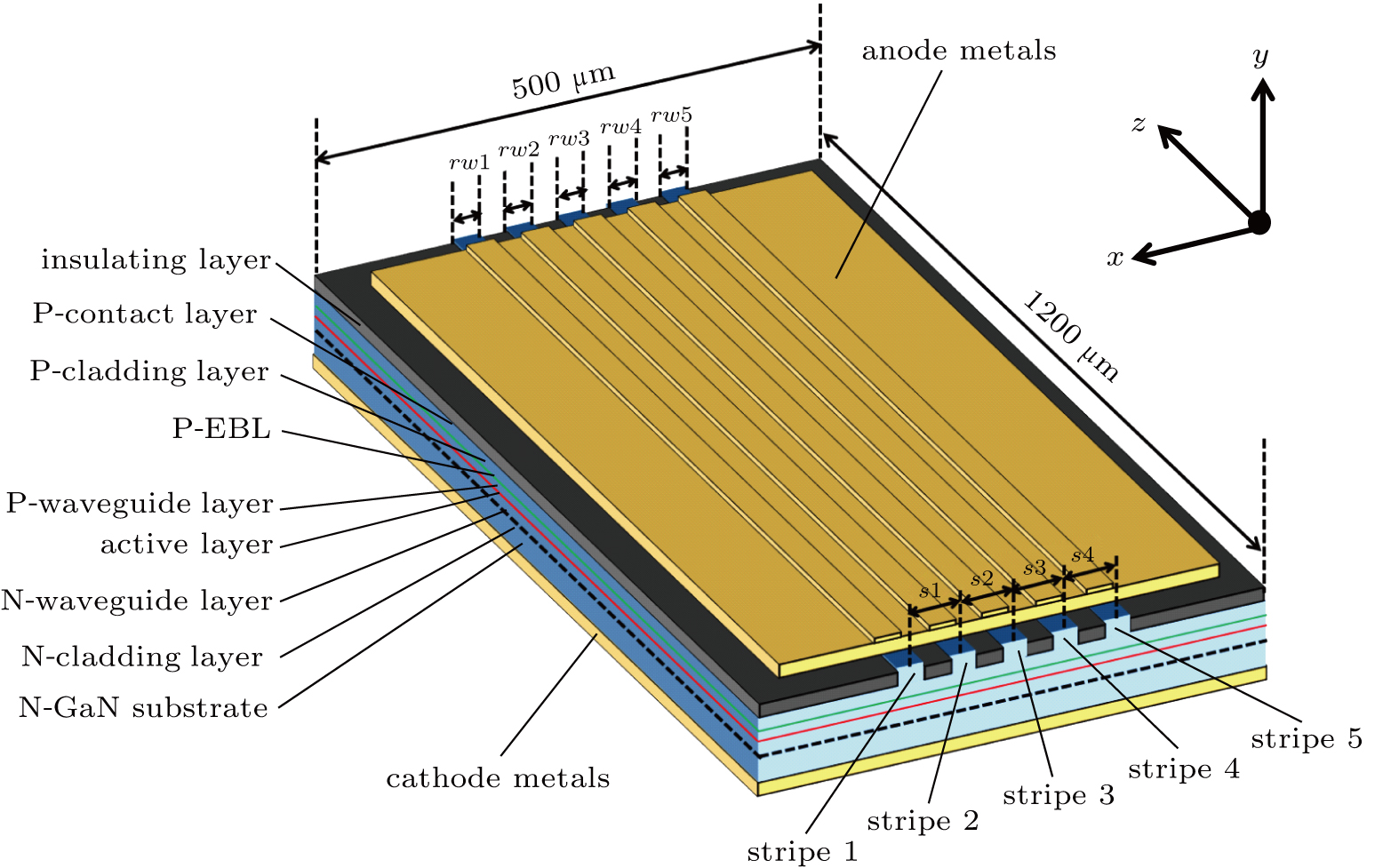

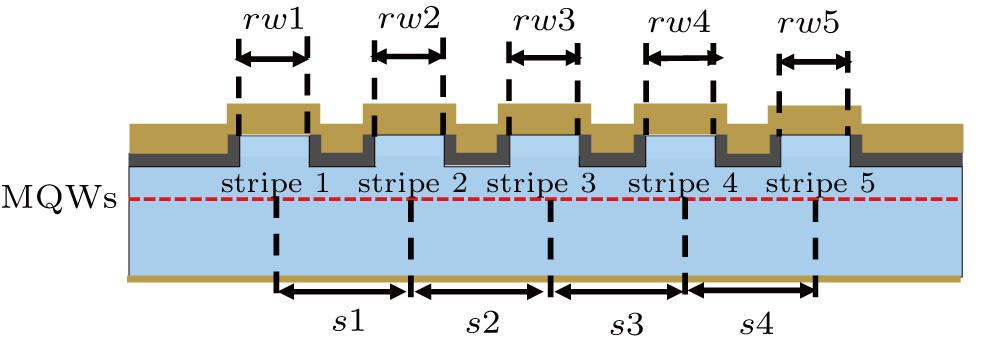

Three-dimensional TO-9 packaged LD mini-array model is built for thermal simulation. Figure

Table

| Table 1.

Material parameters in the simulation at 300 K. . |

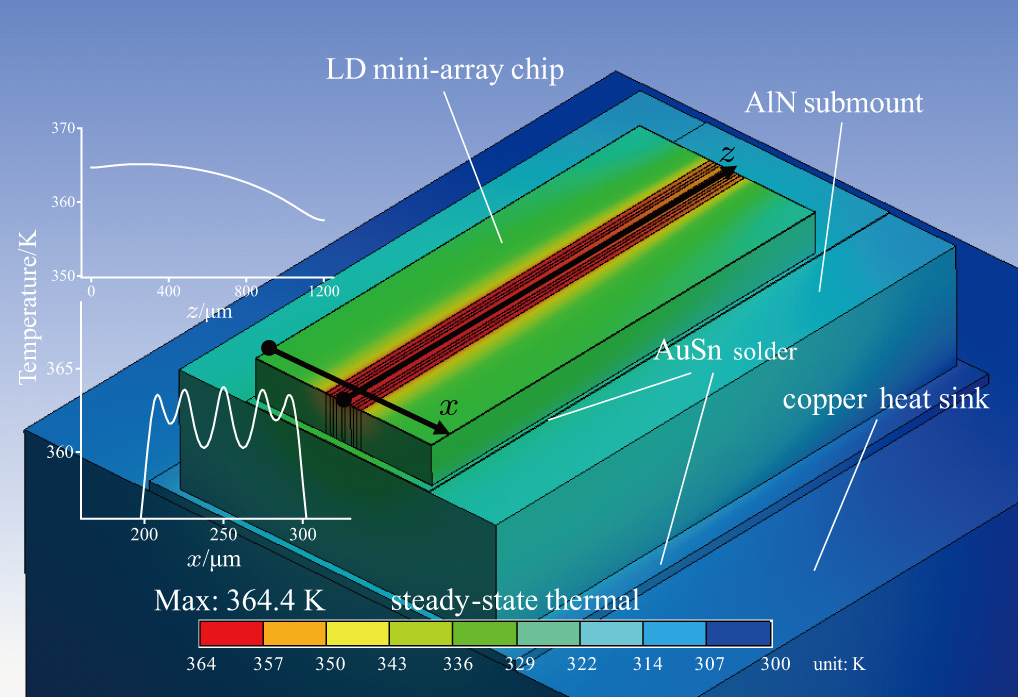

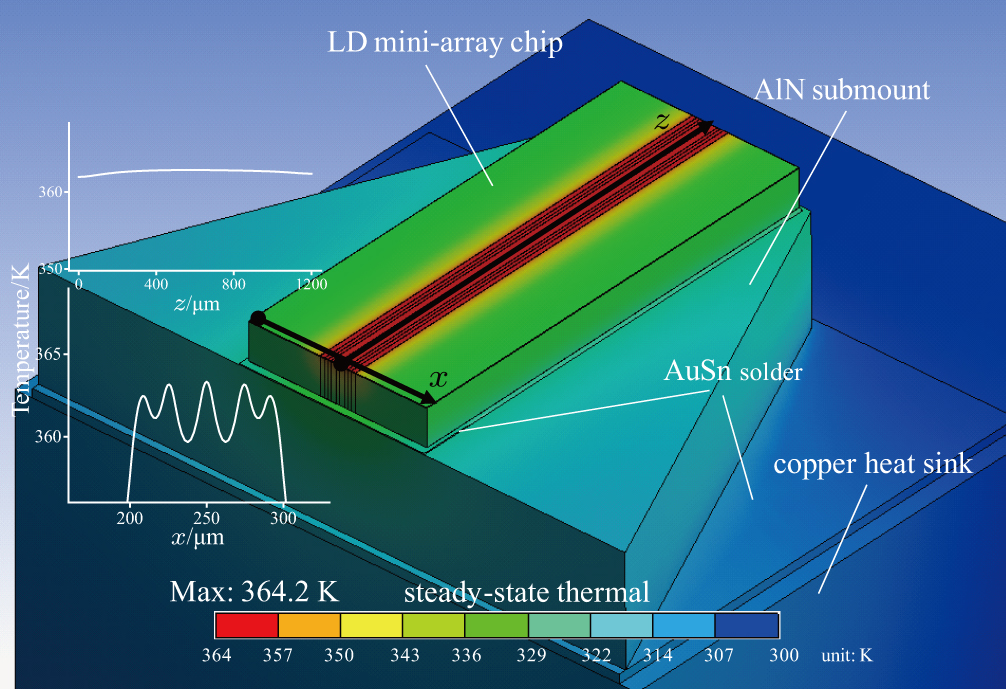

By using the parameters mentioned above, we calculated the temperature distribution of a GaN based LD mini-array in a TO-9 package, as shown in Fig.

| Fig. 3. (color online) Temperature distributions of GaN-based LD mini-array in a TO-9 package. The inset is the extracted temperature data along the x-axis and the z-axis. |

To improve the temperature uniformity of the LD mini-array chip, the temperature distribution among the stripes and along the cavity direction is separately optimized by reasonable arrangement of the stripes and the structure of AlN submount. Details are discussed in the following sections.

Figure

| Fig. 5. (color online) Temperature distribution among the stripes (x-axis direction) with different structural parameters: (a) P1, P2, and P3, (b) P2 and P4. |

| Table 2.

Structural parameters in μm. . |

Compared with using structural parameters of P1, adopting structural parameters of P4, as shown in Fig.

As mentioned above, the temperature along the cavity direction (z-axis direction) is also nonuniform. As shown in Fig.

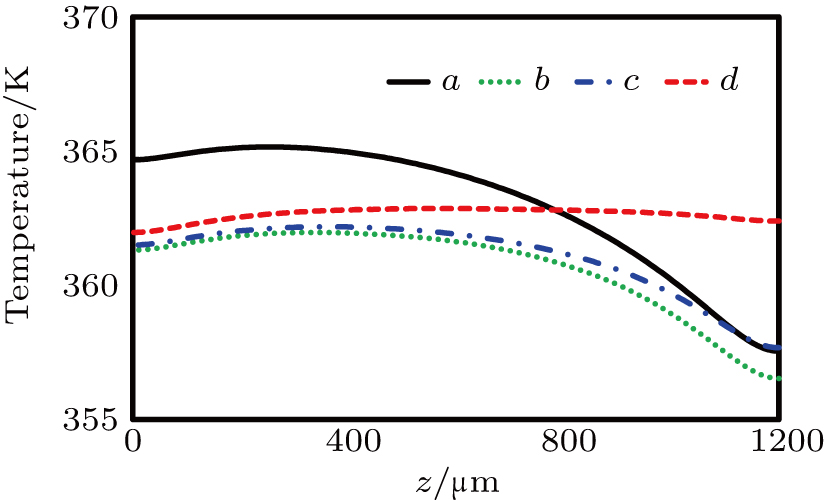

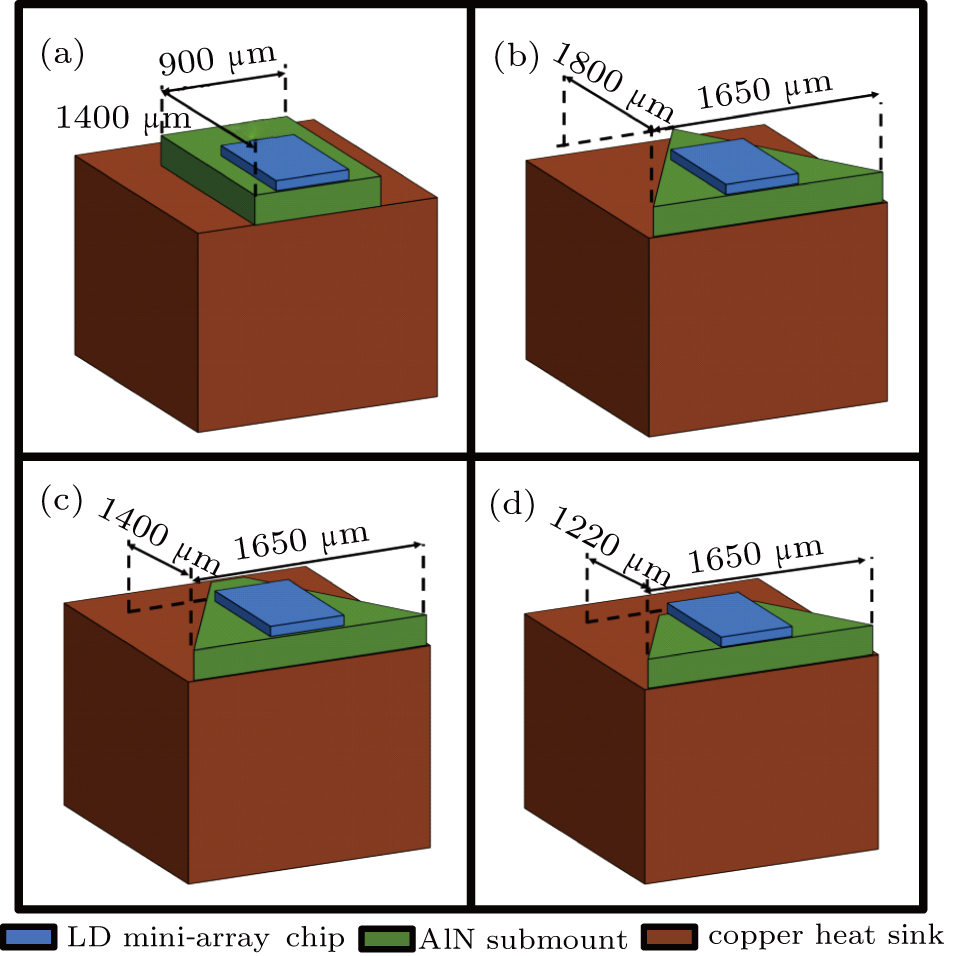

Figures

| Fig. 7. (color online) Schematic diagram of different AlN submount structures. (a) Rectangular AlN submount. (b) Triangular AlN submount. (c) and (d) Trapezoid AlN submount. |

By optimizing the structural parameters and using a trapezoid AlN submount, the temperature difference among the stripes and along the cavity direction are less than 0.4 K and 0.5 K, respectively, as shown in Fig.

We have calculated the temperature pattern of a GaN-based LD mini-array with 5 stripes in a TO-9 package and optimized the temperature distribution by reasonable arrangement of the stripes and using the trapezoid AlN submount. From the analyses it is suggested that the temperature distribution among the stripes can be adjusted by the widths of stripes and the spacing between stripes, and the temperature distribution along the cavity direction can be adjusted by optimizing the structure of AlN submount. When the input power of LD mini-array is 10 W, by using the optimal structural parameters and a trapezoid AlN submount, the temperature variation among stripes is less than 0.4 K and along the cavity direction is less than 0.5 K. Meanwhile, comparing with the conventional structure, the highest temperature decreases from 366.7 K to 364.2 K. Regardless of the variation of the input power, the temperature fluctuations among stripes and along cavity direction are always within controllable range. As a result, the lasing wavelength uniformity and the reliability of the GaN based LD mini-array can be improved.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] |