† Corresponding author. E-mail:

‡ Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 61335004 and 61505003), the National High Technology Research and Development Program of China (Grant No. 2015AA017101), and the National Key Research and Development of China (Grant No. 2016YFB0400603).

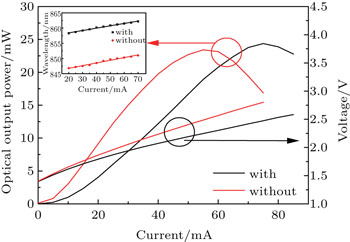

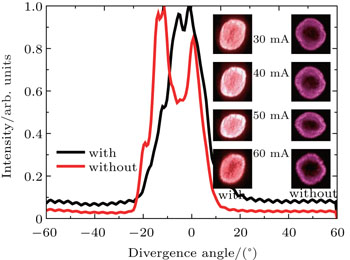

Silver nanowire (AgNW) film was proposed to apply on the surface of the vertical-cavity surface-emitting lasers (VCSELs) with large aperture in order to obtain a uniform current distribution in the active region and a better optical beam quality. Optimization of the AgNW film was carried out with the sheet resistance of 28.4 Ω/sq and the optical transmission of 94.8% at 850 nm. The performance of VCSELs with and without AgNW film was studied. When the AgNW film was applied to the surface of VCSELs, due to its better current spreading effect, the maximum output optical power increased from 23.4 mW to 24.4 mW, the lasing wavelength redshift decreased from 0.085 nm/mA to 0.077 nm/mA, the differential resistance decreased from 23.95 Ω to 21.13 Ω, and the far field pattern at 50 mA decreased from 21.6° to 19.2°. At the same time, the near field test results showed that the light in the aperture was more uniform, and the far field exhibited a better single peak characteristic. Various results showed that VCSELs with AgNW on the surface showed better beam quality.

By virtue of the structural characteristics, vertical-cavity surface-emitting lasers (VCSELs) have the advantages of high efficiency, low divergence angle, easy to fabricate into two-dimensional arrays, etc.[1–3] Recently, VCSELs with apertures larger than 100 μm have found new applications as a pumping source due to their high output optical power. However, it is difficult to obtain a better optical beam quality due to the non-uniform current distribution in the active region, which then causes a non-uniform gain and the filament phenomenon in the far field pattern of the lasers.[4] The crowding of carriers at the aperture’s edge will also cause Joule heating and then bent-down of the optical output power. Hence, improving the current distribution uniformity in the active region is important for obtaining higher output power and better optical beam quality from VCSELs with large aperture.

Increasing the doping concentration of the p-type distributed Bragg reflectors (DBR) could improve the carrier’s lateral spreading, while this would increase the light absorption loss. At present, different kinds of electrode structures have been used to improve the current spreading in the active region. For example, the radiation bridge electrode has been used instead of the traditional ring electrode.[5] Optimizing the size and the shape of the bottom electrode and the distance between the top and the bottom electrodes could also reduce the current density at the boundary of the active region.[6] ITO, which was widely used in the LED field, was applied in GaN VCSELs due to the relatively low doping concentration of the p-type GaN, which could effectively increase the carrier distribution uniformity.[7] However, indium is a precious resource. Many nanometer materials have been proposed to replace ITO.[8–10]

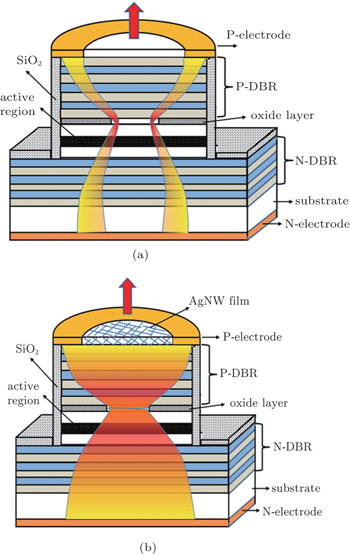

In this paper, a silver nanowire (AgNW) film with the sheet resistance of 28.4 Ω/sq and the optical transmission of 94.8% at 850 nm was proposed to apply on the VCSELs’ surface to improve the uniformity of the carriers in the active region, as shown in Fig.

The VCSELs’ structure was grown on an n-type GaAs substrate by the metal organic vapor phase deposition. The bottom n-type DBR contained 34.5 pairs Si-doped Al0.9Ga0.1As/Al0.12Ga0.88As for high optical reflectivity. The selection of 12% Al component was due to the lasing wavelength being designed to be 850 nm. Then, the undoped active region contained three GaAs/AlGaAs quantum wells centered at the anti-node of the optical standing wave within the one-wavelength cavity, with a photoluminescence peak at 835 nm. The top p-type DBR, above the active region, consisted of 20.5 pairs C-doped Al0.12Ga0.88As/Al0.9Ga0.1As. The graded interfaces, whose thickness was 20 nm, were used both on the top and the bottom DBR layers to reduce the differential resistance and maintain the low free carrier’s absorption loss. A single Al0.98Ga0.02As oxidization layer in the p-type mirror adjacent to the active region was employed to form the oxide aperture for voltaic and optical confinement. A highly doped 25 nm GaAs ohmic contact layer was grown on the top.

The Al0.98Ga0.02As layer was exposed by a wet etching process. The wet nitrogen oxidation process was then carried out in a furnace with a temperature of 400 °C, the N2 flow of 1 L/min, and a water temperature of 90 °C to obtain a low refractive index oxide layer for the carriers and light confinement. Figure

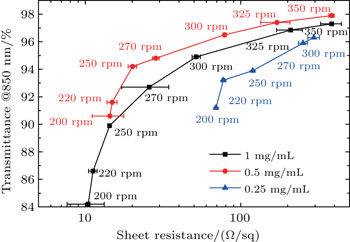

The Ag nanowires were prepared following the reported procedure.[11] In brief, 0.5 g glucose and 0.1 g polyvinyl pyrrolidone (PVP) were dissolved in 35 ml deionized water to form a solution. Then, 0.5 ml freshly prepared 0.1 M aqueous AgNO3 solution was added under vigorous stirring. The mixture was transferred into a 40 ml Teflon-sealed autoclave and heated at 140 °C for 10 h. After the reaction, the autoclave was allowed to cool in air and the product was purified by 3–5 centrifugation/rinsing/redispersion circles. Then, the AgNW re-dispersed in isopropyl alcohol due to better dispersibility for different concentrations. Figure

Figure

The near field patterns of the VCSELs with and without AgNW film under the injection current of 30–60 mA are demonstrated in the inset of Fig.

VCSELs with and without AgNW film on the top surface were fabricated with a sheet resistance of 28.4 Ω/sq and an optical transmission of 94.8% at 850 nm. Due to the relief of the carrier crowding effect, the maximum output power increased from 23.4 mW to 24.4 mW and the wavelength redshift decreased from 0.085 nm/mA to 0.077 nm/mA. Uniform near field images were obtained under current injection from 30 mA to 70 mA. Correspondingly, the far field pattern at 50 mA decreased from 21.6° to 19.2°. The various results showed that VCSELs with AgNW on the surface showed better beam quality.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 |