† Corresponding author. E-mail:

Project supported by the National Key Research and Development Program of China (Grant No. 2017YFB0404800).

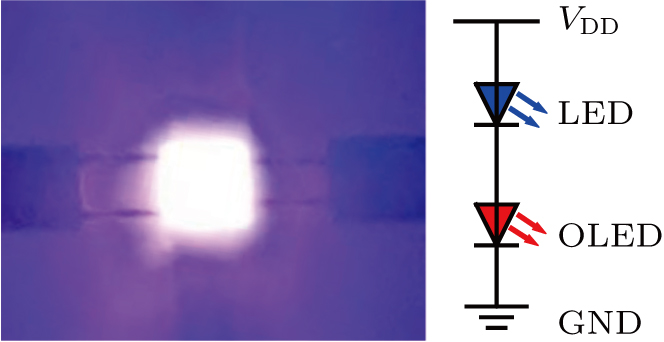

We present a novel stackable luminescent device integrating a blue light emitting diode (LED) with a red organic LED (OLED) in series. The anode of the OLED is connected with the cathode of the LED through a via in the insulation layer on the LED. The LED–OLED hybrid device is electroluminescent and two electroluminescence (EL) peaks (the blue peak around 454 nm and the red peak around 610 nm) are observed clearly. The effect of the indium tin oxide (ITO) layer on the device performance is analyzed. Compared with the individual LED and OLED, their combination shows great potential applications in the field of white lighting, plant lighting, and display.

Recently, light emitting diodes (LEDs),[1–3] organic LEDs (OLEDs),[4–10] polymer LEDs,[11–15] and other solid-state lighting devices have received increasingly attention in the field of lighting. Meanwhile, the blue LEDs + yellow phosphor (YAG:Ce) has become the mainstream because of its high luminous efficiency, low energy consumption, and long lifetime. At present, the commercial white LEDs (WLEDs) based on blue LEDs and YAG:Ce have a luminous efficiency of up to 150 lm/W. However, due to the absence of red light in the spectrum, the low color rendering index (CRI) (Ra < 80) and high correlated color temperature (CCT > 4500 K) are hardly remedied for the commercial WLEDs.[16–19] Accordingly, the WLEDs combining red, green, and blue (RGB) LEDs were introduced to improve the CRI and reduce the CCT. Nevertheless, the combination of RGB LEDs had low efficiency, complex manufacturing process, and high cost. In the plant factory, the similar combination of blue and red LEDs was utilized to meet the blue light ranging from 400 nm to 510 nm and the red light ranging from 610 nm to 720 nm demanded for the plant growth.[20]

In the field of LED display, the Mini-LED 4 K/8 K displays with dot pitch less than 0.5 mm will be widely used in the conferences and command centers while the Micro-LED displays with dot pitch less than 50 μm have received widespread attention due to the applications in augmented reality (AR) and virtual reality (VR). Because it is impossible to grow GaN materials for green and blue LEDs and GaAs materials for red LEDs on the same wafer, the full-color LED displays are manufactured by arranging the blue, green, and red discrete LEDs on the printed circuit board (PCB) by the chip on board (COB) process.[21] However, this scheme severely restricts the further reduction of the pixel pitch and affects the enhancement in resolution. In addition, the micro flip-chip red LEDs have a complicated manufacturing process, low yield, and high cost due to the removal of the conductive and opaque GaAs substrate. It is also a challenge for micro red LEDs based on GaAs to reach a higher external quantum efficiency (EQE).

In order to solve the application problems of LEDs mentioned above, we try to introduce the OLEDs into the field of LED lighting and display. On the one hand, it can be more easily realized for lighting with high CRI to stack the red OLED on the green and blue LEDs. On the other hand, the display with ultra-small pixel pitch can be accomplished by arraying the green and blue LEDs and red OLEDs. The EQE of the red phosphorescent OLEDs can achieve 35.6%,[22] which makes it possible to combine blue and green LEDs with red OLEDs.

In this paper, we explore the process compatibility between LEDs and OLEDs and prepare a stackable luminescent device combining a blue LED with a red OLED. The photoelectric parameters are measured and analyzed. The approach to combining LEDs with OLEDs is extremely novel and this work lays a foundation for the subsequent research on white lighting devices and full-color displays that combine LED and OLED.

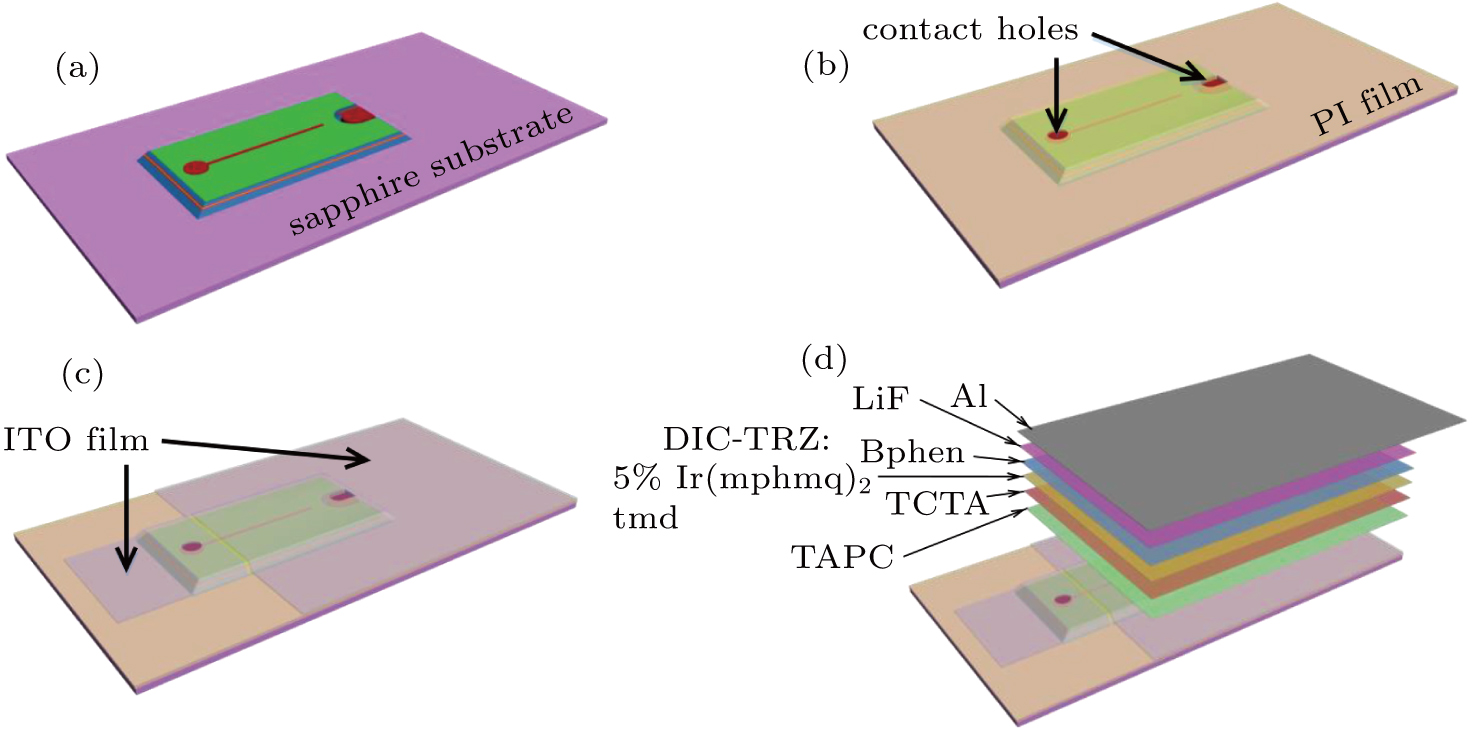

The stackable luminescent device was obtained through the fabrication of InGaN/GaN-based blue LEDs and the process of conventional red OLEDs. Firstly, the epitaxial structure of blue LEDs was grown on a 2″ c-plane patterned sapphire substrate (PSS) by the metal–organic chemical vapor deposition (MOCVD), which was composed of a 4.0-μm-thick undoped GaN buffer layer, a 2.0-μm-thick Si-doped n-GaN layer, 9 pairs of InGaN (2.4 nm)/GaN (14 nm) multiple quantum wells (MQWs), a 40-nm-thick p-AlGaN electron blocking layer, and a 100-nm-thick Mg-doped p-GaN layer. Then, a 280-nm-thick indium tin oxide (ITO) layer was deposited by the electron beam (EB) evaporation technique onto the wafer as the current spreading layer as well as the ohmic contact layer of p-type GaN. Next, the mesa structure was successively formed by the photolithography and inductively coupled plasma-reactive ion etching (ICP-RIE) process. Subsequently, Cr/Al/Cr/Pt/Au metal layers were deposited by electron-beam evaporation and patterned by a lift-off process. The structure of the LED device was almost formed as shown in Fig.

Figure

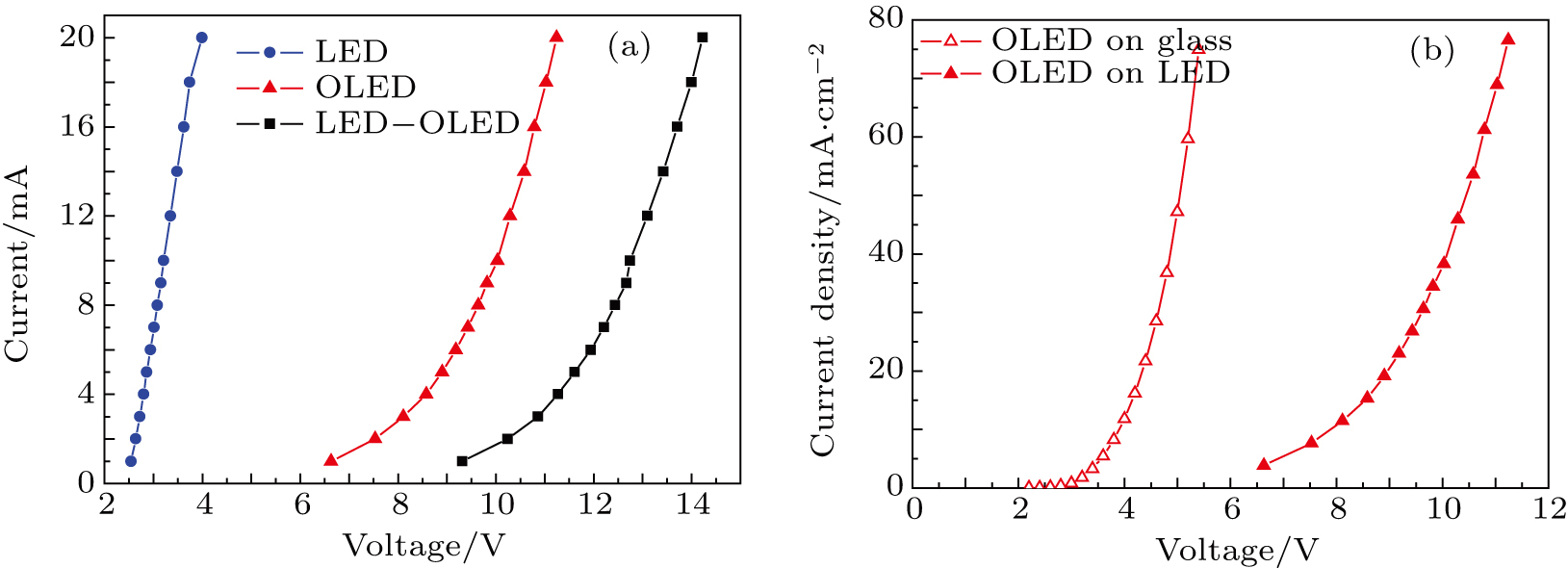

| Fig. 3. (a) The I–V characteristics of blue LED, red OLED, and LED–OLED hybrid optical device, and (b) J–V curve of OLEDs on LED and on ITO-coated glass. |

| Table 1. Square resistance (R□) of 100-nm-thick ITO before and after RTA. . |

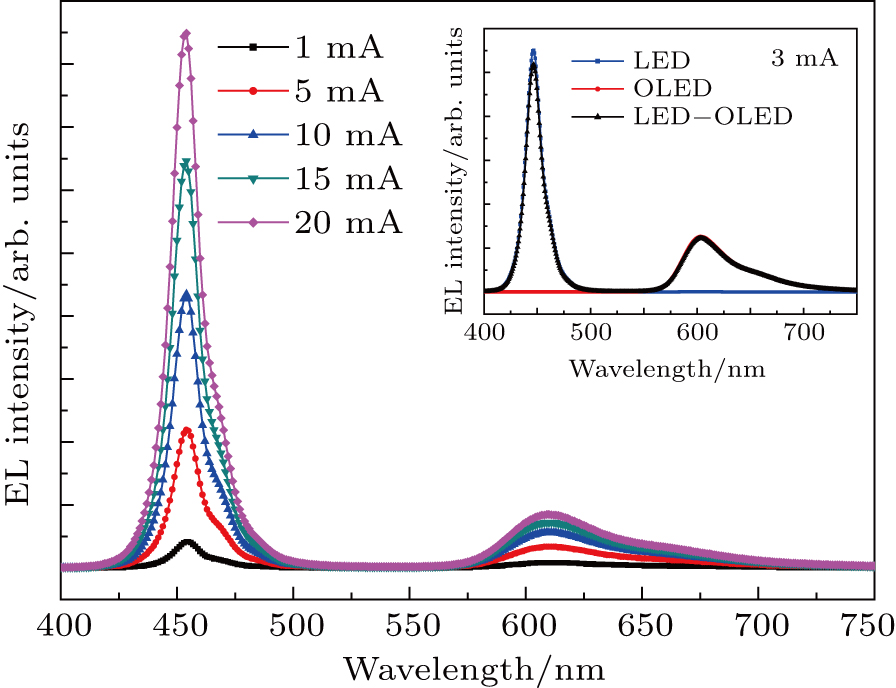

The electroluminescence (EL) spectra of the LED–OLED hybrid optical device under various current injections are shown in Fig.

| Fig. 4. EL spectra of LED–OLED hybrid optical device under various current injections with inset showing EL spectrum of blue LED, red OLED, and LED–OLED hybrid device at 3 mA. |

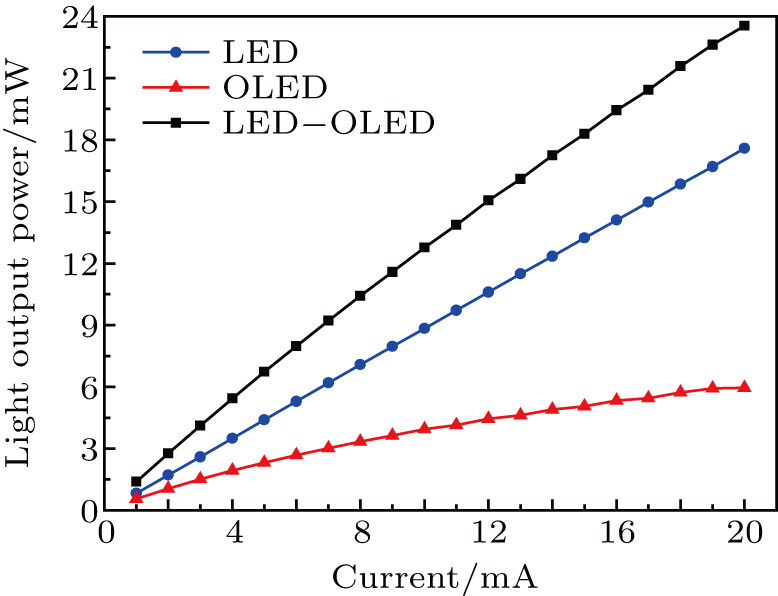

The light output power (LOP) of the LED, OLED, and the hybrid optical device under various current injections are shown in Fig.

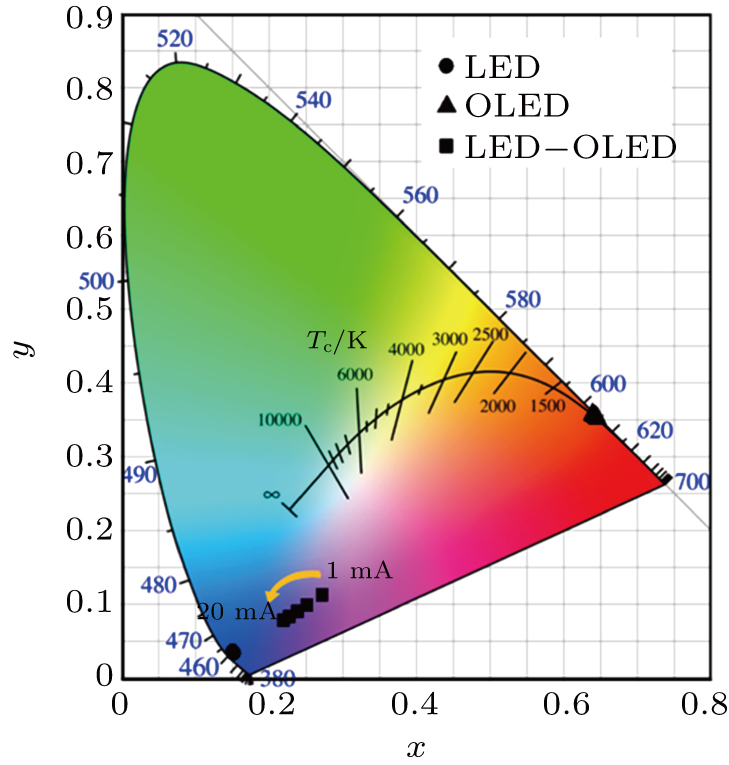

| Fig. 6. Color coordinates of LED, OLED, and LED–OLED hybrid optical devices in CIE 1931 chromaticity diagram. |

For the LED lighting, unlike the traditional scheme of blue LEDs + yellow phosphor, a novel approach is proposed to achieve EL of the blue LED and red OLED simultaneously without additional drive. However, the brightness and color of the light emitted from the LED and OLED need to be adjusted. According to the EL spectra of the hybrid device in Fig.

This study also provides a new idea for fabricating the full-color flat panel display. At the present stage of the development of LED display, the feature of high resolution is pursued, which means that the size of the subpixel is reduced. However, the external quantum efficiency of red LEDs decreases too fast as the size decreases. Besides, the flip-chip red LEDs used for transfer have a complicated manufacturing process and high cost due to the removal of the conductive and opaque GaAs substrate. For the field of OLED display, although the blue phosphorescent OLED has relatively high power efficiency, the operation lifetime is short and the color is sky-blue. By comparison, the lifetime and color of the blue triplet-triplet fluorescence (TTF) OLED are acceptable but the power efficiency is much low.[29–31] At the same time, it is worth noting that the blue LEDs and red OLEDs have excellent performances in their respective display fields. This study demonstrates the feasibility of combining blue LEDs with red OLEDs and shows the possibility to realize the full-color flat panel display.

In this work, we fabricated a stackable luminescent device integrating a blue LED with a red OLED in series. The LED–OLED hybrid device is a two-terminal EL device without additional drive. The EL spectrum indicates that the hybrid device has an excellent lights-mixing effect. However, the photoelectric performance of the red OLED needs to be further optimized. This combination of the blue LED and red OLED has the potential applications in the field of white lighting, plant lighting, and full-color flat panel display.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] |