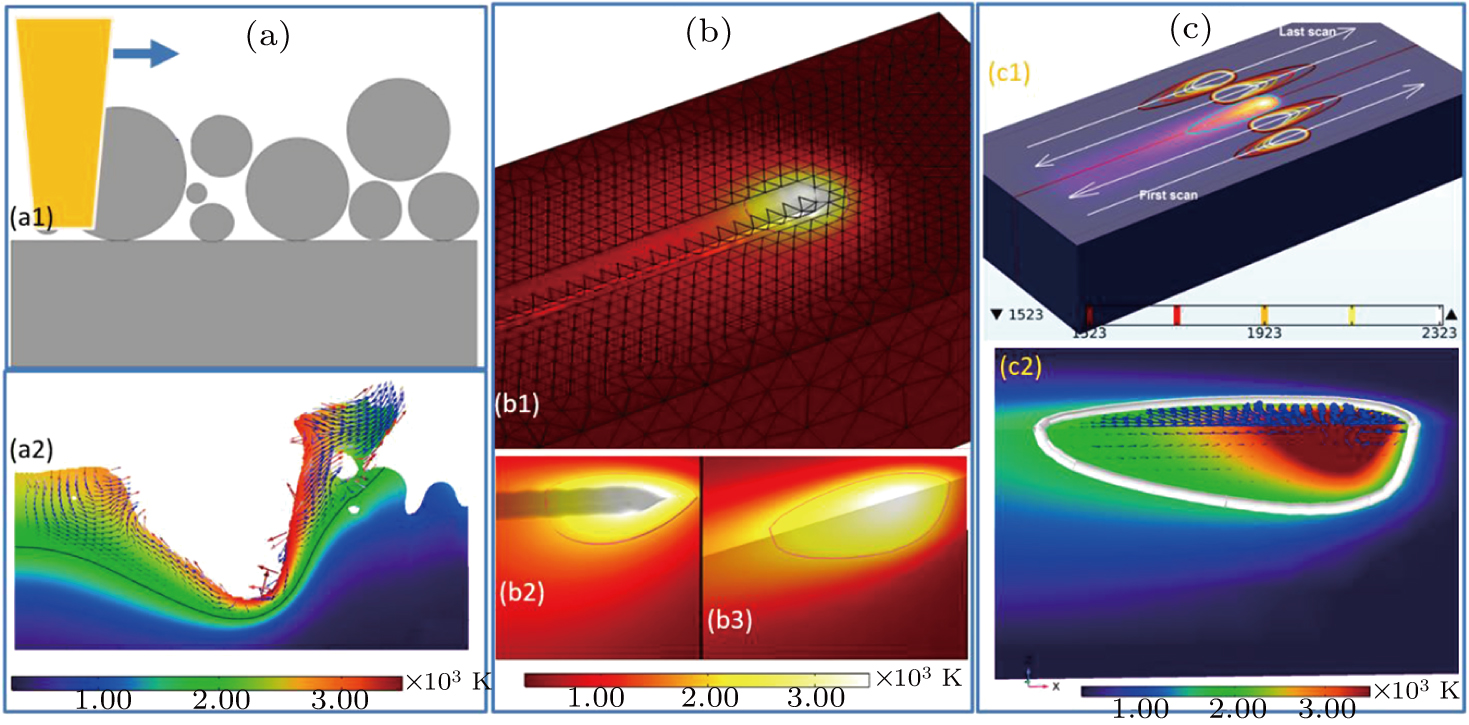

Overview of finite elements simulation of temperature profile to estimate properties of materials 3D-printed by laser powder-bed fusion

Different levels of approximation commonly used in simulation of SLM process (the case studied on 316L SS). In (a): the most ideal approximation considering the topological changes that follows the melt pool dynamics; (a1) gives the illustration and (a2) gives the simulated temperature profile and mass flow for