† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 51302055).

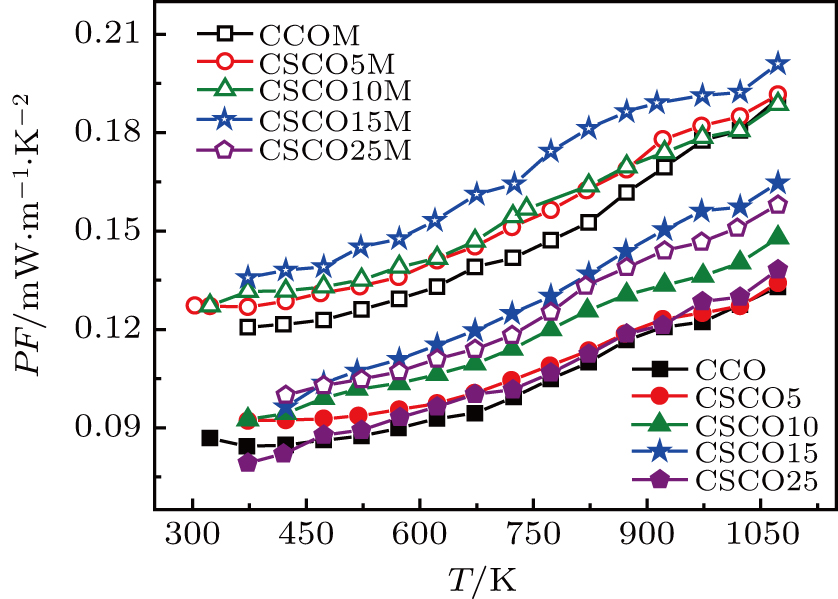

We fabricate Sm-doped Ca3Co4O9+δ (CCO) bulk materials in magnetic field during both processes of chemical synthesis and cold pressing. The structure and electrical performance of the samples are investigated. With the increasing Sm concentration, the electrical conductivity 1/ρ decreases and the Seebeck coefficient α increases. As a result, the power factor (PF = α2/ρ) is raised slightly. After applying magnetic field, the extent of texture, grain size and density of all the bulk materials are improved obviously, thereby an enhanced electrical conductivity can be gained. Additionally, the degeneracy of Co4+ state in the CoO2 layer of CCO is also increased as the magnetic field is used in the preparing process, which results in an enhanced α. The Ca2.85Sm0.15Co4O9+δ prepared in magnetic field shows the largest power factor (0.20 mW⋅m−1⋅K−2 at 1073 K).

As a functional material used for the conversion between thermal and electric energy, thermoelectric materials are investigated widely.[1–4] The electrical transport is usually evaluated by the power factor α2/ρ, where α and ρ are the Seebeck coefficient and the electrical resistivity, respectively.[5]

Ca3Co4O9+δ has attracted continuous attention because of both the coexisting high Seebeck coefficient and thermal stability.[6] The CCO is composed of two misfit-layered subsystems of CoO2 layer and Ca2CoO3 layer along the c axis.[7] Co3+ and Co4+ have three kinds of spin states, respectively, including low spin state (LS), intermediate-spin state (IS) and high spin state (HS).[8] The special structure as described above makes it possible to optimize electrical conductivity and Seebeck coefficient simultaneously.[9]

The rare earth substitutions at Ca-sites are effective in improving the Seebeck coefficient α. For instance, Nong et al. reported that the α values of CCO can be enhanced significantly by rare earth substitution at Ca-site, such as Lu, Dy and Ho.[10]

Wang et al. reported that Sm doping can effectively improve thermoelectric properties of CCO materials.[11] The substitutions of the high valence ions for calcium sites may improve α from the reduced number p of holes in p-type semiconductor. To consider the similar ionic radius and average higher valence between Sm ions and Ca ions, we choose to utilize Sm elements to substitute Ca sites.

The misfit layered structure of CCO shows highly anisotropic properties, which leads to high resistivity for randomly oriented poly-crystalline materials. To decrease resistivity, many efforts have been taken to enhancement of the textured degree. Most of them improve the textured extent of ceramic materials by spark plasma sintering or hot pressing.[12,13] Additionally, Torres and Chen et al. have gained textured CCO materials by reducing the sizes of precursor powders.[14,15] Recently, more and more attentions focus on tuning physical properties of materials by inducing magnetic field in prepared process. Due to the CCO’s magnetic anisotropy and the coexistence of different spin states, applying uniform magnetic field is more helpful to form textures. Huang et al. reported that the textured degree of CCO can be obviously improved by applying high magnetic field (4 T and 8 T) in the sample sintering process.[9] However, in such a strong magnetic field environment it is difficult to obtain CCO generally and the cost is expensive. Several reports have described that the textures may be produced and the spin can reorient by inducing weaker magnetic field during the process of chemical reaction.[16,17] For example, Du et al.[18] synthesized Fe3O4 nanoparticles with orderly arrangement under 0.4 T magnetic field. In addition, the defect splitting and electron pumping towards higher energy level can happen as magnetic field reach 0.1 T in CCO materials.[19]

Therefore, we prepared the precursor powders of Ca3–xSmxCo4O9+δ firstly by sol-gel method under 0.5 T uniform magnetic field. Secondly, the CCO powders were cold pressed to pellets in 0.3 T uniform magnetic field. Finally, the above pellets were further hot-pressed and sintered. The effects of Sm doping and magnetic field utilizing on the structure and electric properties of CCO ceramics are studied in detail.

To synthesize Ca3–xSmxCo4O9+δ powders, we used distilled water to dissolve nitrates of Ca, Sm and Co. Drop 1 mol/l citric acid into the above nitrate solution slowly until the pH value equals 2. In 0.5 T magnetic field, the above mixed liquid was stirred at 353 K until forming colloid, and then the colloid was dried. To decompose the organic molecules and nitrates, the dry gel was burned by self-propagating method. The precursor was annealed for 6 h at 1073 K to form CCO powders. The grinding CCO powders were cold pressed firstly in magnetic field (0.3 T). The dense CCO bulks were prepared by further hot-pressing at 493 K for 1.5 h (40 MPa), and then sintering at 1123 K for 12 h. For convenience, the x = 0–0.25 Sm-doped samples are named as CCO, CSCO5, CSCO10, CSCO15 and CSCO25, and the corresponding samples prepared under magnetic field are named as CCOM, CSCO5M, CSCO10M, CSCO15M and CSCO25M, respectively.

The crystal structure of the synthesized Ca3–xSmxCo4O9+δ samples was measured (Fig.

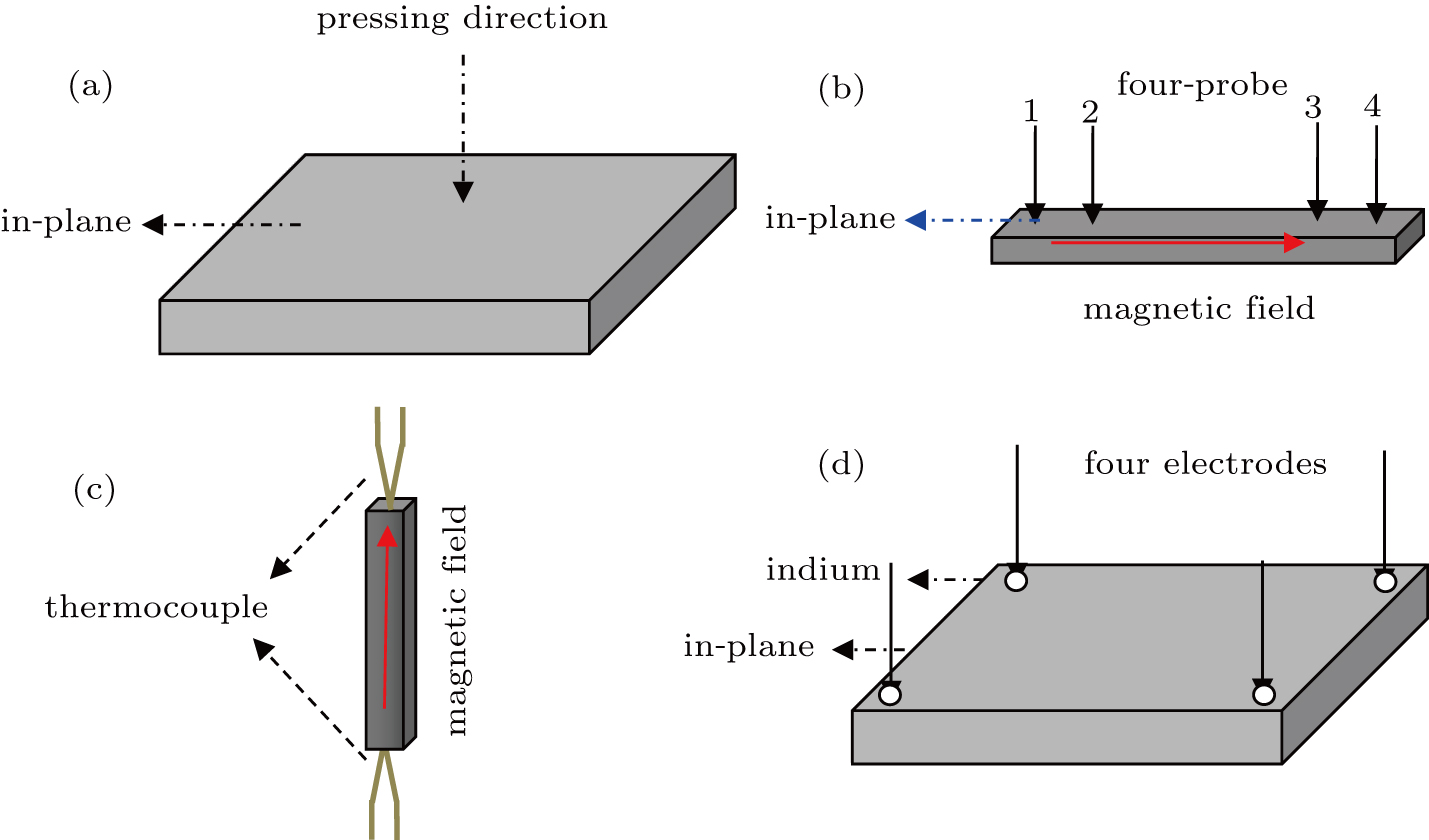

| Fig. 1. Schematic diagrams of the samples for the measurements of (a) x-ray diffraction, (b) electric resistivity, (c) Seebeck coefficient, and (d) Hall coefficient. |

The morphological characteristics were tested by a scanning electron microscope (SU-70), and the energy dispersed spectrum (EDS) was measured. We measured the density using the Archimedes principle. The samples with the size of 13 mm × 2 mm × 2 mm were used for testing resistivity, which were carried using the conventional DC four-probe method (Fig.

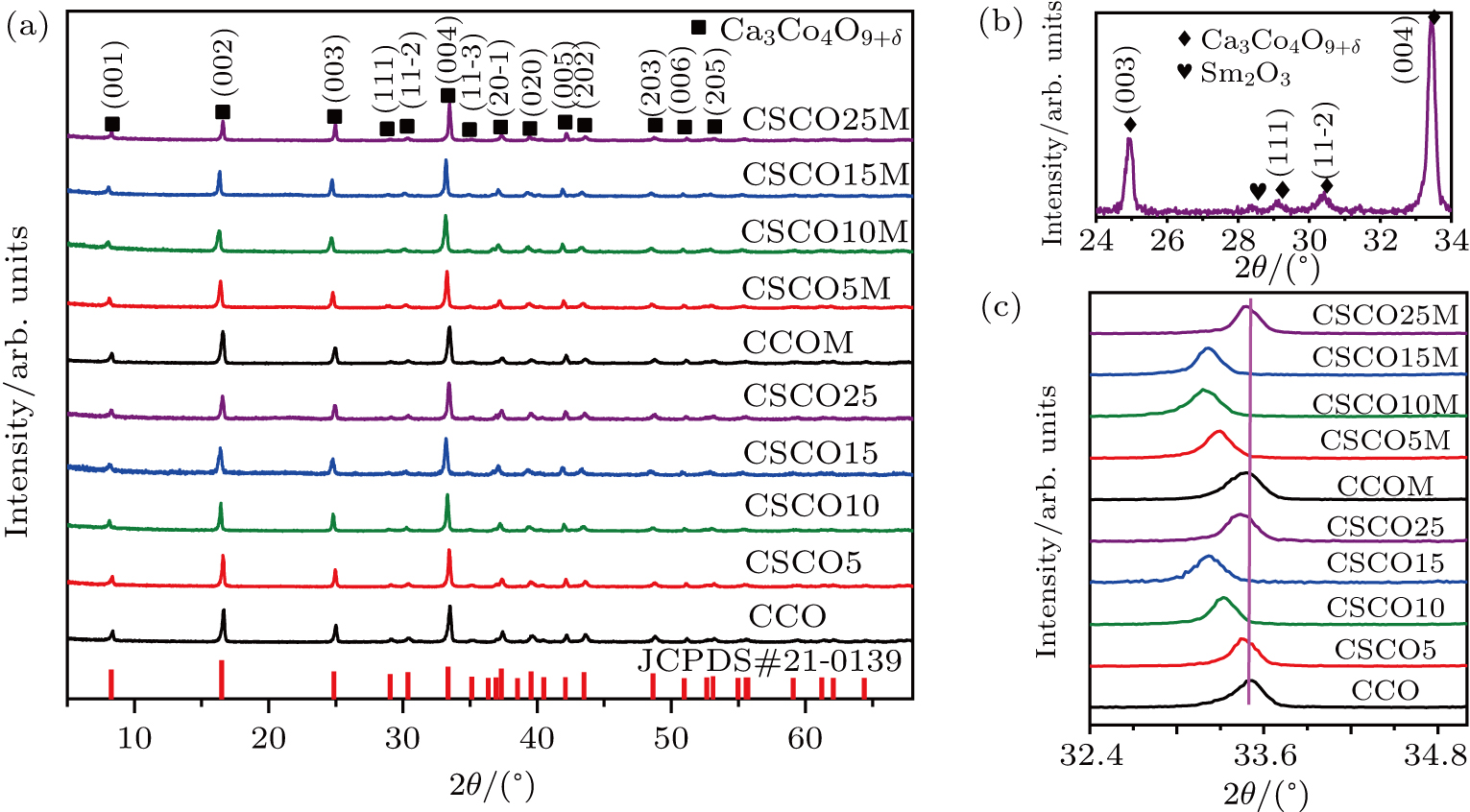

The x-ray diffraction patterns of the Sm-doped samples are presented in Fig.

| Fig. 2. (a) XRD patterns of Sm-doped bulk materials, (b) the enlarged partial diffraction peaks of the CSCO25 sample, (c) the enlarged (004) diffraction peaks of the samples studied. |

Table

| Table 1. Summaries of lattice parameters, Lotgering factor F and relative density (RD) of the Sm-doped samples. . |

Lotgering factor F was explored on that basis of x-ray diffraction data, which was summarized in Table

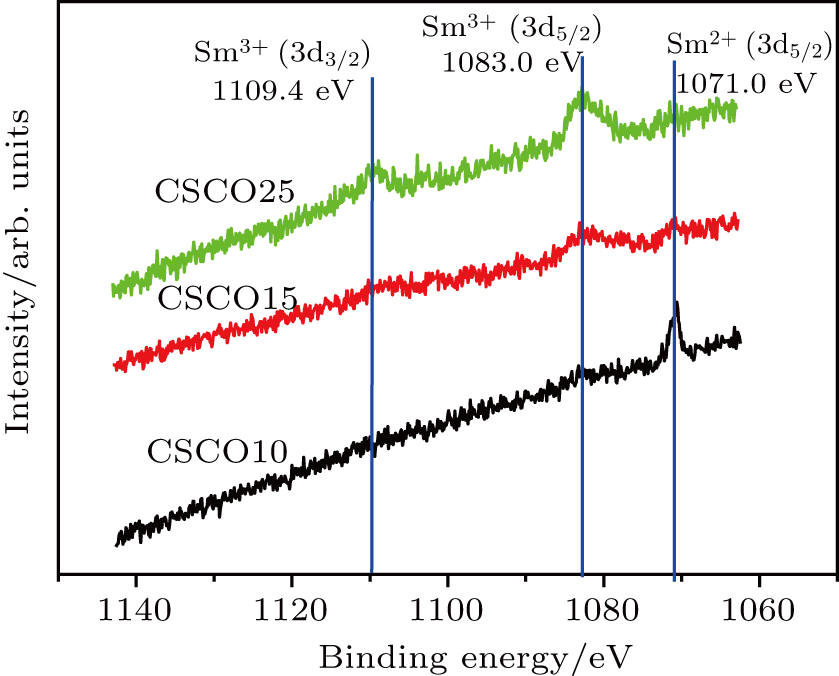

The interest to the samarium compounds gives rise due to the existence of mixed valence state of samarium ions. According to Brunckova et al.,[24] the XPS spectrum of Sm 3d consists two components related to Sm3+ (4f5) and Sm2+(4f6). To identify the valence state of samarium ions, the XPS investigation is carried out. For the x = 0.05 sample, the Sm concentration is too low to identify the diffraction peaks of Sm ions. Thus, the XPS spectra of the Ca3–xSmxCo4O9+δ (x = 0.1–0.25) samples are given in Fig.

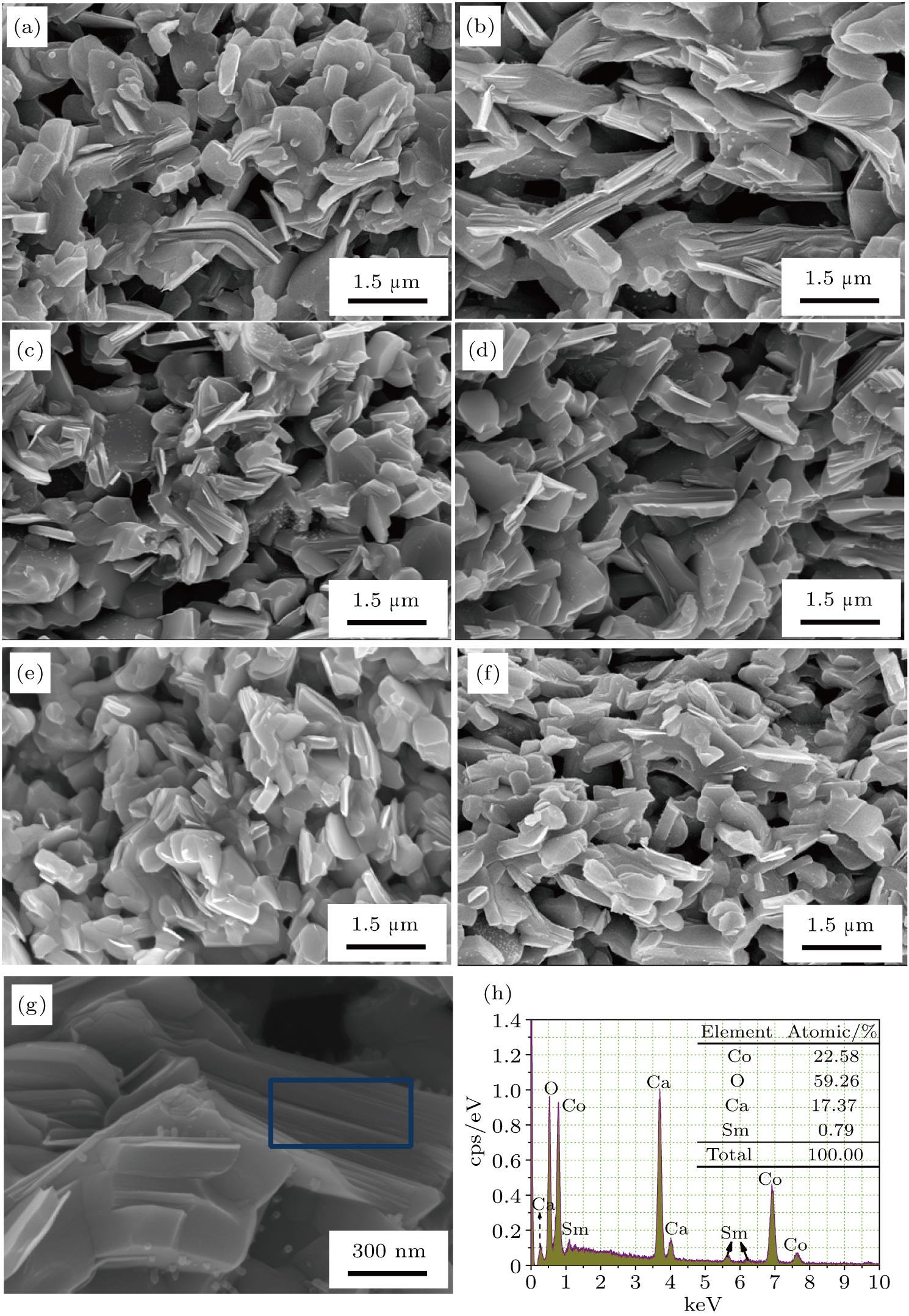

Figure

| Fig. 4. Fractured cross-sectional SEM images of bulk materials: (a) CCO, (b) CCOM, (c) CSCO5, (d) CSCO5M, (e) CSCO15, (f) CSCO15M, (g) CSCO15, and (h) EDS of CSCO15. |

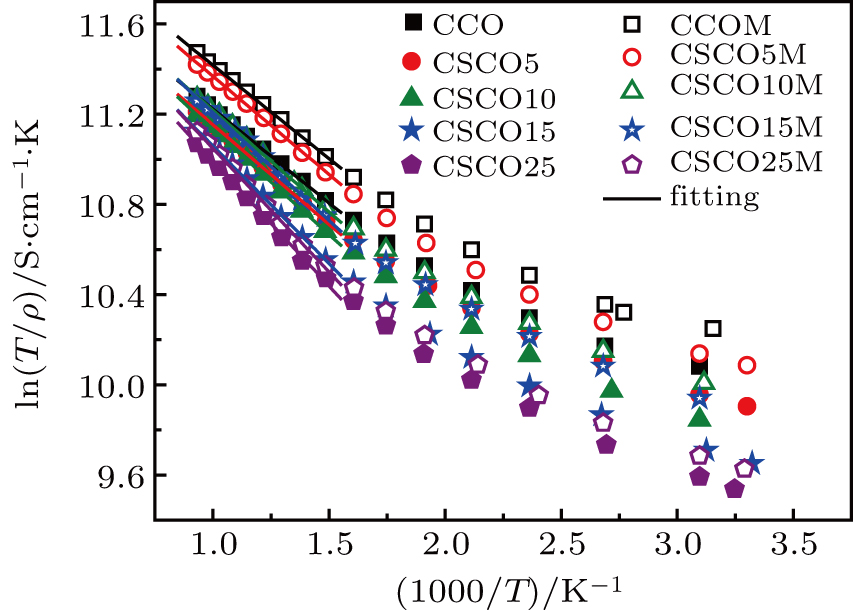

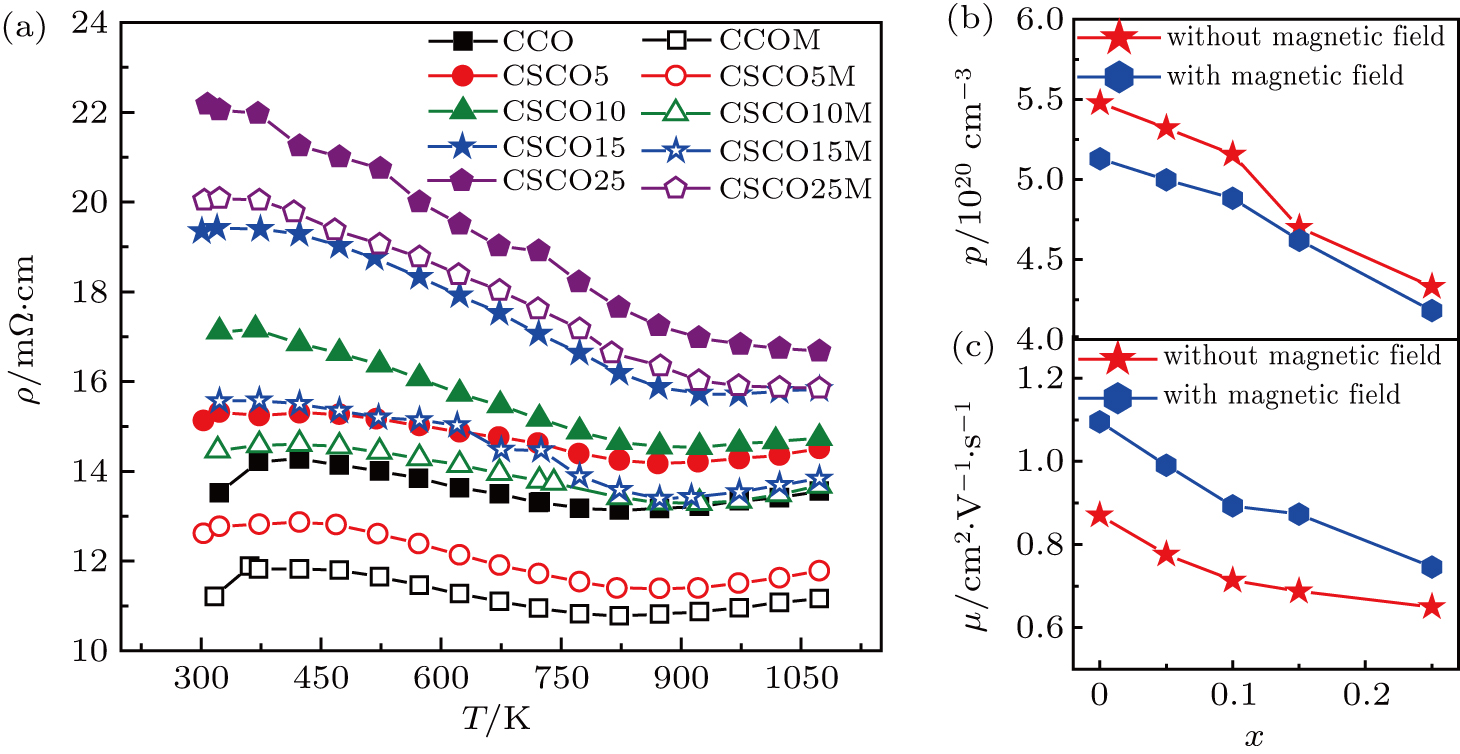

The electrical resistivity ρ of Ca3–xSmxCo4O9+δ bulk materials is plotted in Fig.

| Fig. 5. Electrical properties of Sm-doped CCO: (a) electrical resistivity ρ versus temperature T, (b) and (c) relationship of hole concentration p and mobility μ with doping amount x. |

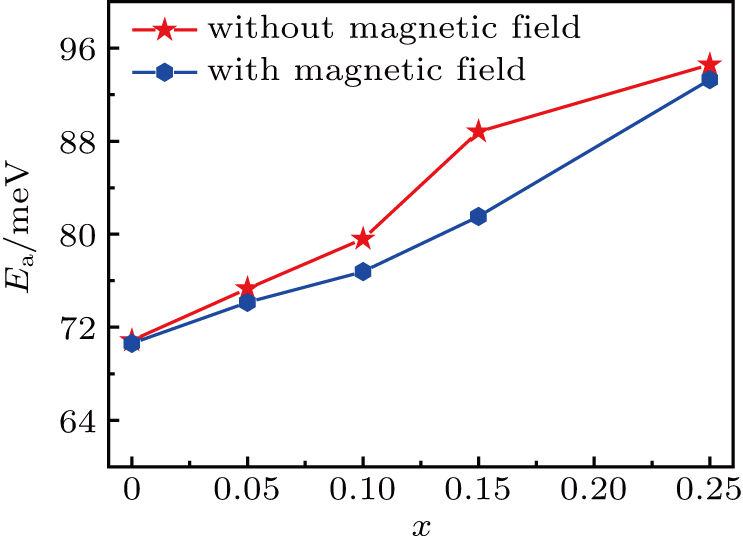

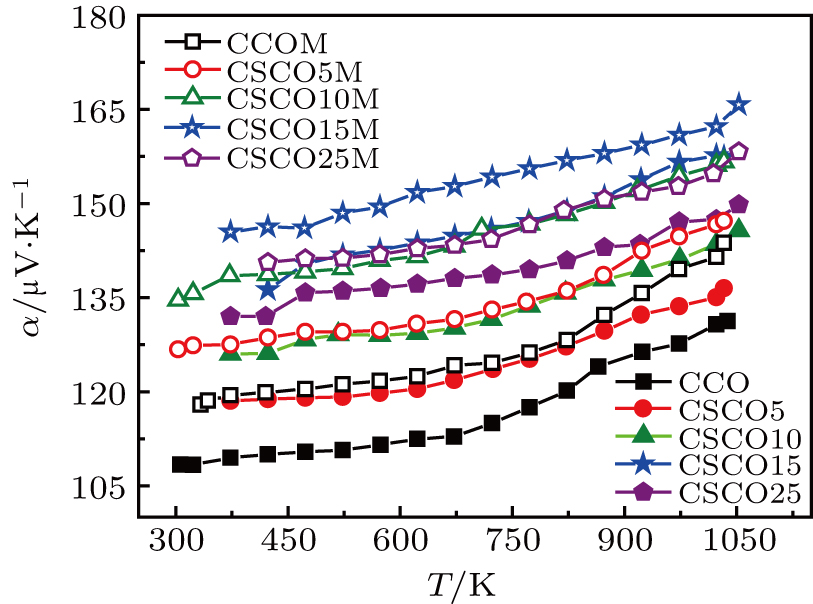

Figure

Figure

Figure

In the Ca3Co4O9+δ system, α may be expressed by the modified Heikes equation:[31]

The power factor PF for all the specimens increases with temperature because of the enhancement in both 1/ρ and α (Fig.

Ca3–xSmxCo4O9+δ bulk materials with high orientation have been obtained by the inducement of magnetic field, and the structure and electrical performance are studied in detail. The results show that samarium doping can cut down the texture and the number of the holes. Thus, the 1/ρ decreases and α increases, which results in high PF. Utilizing magnetic field to synthesize Ca3–xSmxCo4O9+δ bulk materials can improve the PF effectively. The present study describes that the electrical properties of Ca3Co4O9+δ can be enhanced by applying magnetic field and doping samarium.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] |