† Corresponding author. E-mail:

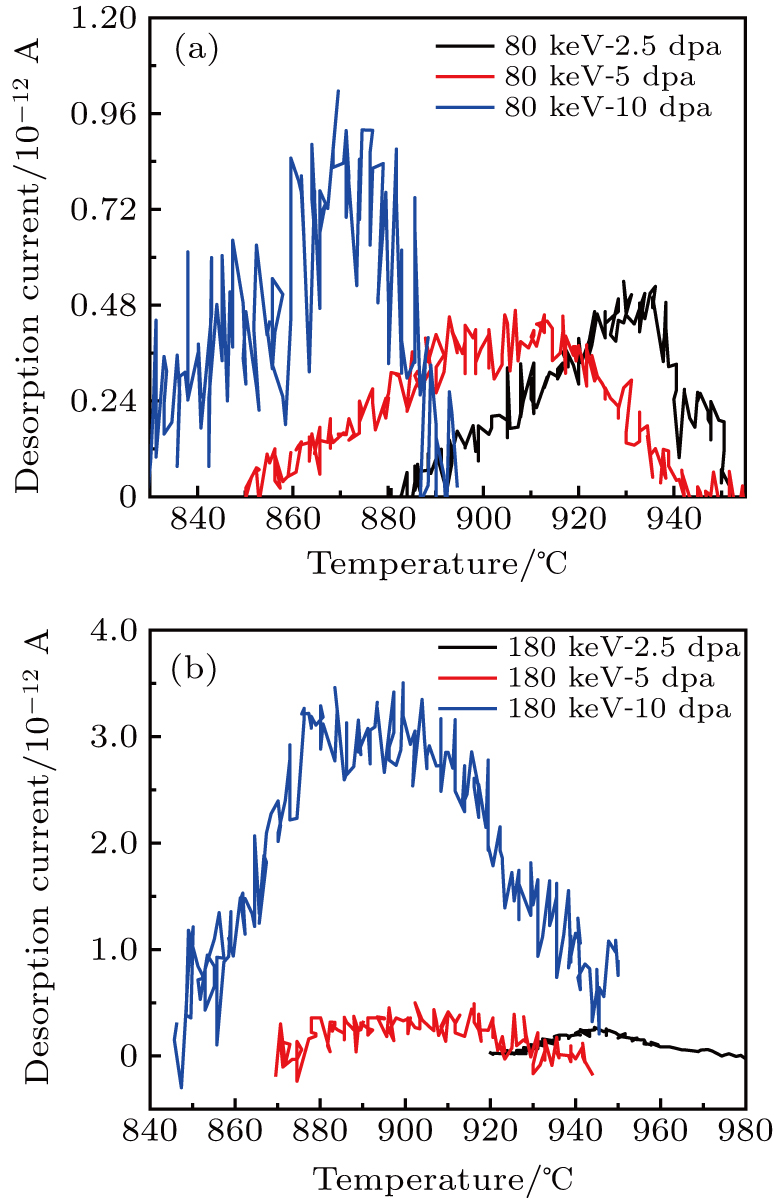

The nickel-base alloy is one of the leading candidate materials for generation IV nuclear reactor pressure vessel. To evaluate its stability of helium damage and retention, helium ions with different energy of 80 keV and 180 keV were introduced by ion implantation to a certain dose (peak displacement damage 1–10 dpa). Then thermal desorption spectroscopy (TDS) of helium atoms was performed to discuss the helium desorption characteristic and trapping sites. The desorption peaks shift to a lower temperature with increasing dpa for both 80 keV and 180 keV irradiation, reflecting the reduced diffusion activation energy and faster diffusion within the alloy. The main release peak temperature of 180 keV helium injection is relatively higher than that of 80 keV at the same influence, which is because the irradiation damage of 180 keV, helium formation and entrapment occur deeper. The broadening of the spectra corresponds to different helium trapping sites (He–vacancies, grain boundary) and desorption mechanisms (different HenVm size). The helium retention amount of 80 keV is lower than that of 180 keV, and a saturation limit associated with the irradiation of 80 keV has been reached. The relatively low helium retention proves the better resistance to helium bubbles formation and helium brittleness.

Irradiation of energetic particles produces a large number of irradiation defects,[1] such as interstitial atoms, vacancies, dislocation rings, voids, and bubbles. The interstitial atoms and vacancies further evolve and aggregate to form clusters, gap/vacancy dislocation rings, stacking fault tetrahedrons, voids,[2] etc. Furthermore, it can cause materials swelling, rapid creep, hardening, and embrittlement, which accelerates the degradation of the material macroscopic properties and seriously threatens the safe operation and service life of nuclear reactors.[3,4] Therefore, the nuclear materials are critical to the successful operation of nuclear energy systems.

Structural materials used in generation IV nuclear power plants should maintain integrity when serving in high temperature environment.[5] Also, they could undergo high neutron doses ranging from tens to hundreds of displacement per atom (dpa) according to their different positions to the reactor core. A recent review of the radiation effect on nickel-base alloys indicated that the main cause of embrittlement is the transmutation-induced helium and hydrogen.[6] However, the irradiation effects on nickel-based superalloy are little understood compared to the widely used stainless steel. Therefore, it is necessary to obtain the new experimental data of nickel-base alloys in order to predict their performance after long service in harsh environment.

When nickel is irradiated by high energy particles and neutrons, helium atoms are generated by the nuclear reaction of (

The interactions among helium atoms,

In the present studies, a nickel alloy, has been chosen to investigate the helium damage and desorption. From release peaks of TDS, the amount of helium desorption, helium trapping sites, helium retention behavior, and the dissociation characteristics are inferred.

The specimens were prepared by grinding with SiC grit paper and polishing with 0.02

The concentration reading given by the mass spectrometer could not be used directly, and a calibration using a mixture of argon and helium was carried out, where argon was the inert carrier gas used in the experiment. At any given time during the experiment, the following relationship holds:

During heating, with carrier Ar used (He supply switched off), the unknown quantity to be calculated (helium desorption) is given by the

The chemical composition of the alloy is presented in Table

| Table 1. Chemical composition of the nickel alloy (wt.%). . |

The distributions of displacement damage (dpa) and He ion concentration with depth are displayed in Figs.

Vacancies, dislocations, grain boundaries, and other defects have strong ability to bind helium atoms, which can serve as the preferred nucleation region of helium bubbles. When there are some inherent defects in the matrix, or the defects resulted from helium irradiation, the helium atoms will diffuse directly to these defects and aggregate into helium bubble nuclei. The helium bubbles are brought to the grain boundary with movable dislocations, then they move to the phase boundaries and surface.[24] The energy and movement mechanism of helium atoms in Ni-base alloy can be inferred from the release peaks. When different types of helium trapping site’s adsorption enthalpy are reached, the current appears high values and shows various peaks. The actual helium desorption current was calculated using the difference between the baseline value and the measured peak values. To extract the base line, the trendline was used by the polynomial fit, of which the order was varied between 2nd and 5th to get the best fit. The base line values were then calculated using the equation of the line. In order to get the baseline values accurate enough, the number of significant figures used was at least three more than the order of the polynomial.[25]

Figure

The data shows a trend that the peaks of the specimen with the higher dpa move to a lower temperature range. For the 80 keV helium implanted alloy, the desorption peak appears at the temperatures of ∼ 930 °C, 900 °C, and 870 °C for 2.5 dpa, 5 dpa, and 10 dpa, while it shows peak at ∼ 950 °C, 900 °C, and 880 °C for 2.5 dpa, 5 dpa, and 10 dpa of 180 keV irradiation. The shift of the main peak position reflects the change of the diffusion activation energy. In addition, it suggests there is a lower adsorption enthalpy for helium in the nickel alloy at higher irradiation damage/fluence. This could be the result of the formation of irradiation induced lattice defects and vacancy clusters, which allow for faster and lower activation energy diffusion within the alloy. Another observation is that the 80 keV peaks all occur at a lower temperature than the 180 keV ones for the equivalent dpa, showing that less energy is required for desorption, or less time for it to start occurring. For the 180 keV irradiation, the induced damage,

From the peak broadening, it is reasonable to infer that there are many different forms of activation energy, or many adsorption forms with different adsorption enthalpy. The different helium desorption peaks correspond to different helium trapping sites. The formation energy of He and vacancy is about one half of that of interstitial He atom. In the grains, the preferred occupied area of He atom is vacancy, rather than dislocations. While the most advantageous location to accommodate He atoms is the grain boundary. The desorption current in the low temperature could be attributed to the solid helium interaction of interstitials and dislocations in the grain boundary, and the desorption current in the high temperature to its release from the cavities.

The desorption temperature is higher than 900 °C (0.5Tm), corresponding to the release of the trapped helium from the cavities. The adsorption enthalpy of He atoms to different cavities is different. The thermal desorption of He corresponds to a single He atom desorbing from the bound states of vacancy groups of different sizes. With the increase of temperature, the average size of residual

The total number of helium atoms desorbed can then finally be calculated using the equation

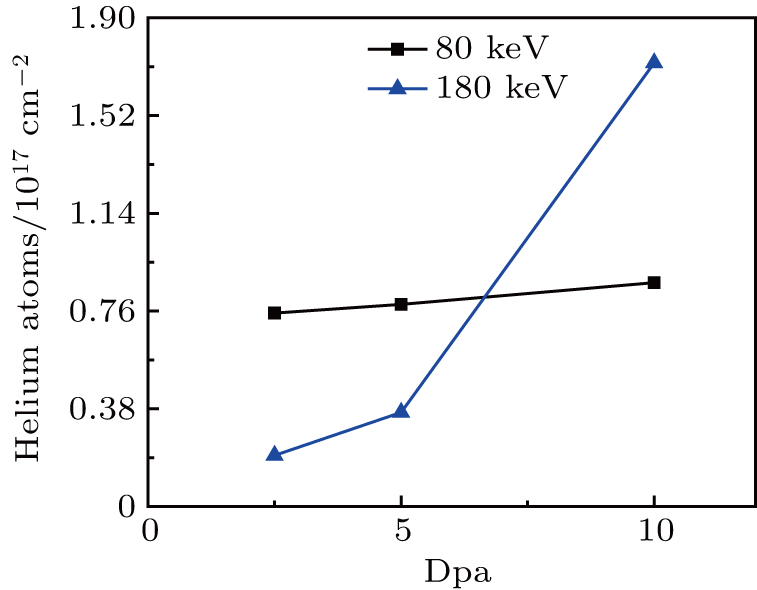

Figure

| Fig. 3. Helium desorption amount for different irradiation and fluence which showed a desorption peak. |

| Table 2. The irradiation influences, helium desorption amount, and retention percent of different irradiation specimens. . |

Based on the 180 keV specimens, it is thought that the total helium desorption increases with dpa. The greater the irradiation damage, the more helium is likely to be trapped within the specimen. This helium desorption behavior suggests that diffusion is the rate limiting step.

From the TDS release peaks, the helium dissociation characteristics, trapping sites, and helium retention of nickel alloy are discussed. The desorption peaks shifted to a lower temperature with a higher dpa, suggesting the greater irradiation damage induced lattice defects and lower activation diffusion enthalpy. The TDS peaks suggested different helium trapping mechanisms. The peak broadening of higher dpa corresponds to many different forms of activation energy, and adsorption forms with different adsorption enthalpy. With higher dpa, the temperature range of the peaks increased, because the greater irradiation damage with more complex process made helium atoms desorbed from the grain boundary and different

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] |