† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 11875295 and 11535003), Provincial Science and Technology Major Project of Anhui Province, China (Grant No. 17030801035), and Key Program of 13th Five-year Plan, CASHIPS, China (Grant No. KP-2017-25).

To obtain large-volume non-thermal arc plasma (NTAP), a multiple NTAP generator with three pairs of electrodes has been developed. The arc plasma characteristics, including dynamic process, spatial distribution, and rotation velocity in the discharge zone, were investigated by high speed photograph and image processing methods. The results showed that the dynamic behaviors and spatial distribution of the arc plasma were strongly related to the electrode configuration. A swirl flow of multi-arc plasma was formed by adjusting the electrode configuration, and a steady luminance area was clearly observed in the center of the discharge zone. Moreover, the size of the luminance area increased by decreasing the gas flow rate. The electrical connection in series could be formed between/among these arc columns with their respective driving power supplies in the multi-arc dynamic evolution process. An approximately periodical process of acceleration and deceleration of the arc rotation velocity was observed in the multi-arc generator with swirl flow configuration. In general, the mean velocity of arc rotation was higher in the multi-arc generator with swirl flow configuration when a pair of electrodes driven by a power supply were opposite to each other rather than adjacent.

Due to having the advantages of both thermal and cold plasmas, there has been an increasing interest in the warm plasma in recent years. Compared with the thermal and cold plasmas, it maintains moderate gas temperature (typically in the range of 1500–4000 K) and relative high concentration of radical species, which significantly improve the chemical reaction rate.[1,2] Therefore, the warm plasma has great application potentials in various fields, such as CH4–CO2 reforming,[3–7] combustion enhancement,[8–11] degradation of pollution,[12,13] material surface processing,[14–17] and material preparation.[18,19] The non-thermal arc discharge that produces non-thermal arc plasma (NTAP) is one of the fundamental methods for warm plasma generation, whose non-thermal characteristics are mainly realized by reducing the discharge current and/or keeping it in an unsteady-state. However, it has the disadvantages of arc plasma, such as small arc volume and arc instability.[1,19,20] Furthermore, the instability of NTAP (e.g., gliding arc plasma) is more severe compared with that of arc thermal plasma, since it periodically experiences the instability process from ignition to extinction, and its arc root has a wider range of motion.

Various types of NTAP generators have been developed to solve the whole or partial mentioned problems in recent years.[1,2,19–24] For enlarging the NTAP volume, one of the solution was to increase the sweeping area of the arc column in unit time. Many researchers, including Gangoli et al.,[1,2] Wang et al.,[19] and Zhu et al.[20] have investigated the effect of a magnetic field on arc, and a large time-average volume of NTAP was produced in a gliding arc plasma generator by applying an axial magnetic-field. Multi-arc plasma was an alternative method to enlarge the arc size by increasing the number of arcs per unit volume.[21,22] Tetsuro et al.[21] developed a multiple arc plasma generator with six knife-shaped electrodes, which was driven by a power supply with a six-phase transformer to form a six-phase 50 Hz alternating-current output. However, due to a single power supply used in the device, the multiple arcs did not exist inside the arc chamber at the same time. Another method that was used to enlarge the arc volume was glow-type discharge in NTAP by adjusting the experimental parameters, such as gas flow rate and discharge power, to meet the energetic balance between the input electrical energy and energy dissipation due to the convective cooling of the plasma column.[22–24] However, this process is difficult to control in practical industrial applications, because this type of discharge plasma is prone to change into shrinking arc under a minor disturbance.

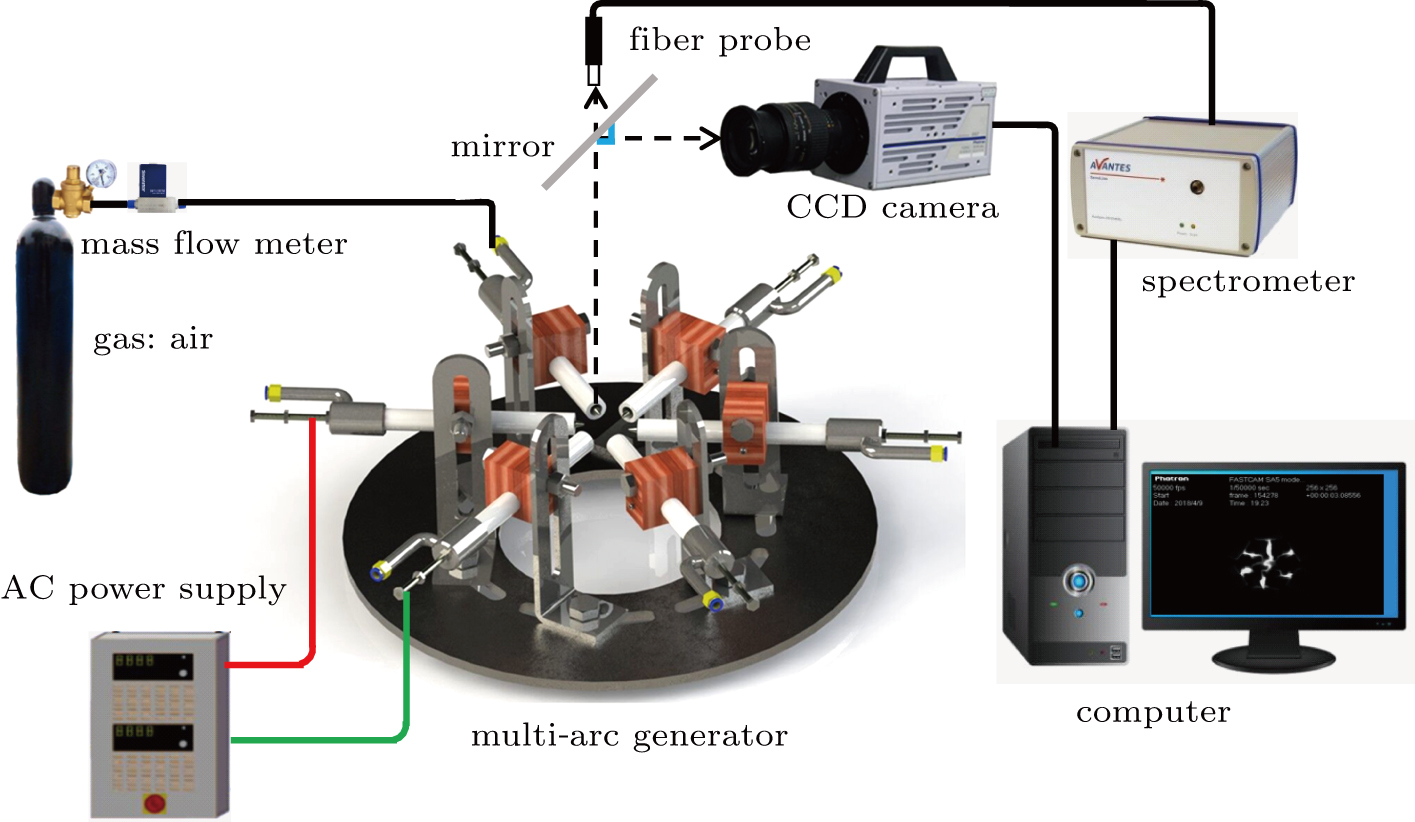

In the present work, inspired by an invention patent of Xia et al.,[25] we developed a novel non-thermal multi-arc plasma generator with three pairs of electrodes to obtain large size NTAP, which was driven by three independent high-frequency power supplies. The high-speed image technique was employed to diagnose the dynamics and spatial distribution of the multi-arc plasma. The spatial distributions of arc plasma in the multi-arc generator were investigated by means of discharge image processing, which was combined with cross-correlation analysis to calculate the arc rotation velocity.

Figure

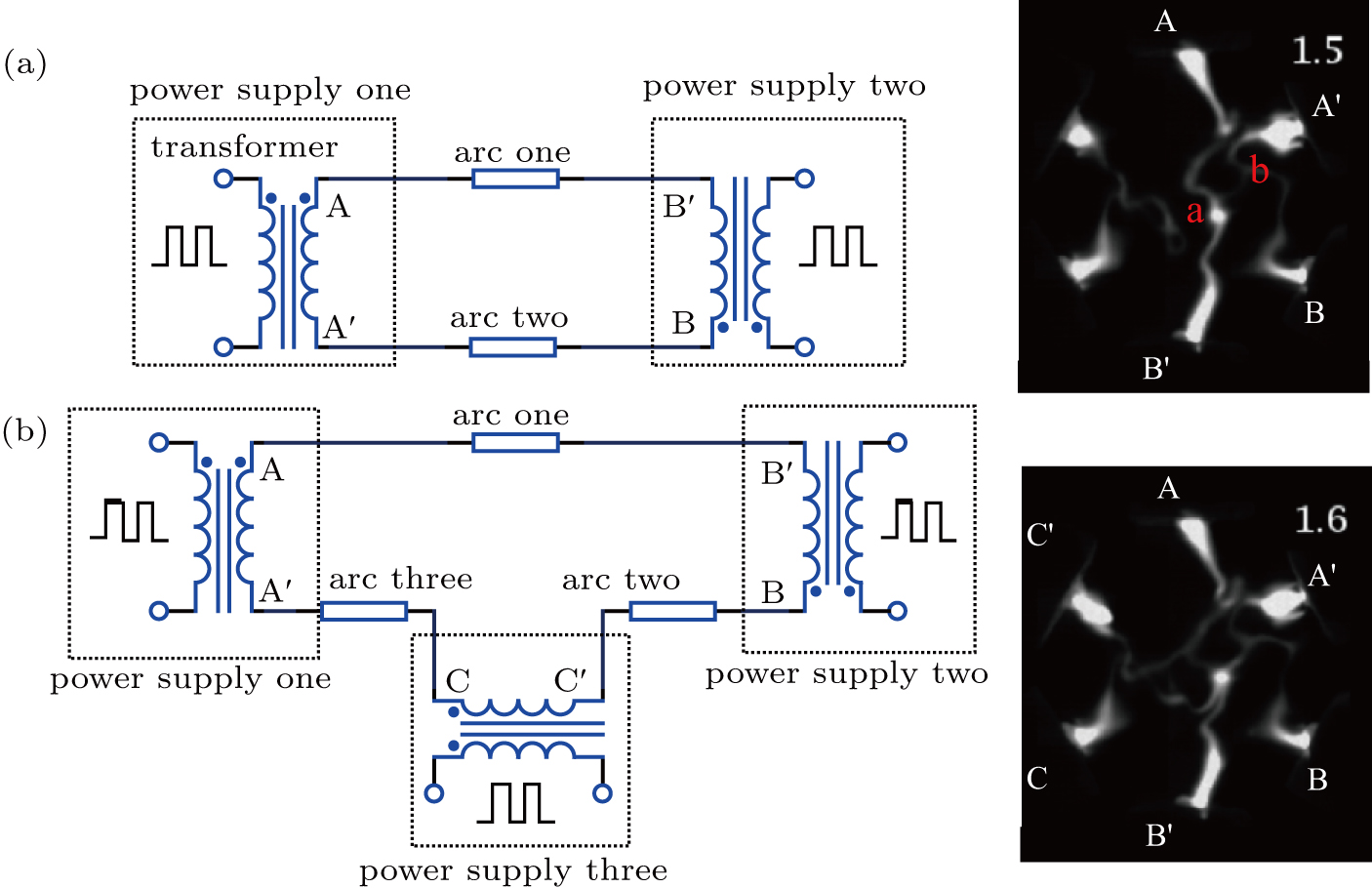

The main circuit schematic of the power supply used in the multi-arc generator is shown in Fig.

The properties of the multi-arc discharge, such as discharge area, fluctuation, and arc rotation velocity were investigated by data processing of the arc discharge image. The digital image processing technique[26,27] was used to calculate the discharge area. The image correlation analysis method was employed to determine the arc rotation velocity.

The gas temperature of the arc plasma was determined by using diatomic molecule OH (A2Σ → X2Π, 0–0) spectral line fitting method.[28,29] The emission spectrum of the multi-arc discharge plasma was obtained in the center of the discharge zone by an AvaSpec-2048 spectrometer with a resolution of 0.1 nm in the spectral range from 200 nm to 1100 nm.

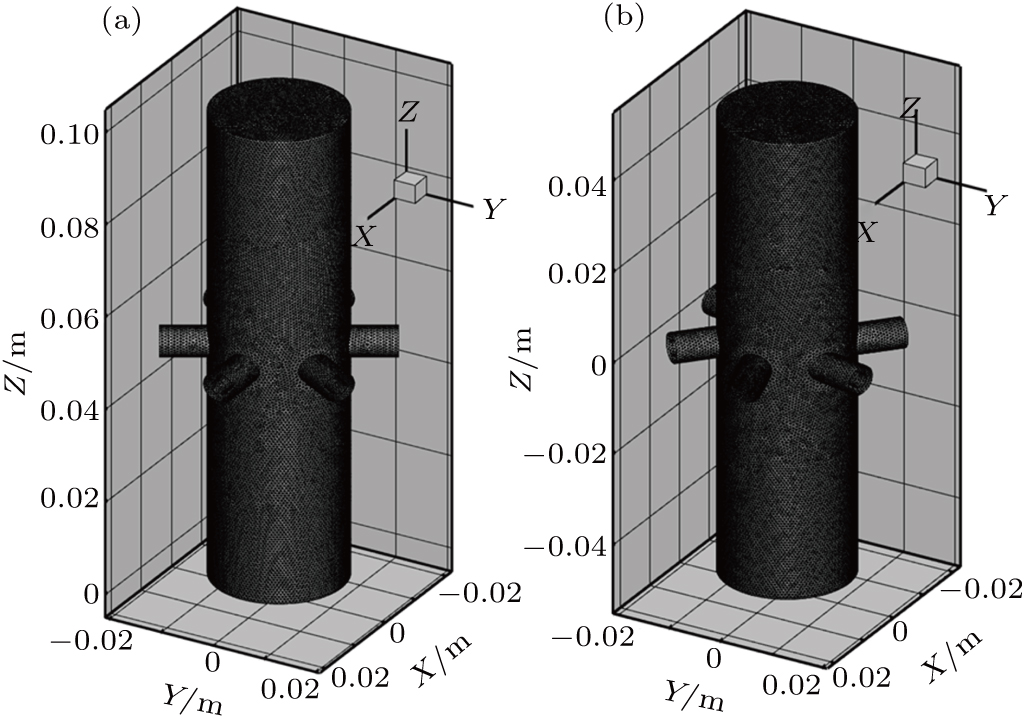

The gas flow has a great influence on the dynamic characteristics of the arc. In the experiment, due to the introduction of multiple airflows into the discharge zone, the distribution of the gas flow field was complicated. In order to evaluate the effect of the electrode configuration on the distribution of the flow field in the multi-arc generator, a series of numerical calculations using the software FLUENT were performed to obtain the specific parameters of its structure including the spacing and angle between the electrodes. Finally, two typical electrode configurations of the multi-arc generator were determined, and their geometric model and finite element mesh are shown in Fig.

| Fig. 3. Geometric model and finite element mesh of the multi-arc generator with (a) opposite-flow configuration and (b) swirl-flow configuration. |

Figure

According to the gas flow field analysis mentioned above, four typical electrode configurations for the multi-arc generator were determined by taking consideration of the connection order between the outputs of the power supply and the electrodes, which were denoted as configuration 1 (C_1), configuration 2 (C_2), configuration 3 (C_3), and configuration 4 (C_4), as shown in Fig.

Figure

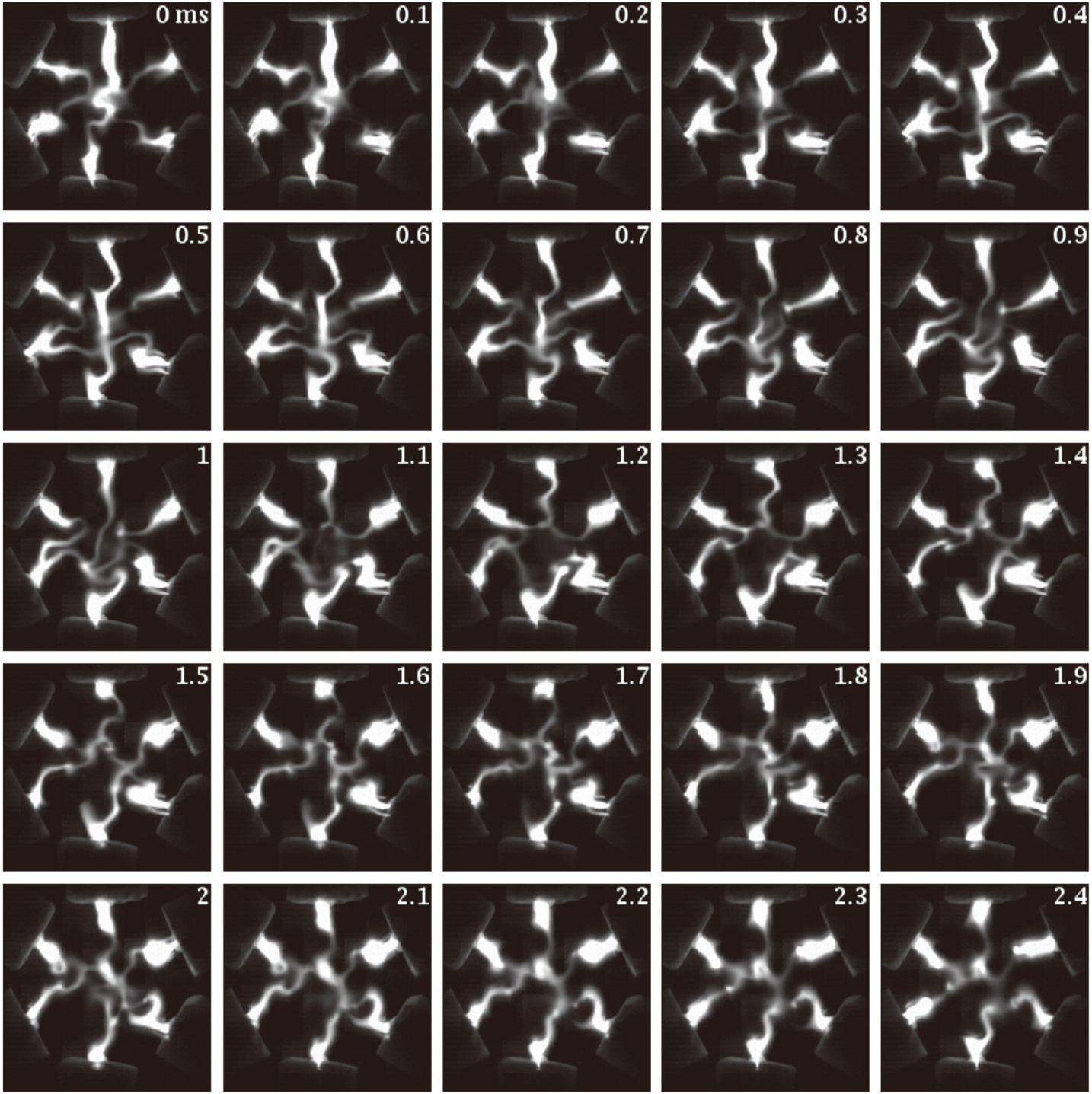

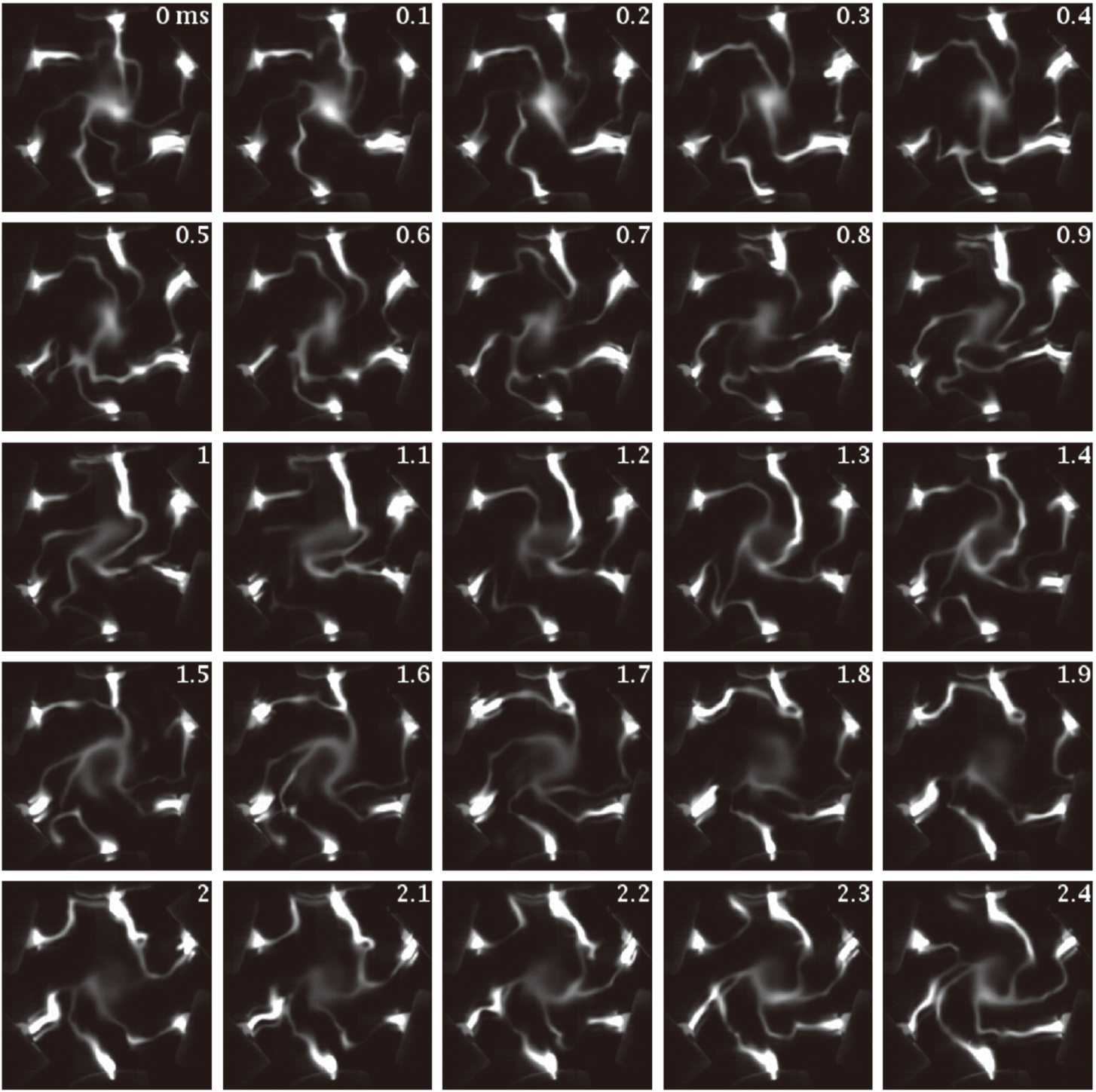

| Fig. 6. Typical successive discharge images in multi-arc generator with C_1. The numbers give the time in millisecond. |

Figure

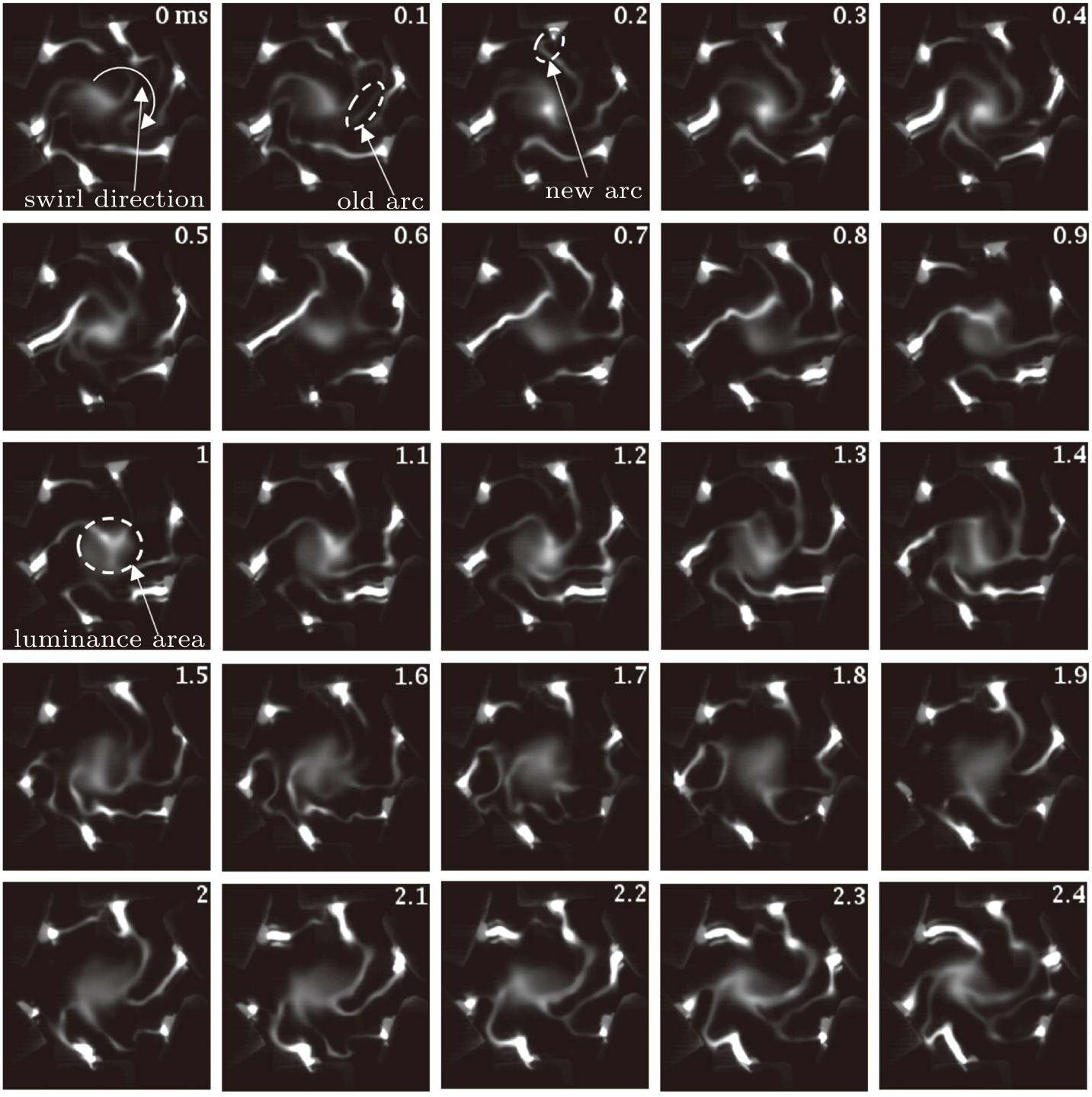

The typical discharge images in the multi-arc generator with C_3 and C_4 are shown in Figs.

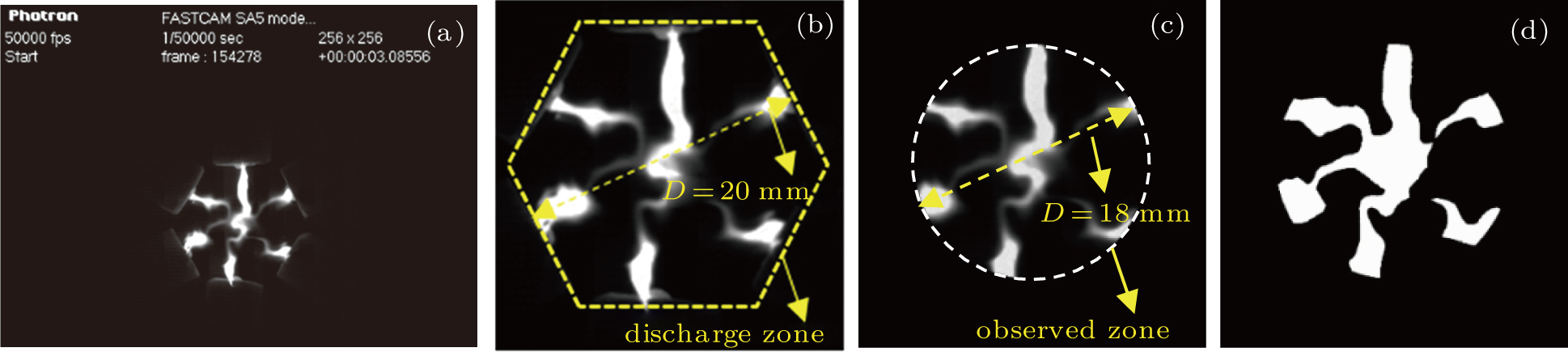

The spatial distribution of the arc is an important character for the multi-arc generator. Here, the parameter of the luminance ratio with different observing zone chosen was introduced to investigate the arc spatial distribution in the discharge zone, which is based on an assumption that the high-brightness region can be regard as arc covered or high temperature zone.[26,27] By analyzing and processing the discharge image, the parameters were obtained and the detail procedures are listed as follows:

The origin discharge image (shown in Fig. Circular observing zones with diameters of 4 mm, 10 mm, 16 mm, and 20 mm were introduced, as shown in Fig. Converting the grayscale image into a binary image in black and white by setting a luminance threshold value of 7000, as shown Fig. Calculating the luminance area according to the grayscale value of each pixel in the observing zone. The luminance area ratio was obtained by a calculation of the luminance area divided by the area of the observing zone.

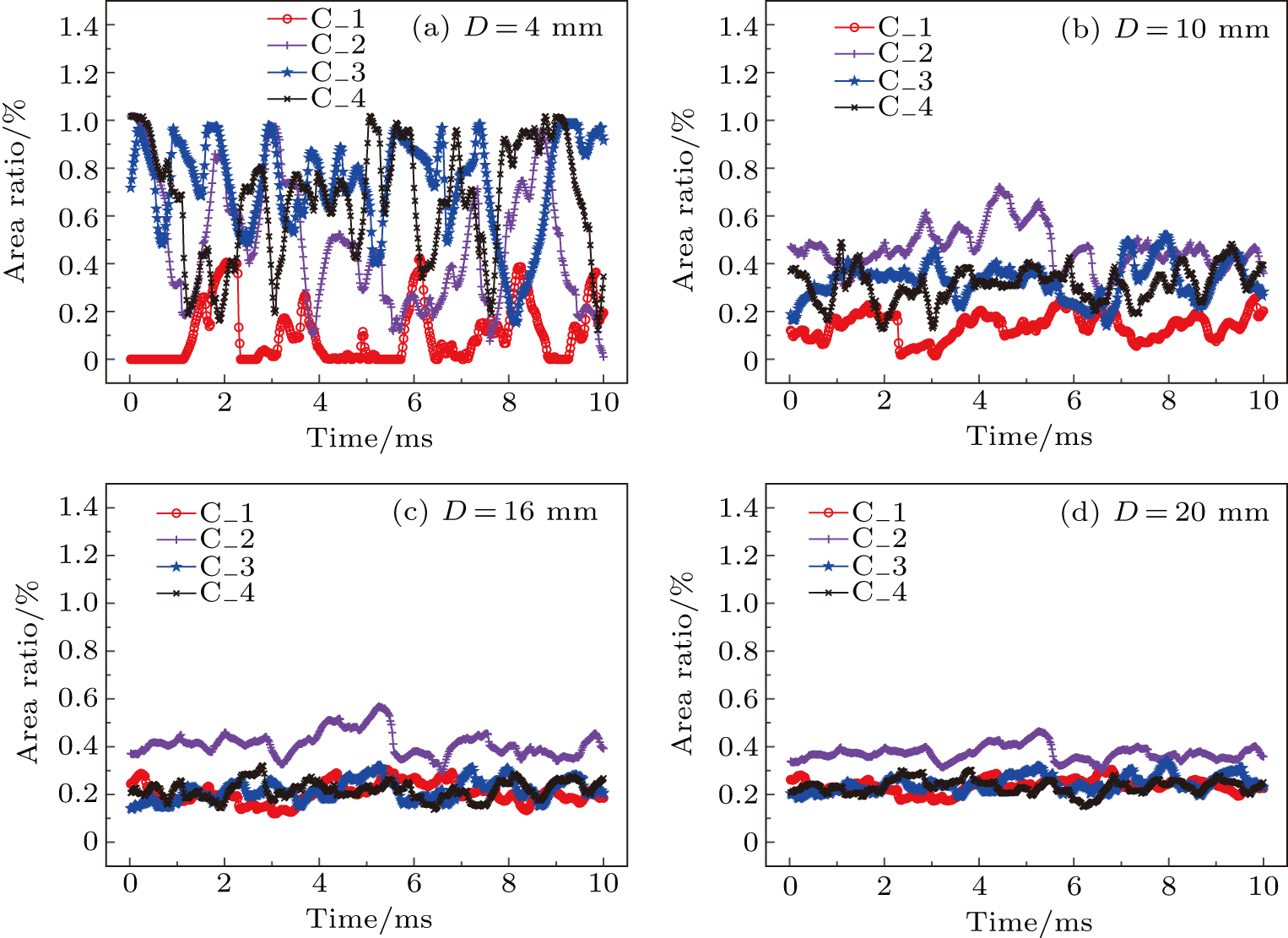

Figure

| Fig. 12. The TR-LAR of four electrode configurations in different observing zones in the multi-arc generator. (a) D = 4 mm, (b) D = 10 mm, (c) D = 16 mm, and (d) D = 20 mm under C_1, C_2, C_3, C_4. |

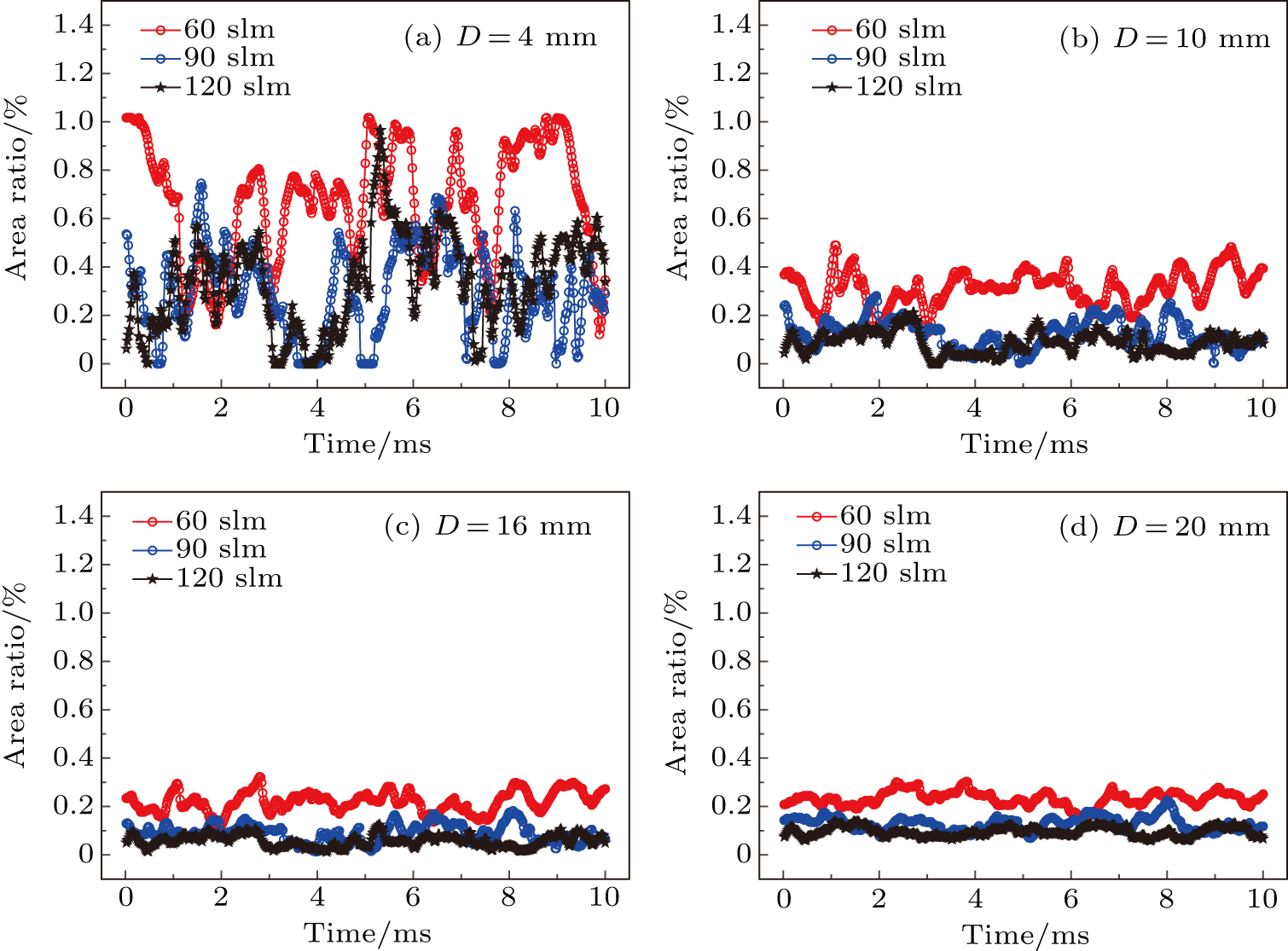

The effect of gas flow on the time-resolved luminance-area ratio in the multi-arc generator with C_4 in different observing zones is presented in Fig.

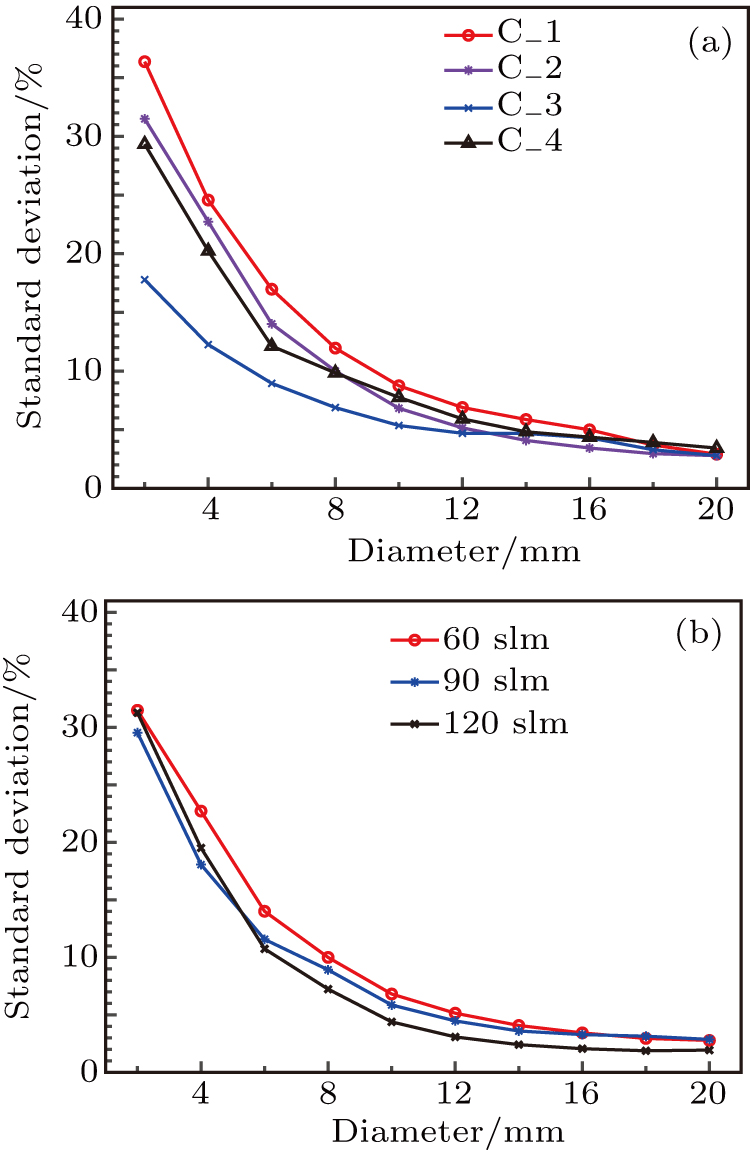

As an effective tool to reflect the dispersion degree of signal, standard deviation was utilized to evaluate the stability of arc spatial distribution in the multi-arc generator. The standard deviation of luminance area ratio (SD-LAR) can be obtained according to the following equation:[30,31]

|

The effect of electrode configurations and gas flow rate on the standard deviation of luminance area ratio is presented in Fig.

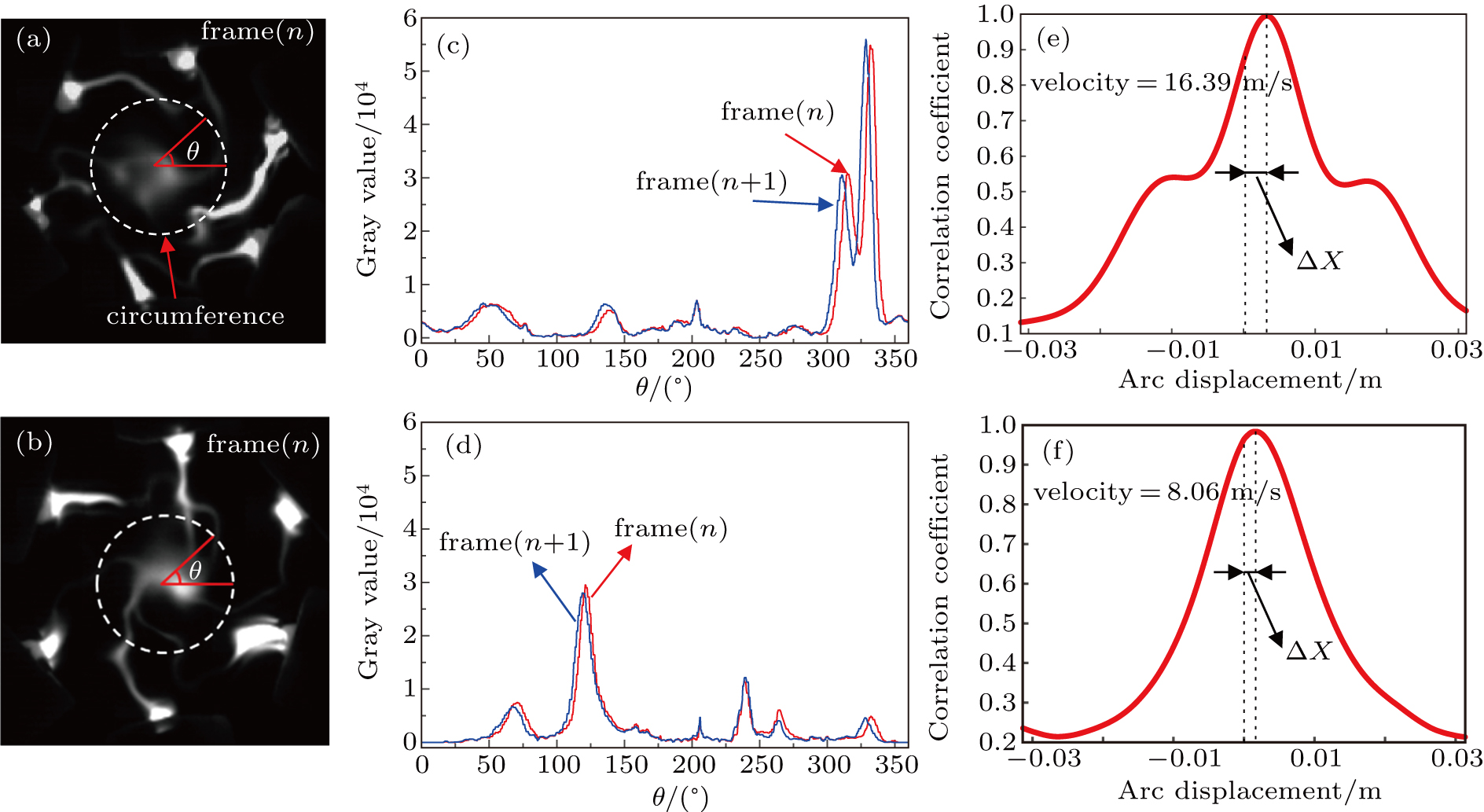

In the multi-arc generator with C_3 and C_4, the arc plasma rotated in the discharge zone due to the swirling field produced, which was caused by the electrode configuration. The arc movement is an important process that affects the heat and momentum transfer between the arc column and its surrounding media in its industrial application, and therefore the arc movement velocity is one of the key parameters for better understanding of this process. The high-speed photography is an effective technical mean to determine this parameter, and the image processing method is one of the key links to obtain it. Zhu et al.[32] calculated the arc plasma velocity based on the nearest method to match a certain point of the arc column between two consecutive frames of images. By comparing and looking for the same position of arc column from two consecutive frames of images, the displacement of the arc motion is determined, and the arc column velocity can be obtained. However, this method cannot be used in our multi-arc system, because the boundary of each arc column was hard to be identified in the circumstance of multiple arcs confluence. Here, cross-correlation analysis based on probability statistics was introduced to calculate the arc rotation velocity (varc) in the multi-arc generator with C_3 and C_4, since the multiple arcs can be treated as a whole in this method. In the experiment, the multiple arcs as a whole rotated in the discharge zone, as a result, the spatial position of the arcs in the frame can be regarded as the corresponding position after the arcs in the previous frame rotates by an angle. This is the basis of using correlation analysis theory to obtain varc. Before the calculation of varc, several assumptions are listed as follows:

Owing to the symmetry of the multi-arc generator, the differences among the rotation velocity magnitudes of multiple arcs were ignorable. The varc was only calculated in the Z = 0 plane. Compared with varc, the radial velocity was ignorable. The fluctuation effect of gray-value distribution of discharge image on the cross-correlation coefficient was ignorable within the time step between two successive frame images.

In detail, the discharge images were processed as follows:

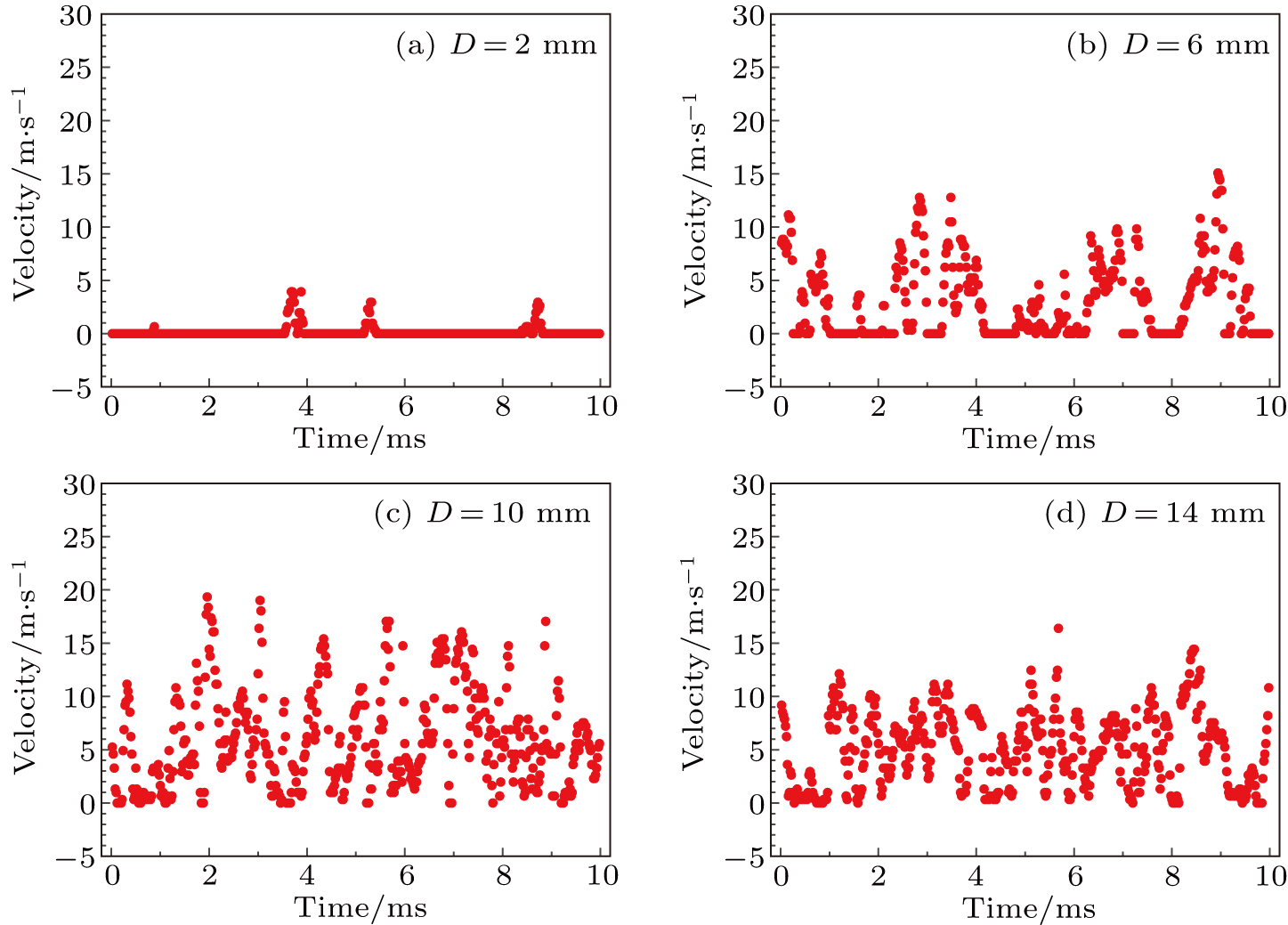

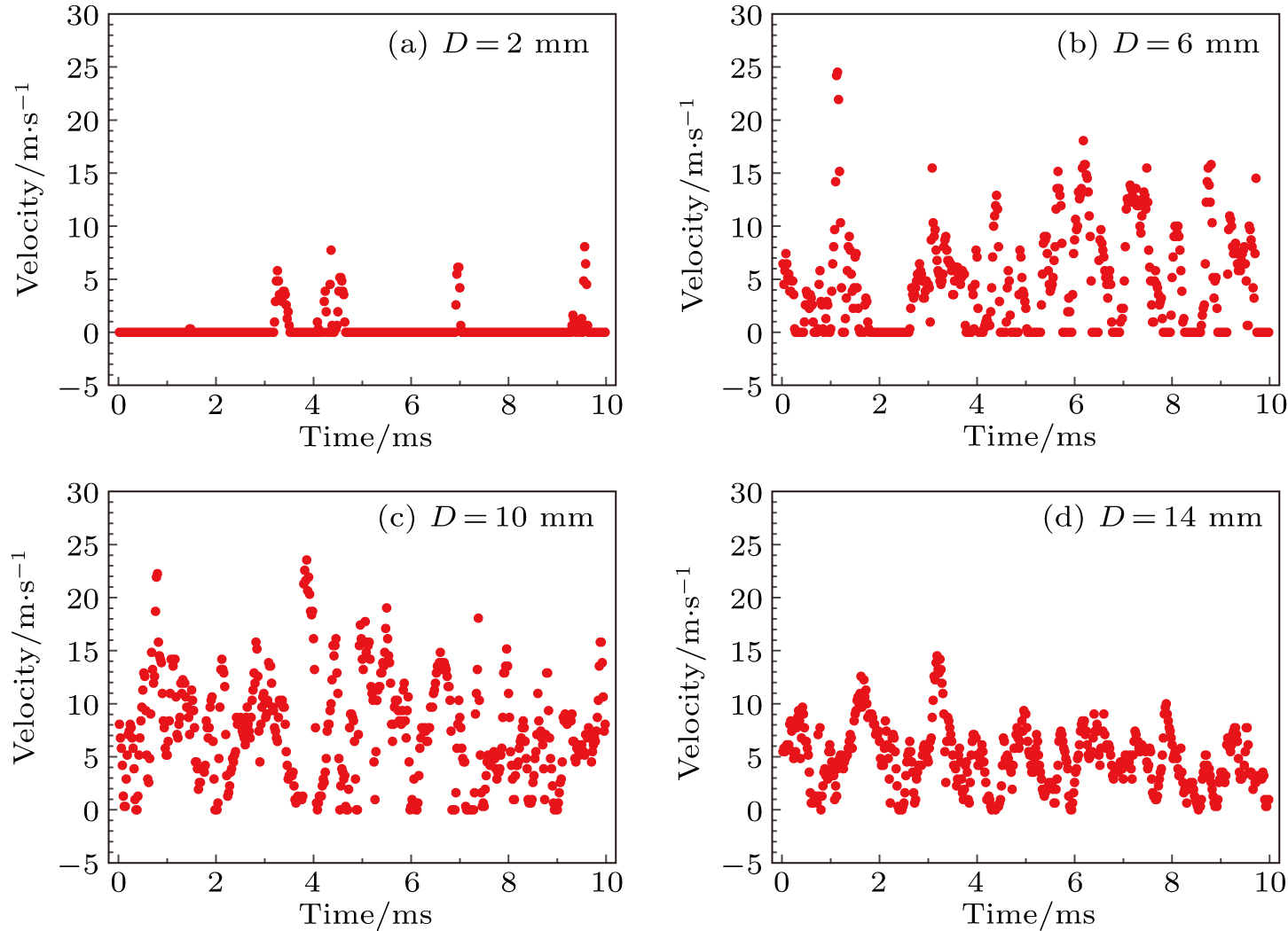

Extract the discharge zone shown in Figs. Enlarge the image size by five times without distortion in order to improve the spatial resolution. Extract the grayscale value of pixels along the circumference of the observing zone with diameters of 2 mm, 6 mm, 10 mm, and 14 mm from two successive frame images n and n + 1. Spread the gray value distribution along the circumference of the observing zone as shown in Figs. The cross-correlation coefficient between two gray value distributions as a function of the arc displacement (ΔX) is shown in Figs. The varc was calculated by varc = ΔX/Δt, where Δt is the time step, whose value was 0.02 ms, the time interval between two successive images.

Figure

| Fig. 16. The varc under different circles in multi-arc generator with C_3. (a) D = 2 mm, (b) D = 6 mm, (c) D = 10 mm, and (d) D = 14 mm. |

The wave crest in the gray value distribution shown in Figs.

|

| Fig. 17. The varc under different circles in multi-arc generator with C_4. (a) D = 2 mm, (b) D = 6 mm, (c) D = 10 mm, and (d) D = 14 mm. |

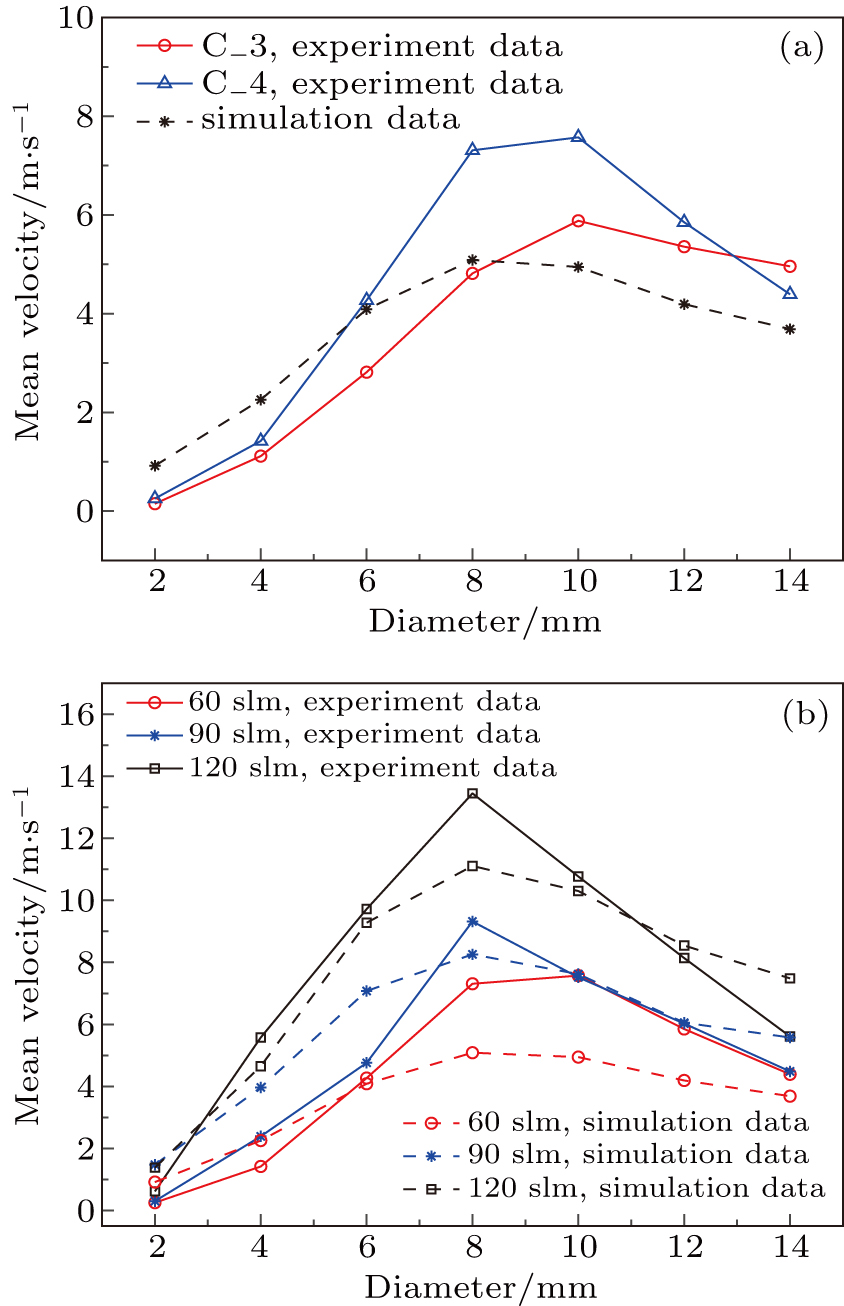

In order to clearly distinguish the difference between the varc of C_3 and that of C_4, the mean varc was introduced to describe the arc time-average rotation rate, which was obtained by taking average of varc in 10 ms. The mean varc as a function of the diameter under different electrode configurations together with the simulation results is shown in Fig.

The effect of the gas flow rate on the mean varc together with the simulation results is shown in Fig.

The errors brought by the experiment and this method are discussed as follows. First, the varc among multiple arcs may have small differences, which are mainly caused by the slight asymmetry of the multi-arc plasma generator. In our plasma generator, there are 1% differences among the six gas sources in our device and slight geometry flaws of electrodes themselves together with electrode configuration. Second, the maximum of cross-correlation coefficient ranges from 98% to 100%, which is mainly due to the fluctuation of arc plasma in the discharge zone. Third, it is difficult to obtain the accurate arc displacement utilizing cross correlation analysis method when the distribution of gray value of arc plasma is relatively homogeneous, e.g., at the diameter of 2 mm. Finally, the resolution of the CCD camera is another factor influencing the measurement accuracy. The area of each pixel in this study denotes the actual spatial resolution of 0.0576 mm2, which means that the resolution of varc is 0.24 m/s.

In summary, the characteristics of AC arcs in the multi-arc generator with four electrode configurations have been investigated using high-speed photography, and an attempt has been made to measure the discharge area, the stability of discharge area, and the rotation velocity of multiple arcs. Several conclusions drawn from this paper are listed as follows.

(I) The spatial distribution of arc plasma, the arc plasma size, and its stability were strongly related to the electrode configuration. The opposite and swirl gas flows in the discharge zone could be obtained by adjusting the electrode position arrangement. In the electrode configuration with swirl flow, a luminance region in the center of the discharge zone was formed in C_3 and C_4. Moreover, the luminance region of arc plasma was more stable in C_3 and C_4 compared with that in C_1 and C_2. Besides, by adjusting the electrical connection order between electrodes and power supplies in the electrode configuration with swirl flow, the arc spatial distribution in C_3 was more stable than that in C_4.

(II) During the motion of multiple arcs, two or three arc columns maybe connect together in the discharge zone, and thus two or three arc columns together with their respective driving power supplies may be electrically in series operation.

(III) The varc approximately periodically changes in the multi-arc generator with swirl flow configuration. In general, the magnitude of varc can be enhanced by increasing the gas flow rate and using the electrode configuration with C_4. Under the experimental parameters of 120 slm gas flow rate and electrode configuration with C_4, the maximum mean of varc reached about 13.4 m/s.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] |