† Corresponding author. E-mail:

Amorphous (Fe40Ni40B19Cu1)100−xNbx (x = 1, 3, 5, 7) ribbons are prepared by using the melt-spinning method. We find that the glass forming ability (GFA) of the as-melt spun ribbons is significantly improved by adding Nb element. In addition, the thermal stability evaluated in steps of

FeNi based nanocrystalline alloys have shown great potential applications in power electronics due to the advantages of high thermodynamic stability, high glass forming ability (GFA) and good soft magnetic properties.[1–6] In general, nanocrystalline magnetic alloys are obtained by being annealed on magnetic amorphous alloys because proper annealing can relieve the internal stress of the as-melt spun amorphous alloy.[7] Also, after annealing the alloy, the ferromagnetic exchange reaction between soft magnetic nanocrystallites can average out the magnetocrystalline anisotropy and improve the soft magnetic properties if the size and distribution of the nanocrystallites are well controlled.[8–10]

Besides, substitution or addition of insoluble elements such as Cu can act as heterogeneous nucleation sites to facilitate the precipitation of primary crystalline phase. Large atoms such as Nb, Ta, W, and Cr can serve as inhibitors to prevent the grain from growing which is beneficial for improving the soft magnetic properties and glass forming ability (GFA).[11–15] Previous study has suggested that the order of ability to substitute elements in refining grain size of Fe–M–Cu–Si–B alloys is

In this work, Nb is added into the Fe40Ni40B19Cu1 system, and the effect of Nb content on the thermal stability and the influence of annealing conditions on the crystallization process, microstructures and the magnetic properties of Fe–Ni–B–Cu–Nb alloys are investigated.

Master alloys with nominal compositions of (Fe40Ni40B19Cu1)100−xNbx (x = 1, 3, 5, 7) were prepared by induction melting the mixtures of high-purity elements (Fe:99.99 at.%, Ni:99.99 at.%, B:99.99 at.%, Cu:99.99 at.%, Nb:99.97 at.%,) under an argon atmosphere. The alloys were melted three or four times to achieve homogenization. Then, the master alloys were fabricated in the form of ribbons with about 2 mm in width and

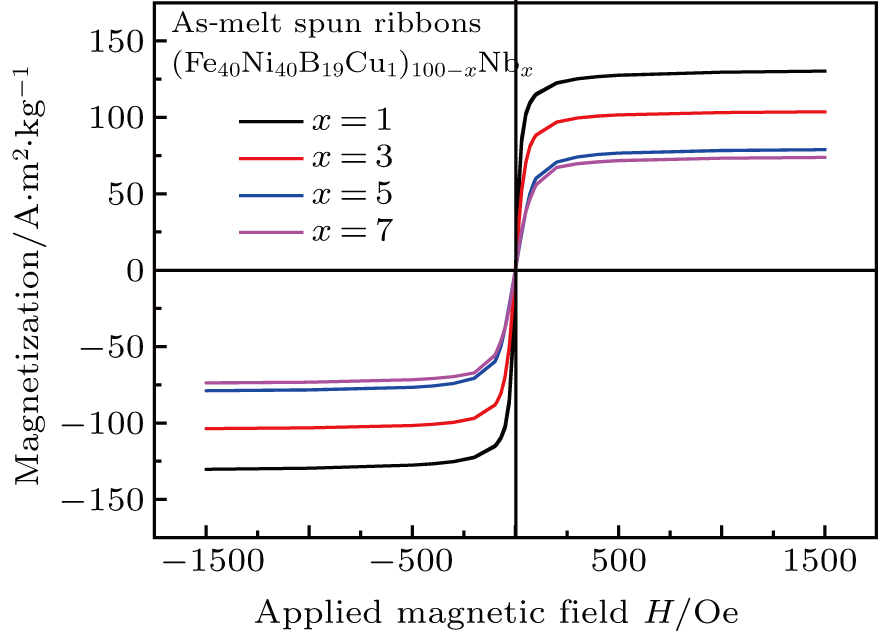

Figure

| Table 1.

Actual atomic percentage of (Fe40Ni40B19Cu1)100−xNbx (x = 1, 3, 5, 7) as-melt spun ribbons. . |

Figure

| Fig. 3. XRD patterns of as-melt-spun (Fe40Ni40B19Cu1)97Nb3 ribbons annealed at different temperatures. |

| Table 2.

Thermal stabilities of (Fe40Ni40B19Cu1)100-−xNbx (x = 1, 3, 5, 7) as-melt spun ribbons . |

Figure

| Fig. 4. Saturation magnetization (Ms) versus coercivity (Hc) of as-melt spun (Fe40Ni40B19Cu1)100-−xNbx (x = 1, 3, 5, 7) ribbons. |

| Fig. 5. Saturation magnetization (Ms) and coercivity (Hc) versus Nb content for (Fe40Ni40B19Cu1)100-−xNbx (x = 1, 3, 5, 7) alloy. |

| Table 3.

Values of Hc and Bs (or Is) of FeNi magnetic alloys. . |

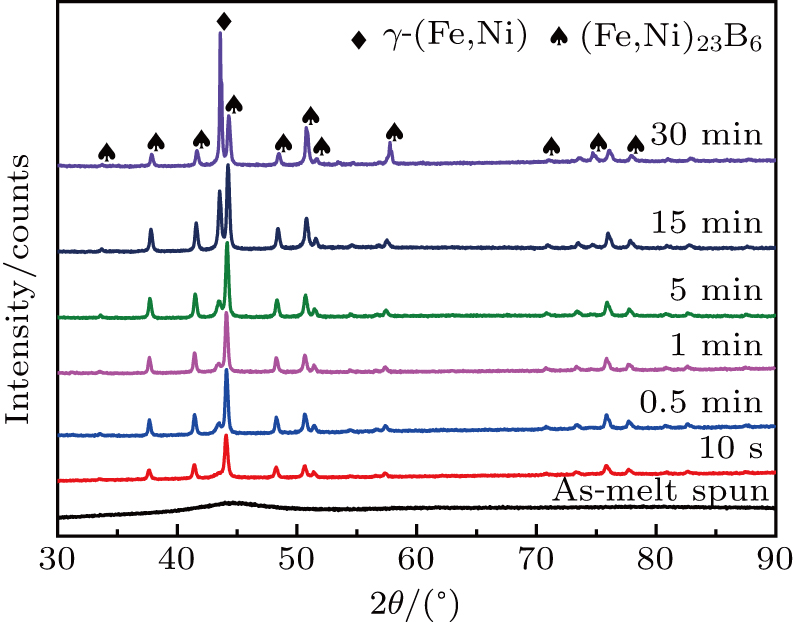

Figure

| Fig. 6. XRD patterns of as-melt-spun (Fe40Ni40B19Cu1)97Nb3 ribbons annealed at 809 K for different times. |

The values of crystallization activation energy E1 ((Fe,Ni)23B6) and E2 (γ-(Fe, Ni)) for the first 2 exothermic peaks of (Fe40Ni40B19Cu1)97Nb3 ribbons are calculated by both Kissinger equation and Ozava equation and the results are listed in Table

| Table 4.

Crystallization activation energy of as-melt-spun (Fe40Ni40B19Cu1)97Nb3 ribbons. . |

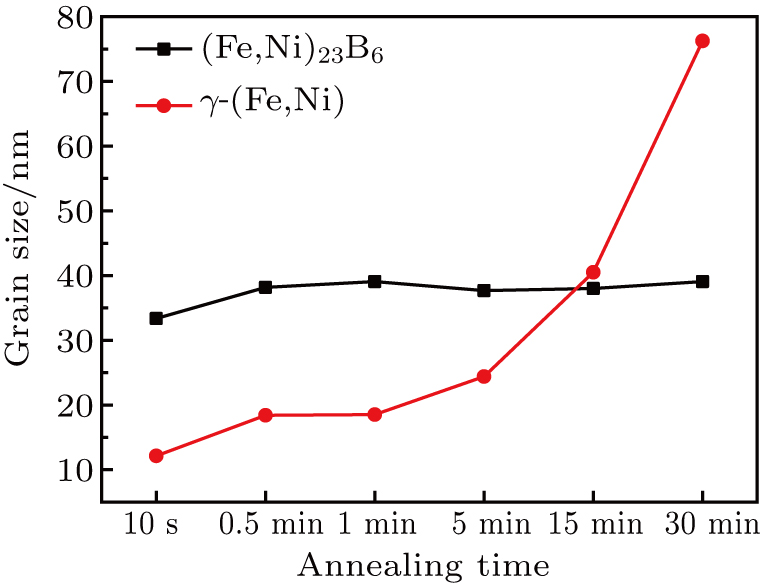

In order to further investigate the effect of grain size on soft magnetic properties, the average grain size of (Fe, Ni)23B6 phase and γ (Fe, Ni) phase for the (Fe40Ni40B19Cu1)97Nb3 ribbons are estimated by using Scherrerʼs equation and the results are shown in Fig.

| Fig. 7. Dependence of grain size of (Fe, Ni)23B6 and γ-(Fe, Ni) on annealing time in (Fe40Ni40B19Cu1)97Nb3 ribbon at 809 K. |

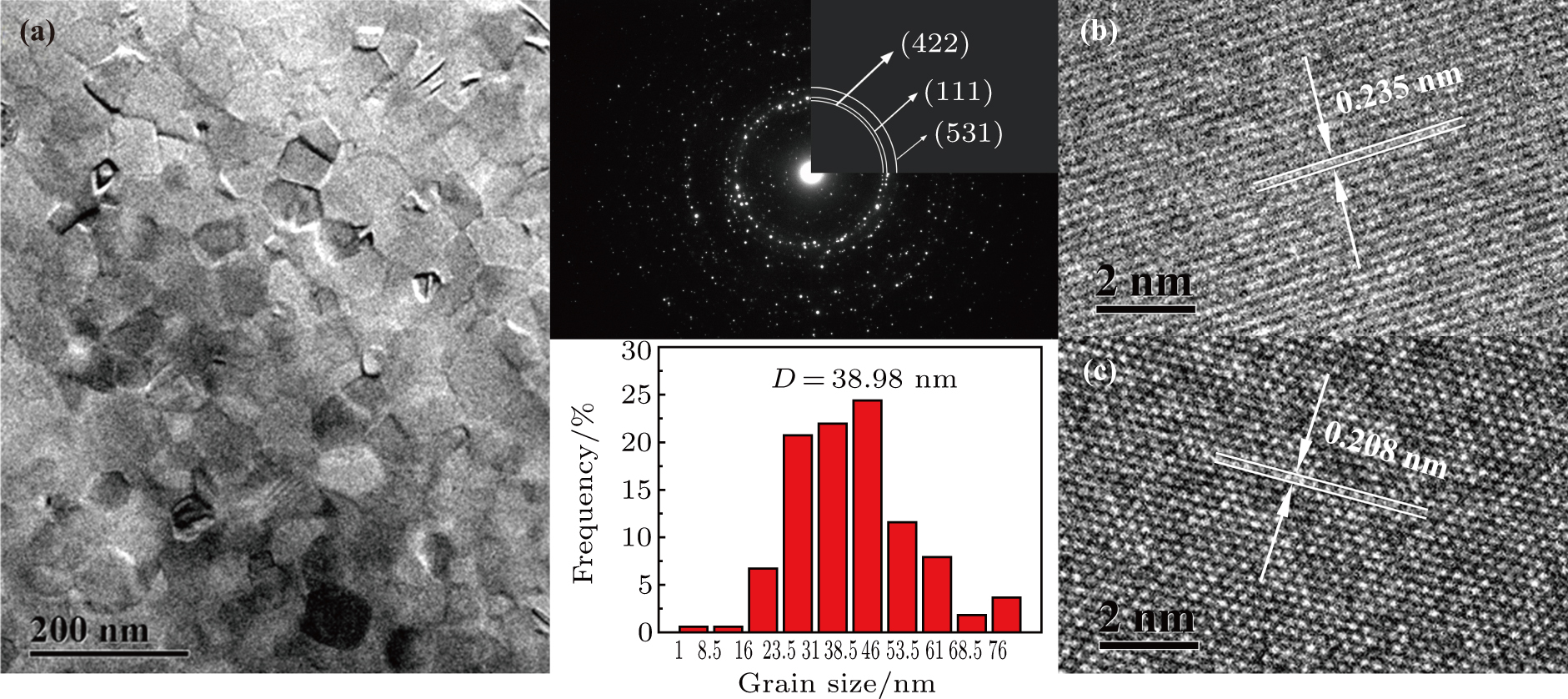

Figure

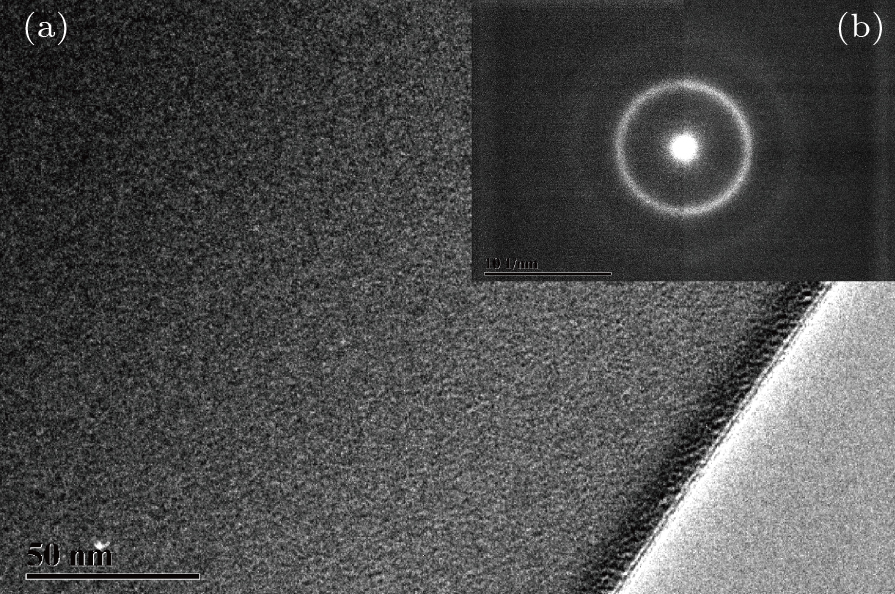

Figure

| Fig. 9. (a) TEM bright field image and (b) SAED pattern for as-melt-spun (Fe40Ni40B19Cu1)97Nb3 ribbon. |

In this work, we investigate the effects of Nb addition on glass forming ability and thermal stability of as-melt spun (Fe40Ni40B19Cu1)100-−xNbx (x = 1, 3, 5, 7) ribbons, and the effect of annealing time on the magnetic properties of the (Fe40Ni40B19Cu1)97Nb3 ribbon. Several conclusions are drawn below.

(i) With the addition of Nb element, the GFA and thermal stability of (Fe40Ni40B19Cu1)100-−xNbx (x = 1, 3, 5, 7) ribbons are greatly improved.

(ii) The as-melt spun ribbon with 3 at.% Nb exhibits a lowest coercivity of 2 A/m and relatively large saturation magnetization of

(iii) (Fe,Ni)23B6 phase is first precipitated in the (Fe40Ni40B19Cu1)97Nb3 ribbon when annealed at 809 K for 10 s followed by the formation and growth of γ-(Fe, Ni) phase with the longer annealing time.

(iv) With the further increase of annealing time, the growth of (Fe,Ni)23B6 grain and γ-(Fe, Ni) grain degrades the overall magnetic properties.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] |