† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 11427810), the National Key Research and Development Program of China (Grant No. 2016YFA0401503), and the Project for Science and Technology Plan of Sichuan Province, China (Grant No. 2015GZ0053).

The DIA-type Kawai cell possesses a larger volume and a quasi-hydrostatic pressure environment and has been widely used in materials’ synthesis and x-ray diffraction experiments. However, few high-pressure in situ neutron diffraction experiments were performed in the DIA-type Kawai cell because there is no wide window for neutron diffraction and the second-stage anvils and guild block material attenuates the neutron signal significantly. In this work, we tentatively modified the normal DIA-type Kawai cell (MA 2-6-8) into a MA 2-8 mode by removing the six first-stage tungsten carbide anvils. As a consequence, the eight tungsten carbide anvils (Kawai cell) are directly driven by the guide blocks. The results of ex situ and in situ pressure calibration show that the cell pressure can reach 5 GPa with small truncation edge lengths (TEL) of 3 mm even at the load of 300 kN. It suggests that this MA 2-8 cell may open a new way for high-pressure and high-temperature in situ neutron diffraction.

With respect to high-pressure in situ x-ray diffraction, high-pressure in situ neutron diffraction (HPND) provides a unique tool at extreme condition for probing crystallographic structures of the many important materials containing light atoms including H(D), Be, B11, C, and N,[1–6] and giving structural information of liquid and glassy materials.[7–10] Besides, HPND provides indispensable information for understanding the chemical composition, stability, and optical properties.[11] However, in contrast with synchrotron sources, the intrinsically weak sources of neutron radiation available, reactor or spallation-based sources, demand large sample volume, leading to the compromise between data quality and maximum attainable pressures. According to experience and some semi-empirical considerations, the maximum achievable pressure Pmax is approximately proportional to an inverse power of volume V, i.e.

During the past years, many high-pressure devices had been developed for neutron diffraction experiments, such as McWhan-type cylinder-piston cell[13] and opposed-anvils cell.[16,17] Nowadays the Paris-Edinburgh press equipped with the toroidal opposed cupped anvils has been widely employed in the HPND experiments.[12,18] A key feature of PE press is their small volume and “compactness”, i.e. their high capacity compared to their mass. A V3 (VX3) press has a capacity of 250 tones but only a mass of 50 kg,[19] which is crucial for neutron diffraction because of the very limited space in the neutron beam-line. This high-pressure device generates a wide range of pressures up to 10 GPa with single toroid tungsten carbide anvils and to 25 GPa with double toroid sintered diamond anvils.[18,20] However, this uniaxial-loaded opposed-anvil cell usually generates large stress due to the absence of liquid transmitting medium.[18] Furthermore, because of the limitation of the cell volume improvement it is impossible for high-temperature experiments, which usually requires a mass of ceramic pressure-transmitting medium working as a thermal and electrical insulator. Alternatively, multi-anvil (MA) cell, such as cubic anvil and octahedral anvil cell, possesses a larger cell volume and a quasi-hydrostatic pressure environment and has been widely used in diamond synthesis[21] and x-ray diffraction experiments.[22] However, because of the limited space at neutron diffraction beam-line many large volume apparatuses are not suitable choices. The uniaxial-loading DIA-type apparatus has a smaller volume and the uniaxial-loading is transferred to the six-anvil by upper and lower guild blocks. In order to further enhance the cell pressure, an assembly of eight cubic anvils of tungsten carbide or sintered diamond with the octahedral pressure medium and gaskets, the Kawai cell, is squeezed by the six first-stage anvils.[21] This MA 2–6-8 type apparatus has the advantage of producing homogeneous pressures at larger sample volumes over competitive high-pressure devices such as the diamond anvil cell (DAC).[23–25] The attainable pressure and temperature can reach 83.7 GPa and 1500 K using sintered diamond as the second-stage anvil.[26]

Unfortunately, few high-pressure in situ neutron diffraction experiments were performed in the DIA-type Kawai cell. Although this guide block system is a simple and effective way to produce high pressure, there is no wide window for neutron diffraction and the second-stage anvils and guild block material attenuates the neutron signal significantly. In this work, in order to obtain larger space for angle-dispersion neutron diffraction, we tentatively modified the DIA-type Kawai cell (MA 2–6-8) into MA 2/8, suggesting that the six first-stage anvils are removed and the assembly of eight cubic anvils of tungsten carbide is driven by the guide blocks directly. Then we performed high-pressure in situ neutron diffraction using the apparatus based on the neutron scattering facility (Fenghuang) of China Mianyang Research Reactor (CMRR). The pressure can reach 5 GPa with truncation edge lengths 3 mm at the load of 300 kN.

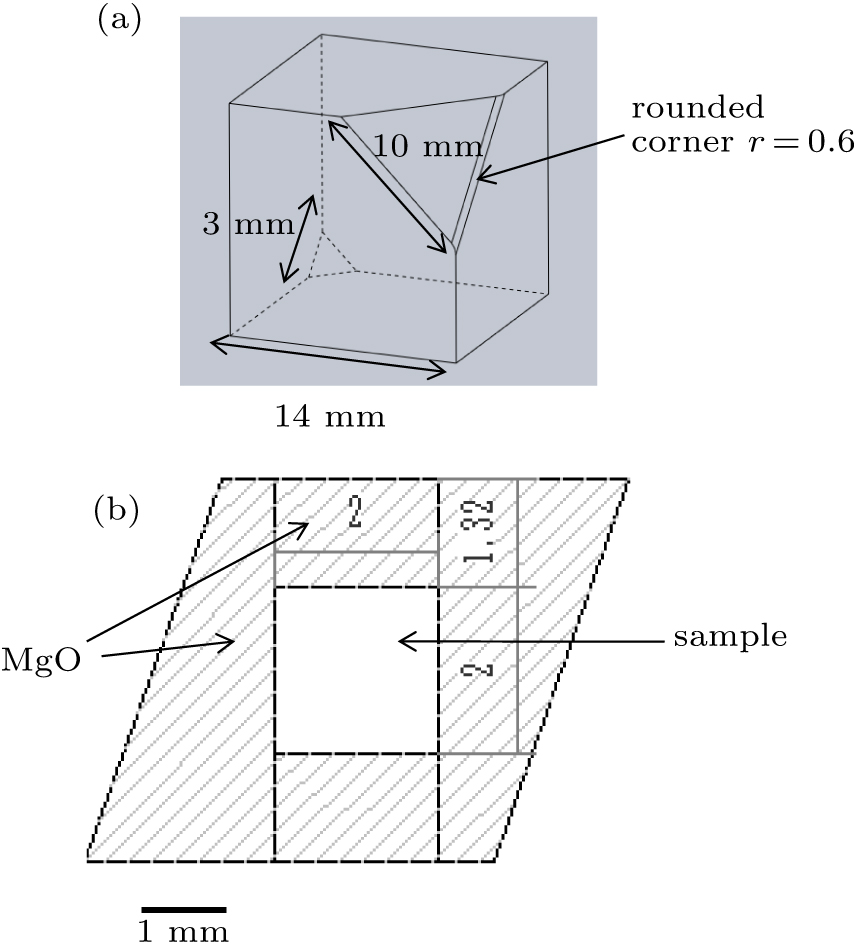

The MA2-8 cell is mainly divided into two parts, guide blocks and the gasket-sample assembly. Figure

| Fig. 1. (a) Overall diagram of the modified DIA-type Kawai cell. (b) The mode of high pressure neutron diffraction. |

Figure

| Fig. 2. (a) The optimization of the second-stage anvils. (b) The cross section of the octahedron transmitting pressure medium. |

The octahedral edge length (OEL) of the pressure medium and the size of the TEL are the key points determining the volume of the sample and limitation of the cell pressure.[27] We design two kinds of small TEL, 1.5 mm and 3 mm. Then we used an empirical method called “limiting compression volume ratio φ” to determine the size of OEL.[28] For small TELs of 1.5 mm and 3 mm, the corresponding OELs are 5.7 mm and 8.2 mm, respectively. The pressure media were octahedral MgO, which is a commonly used pressure medium owing to its large bulk modulus.[29,30] For the gaskets, we used raw pyrophyllite with a thickness of 2.45 mm (T) and a width of 2.94 mm (W) for a TEL of 3.0 mm, while T = 1.98 mm and W = 2.37 mm were used for a TEL of 1.5 mm. Figure

A series of pressure calibration experiments were carried out for the 2/8-type cell, including resistance calibration and in situ neutron diffraction. The ex situ pressure generation tests of the 2/8-type cell were carried out using the 300 kN servo-hydraulic press installed in the lab of High-pressure Science and Technology, Sichuan University. The machined octahedron transmitting pressure medium was cut in half, and the pressure maker was put inside it. A bit of the pressure maker was placed in the middle of the pressure media for pressure evaluation. Copper foil (0.1 mm thickness) was used as a wire, connected to the second-stage anvils and pressure maker. The assembled two-stage pressurization unit was put into the upper guild block and lower guild block to carry out a pressure calibration experiment. The phase transitions of ZnTe at 5 GPa was used as pressure fixed points to determine generated pressures, a piece of ZnTe single crystal was crushed into coarse-grained powder (grain size of

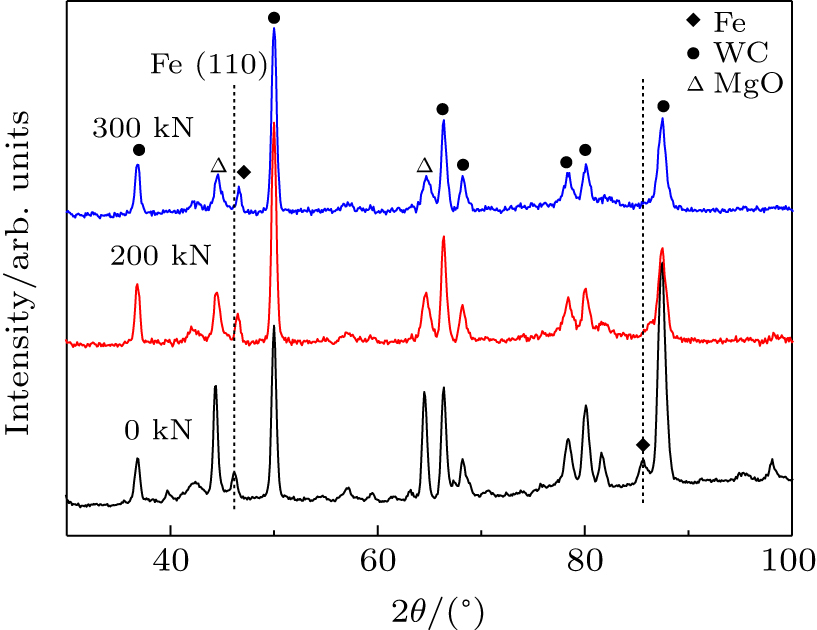

The high-pressure in situ neutron diffraction experiments are performed on a high-pressure neutron diffraction spectrometer (Fenghuang) at the China Mianyang Research Reactor (CMRR). The monochrome beam with a wavelength of 1.59 Å was adopted for all neutron diffraction patterns. The detector consists of 70 3He counting tubes, scanning the diffraction angle from 8° to 172°. The size of incident neutron beam at sample position is about 2 × 3 cm2.[31] The loading force is generated by the 2000 kN Paris-Edinburgh press.[32] An iron cylinder (99.99%, Alfa Aesar, US) with a size of

Figure

| Fig. 3. ZnTe pressure calibration results and fitted curves at room temperature. Pressure generation is based on 5.7/1.5 assembly using 14-mm tungsten carbide cubes as second-anvil. |

Figure

Figure

We have developed a new DIA type Kawai cell (2/8-type cell) for high-pressure in situ neutron diffraction. This device mainly consists of upper and lower guide blocks, and a two-stage pressurization unit that is composed of second-stage anvils, a pressure medium, and twelve gaskets. The maximum pressure that is achieved by this device is 5 GPa via the pressure calibration of resistance. The device has also been tested for high pressure in situ neutron diffraction. A pressure of 4.5 GPa is achieved using an 8.2/3 assembly at the loading 300 kN. Compared with the traditional PE press for in situ neutron diffraction, the new DIA type Kawai cell has a significant advantage in heating. This Kawai cell can provide steady internal heating rather than applying power directly to the anvil as in the PE press. In the future, the pressure range could be further expanded by replacing tungsten carbide anvil with polycrystalline diamond anvil. We will do high temperature and high pressure experiments, which will promote the progress in high pressure and high temperature in situ neutron diffraction.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] |