† Corresponding author. E-mail:

Project supported by Postgraduate Research & Practice Innovation Program of Jiangsu Province, China (Grant No. KYCX18_0249).

A novel multi-cavity Helmholtz muffler is proposed. The multi-cavity Helmholtz muffler is composed of steel structures and silicone membranes. With suitable construction, the Helmholtz muffler can be designed to exhibit negative mass density in low frequency, and the muffling frequency can be adjusted when we change the internal structure of the cavity, which will be very attractive for noise control. In this paper, we investigate the influence of the membranes and the cavities on noise reduction characteristics with theoretical calculations and simulations. The results show that the numbers of membranes and the volumes of the cavities can have a great effect on the position of the muffling frequency. The number of cavities can have a great effect on the width of the muffling frequency (reduce the noise by 10 dB). With different combinations of the membranes and cavities, we can get different muffling frequencies, which can meet different muffling demands in practical applications and is more flexible than the traditional Helmholtz cavity.

In modern naval warfare, submarines[1] play an indispensable role, and anti-submarine detection has developed towards low frequency.[2] Controlling the low-frequency noise to avoid being detected by the enemy is the key to improving the stealth performance of the submarine.[3] However, it is difficult to control the noise of submarines from the source for many complex reasons, designing a kind of muffler[4] with low frequency noise reduction characteristic is very important.

Because there are many limitations in the practical engineering application of traditional materials, artificial composite materials with special physical properties have become the focus of attention.[5] In the last 20 years, artificial composite materials have expanded into the field of dynamics, used for flexible regulation of mechanical waves, such structures are called phononic crystals.[6–8] Then, in the modern industrial equipment and products of miniaturization, integration, and lightweight backdrop, people have made further development of the new type of artificial microstructure feature size of subwavelength, later known as acoustic metamaterial.[9–12] The equivalent physical properties of acoustic metamaterials exhibit either ‘single negative’ or ‘double negative’ properties,[13] which perform as low frequency sound absorption and low frequency sound insulation in the process of sound wave propagation. Guided by this theory, many researchers have designed many devices to filter wave or reduce noise in low frequency. Fang et al.[14] designed a kind of Helmholtz cavity, they showed that the equivalent volume modulus of the whole structure is negative when the sound frequency is in the bandgap. In his paper, the Helmholtz cavity is arranged perpendicular to the direction of sound propagation, the sound waves can trigger fluid movements in the neck of each cavity, when the excitation frequency is close to the characteristic frequency of the cavity, the response of the volume modulus would be excited, it is related to

However, many acoustic metamaterials with either single negative or double negative[18] properties cannot reduce noise in a relatively wider frequency range although they have one or more muffling peaks. Besides, the position of the muffler frequency cannot be regulated systematically in many metamaterials. We design a new kind of metamaterial with multi-cavity Helmholtz muffler with membrane structure in this paper. We also investigate the influence of the number of membranes and the volumes of the Helmholtz cavities on the frequency of noise reduction. By changing the number of the rubber and the volume of the cavity, we can obtain different muffling frequencies and different widths of the muffling frequency. We can also rough and fine adjust the peak of the muffling frequency to meet different muffling demand. When we place the muffler in the water, increase the number of Helmholtz cavities and stack more layers of silicone membranes, the range of frequency to reduce noise can become wider and show the tendency to move to lower frequencies. This new kind of muffler provides a new idea for the design of underwater acoustic structures.

The Helmholtz cavity in Ref. [14] showed that this metamaterial has a negative volume modulus around 32 kHz, the negative volume modulus is the same as the negative mass density. It can also turn sound waves into falling waves, so the transmission loss around this frequency shows up. The acoustic metamaterial can have a very good acoustic absorption around 32 kHz. In our research, we proposed a new concept of multi-cavity Helmholtz muffler with membrane structure. We added several cavities in our muffler structure on the basis of the original Helmholtz cavity, and made the position and width of the sound absorption frequency adjustable by changing the number of membranes and the volumes of the cavities. The new structure can meet different muffling demands in the practical application and it is more flexible than the traditional Helmholtz cavity.

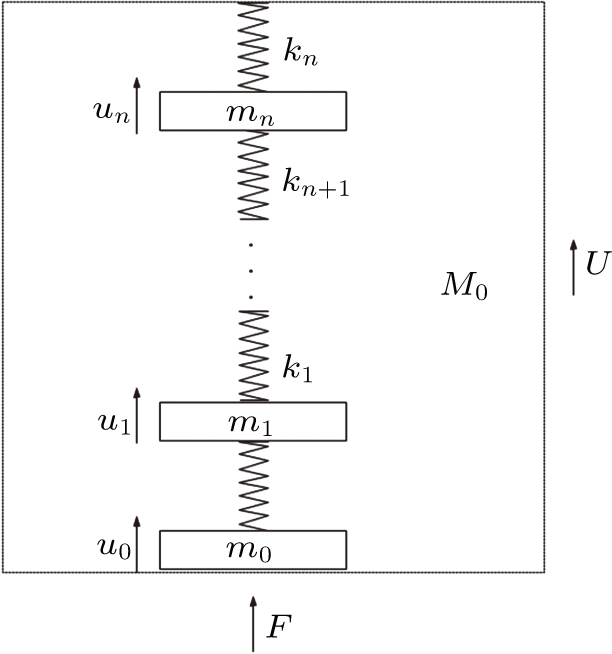

In order to study the influence of the membrane (silicone) on the negative mass density of the Helmholtz cavity, we add different numbers of membranes in the Helmholtz cavity (

Figure

For studying the mass–spring unit cell in Fig.

We use MATLAB (R2016a) to compute the relationship between the displacement ui of each mass block and the displacement U of the whole Helmholtz cavity, equation (

We add up all equations in Eq. (

The effective mass density ρeff can be expressed as

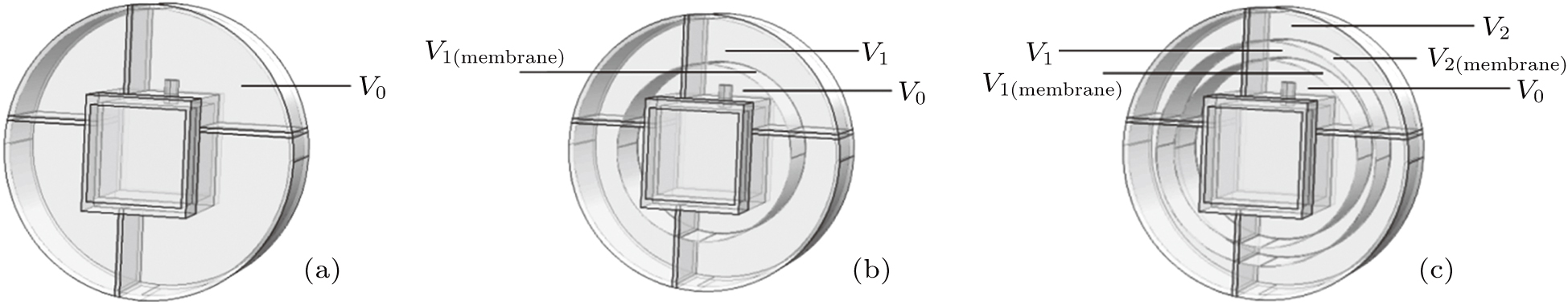

We consider one of the Helmholtz cavities which is shown in Fig.

| Fig. 3. The internal structure of one of the Helmholtz cavities: (a) the number of the membrane is n = 0, (b) n = 1, (c) n = 2. |

| Fig. 4. The dimensionless equivalent density in the muffler with a single Helmholtz cavity: (a) the number of the membranes is n = 0, (b) n = 1, (c) n = 2. |

| Table 1.

The material parameters. . |

In order to further verify the feasibility of the analytical solution after simplifying the model, the node-based smoothed finite element method (NS-FEM) is used to conduct a comparative analysis of the muffler structure.[19]

Applying the divergence theorem, the smoothed strain gradient matrix

The stiffness matrix can be assembled as

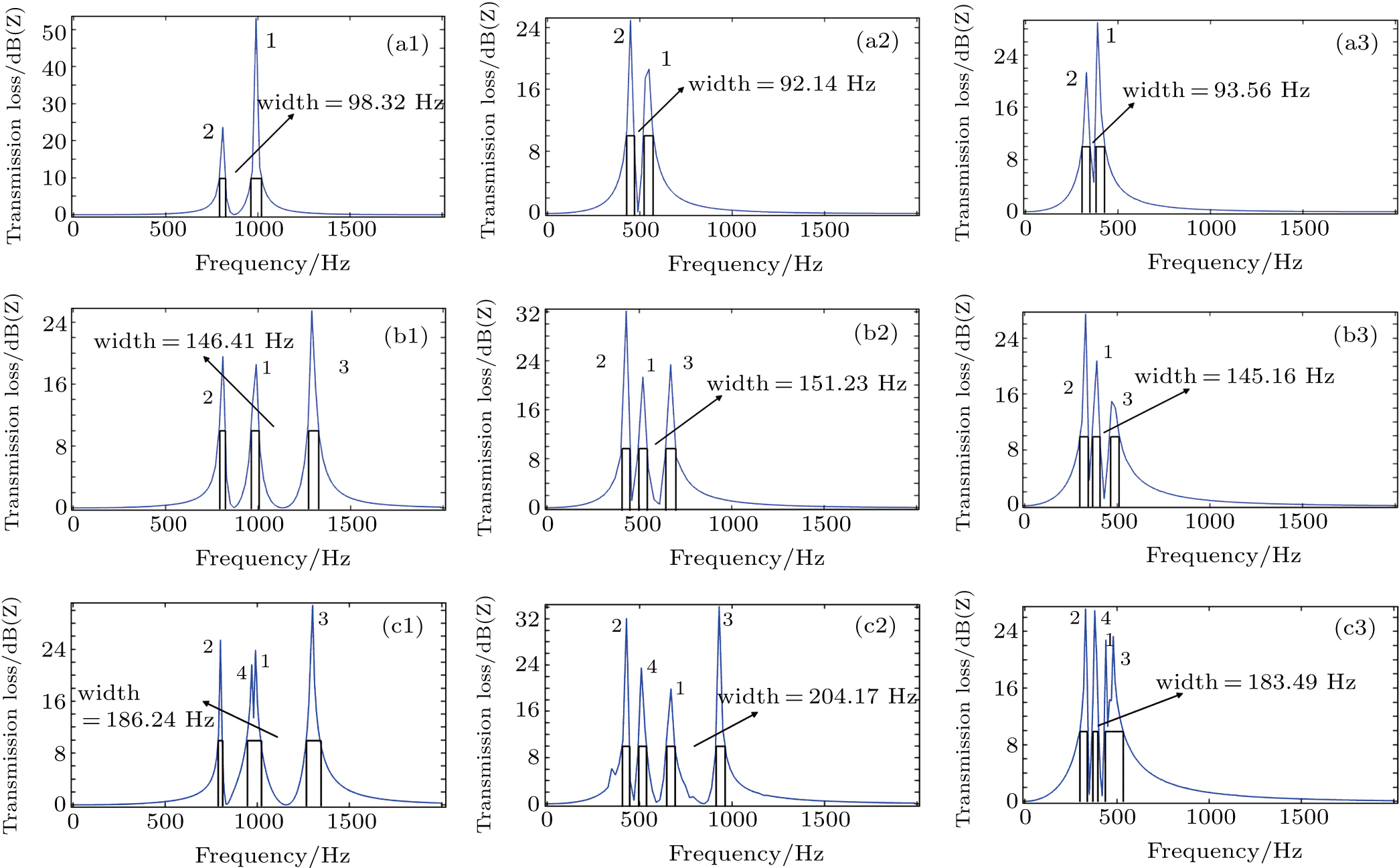

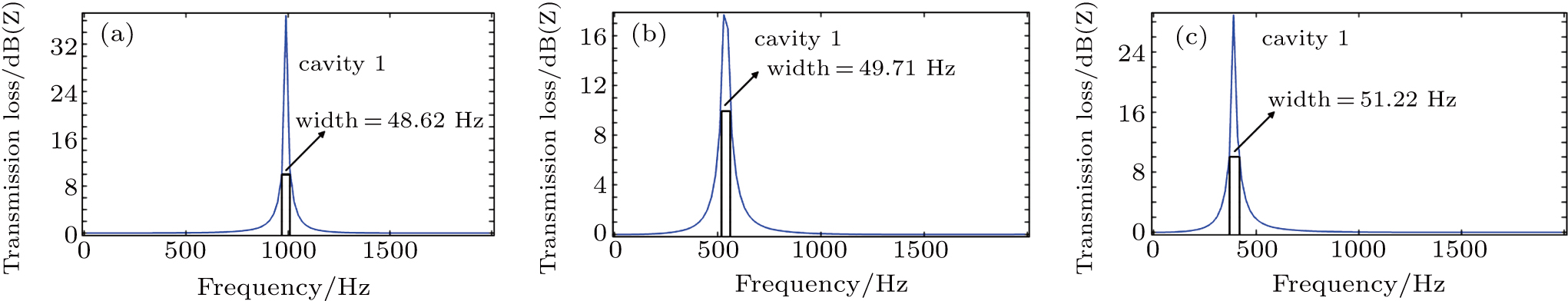

The above-mentioned analytical examples have shown that the frequency of negative mass density can be changed by choosing different numbers of membranes. In this section, we consider the influence of the Helmholtz cavity on the muffling frequencies. Figure

| Fig. 6. Transmission loss of single-cavity Helmholtz muffler: (a) the number of membrane n = 0, (b) n = 1, (c) n = 2. |

Figure

From the simulation, we can draw the conclusion that the number of rubbers determines the position of the muffling frequency and the volume of cavity can fine adjust the muffling frequency, while the number of cavities determines the range of muffling frequency. This discovery provides us more choices for constructing the submarine muffler.

It can be seen that the attenuation peak will be very close or even overlap when the volumes of two cavities are similar. We make

| Fig. 10. (a) The influence of volumes on the peak frequency of the transmission loss, (b) the influence of volumes on the width of noise reduction frequency below 10 dB. |

From what has been discussed above, we can obtain three effective methods to regulate the position and width of the sound absorption frequency of this muffler, the first is in order to get the continuous and wider muffling frequency, we can make the volume of the four cavities equal, the second is we can change the number of rubbers which are added into the multi-cavity to change the general position of the muffling frequency, the third is we can change the volumes of multi-cavity between 5000 mm3 to 10000 mm3 to fine adjust the muffling frequency.

We introduced a multi-cavity Helmholtz muffler with membrane structure and investigated the influence of the number of Helmholtz cavities and silicone membranes on noise reduction characteristics. In this paper, the relationship between the equivalent negative mass density and the number of membranes was deduced based on the equivalent model, and the muffling frequency has a good agreement with the simulation. We found that the position of the muffling frequency is determined by the number of membranes, with the increase of the number of the membranes in the cavity, the frequency may decrease greatly, which provides us with a way to roughly regulate the position of the muffling frequency. In contrast, the volume of cavity can slightly affect the muffling frequency, when we increase the volume from 5000 mm3 to 10000 mm3, the muffling frequency only goes down from 1000 Hz to 500 Hz, which states that we can use the volume of cavity to fine tune the muffling frequency. Moreover, when we make the volumes of the four cavities equal, the muffling frequency becomes continuous and the width becomes wider, and the muffling frequency can also decrease with the increase of the volumes. Besides, the width of the frequency has nothing to do with the volume, so we can fine adjust the muffling frequency without having to consider the decrease of the width of noise reduction frequency. By changing the number of rubbers and the volume of the cavity, we can get different positions of muffling frequency and different widths of muffling frequency. We can also rough and fine adjust the peak of the muffling frequency to meet different muffling demands, which means in modern naval warfare, we can design different kinds of muffler structures according to the noise frequency of the submarine itself, and so make the submarine avoid being detected by an enemy's radar. The theoretical and simulation investigations in our work may provide guidelines for designing novel muffling structures for submarine.