Elastocaloric effect and mechanical behavior for NiTi shape memory alloys

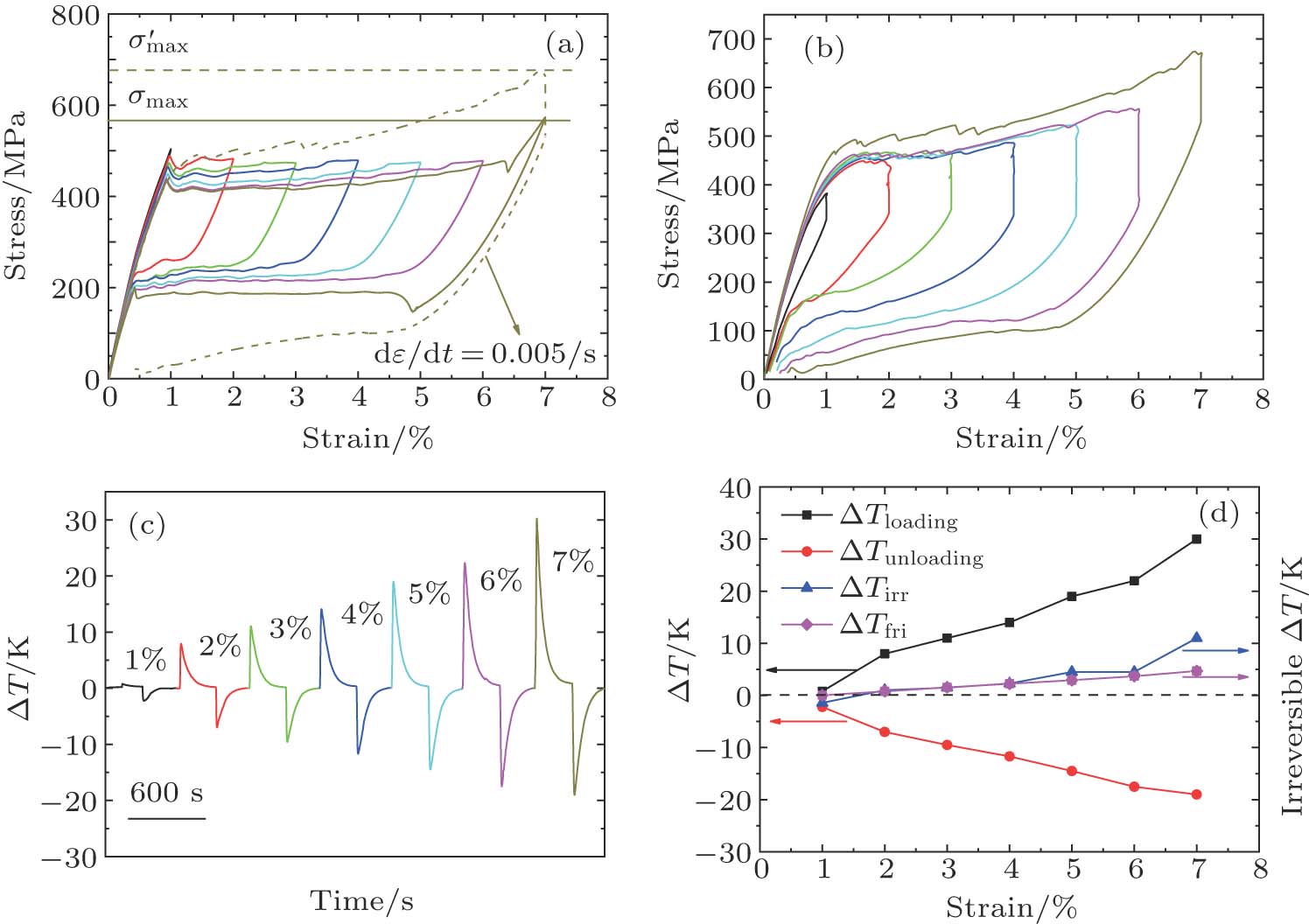

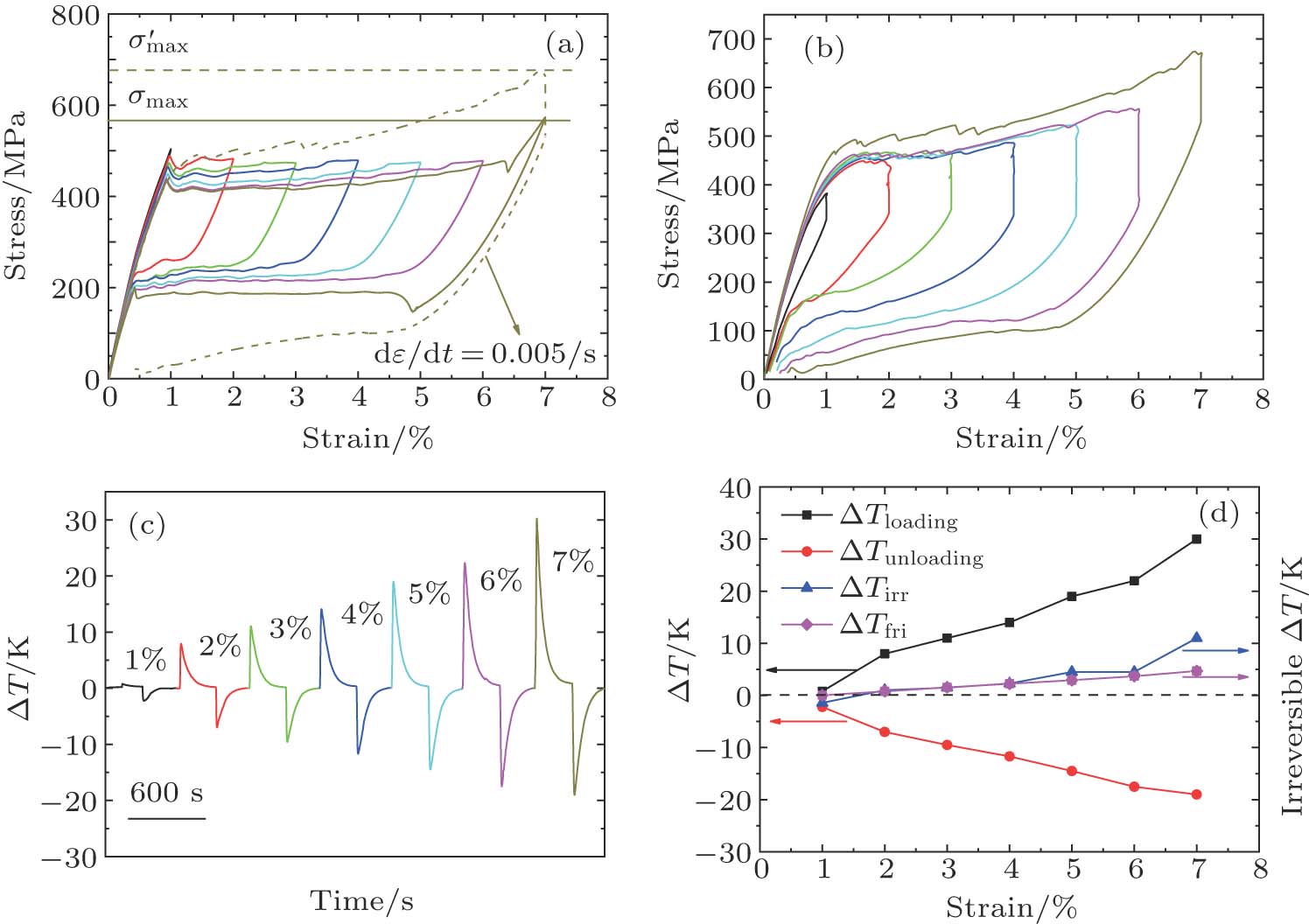

(color online) (a) Stress–strain curves at different strain levels (ε = 1%–7%) under an approximately isothermal condition (low strain rate of

Elastocaloric effect and mechanical behavior for NiTi shape memory alloys |

|

(color online) (a) Stress–strain curves at different strain levels (ε = 1%–7%) under an approximately isothermal condition (low strain rate of |

|