† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 11304409 and 61705028), the Natural Science Foundation of Chongqing City, China (Grant Nos. csct2013jcyjA4004 and cstc2017jcyjA0893), the Scientific and Technological Research Program of Chongqing Municipal Education Commission, China (Grant No. KJ1500422), and the Postgraduate Research Innovation Foundation of Chongqing City, China (Grant No. CYS17240).

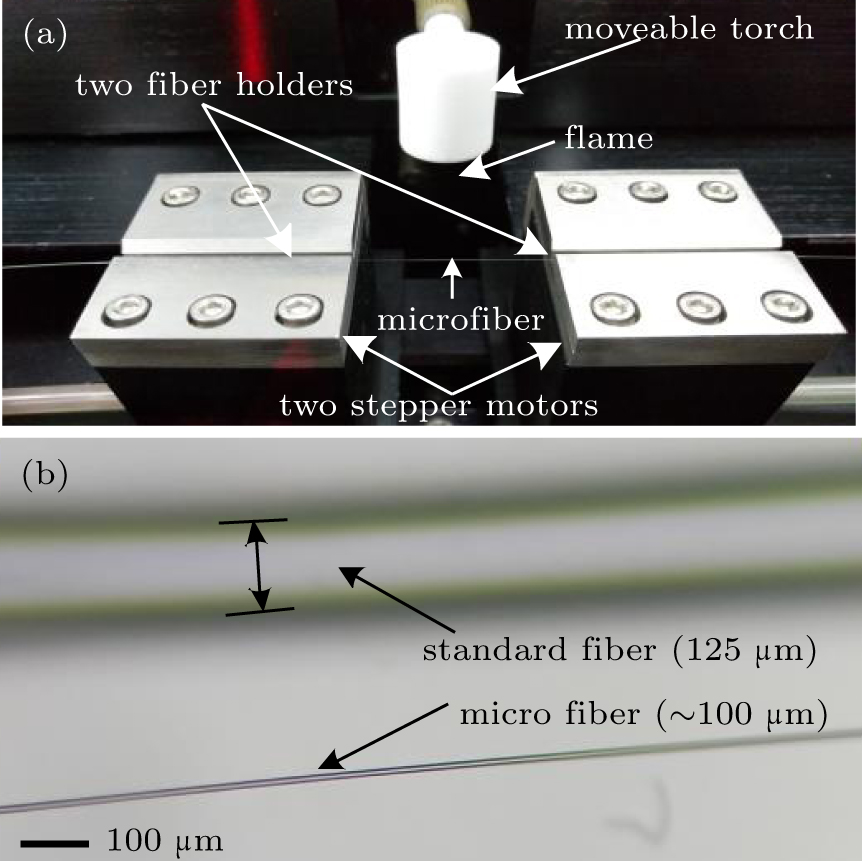

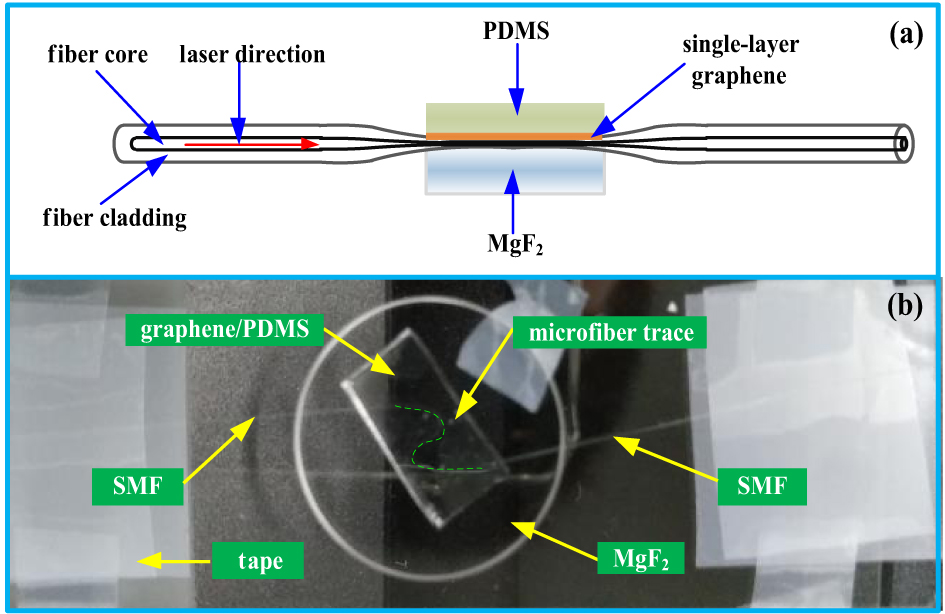

Using graphene-covered-microfiber (GCM) as a saturable absorber, the generation and evolution of multiple operation states are proposed and demonstrated in passively mode-locked thulium-doped fiber laser. The microfiber was fabricated using the flame brushing method to an interaction length of ∼ 1.2 cm with a waist diameter of ∼ 10 μm. Graphene layers were grown on copper foils by chemical vapor deposition and transferred onto the polydimethylsiloxane (PDMS) to form a PDMS/graphene film, which allowed light-graphene interaction via evanescent field. With the increase of the pump power from 1.25 W to 2.15 W, five different lasing regimes, including continuous-wave, conventional soliton mode-locking, multi-soliton mode-locking, a period of transition, and noise-like mode-locking, were achieved in a fiber ring cavity. To the best of our knowledge, it is the first report of the generation and evolution of multiple operation states by covering graphene on the microfiber in the 2-μm region. The results demonstrate that GCM can be a promising method for fabricating all fiber SA, and the switchable operation states can provide more portability in complex application domain.

Thulium-doped fiber lasers (TDFLs), owing to their wide applications in remote sensing, optical communication, laser medical system, and gas sensing, have attracted considerable interest.[1] At present, passively mode-locked TDFLs incorporating an artificial or real saturable absorber (SA) have been primarily used as novel laser sources.[2–11] Among these mode-locking techniques, nonlinear polarization rotation (NPR)[2] and nonlinear amplification loop mirror (NALM)[3] mode-locking have the characteristic of a high damage threshold but are extremely sensitive to environmental fluctuations. Usually, such drawbacks are not desirable in applications of medical treatment and scientific research. Recently, graphene,[4–7] carbon nanotubes (CNTs),[8] transition metal dichalcogenides (TMDs),[9] topological insulators (TIs),[10] and black phosphorus[11] are being considered as a kind of potential SA for passively mode-locked TDFL. Among them, graphene has become the focus of attention from many researchers because of its many features including low saturable absorption threshold, controlled modulation depth, ultrafast recovery time (100 fs–200 fs), wide spectrum range (300 nm–2500 nm), and easy integration with optical system, which make it stand out in all kinds of mode-locking materials.

Up to now, the use of graphene as an SA has been demonstrated in passively mode-locked TDFL.[4–7,12–20] The structure of SA is fabricated using two common methods, i.e., by coupling graphene films[4–7,12–14] and nanomaterial[20] on the fiber ferrules of the connector to form an SA of the sandwich structure, or by using the evanescent field occurring on the waist of the microfiber[15,16] or side-polish fiber[17–19] to interact with the graphene. The SA of sandwich structure has its limitations, such as low thermal damage threshold, weak optical absorption, and high insertion loss, which make it unsuitable in a complex natural environment. By contrast, only a small part of the light is required to interact with graphene covered on the microfiber or side-polish fiber. Thus, this structure has many advantages of fast cooling speed, high damage threshold, and compact all-fiber structure in applications of high power fiber lasers. Meanwhile, there are some drawbacks for the use of side-polished fiber-based graphene saturable absorber (GSA), such as difficulties in obtaining a perfect smooth surface. Compared with the side-polished fiber, the microfiber has a simple fabrication process and good symmetry structure by using the mature flame brushing technique. Although the applications of integrated microfiber and graphene as an SA have been reported to generate mode-locking pulses in the fiber laser, most of these works have focused on short-wavelength regions[21–23] and fiber optic sensors.[24] Thus the study of microfiber-based GSA in the 2-μm mode-locked fibers is still very limited[15,16] and the operation states of output pulses are relatively monotonous in the cavity.

In this paper, we report a passively mode-locked TDFL based on a graphene-covered-microfiber (GCM), which is fabricated by combining polydimethylsiloxane (PDMS)-supported monolayer graphene film and microfiber. By increasing the pump power from 1.25 W to 2.15 W, TDFLs obtain different operation states including continuous-wave (CW), conventional soliton mode-locking (CSML), multi-soliton mode-locking (MSML), a period of transition, and noise-like mode-locking (NLML). All-fiber structure of GCM device allows power scalability with the potential of high power mode-locking operation. Then the operation of switchable fiber lasers can provide more portability in a wide range of applications.

A commercial fiber taper system (SCS-4000) and flame brushing technique are used to fabricate the microfiber, as shown in Fig.

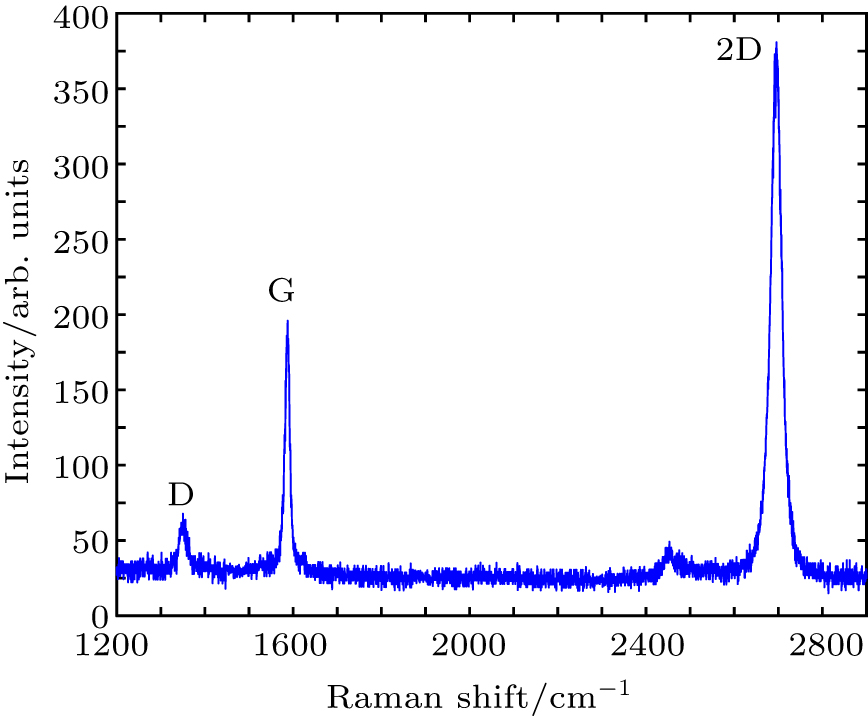

The graphene film used in the TDFL was directly grown by chemical vapor deposition (CVD) method on a copper substrate. Figure

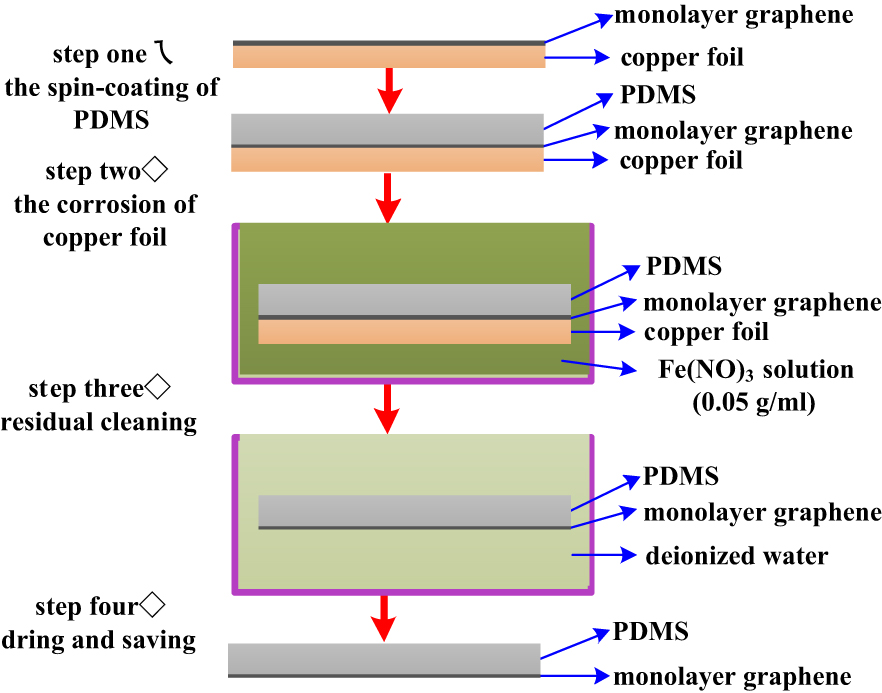

In order to reduce the contamination, a wetting transfer method was applied to transfer the monolayer graphene with a size of 1 cm × 0.5 cm from the copper substrate to PDMS film (∼ 1-mm thickness). The specific transfer process is shown in Fig.

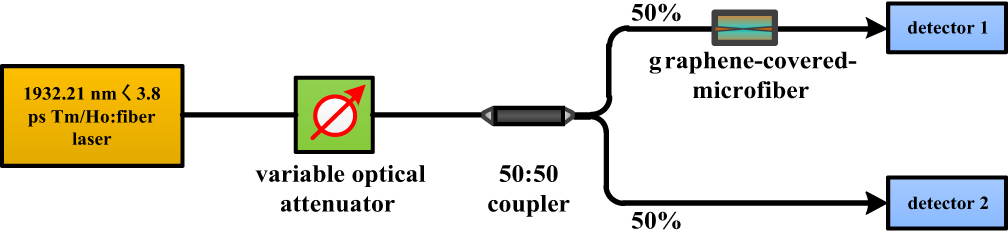

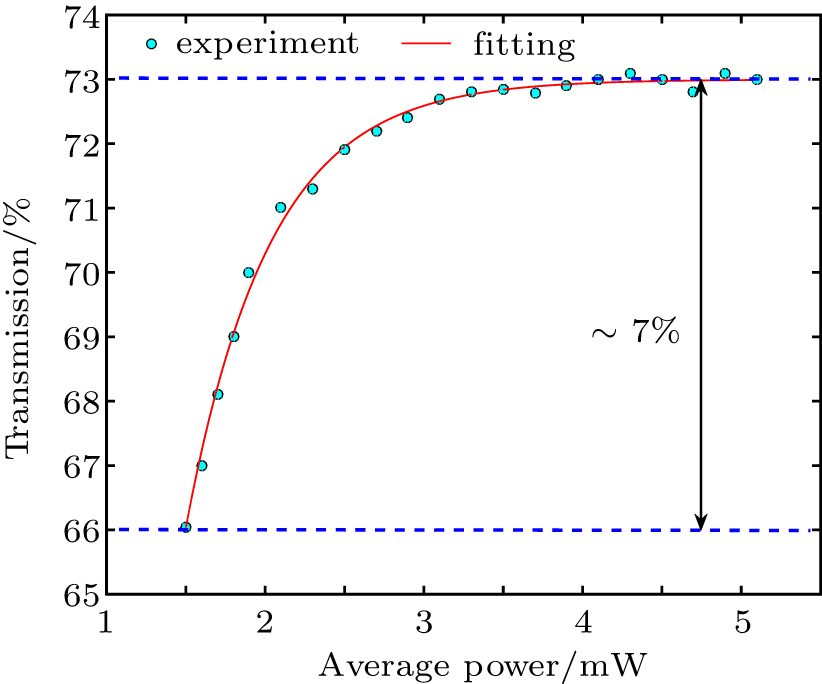

Figure

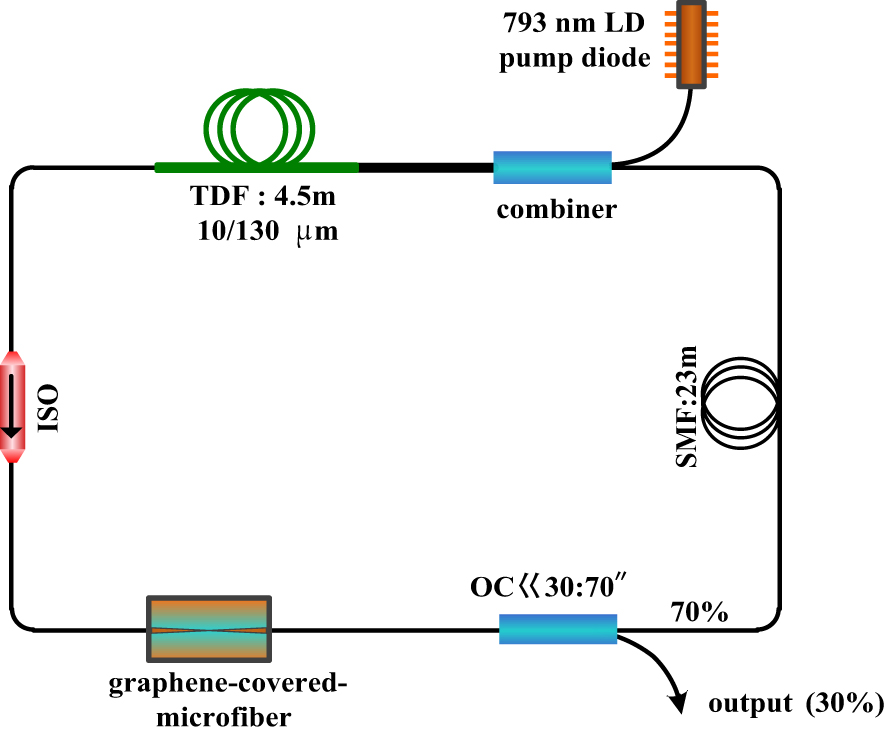

The experimental setup of the TDFL is sketched in Fig.

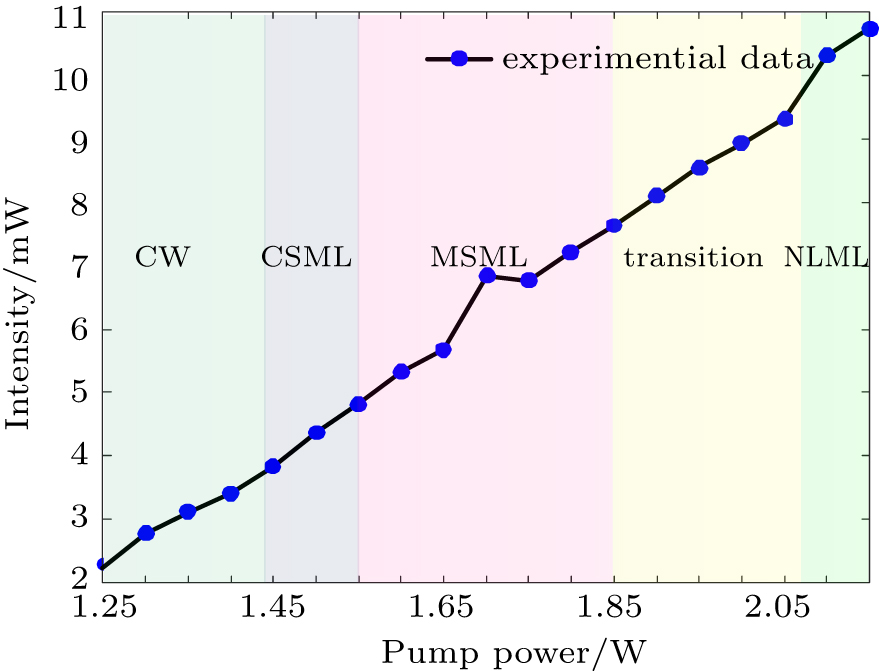

First of all, we demonstrate the output characteristic of the TDFL without incorporating the graphene/PDMS film. By adjusting the pump power in a wide range, the laser can only work in CW state, which excludes the possibility of self-mode-locking and the mode-locking of nonlinear effect in the cavity. Then, a small sample of graphene (1 cm × 0.5 cm), which is cut from graphene/PDMS film, is covered on the waist of the microfiber. As the pump power increases from 1.25 W to 2.15 W, TDFL can be operated in five different lasing regimes around the threshold. These operating regimes include CW (1.25 W–1.44 W), CSML (1.44 W–1.55 W), MSML (1.55 W–1.85 W), a period of transition (1.85 W–2.02 W), and NLML (2.02 W–2.15 W). Each pulsed regime corresponding to a given pump power span is depicted in Fig.

| Fig. 8. (color online) Average output power as a function of the pump power (different colors represent different operating regimes). |

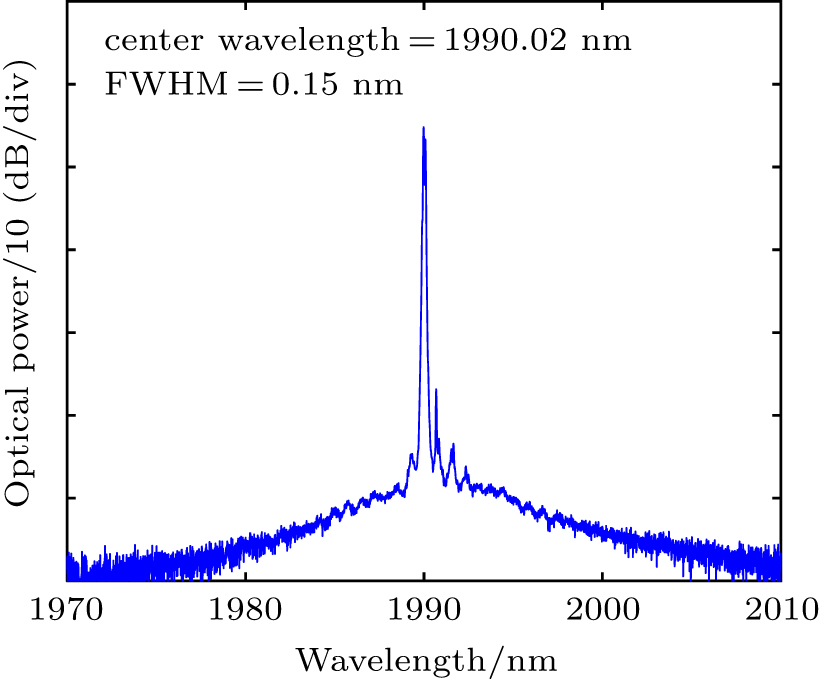

In the experiment, the fiber laser starts to operate in the CW state when the pump power is fixed at 1.25 W. The optical spectrum generated by the seed is shown in Fig.

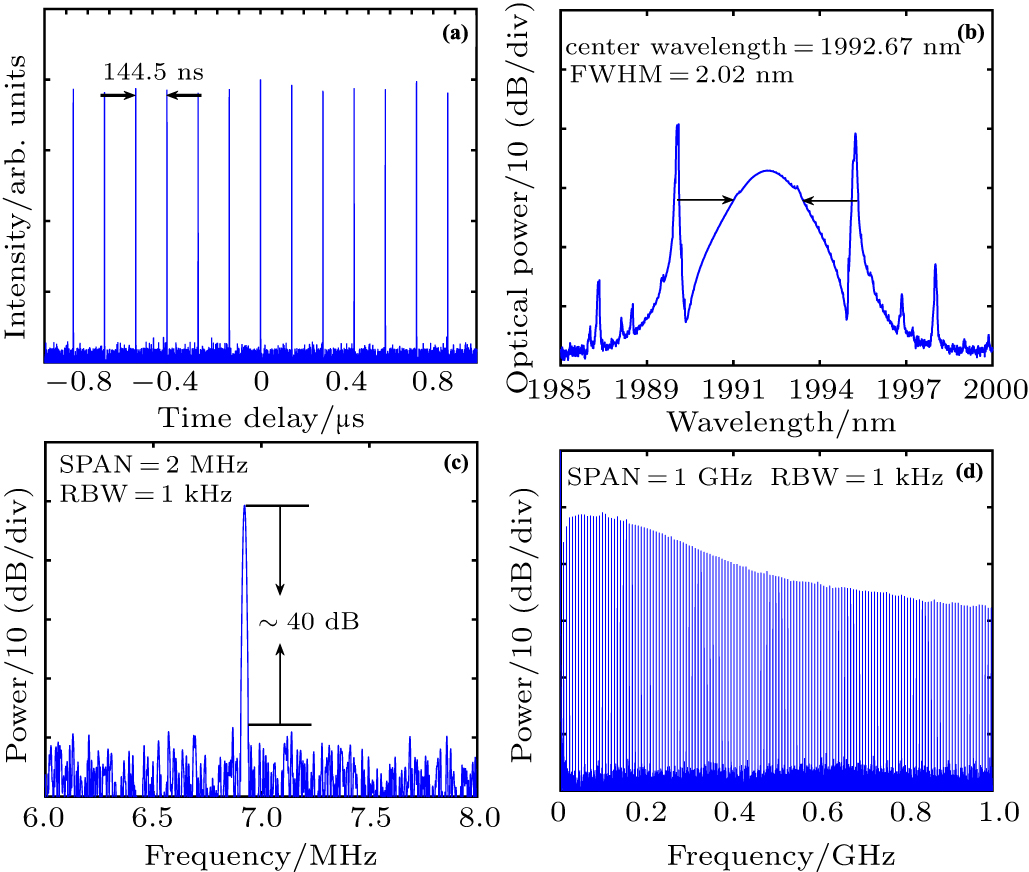

The self-starting CSML operation is achieved at the pumping power of 1.45 W when the pump power continues to increase. To optimize the mode-locked operation, the best performance is observed at a pump power of 1.50 W. Figure

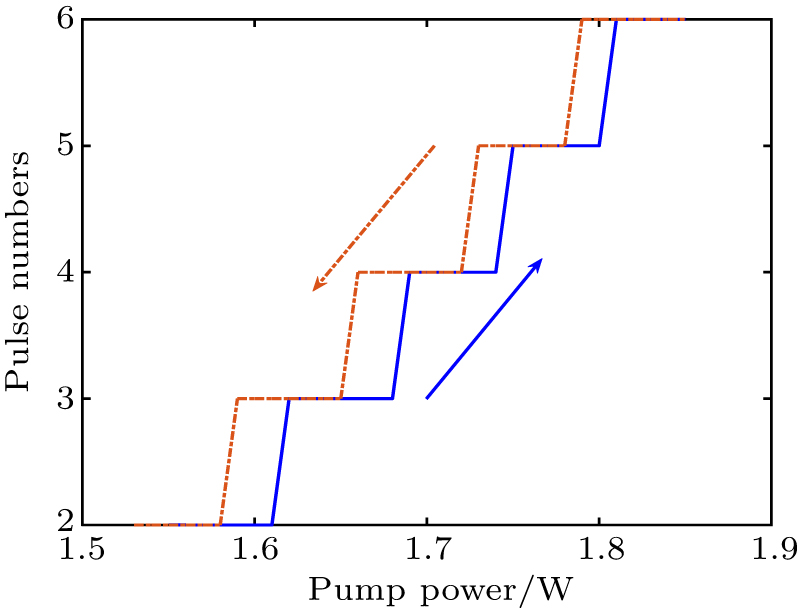

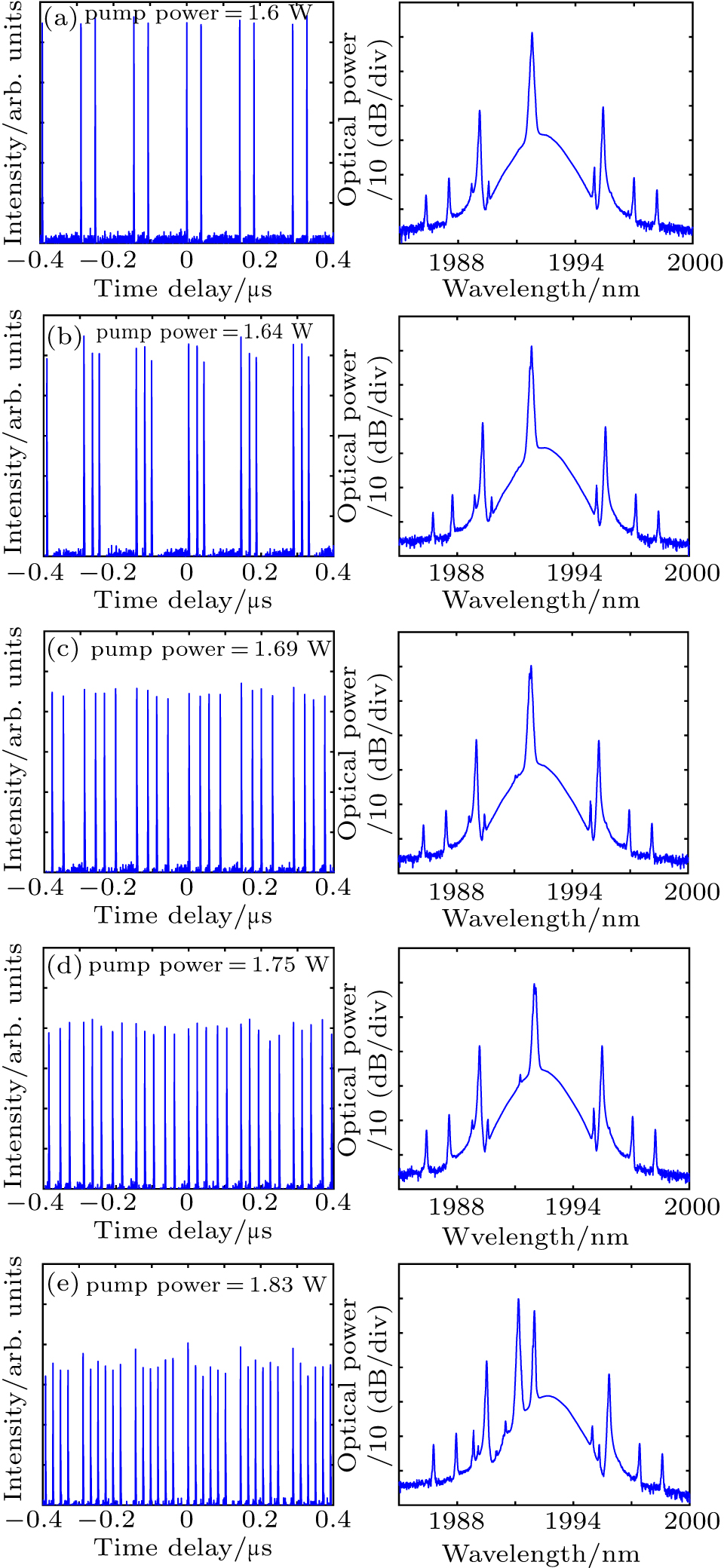

When the pump power exceeds 1.55 W, the stable CSML state is broken and the laser turns into the MSML state. In contrast to CSML, the MSML have two or more pulse sequences, but the period of the round-trip is constant. As the pumping increases from 1.55 W to 1.85 W, the operation states of 2 to 6 soliton pulses are obtained, under a pump power of 1.60 W, 1.64 W, 1.69 W, 1.75 W, and 1.83 W, respectively, as depicted in Fig.

| Fig. 11. (color online) The characteristics of mode-locked TDFL: (a)–(e) pulse sequences under different conditions of the pump power (left) and the corresponding optical spectrum (right). |

In addition, mode-locking operation is still maintained by slightly decreasing the pump power to a relatively low value, generally known as pump hysteresis. For the MSML operation, the generation and annihilation of new soliton pulses also show the pump hysteresis, as shown in Fig.

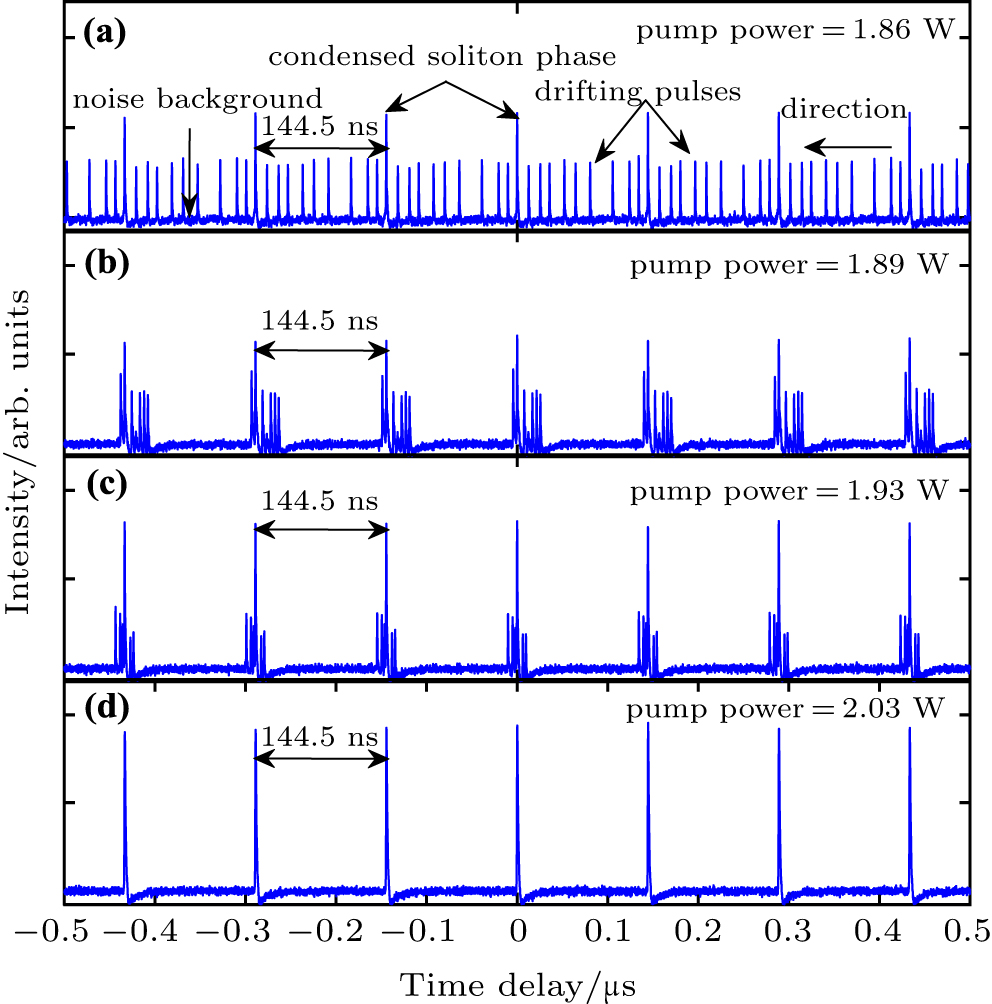

Under the 6-solitons mode-locked operation, the pump power is further increased to 1.86 W. An interesting phenomenon, namely the soliton rain consisting of noise background, drifting pulses, and condensed soliton phase, has been observed, as shown in Fig.

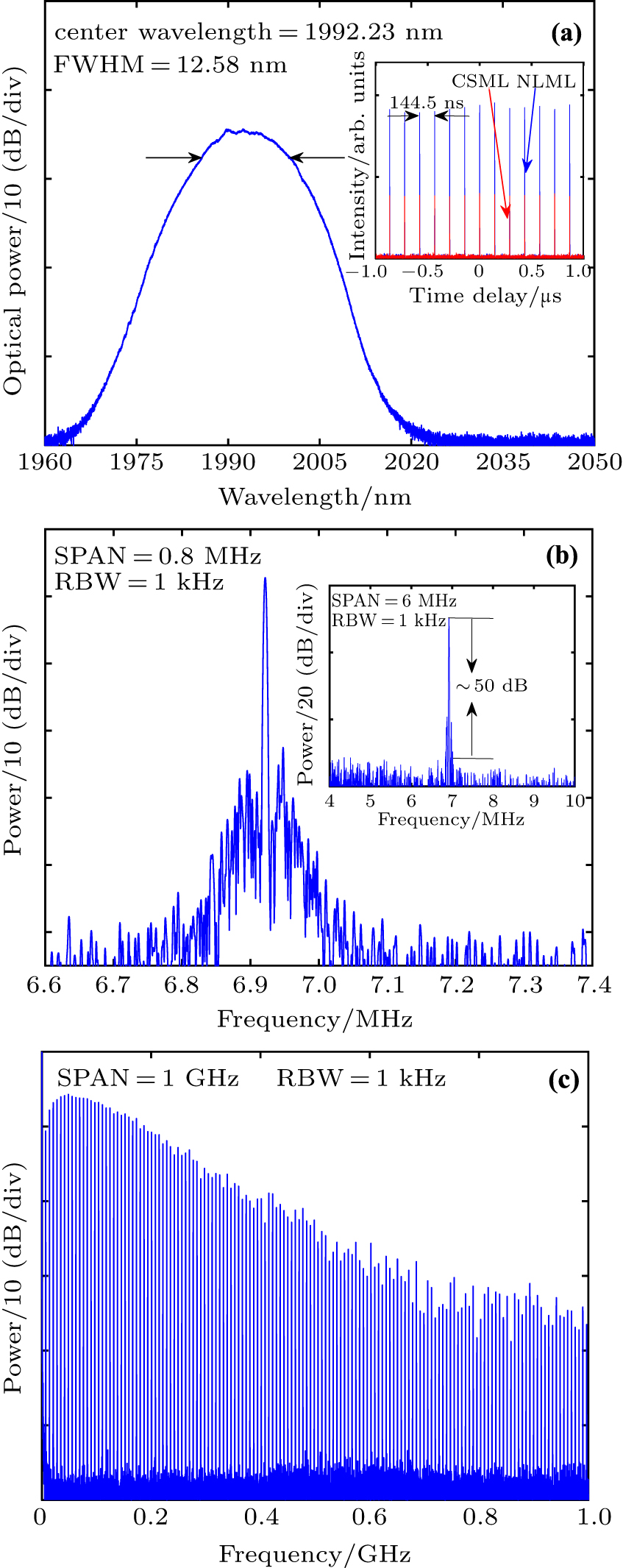

In order to illustrate the difference between CSML and NLML, figure

In this paper, by covering a graphene/PDMS film on the microfiber as an SA, an all-fiber thulium-doped fiber system with five different output characteristics that can be adjusted by increasing the pump power is presented. Firstly, the laser operates in the CW state and soon enters CSML as the pump power increases. When the pump power exceeds 1.55 W, the laser is converted from CSML pulse to MSML pulse with the same energy in the steady state. This phenomenon can be found in all kinds of mode-locked lasers, such as NALM mode-locked laser, NPR mode-locked laser, and other real SA mode-locked laser. That is, it is a common feature of the laser and has nothing to do with mode-locking. The generation of MSML pulses can be attributed to the peak power clamping effect.[34] In general, the soliton energy is related to the cavity structure of the laser. Under the constant cavity parameters, the maximum energy contained by the soliton will be determined. If the SA effect in the cavity is strong enough, increasing the pump power will only cause the formation of MSML pulses at a certain threshold. At the same time, due to the soliton energy quantization effect,[30,31,35,36] the weak soliton pulse becomes stronger by the positive feedback, and the strong soliton behaves oppositely and is weakened. In the end, all pulses reach a steady state with the same peak power.

Meanwhile, the pump hysteresis effect is also found in the process of the MSML. In the past reports,[37,38] Komarov et al.[38] have made an intensive study on the pump hysteresis of passively mode-locked fiber lasers. According to their research, the pump hysteresis stems from the competition between the positive feedback from the nonlinear transmittance of the SA and the negative feedback related to the modulation effect of the pulsed phase modulation. And the generation and annihilation of solitons must go through a continuous increase or decrease of the pump power, which is consistent with our experiment. In addition, there is obvious jitter in switching between adjacent pulses of multi-soliton mode-locking in the experiment. It is necessary to increase or decrease a certain amount of power to stabilize the current state. Hence, when drawing the graph of hysteresis, the switching between adjacent pulses of multi-soliton mode-locking is based on the current stable value. When the pump power is between 1.85 W and 2.02 W, the output pulse shows the evolution of soliton rain to NLML. Compared with CSML, higher pulse energy, larger FWHM, smooth spectrum, and obvious fluctuation of wideband RF are important characteristics of laser operation in a NLML regime.[32,33]

In summary, we have demonstrated an all-fiberized TDFL by using a GCM in the 2-μm region. With the increase of the pump power, phenomena of multiple operation states, mainly including CW, CSML and MSML, a period of transition and NLML, are obtained in the experiment. To the best of our knowledge, this is the first successful application of GCM SA in multiple operation states operating at 2-μm region. This work suggests that the GCM SA is potentially useful for mode-locked pulse laser operations in the eye-safe region. And the operation switchable characteristic can provide a new way to deal with increasingly complex application requirements.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] |