† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 11274188)

A new achromatic phase retarder based on a metal-multilayer dielectric grating structure is designed using the rigorous coupled wave analysis method and the genetic algorithm. The optimized phase retarder can maintain phase retardation around 90° from 900 nm to 1200 nm, and the maximum deviation is less than 4.5% while the diffraction efficiencies of TE and TM waves are both higher than 95%. Numerical analysis shows the designed phase retarder has a high fabrication tolerance of groove depth, duty cycle and incident angle. This achromatic phase retarder is simple in design and stable in performance, and can be widely used in optical systems.

The phase retarder is one of the most common elements in an optical system, which can be divided into the quarter-wave plate, the half-wave plate and the full-wave plate. Conventional phase retarders usually use birefringent material,[1] multilayer dielectric film[2] and liquid crystal.[3] Traditional phase retarders generally can be used only at a specific wavelength, since the phase retardation strongly depends on the wavelength. However, achromatic phase retarders greatly reduce the wavelength dependence of phase retardation, which can realize the modulation of polarized light in a wide spectrum. In recent years, the resonant regime of achromatic phase retarders has attracted more attention, where the grating period is close to the incidence wavelength. Kikuta et al.[4] first achieved an achromatic quarter-wave plate by utilizing the dispersion of effective refractive indices theoretically. According to this method, Nordin and Deguzman[5,6] realized an element functioning as an achromatic quarter-wave plate in mid-infrared wavelength. Bokor et al.[7] designed an achromatic quarter-wave plate from 470 nm to 630 nm. Yi[8] designed a sub-wavelength grating achromatic phase retarder on fused silica at 400–800 nm visible light. Kang et al.[9] proposed a combination of four sub-wavelength structured gratings used as an achromatic quarter-wave plate, which was applied to MWIR (

In this paper, an achromatic phase retarder based on the metal-multilayer grating (MMDG)[11–14] is designed. The designed phase retarder can be used at wavelengths ranging from 900 nm to 1200 nm, where its retardation can maintain about 90° ± 4°, while the diffraction efficiencies of TE and TM waves are higher than 95%. Furthermore, the performance modulation of the grating parameters on the phase retardation is analyzed.

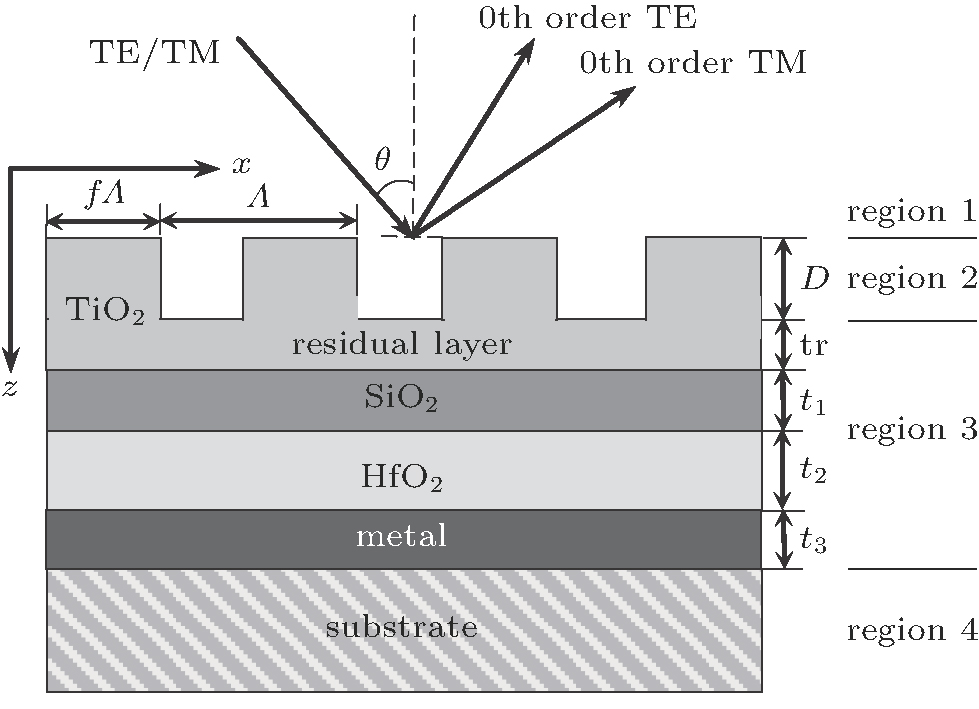

As shown in Fig.

| Fig. 1. Schematic diagram of the metal-multilayer dielectric grating used as an achromatic phase retarder with surface-relief, double-layer dielectric and metal-layer gratings. |

Given that the wavelength of incident light is comparable to the grating period, the designed phase retarder reflects the TE and TM waves in the 0th order, thus the scalar analysis is no longer applicable. Therefore, the rigorous coupled wave analysis (RCWA) method does not hold true for calculating the diffraction efficiency of the MMDG structure.[15] The RCWA method enables the exact solution of the system of Maxwell equations built by the electromagnetic field from a grating.[16,17] With the enhanced transmission method to improve the traditional coupled wave analysis, the numerical instability problem encountered in the process of calculating the etched grating is well solved.[18,19]

As depicted in Fig.

|

|

|

Then the phases of TE and TM waves are obtained with the diffraction amplitude coefficient as follows:

|

Thus, the phase retardation of TE and TM waves is obtained as follows:

|

Here, a certain layer below the surface relief structure was not etched in the fabrication process. The residual layer was regarded as a waveguide exerting significant influence on diffraction efficiency.[20] Therefore, TiO2 (n = 2.3) was chosen as the surface relief and residual layer material because of its high refractive index over a broad bandwidth. Meanwhile, the substrate was made of fused silica.

As can be seen in Fig.

With the metal layer made of Ag, the number of dielectric layers in the MMDG is reduced to only two, meanwhile providing a high reflection efficiency.[22] The MMDG structure also presents a high laser-induced damage threshold over a broad wavelength.[23] Moreover, the fabricated MMDG can efficiently separate the incident waves through polarization. Due to the sub-wavelength structure of the MMDG and the different boundary conditions of the electromagnetic wave, the TE and TM waves exhibit phase displacement while propagating in the MMDG. This observation implies that the TE and TM waves are separated during MMDG modulation.

In order to obtain a smaller deviation of phase retardation as well as higher diffraction efficiency by optimizing MMDG parameters, here a merit function (MF) is defined as

|

In this design, a genetic algorithm (GA)[24] is used to optimize the parameters of the given MMDG structure. To obtain the optimal structure of the achromatic phase retarder, parameters such as {D, f, Λ, θ, tr, t1, t2,

We optimize the given structure by using the merit function over the range of 900–1200 nm. The corresponding parameters of the designed phase retarder are listed in Table

| Table 1.

Optimized parameters of the MMDG. . |

According to the parameters in Table

| Fig. 2. (color online) Designed MMDG characteristics spectrum with TE and TM waves, showing wavelength-dependent (a) phase retardation and (b) diffraction efficiency. |

The phase retardation and diffraction efficiency calculated by RCWA are shown in Fig.

The fabricated grating normally has a minor difference from the designed structure because of the complexity of the production. It is especially necessary that the fabrication deviation should not substantively influence the characteristics of the grating. Thus, favorable fabrication tolerance is extraordinarily necessary for grating fabrication.[25] To show how the deviation of groove depth, duty cycle and incident angle affect phase retardation intuitively, the three-dimensional graphs of the phase retardation with TE and TM waves in the 0th order are depicted in Fig.

| Fig. 3. (color online) Dependence of fabrication tolerance on (a) groove depth, (b) duty cycle, (c) incident angle in a wavelength range of 900–1200 nm. |

Figure

Figure

| Fig. 4. (color online) Effects of deviation of (a) groove depth, (b) duty cycle, and (c) incident angle on phase retardations of TE and TM waves. |

According to the current fabrication techniques, controlling the grating groove depth is very difficult, where the error is usually controlled at

Figure

Furthermore, when the device is employed, the installation deviation will cause the incident angle to deviate from 30° to the grating surface (

As can be seen in Fig.

According to the previous analysis, the considerable fabrication tolerance has provided a perfect guarantee for the grating fabrication and fine characteristics in an optical system.

In this paper, a new achromatic phase retarder based on MMDG is designed theoretically by RCWA and optimized by GA. Numerical results show that the designed phase retarder at 900–1200 nm exhibits high reflected diffraction efficiency and a small deviation of phase retardation, with diffraction efficiency higher than 95% for TE and TM waves in the 0th order over 300 nm bandwidth, while phase retardation deviation is less than 4°. Fabrication deviation analysis indicates that the designed MMDG has favorable tolerance and can be easily fabricated. The results suggest that the optimized MMDG has potential applications as the phase retarder in optical fibers, laser systems and optical elements.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] |