† Corresponding author. E-mail:

Project supported by the Ministry of Education and Science of Russian Federation (State Task No. 3.1283.2017/4.6).

Commercially pure polycrystalline aluminum of grade A85, as a test material, is investigated. Using scanning and transmission electron microscopy the aluminum fine structure and fracture surface are analyzed. Fractures are studied in the regime of creep with and without a simultaneous effect of 0.3-T magnetic field. It is found that the application of a magnetic field in a linear stage of creep leads to substructure imperfection increasing. Furthermore, the magnetic field effect on aluminum in the process of creep causes the average scalar density of dislocations to increase and induces the process of dislocation loop formation to strengthen. Fractographic investigation of the fracture surface shows that in the fibrous fracture zone the average size of plastic fracture pits decreases more than twice under creep in the condition of external magnetic field compared with in the conventional experimental condition. In a shear zone, the magnetic field causes the average size of fracture pits to decrease. Experimental data obtained in the research allow us to conclude that the magnetic field effect on aluminum in the process of creep leads to the fracture toughness value of the material decreasing, which will affect the state of defect substructure of the volume and surface layer of the material. The influence of the magnetic field is analyzed on the basis of the magneto-plasticity effect.

Intensive development of engineering and modern technologies leads to the production of powerful energy devices generating magnetic and electric fields. As the majority of structures and mechanisms working in the condition of mechanical loads (e.g. creep) are subjected to fracture, the study of metal behavior in the conditions of an external energy effect is necessary for analyzing their service lives.[1–7]

In the last decade a lot of investigations were carried out and indicated that even a weak magnetic field (1 T) is able to change substantially the kinetic process, integral strength, and plastic characteristics of the solid body subjected to deformation.[8–12] It is conventional to relate the nature of this phenomenon to the spin conversion in impurity centers, which results in their electron structure transformation and corresponding decrease in their interaction with dislocations.[13,14] It facilitates the dislocation displacement (it plastifies the material) reducing the deformation properties relating to the mean path between obstacles.

Unfortunately, the investigations devoted to establishing the magnetic field effect on the process of plastic deformation of polycrystalline metals are insufficient. For understanding the physical nature of metal fracture under creep conditions in a magnetic field, it is necessary to conduct a complex investigation including the studies of dislocation substructure evolution at different degrees of deformation and relief of fracture surface, which are to be studied in this paper.

Commercially pure polycrystalline aluminum A85 was chosen as a test material. The samples had the shape of plates with a size of 150×5×0.46 mm. Preliminary preparation of the initial structure consisted in recrystallization annealing at 770 K for 2 hours. Then at room temperature the samples were subjected to creep with constant tensile stress δ = 65 MPa up to fracture (

The structures of samples were studied by transmission electron diffraction microscopy, where the foils in transmitted light were prepared from the volume of the material located in the central part of the sample (at

The substructures formed in aluminum under creep (

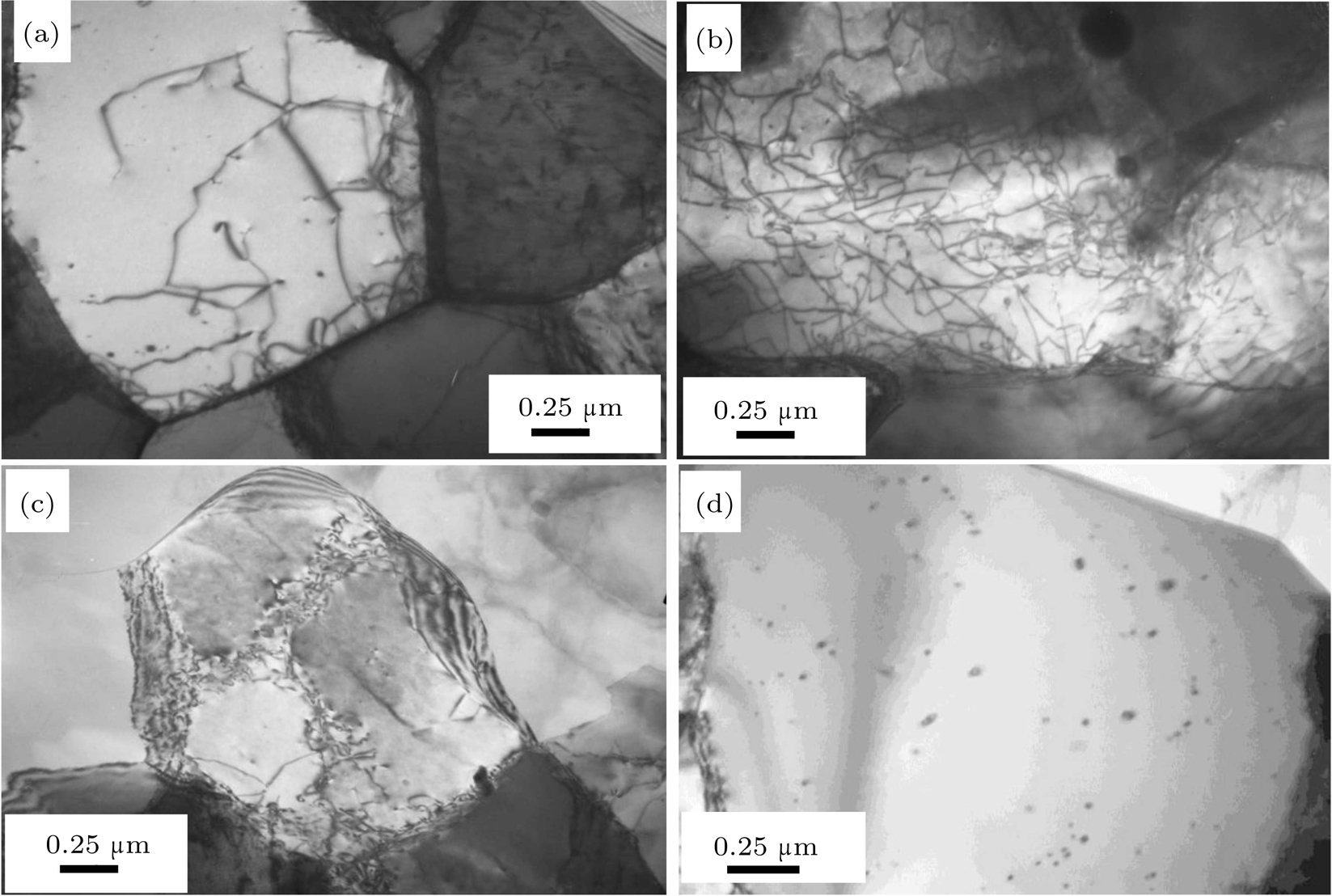

In the volume of cell-blocks, different dislocation substructures are revealed: chaotic, net-like, cellular structure, and dislocation loops as shown in Figs.

| Fig. 1. Types of dislocation substructures formed in aluminum under creep: chaotic (a); net-like (b); cellular one (c); dislocation loops (d). |

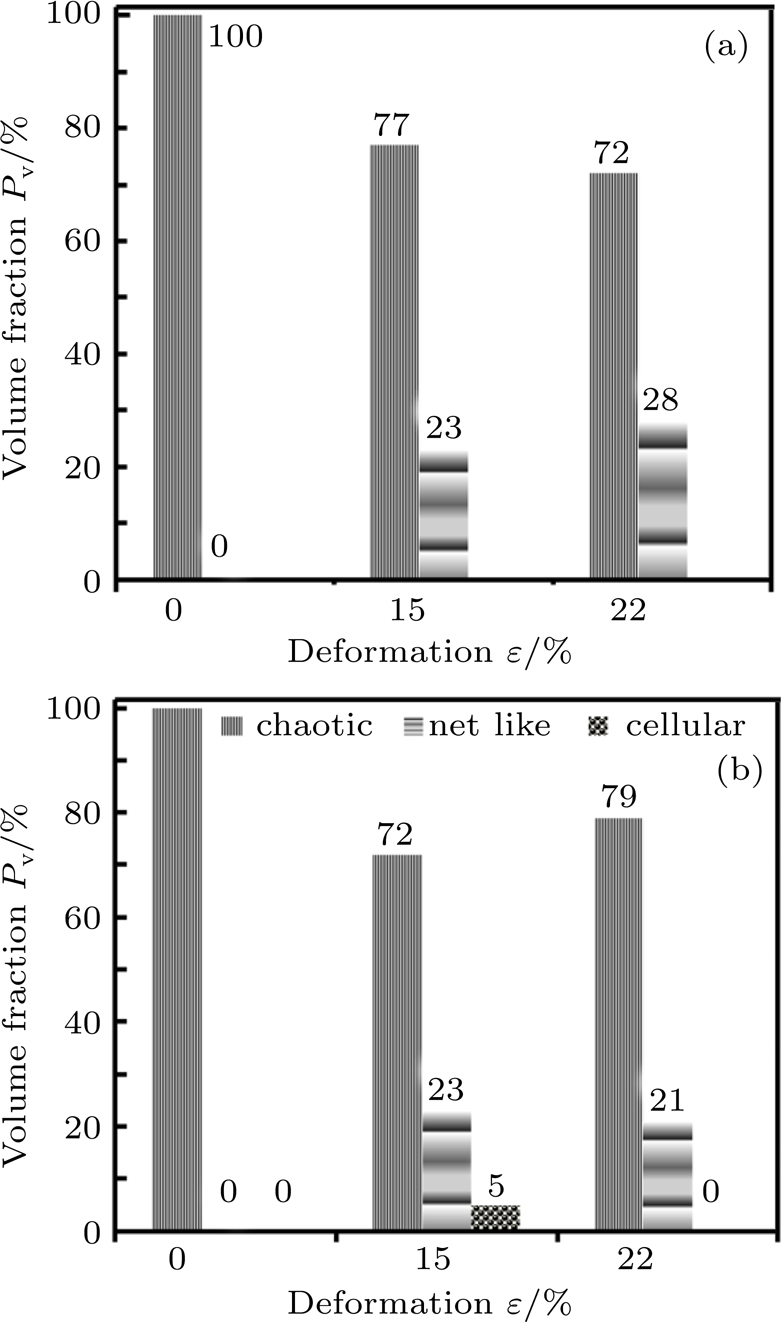

Scalar dislocation density and volume fraction of substructure type are used as the parameters characterizing the dislocation substructure. The results of quantitative analysis of dislocation substructure are shown in Figs.

| Fig. 2. Distributions of volume fraction of dislocation substructure types depending on value of deformation without magnetic field (a) and with B = 0.3 T (b). |

| Fig. 3. (color online) Variations of average scalar dislocation density (a) and dislocation loops (b) with deformation without magnetic field and with B = 0.3 T. |

When analyzing the results shown in Figs.

In the volume of the material adjacent to the fracture zone the chaotic, net-like and cellular dislocation structures and dislocation loops are revealed. The main dislocation structure is a chaotic one, which is independent of the magnetic field effect (Fig.

Studies of fracture zone structure (

Accordingly, the external magnetic field results in the intensification of the process of vacancies and interstitial atoms formation under creep of aluminum. The dislocation loops and dislocations in the material at their sufficiently high density can increase the material strength.

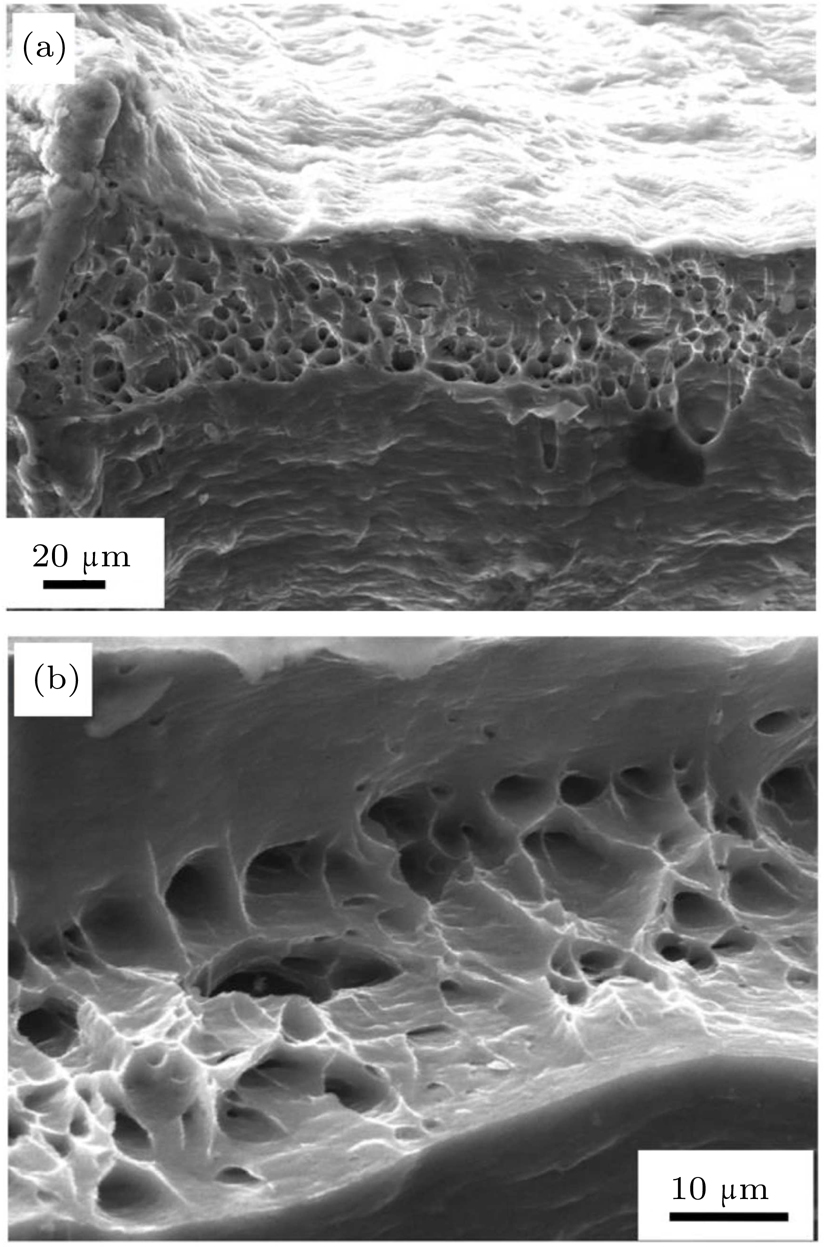

Macroscopic view of the fracture surface of an aluminum flat sample fractured in tension in conditions of creep is shown in Fig.

| Fig. 4. Fractographs of fracture surfaces. Creep in the usual condition (without magnetic field) (a) and with an external magnetic field (b). |

Typical fractographs for tested samples demonstrating fracture pits are shown in Fig.

The test shows that pit growth occurs by slipping gliding of the material along many active systems. Consequently, regardless of the creep testing procedure the aluminum fracture surface are plastic ones with high density of slip bands and deep pits are indicative of the high local plasticity of the material.

Deformation of aluminum in the condition of creep results in the formation of the fracture surface with a wide range of sizes of plastic fracture pits (Fig.

Shear zones in the studied samples also contain plastic fracture pits (shear pits) (Fig.

The shape and pit depth (micropores) may be related to fracture toughness under the condition of one material testing and an identical scheme of loading. Deep conical pits are often observed in fractures of very ductile materials.[15] It is believed that the increase in crack resistance is accompanied by the increase in pit depth at the fracture surface. If the pit depth of plastic fracture is assumed to be proportional to pit size then it can be concluded that the use of an external magnetic field facilitates some decrease of the fracture toughness of aluminum in the condition of creep.

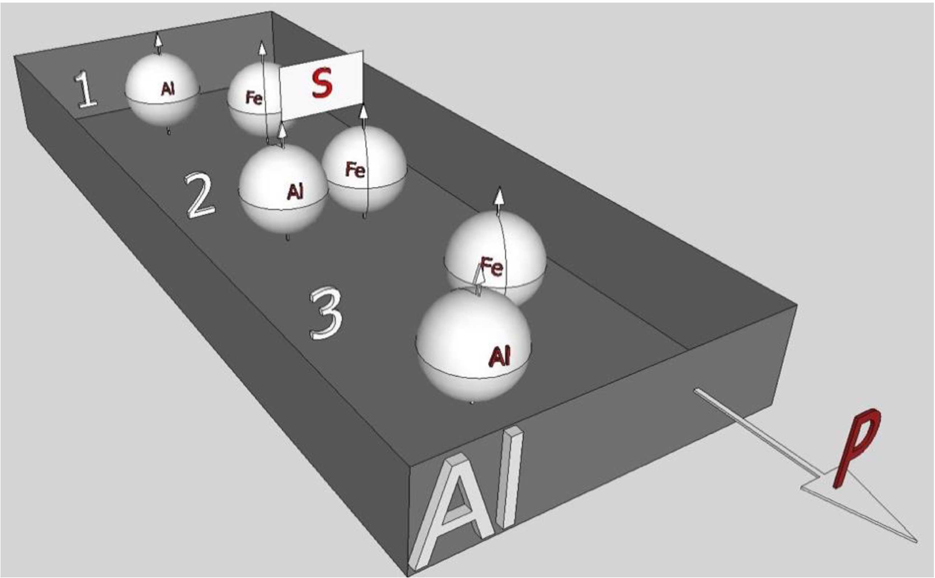

Now, we consider the behavior of metallic material atoms in an external magnetic field.

Aluminum is a paramagnetic material, a substance, whose magnetic moment is not equal to zero, possessing paramagnetic properties. The valence electron shell of an aluminum atom consists of three electrons but the shell itself has the form 3s23p. Therefore, it is paramagnetic and the magnetic moment of its atom is not equal to zero. The admixture in aluminum A 85 contains an iron content of 0.22% of mass fraction. Iron, in turn, is ferromagnetic and has eight valence electrons: 4s2 and 3d6.

In the process of plastic deformation, there occur continuous interactions of dislocations with each other and also with point defects that may be para- or ferro-magnetic interstitial and substitutional atoms, which are iron atoms in our case.

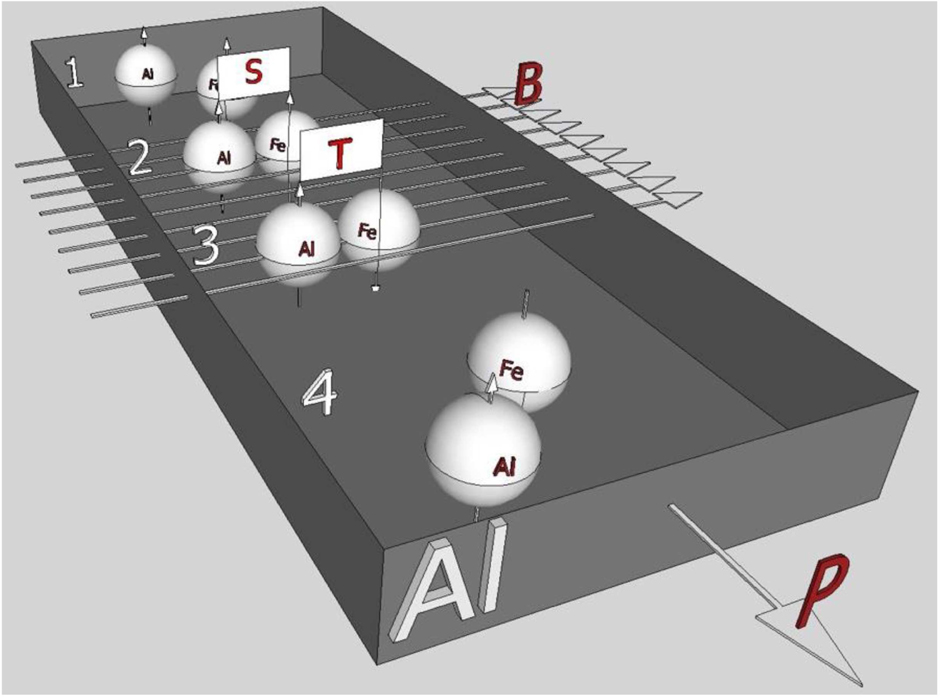

If the interaction of dislocation of paramagnetic material with ferromagnetic impurities and other dislocation is assumed to not only have the elastic characteristic but also be accompanied by the formation and breakage of a covalent bond between them, then it may be noted that the interaction of dislocation is an additional factor of dislocation retardation because additional energy is necessary for breaking the covalent bond (Fig.

| Fig. 6. (color online) Interactions of aluminum atoms with iron atoms in the process of plastic deformation without magnetic field. |

The formation of a covalent bond between one atom belonging to dislocation and ferromagnetic impurity defect or atom of other dislocation is possible because both aluminum and iron atoms have electrons with unpaired spin.[8,16] Thus, the process of plastic deformation is accompanied by chemical reactions that are repeated many times.

We come to consider the running of the plastic deformation process in time in the absence of a magnetic field. Figure

| Fig. 7. (color online) Interactions of aluminum atoms with iron atoms in the process of plastic deformation under the action of magnetic field. |

From the above discussion it may be concluded that a magnetic field has an indirect effect on the process of plastic deformation. It may be supposed that the magnetic field, when affecting the covalent bond, transforms a radical pair from the singlet state to a triplet one, which makes its breakage easier because the energy necessary for breakage of a radical pair in a singlet stage is larger than in a triplet one (Fig.

The studies of commercially pure aluminum show that in the presence of a magnetic field a larger accumulation of scalar density of dislocations takes place. It allows us to study the microstructure of dislocation chaos and the developing process of dislocation loop formation. Investigations of the fracture zone show that in the presence of a magnetic field the intensification of the dislocation loop formation process happens, assisting in material strength increase. By scanning electron microscopy it is observed that in the presence of a magnetic field the fracture surface (with pits of plastic fracture) formed has a smaller average size than in the ordinary conditions of the experiment. From these results it can be concluded that the magnetic field leads to some decrease in fracture toughness of commercially pure aluminum under the deformation in creep condition, which can affect the state of defect substructure volume and the surface layer of the material. A magnetic field has an indirect effect on the process of plastic deformation. It may be supposed that a magnetic field, when affecting the covalent bond, transforms a radical pair from the singlet state to the triplet one, and thus makes its breakage easier because the energy necessary for breaking the radical pair in a singlet stage is larger than in a triplet one.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] |