† Corresponding author. E-mail:

We investigated the steady state gamma-ray radiation response of pure-silica-core photonic crystal fibers (PSC-PCFs) under an accumulated dose of 500 Gy and a dose rate of 2.38 Gy/min. The radiation-induced attenuation (RIA) spectra in the near-infrared region from 800 nm to 1700 nm were obtained. We find that the RIA at 1550 nm is related with hydroxyl (OH−) absorption defects in addition to the identified self-trapped hole (STH) defects. Moreover, it is proposed and demonstrated that reduced OH− absorption defects can decrease the RIA at 1550 nm. The RIA at 1550 nm has effectively declined from 27.7 dB/km to 3.0 dB/km through fabrication improvement. Preliminary explanations based on the unique fabrication processes were given to interpret the RIA characteristics of PSC-PCFs. The results show that the PSC-PCFs, which offer great advantages over conventional fibers, are promising and applicable to fiber sensors in harsh environments.

Photonic crystal fibers (PCFs) offer several distinct advantages compared with the conventional fibers and have been widely used in fiber sensors.[1–3] Two different types of PCFs are commercialized: solid-core PCF and air-core PCF. The application of air-core PCFs is still limited by the reliability, the splicing with other fibers, high costs, and high transmission loss.[4,5] Compared to air-core PCFs, solid-core PCFs are easier to handle and exhibit lower attenuation.[6] Furthermore, most solid-core PCFs are made with pure silica, which is known to be radiation-hardened under gamma-ray radiation. Thus, the pure-silica-core photonic crystal fibers (PSC-PCFs) are possible candidates for sensors in radioactive environments, such as the spaceborne fiber optic gyroscope. However, previous research on the steady-state gammaray radiation responses of PSC-PCFs showed complex results. Girard et al. found that the radiation induced attenuation (RIA) at 1550 nm of PSC-PCF is much higher than that of the conventional pure-silica-core fiber with fluorine-doped cladding.[7] Kosolapov et al. found that the RIA of PSC-PCF is very close to that of pure-silica-core fiber from 400 nm to 900 nm.[8,9] In an earlier study, we found that the PSC-PCF shows significantly higher RIA at 1310 nm and its recovery is slower than that of germanium-doped single mode fiber.[10] Theoretically, the PSC-PCF should be radiation-hardened. However, the practical high RIA makes it unsuitable for harsh environments. The steady-state gamma-ray radiation responses in the near-infrared part of the spectrum, which covers the common operating wavelength in communication and fiber sensors, should be further studied and decreased.

In this paper, we focus on the near-infrared region in the RIA spectrum of PSC-PCF after a steady state gamma-ray radiation with a total dose of 500 Gy and a dose rate of 2.38 Gy/min. We decomposed the RIA spectrum based on the Gaussian model and the defects that have been identified in the literature. It is found that the RIA at 1550 nm is related with not only the identified self-trapped hole (STH) defects but also hydroxyl (OH−) absorption defects. After that, we proposed fabrication improvement to reduce the RIA at 1550 nm based on the reduction of OH− absorption defects. The RIA at 1550 nm is decreased effectively from 27.7 dB/km to 3.0 dB/km. The experiment results demonstrate the contributions of OH− absorption defects to RIA. Preliminary explanations based on the unique fabrication technology are given to interpret the RIA characteristics of the PSC-PCF samples. The results show that the PSC-PCFs are promising for fiber sensors in harsh environments.

The tested fiber samples were fabricated using the stack-and-draw process by FiberHome Telecommunication Technologies CO., Ltd. Figure

| Table 1.

Tested PSC-PCF samples. . |

The experiment setup for measuring the RIA spectrum is shown in Fig.

Two experiments were conducted to investigate the radiation characteristics of the PSC-PCFs. In the first experiment, we irradiated Sample-1 using a 60Co gamma radiation source with a cumulative dose of about 500 Gy and a dose rate of 2.38 Gy/min at room temperature. After irradiation, the tested PSC-PCF sample was annealed at room temperature for a few days until most of the unstable defects were annealed and transformed. Then, we obtained the RIA spectrum of Sample-1. We observed that the RIA spectrum is related with OH− absorption defects to some extent. It is expected that reduced OH− absorption defects could lessen the RIA at 1550 nm. Thus, Sample-3, Sample-4, and Sample-5 were fabricated with different improved processes to remove the residual OH− groups and contaminations in preform bundles. The details are illustrated in Table

At the end of the first experiment, Sample-1 did not exhibit the anticipated lower RIA at 1550 nm than that of the conventional germanium-doped fiber for its pure-silica core and cladding. For example, the RIA at 1550 nm of a germanium-doped fiber without phosphorus in the cladding reaches 4 dB/km.[7] However, Sample-1 showed a significantly high RIA of 28.1 dB/km at 1550 nm. Figure

| Fig. 3. (color online) Measured spectral attenuation of PSC-PCF Sample-1 before (black line) and after irradiation (red line). |

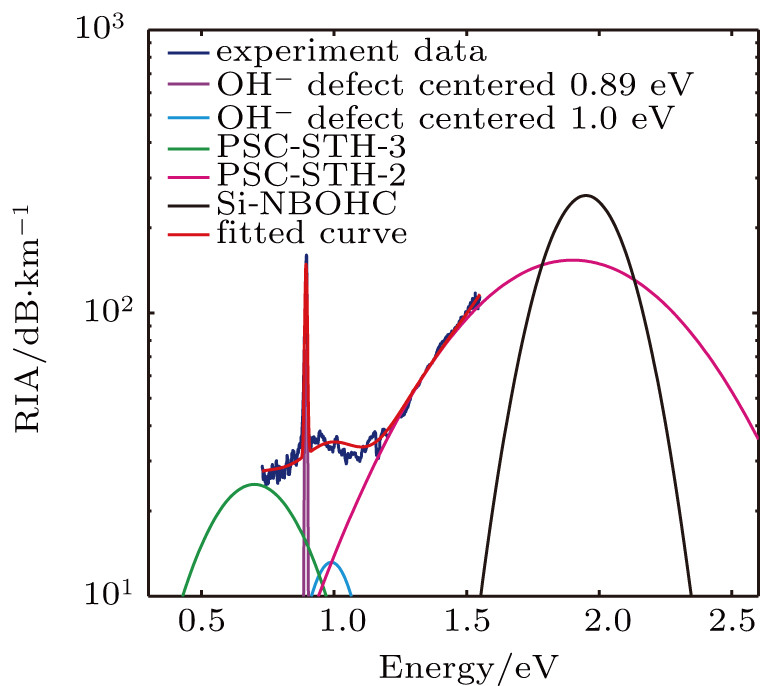

In order to get more information on the defects in the fibers, we fitted the RIA spectrum with Gaussian functions, which are widely assumed for defects absorption in fibers.[12] The fitting formula is shown as

The values of

| Table 2.

Main parameters of Si-related color centers in the literature. . |

The RIA spectrum of Sample-1 is decomposed into three parts including the STH defects, OH− absorption defects, and Si-NBOHC as Fig.

The rest samples in Table

| Table 3.

Measured RIA of the PSC-PCF samples. . |

Figure

| Fig. 6. (color online) Measured spectral attenuation of PSC-PCF Sample-5 before (black line) and after irradiation (red line). |

The Gaussian decomposition result of Sample-5 is shown in Fig.

The RIA spectra of all the four PSC-PCF samples are decomposed using the same method mentioned above. The color center decomposition results are displayed in Table

| Table 4.

Decomposition of the RIA@1550 nm. . |

The significantly higher RIA of Sample-1 in comparison with that of a germanium-doped fiber makes it unsuitable for application in harsh environments. However, the high RIA can be reduced by improving fabrication processes from our results. Here, we present a preliminary explanation of the RIA characteristics in the experiments based on the unique stack-and-draw fabrication processes of the PSC-PCFs. In the fabrication, tens of capillaries and rods form large amounts of silica–air and silica–silica interfaces in preform bundles. Certain defect precursors could be generated at interfaces. Based on this assumption, two hypotheses were proposed to explain the RIA characteristics of PSC-PCFs.

The RIA of PSC-PCF at 1550 nm is mainly attributed to the STH absorption defects from our results. Chernov et al. showed that this kind of defect is stable at low temperature 77 K and unstable at 300 K. Moreover, this absorption was found to be strongly dependent upon the technology of the preform manufacturing and drawing conditions.[13] Kyoto et al. and Henschel et al. interpreted the STH color centers as a change in vibration modes as a result of gamma-ray radiation induced structural defects, which is long-lived.[14,15] Considering the fiber samples in Ref. [13] is only 4 m in length, the fact that we still observe STH defects at room temperature (about 300 K) is probably owing to our high sensitivity by using fiber samples of 200 m in length. From our experiment results, the RIA at 1550 nm drops drastically from 27.7 dB/km to 3.0 dB/km after fabrication improvement. The contributions of OH− absorption defects take up about 8% (about 2.2 dB/km) of the whole RIA at 1550 nm in Sample-2. Most of the RIA reduction results from the decrease of the absorption intensity of STH defects. Thus, the absorption intensity of STH defects is related with fabrication processes, especially the treatment to the raw material, which is consistent with the results in Ref. [13]. Yamaguchi et al. showed that the STH defects are related to the effect of structural disorder.[16] Structural disorder could be induced at interfaces due to the large surface tension during the drawing process. Such STH defects may result from not only special fiber materials but also the interfaces between core and cladding. Many more silica–air and silica–silica interfaces exist in the unique stack-and-draw fabrication processes of PSC-PCFs, which may yield a higher degree of structural disorder or more defect precursors than that of conventional fibers. Thus, the STHs play a dominant role in the RIA of PSC-PCFs at 1550 nm. The density of STHs is also related with the fictive temperature of glass.[16,17] It seems possible to further decrease its contribution by optimizing the drawing parameters. In the next stage, we will investigate such drawing parameters in order to further reduce the PSC-PCF radiation sensitivity.

As is shown in Fig.

We have investigated the steady state gamma-radiation responses of PSC-PCFs in the near-infrared wavelength. The results reveal the dominant role of STH defects in the RIA at 1550 nm. Moreover, we found that OH− absorption defects have contributions to the RIA spectrum. The contribution of OH− absorption defects to RIA at 1550 nm is negligible after fabrication improvement and the RIA at 1550 nm has declined evidently from 27.7 dB/km to 3.0 dB/km. The level of radiation resistance achieved is superior to most commercial Ge-doped single-mode fibers[7,19,20] and conventional PSC fibers[11] at 1550 nm under similar conditions, to the best of our knowledge. Our study provides an explanation of the RIA characteristic of PSC-PCFs based on the unique stack and draw fabrication process, which produces STH absorption defects and the OH− absorption defects. The generation efficiency of defects is also affected by other parameters of the material, fictive temperature for example. It is possible to further decrease their contributions and consequently to fabricate more radiation-hardened PSC-PCFs. Considering the remarkable properties of PSC-PCFs such as low bending loss, design flexibility, and high birefringence with a lower sensitivity to temperature, they are good candidates for future fiber sensors in harsh environments.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] |