† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 60906022), the Natural Science Foundation of Tianjin, China (Grant No. 10JCYBJC01100), the Key Science and Technology Support Program of Tianjin, China (Grant No. 14ZCZDGX00006), and the National High Technology Research and Development Program of China (Grant No. 2013AA014201).

We chose pentacene as a hole injection layer (HIL) to fabricate the high performance blue fluorescent organic lightemitting devices (OLEDs). We found that the carrier mobility of the pentacene thin films could be efficiently improved after a critical annealing at temperature 120 °C. Then we performed the tests of scanning electron microscopy, atomic force microscopy, and Kelvin probe to explore the effect of annealing on the pentacene films. The pentacene film exhibited a more crystalline form with better continuities and smoothness after annealing. The optimal device with 120 °C annealed pentacene film and n-doped electron transport layer (ETL) presents a low turn-on voltage of 2.6 V and a highest luminance of 134800 cd/m2 at 12 V, which are reduced by 26% and improved by 50% compared with those of the control device.

The organic light-emitting diodes (OLEDs) have now been accepted as a dream display owing to their attractive features such as high display quality, slim body, flexibility, low power consumption, and so on.[1–4] Improving their electroluminescent (EL) performance is a primary goal in the development of technological applications. Since OLEDs can potentially be used in portable and wearable electronic devices, the researchers are also interested in the low driving voltage devices based on the point of view of energy saving. Hence, lots of studies have focused on thin films treatments and the exploitation of organic materials for low driving voltage and high luminance.[5–7] Currently, several methods for reducing the driving voltage of OLEDs have been reported. Introducing a p-type or n-type doping structure in the charge transport layer is the most commonly used method.[8–10] However, the co-evaporation process is complicated, and the minor doping ratio is inaccurate to control. It is worth mentioning that inserting an injection layer between the electrode and the organic layer is easy and effective.[11–13]

It is well known that an effective injection layer requires appropriate energy level matching and high carrier mobility.[14] As a p-type material, pentacene is one of the most promising organic semiconductors due to its high mobility and stability, which has been widely used in organic field effect transistors (OFETs).[15,16] Furthermore, some works on OLEDs comprising pentacene thin films have also been reported previously. Shi et al.[17] reduced the hole injection by introducing pentacene thin films to balance the recombination of electrons and holes, which improved the efficiency of the OLEDs. We hope that a pentacene thin film can function as an effective hole injection layer (HIL) in OLED with high carrier injection ability to improve the performance of the OLED. By investigation, the carrier mobility of the pentacene thin film can be improved through thermal annealing in OFETs.[15,18]

In this work, we introduce this method to the OLEDs and reveal that relatively high annealing temperature could induce pentacene to develop into high crystallinity films with highly-ordered, large-sized, and smooth shape. As an HIL in OLEDs, the annealed pentacene film will be used to improve the hole injection ability at a low driving voltage. Simultaneously, the n-doped electron transport layer (ETL) will also be adopted to balance the hole–electron pairs in the emission layer (EML), which results in high luminance and low driving voltage for OLEDs.

The cleaning of the ITO glass substrate with a sheet resistance of 20 Ω/sq is subsequently performed with detergent, deionized water, acetone, and isopropanol in an ultra-sonic bath for 10 min each. After drying, the surface of ITO is treated under UV/O3 for 15 min. All organic films are deposited on a pre-cleaned ITO glass substrate using a thermal evaporation of BOC Edwards Auto 500 thermal evaporation system in an M. Braun 20 G glove box with a deposition rate of 2 nm/min, and an in-situ quartz crystal is used to monitor the thickness of the vacuum depositions. Figure

The thermal annealing tests were carried out in a vacuum oven (VC 20, M. BRAUN). The samples were kept for 1 h at different temperatures (such as 100 °C, 120 °C, and 150 °C). The OLED performance measurements were carried out using a Keithley 2400 source and a PR650 scan spectrometer in a glove box. We characterized the surface morphology and crystallinity of the deposited pentacene films by using atomic force microscopy (AFM, Bruker Innova), scanning electron microscopy (SEM, Rigaku D/max 2500), and x-ray diffraction (XRD, Hitachi SU8010). The energy levels were measured by a Kelvin probe (KP020).

The EL characteristics of the pentacene-based OLEDs with different annealing temperatures were investigated. The structures of different devices are listed as follows:

A: ITO/NPB (40 nm)/ADN:DNCA (30 nm, 6 wt.%)/Bphen (20 nm)/LiF (0.8 nm)/Al (120 nm); B: ITO/pentacene (5 nm)/NPB (40 nm)/ADN:DNCA (30 nm, 6 wt.%)/Bphen (20 nm)/LiF (0.8 nm)/Al (120 nm); the structures of devices C, D, and E are the same as that of device B (pentacene without annealing), except for the pentacene films annealed at different temperatures at 100 °C, 120 °C, and 150 °C.

From Fig.

Here we explored the morphology, roughness, work function of the pentacene films through a series of tests. Figure

| Fig. 3. SEM images showing the morphology of the pentacene films: (a) without annealing sample, (b) 100 °C annealed sample, (c) 120 °C annealed sample, (d) 150 °C annealed sample. |

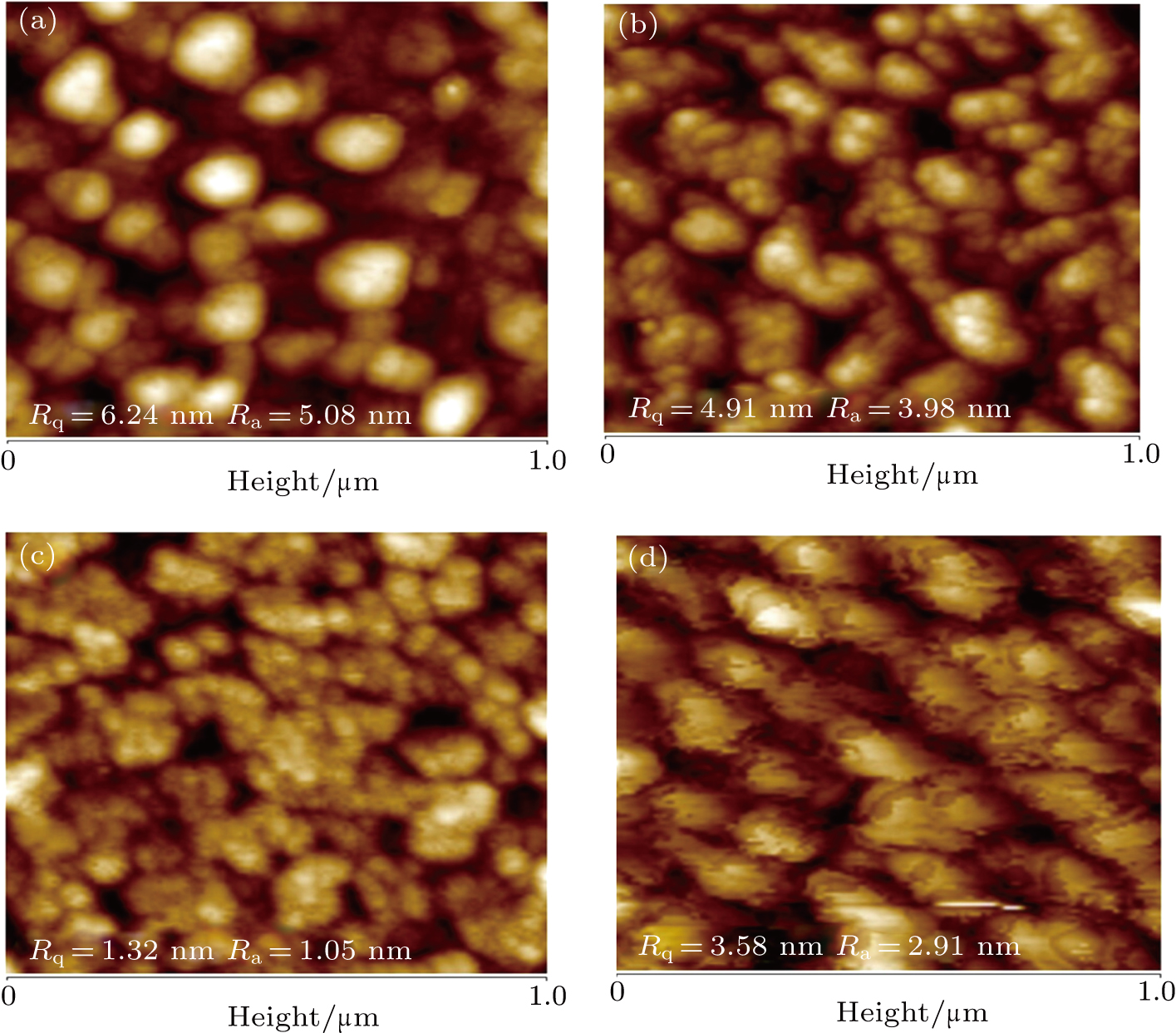

Figure

| Fig. 4. (color online) AFM images (1 μm×1 μm) of 5 nm pentacene thin films on ITO/glass: (a) before and (b)–(d) after annealing (100 °C, 120 °C, and 150 °C). |

To confirm the formation of the crystallinity for the pentacene film and the improvement of the hole injection ability, further exploration is provided through the measurements of XRD and Kelvin probe. Figure

| Fig. 5. (color online) XRD patterns of the pentacene films on sapphire substrate before and after annealing (100 °C, 120 °C, and 150 °C). The thickness of the pentacene film is 50 nm. |

The intensity of the (001) diffraction peak from the thin-film phase of the non-annealed pentacene film is relatively low. When the annealing temperature reaches 120 °C, the intensity of the (001) peak becomes markedly stronger, and a series of (00k) peaks related to the crystalline structure of pentacene are observed. It can be attributed to the fact that some adjacent pentacene grains join together via a recrystallization process under the annealing of 120 °C. Furthermore, 120 °C annealing also facilitates the pentacene molecules to form the bulk phase which is corresponding to the (001′) peak at 6.18°.[19] The bulk phase of pentacene indicates that the adhesion between pentacene and ITO is improved.[21–23] Thus the pentacene film forms a crystalline shape, which optimizes the interface contact between ITO and pentacene molecules. Meanwhile the defects in the pentacene grains could be repaired under appropriate thermal annealing. With the temperature increasing to 150 °C, the intensities of the (00k) peaks are significantly reduced, which indicates that the crystalline structure of pentacene has been damaged.

Figure

Moreover, the carrier mobility of the pentacene films annealed at different temperature was measured by organic field effect transistors. The inset of Fig.

The current density of device D has been improved markedly based on the enhancement of the hole injection ability. However, the brightness of device D is not improved obviously as expected. As is known, the total current density of OLEDs is equal to the current density of the injected electrons from the cathode plus the part of the hole current density flowing to the anode without recombination.[24–26] The injected electrons from the cathode into the EML can be considered as the same due to the equal electrons injection barrier for these devices. However, the current density of device D is higher than that of device B, which results from excessive holes disrupting the balance of recombination. That is to say, excessive holes accumulated in the EML induce exciton quenching. The fraction of hole current density reaching the counter electrode without recombination in device D is higher than that of device B. The unbalanced number of electrons and holes injected into the EML would affect the efficiency and luminance of the devices. To improve the performance of the OLED, the electron injection and transport ability should be enhanced. So we introduced an n-doping ETL in the OLED to enhance the electron transport ability, and further discussed the effect of charge balance.

To prove the above theory, we fabricated another group of OLEDs named devices 1–5. The only difference compared to the previous devices is that we replaced the Bphen (20 nm) by Bphen (10 nm)/Bphen:Mg (10 wt.%, 10 nm). As shown in Fig.

| Fig. 8. (color online) The EL characteristics of devices 1–5: (a) current density–luminance–voltage characteristics, (b) current efficiency–power efficiency–current density characteristics. |

Table

| Table 1.

The EL performances of the OLEDs. . |

We use a simple approach to effectively improve the EL performance of the blue fluorescent organic light-emitting device by introducing the annealed pentacene film as the hole injection layer. The pentacene film can form a highly-ordered, large-sized and smooth lamellar shape after a critical annealing at temperature 120 °C, which could induce the pentacene molecules to develop into a high crystallinity film and improve the hole transport ability of the devices. Furthermore, combined with an n-doped ETL, the electron transport ability has been enhanced so as to improve the charge balance in the EML, which results in a high luminance and a low driving voltage of OLEDs. The optimal OLED (device 4) exhibits a low turn-on voltage of 2.6 V and a driving voltage of 5.1 V at 1000 cd/m2, which are obviously reduced by 0.9 V and 1.4 V respectively compared with those of the control device. Meanwhile, this device also presents a very high luminance of 134800 cd/m2 at 12 V, which is 1.5 times higher than that of the control device. These results indicate that this simple and effective approach may fulfill the requirements of OLED with low driving voltage and high luminance.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] |