† Corresponding author. E-mail:

The relationship between the photometric, electric, and thermal parameters of light-emitting diodes (LEDs) is important for optimizing the LED illumination design. Indium gallium aluminium phosphide (InGaAlP)-based thin-film surface-mounted device (SMD) LEDs have attracted wide attention in research and development due to their portability and miniaturization. We report the optical characterization of InGaAlP thin-film SMD LED mounted on FR4, 2 W, and 5 W aluminum (Al) packages. The optical and thermal parameters of LED are determined at different injection currents and ambient temperatures by combining the T3ster (thermal transient tester) and TeraLED (thermal and radiometric characterization of power LEDs) systems. Analysis shows that LED on a 5 W Al substrate package obtains the highest luminous and optical efficiency.

Indium gallium aluminium phosphide (InGaAlP) light-emitting diodes (LEDs) are devices of high efficiency and long-wavelength region of the visible spectrum, which will play a vital role in various solid-state lighting applications.[1] Thin-film LEDs offer high light extraction efficiency due to the existence of a dielectric coated metal reflector between the active region and the substrate. Hence, this will help to avoid the absorption of emitted light from the active region by the substrate.[2] Following the miniaturization development in microelectronics, surface-mounted device (SMD) LEDs have been employed in today’s technology. Currently, InGaAlP thin-film SMD LEDs are the material of choice in research and development due to their portability and miniature size.[3] Their advantages comprise low power consumption, less heat production, a wide viewing angle, long lifespan, and capability of producing saturated colors with high luminous efficiency.[4] The luminous efficiency is a significant parameter for evaluating the light source.[5] The LED junction temperature depends on the heat source such as current and temperature.[6,7] The luminous efficiency of the light emission drops with the increase in the LED junction temperature.[8–12] The photometric, electric, and thermal parameters of the LED device are dependent on each other.[13] To obtain higher efficiency and light output, the LED chip temperature needs to diminish.[14] Dissipation of the heat generated from the chip to the ambience is the key to reducing the junction temperature. The heat produced in the LED chip should be transferred efficiently to the board and then to the atmosphere to cool the LED system. A good design of the board is one of the solutions to dissipate the heat. A dielectric material in the metal-core printed circuit board (MCPCB) with higher thermal conductivity can improve the thermal characterization and the optical performance of the LED package. Not much work has been found in the literature on evaluating the optical performance of InGaAlP thin-film low power LEDs. Therefore, it is important to investigate the optical performance of the InGaAlP Thinfilm low power LED.

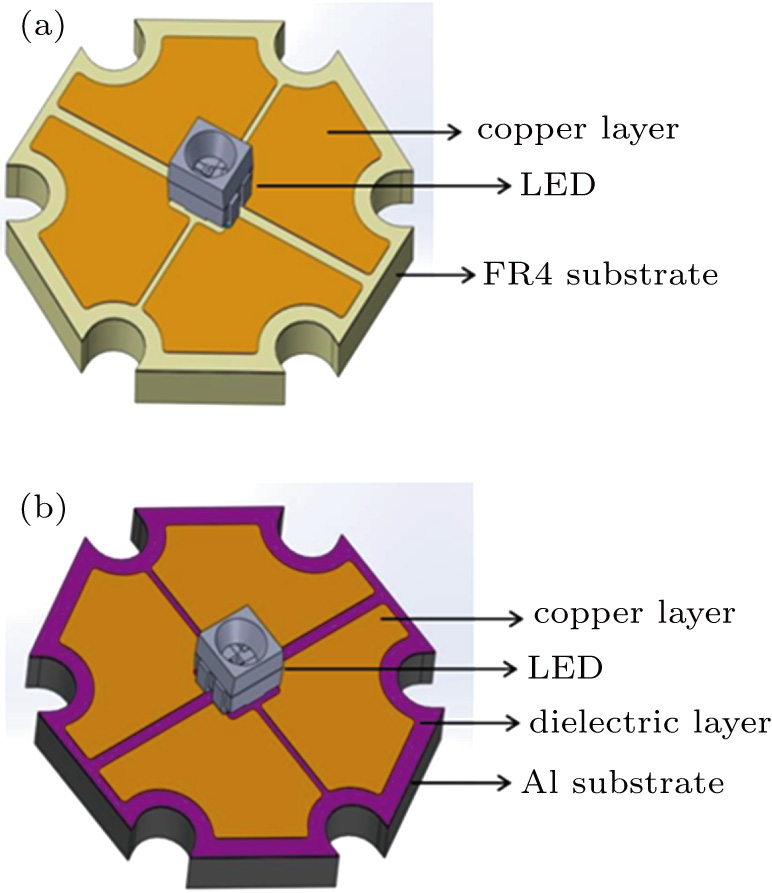

In this study, we present the optical characterizations of InGaAlP thin-film SMD LED mounted on different substrate packages. The substrate packages are FR4 and two types of Al substrate packages with thickness of 1.6 ±0.16 mm. Thermal conductivities of dielectric layers in Al packages are 2 and 5 W/m

LED of amber color and power 0.1855 W was used in this work (LA E67F, Osram Opto Semiconductors). This LED can handle more than its maximum ratings of forward current and ambient temperature (indicated in the manufacturer’s website).[15] The characteristics of the LED under test are demonstrated in Table

| Table 1.

Characteristics of the LED under test. . |

Before the measurements, the LED was attached to the substrates which were FR4 and two Al substrate packages (Fig.

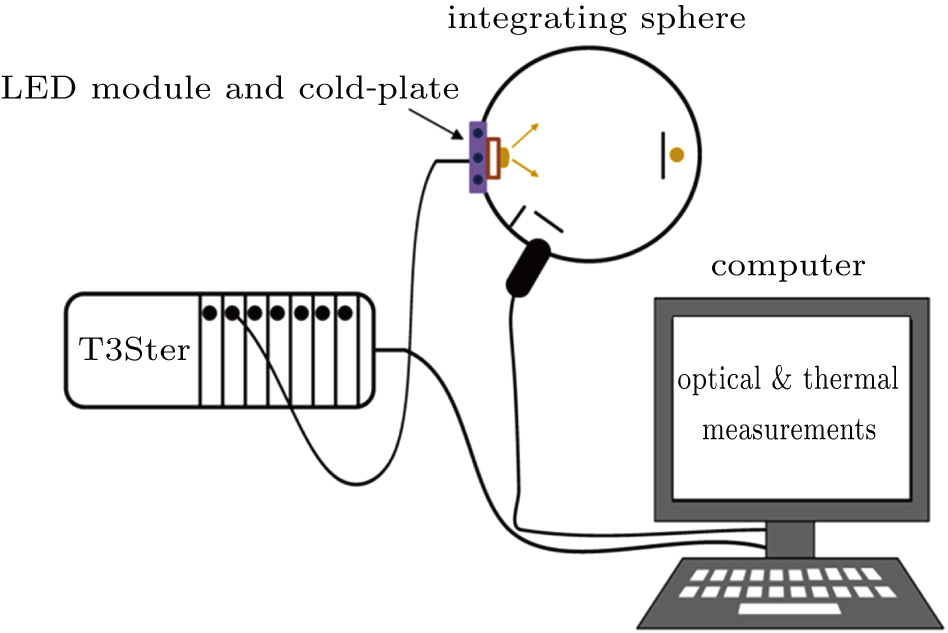

| Fig. 2. (color online) Experimental setup of optical and thermal measurements.[18] |

| Table 2.

Materials data and experiment boundary conditions. . |

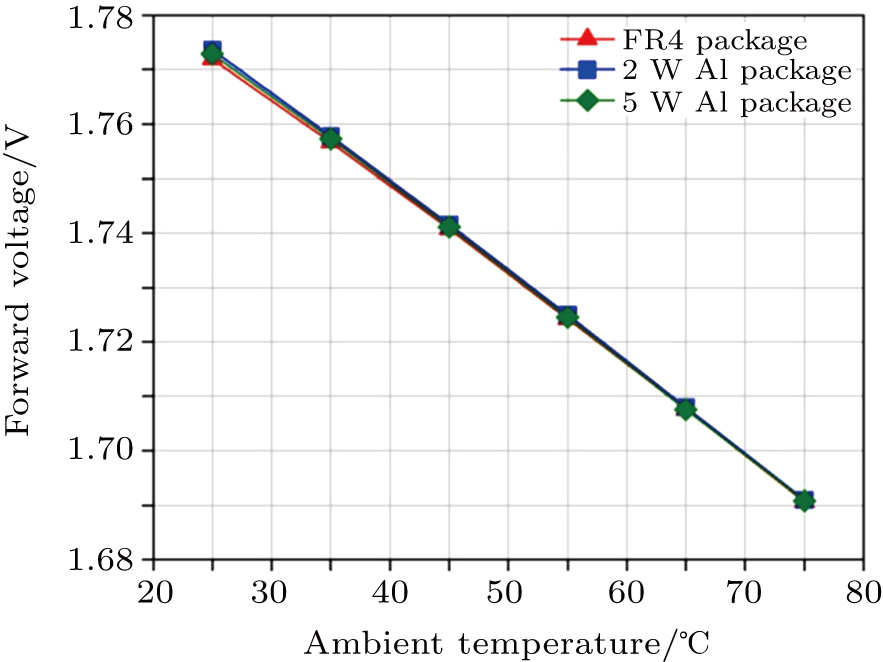

K-factor is the LED calibration factor that can be obtained using the slope of the forward voltage versus ambient temperature curve. For the measurement of K-factor calibration, a sensor current of 1.0 mA and temperature range of 25–75 °C with an increasing step of 10 °C were utilized. The K-factor is calculated by[19]

|

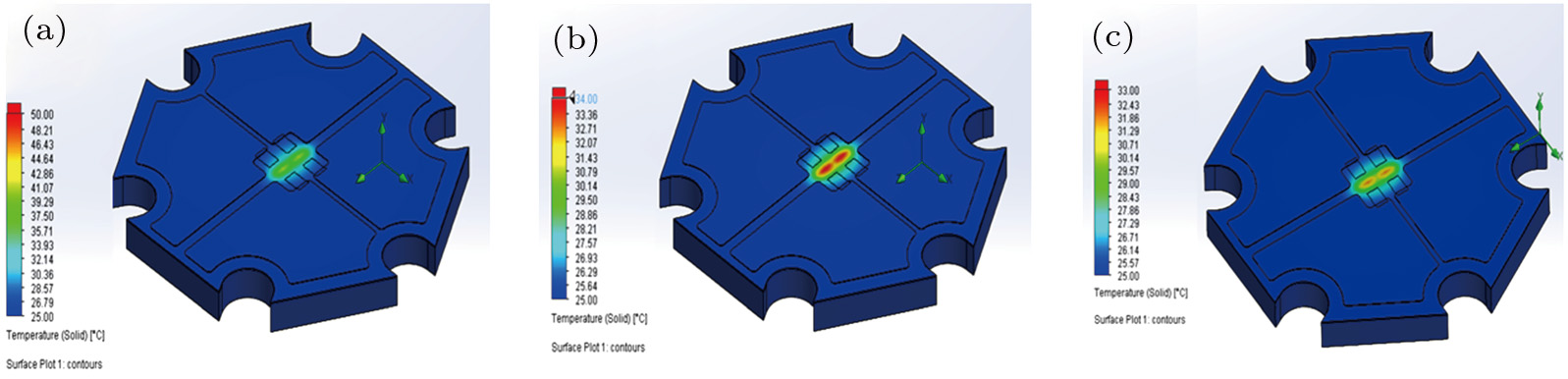

Figure

| Fig. 4. (color online) Heat distribution for (a) FR4, (b) 2 W Al, and (c) 5 W Al packages at 50 mA and 25 °C. |

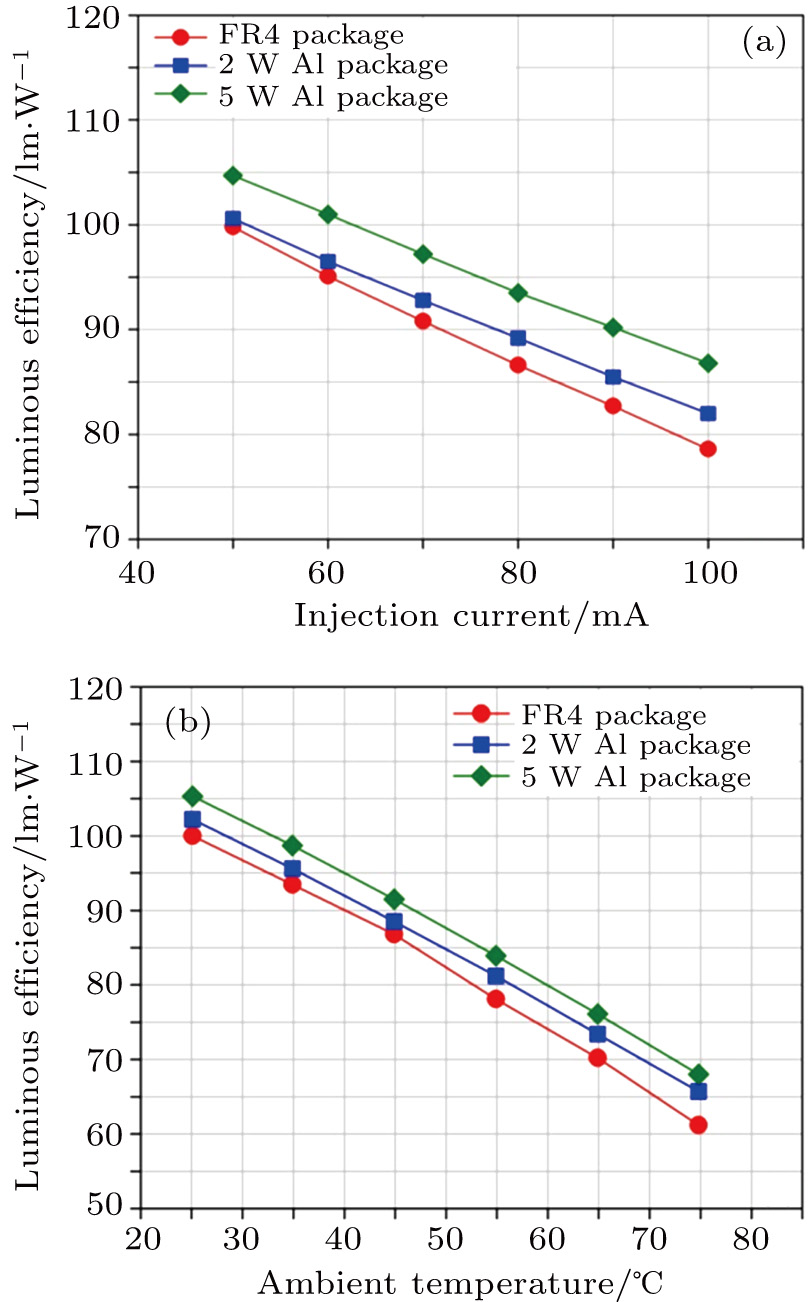

The luminous efficiency (

|

From Fig.

| Fig. 5. (color online) Luminous efficiency of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

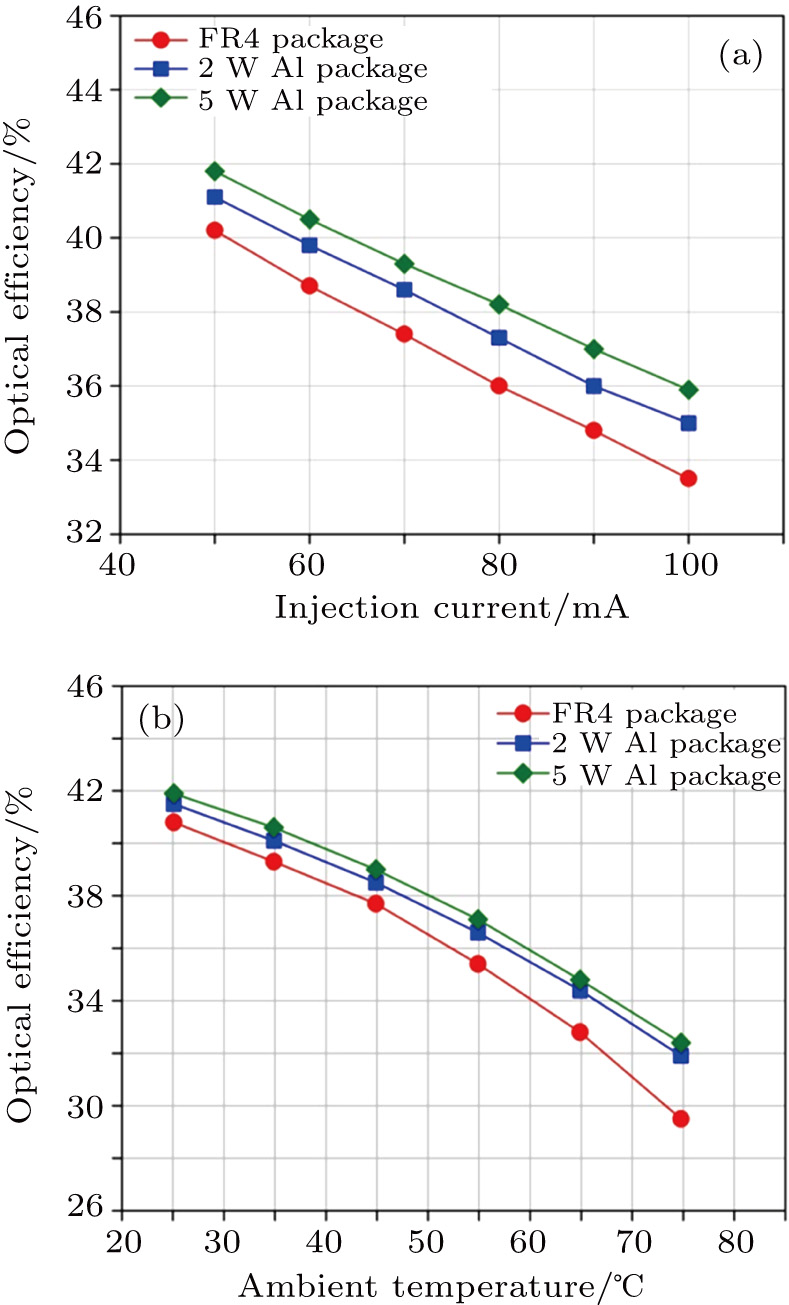

Optical efficiency (

| Fig. 6. (color online) Optical efficiency of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

The drop of

|

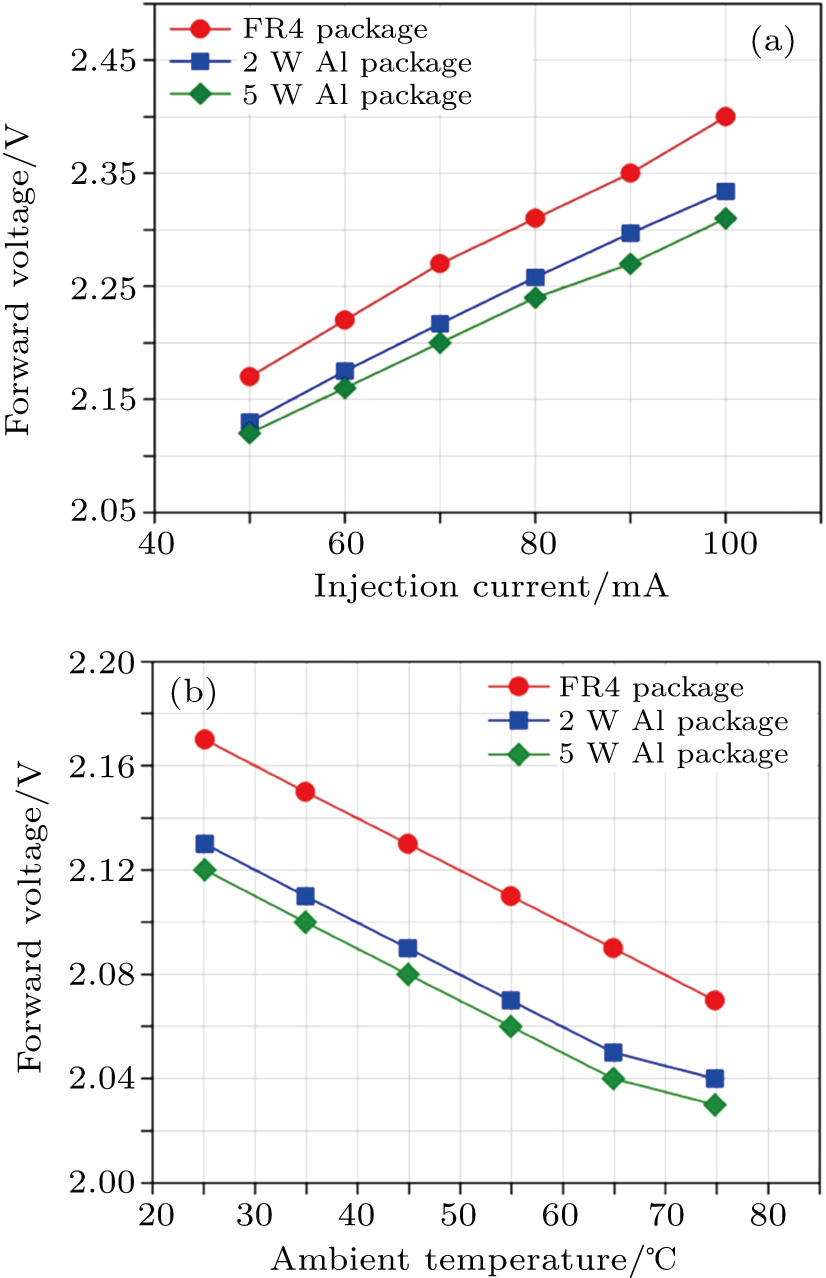

| Fig. 7. (color online) Forward voltage of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

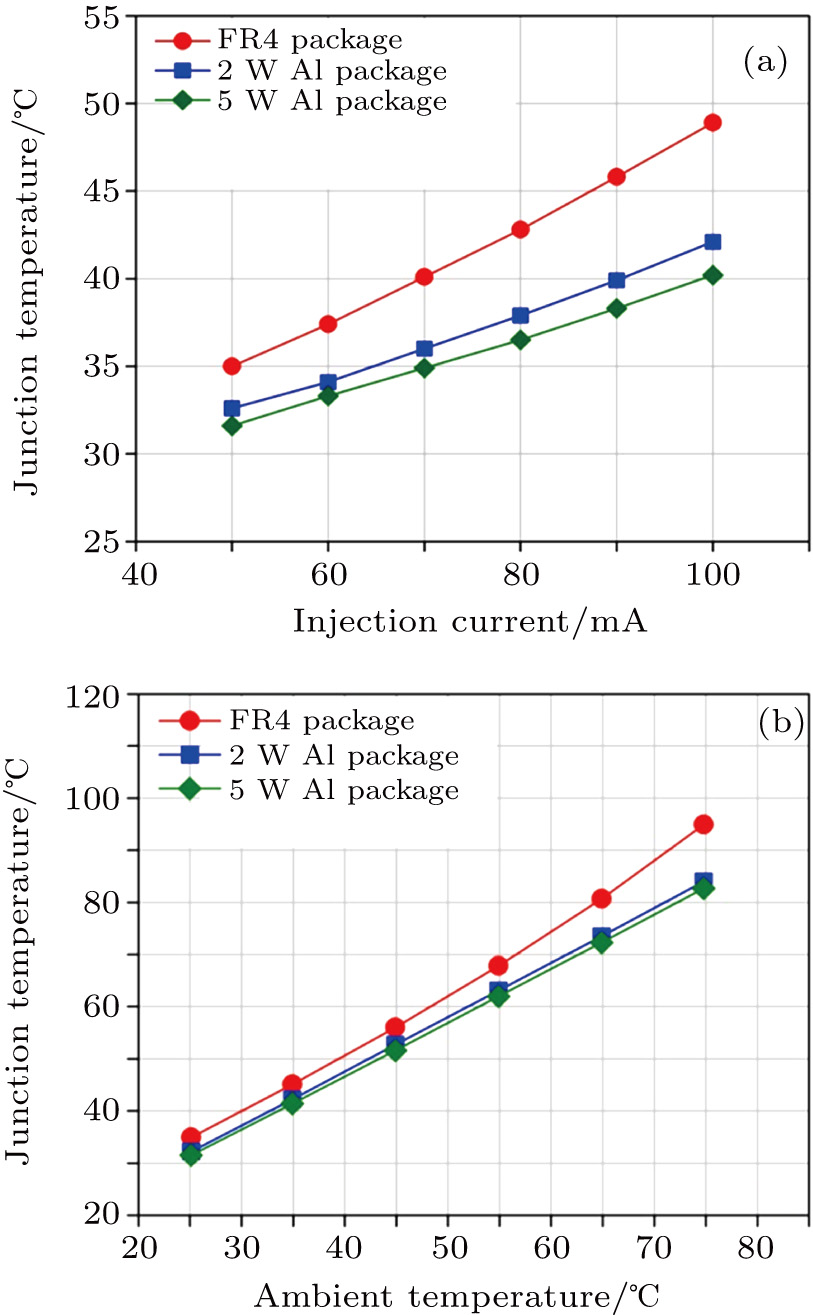

The LED junction temperature affects internal efficiency, maximum light output, and peak wavelength.[37] The forward voltage falls as the junction temperature increases. This is due to the Joule heating effect that derives the relation between the forward voltage and junction temperature. Figure

| Fig. 8. (color online) Junction temperature of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

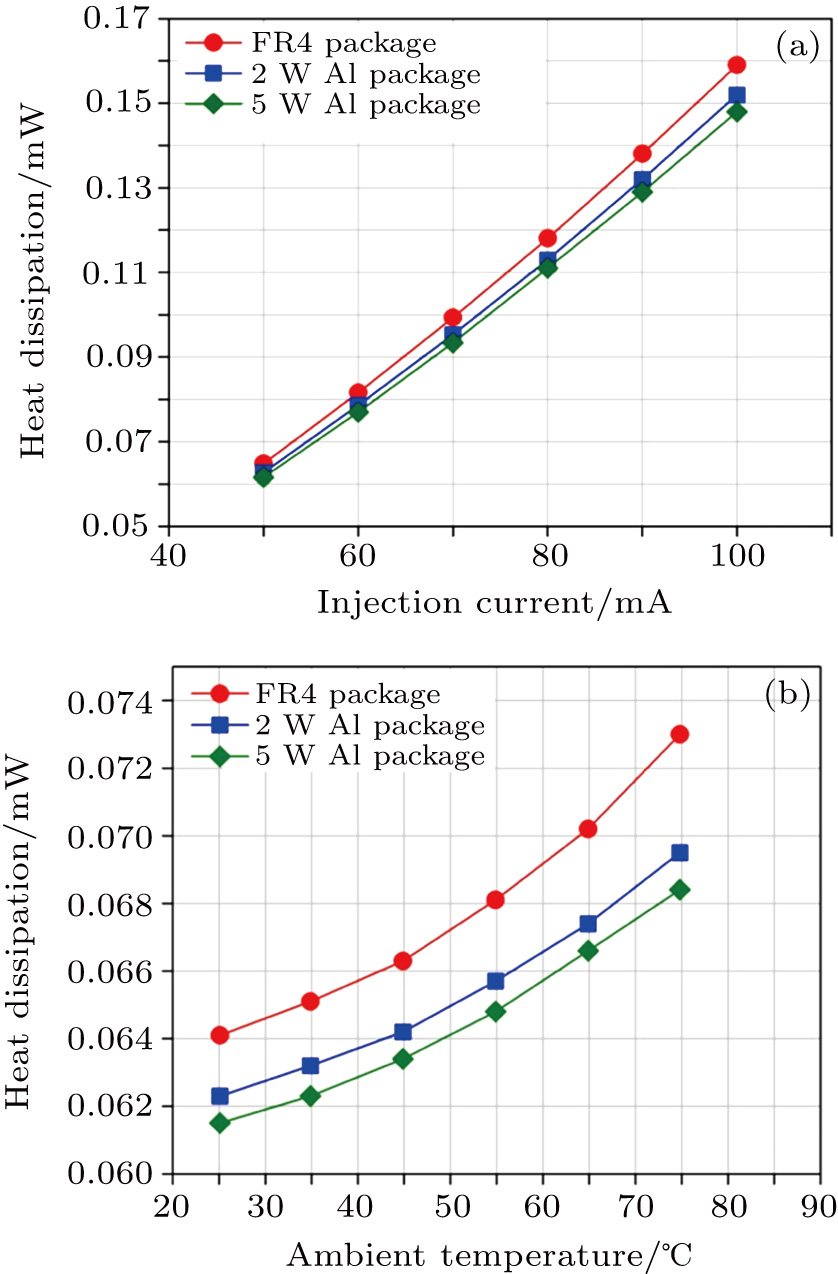

Figure

|

| Fig. 9. (color online) Heat dissipation of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

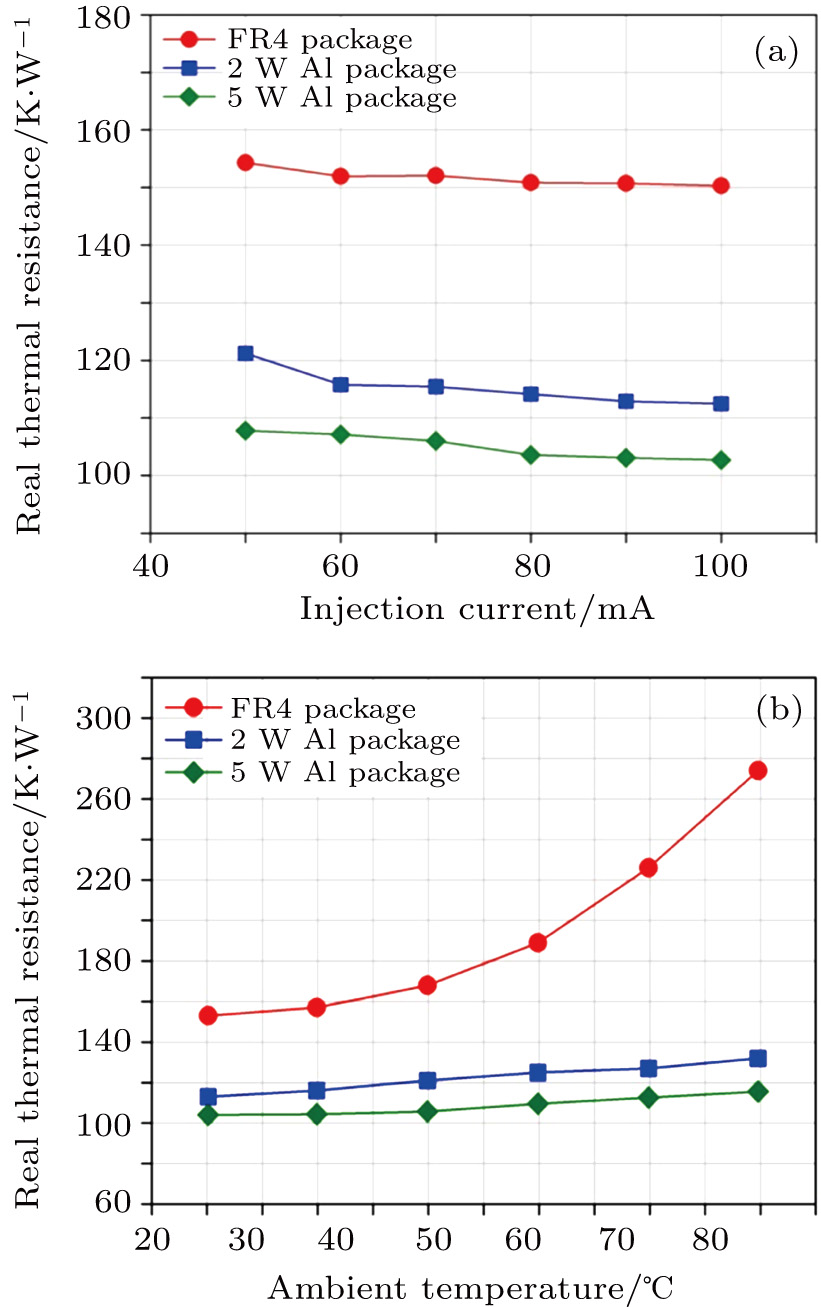

Real thermal resistance from junction to ambient

|

Figure

| Fig. 10. (color online) Real thermal resistance of InGaAlP thin-film SMD LED versus (a) injection current and (b) ambient temperature. |

We also observe from Fig.

The optical performance of InGaAlP thin-film SMD LED mounted on different substrate packages is investigated. The optical and thermal parameters of the LED are determined using the combination of T3ster and TeraLED instruments. The LED optical behavior at various injection currents and ambient temperatures is studied and compared among FR4, 2 W Al, and 5 W Al substrate packages. We find that as the injection current increases from 50 mA to 100 mA at ambient temperature of 25 °C, the luminous efficiency is improved from 5% to 10% between FR4 and 5 W Al substrate packages and from 4% to 6% between 2 W and 5 W Al packages, respectively. For the same range of injection current, the variation in optical efficiency between FR4 and 5 W Al substrate packages is about 4% to 7%. Likewise, the relative increase in optical efficiency between 2 W and 5 W Al packages is approximately from 2% to 3%. In addition, at 50 mA and ambient temperature 25–75 °C, the luminous efficiency is enhanced by 5%–11% between FR4 and 5 W Al packages. Similarly, the relative increase of the luminous efficiency between 2 W and 5 W Al packages is about 3%–4%. Furthermore, the optical efficiency increases from 3% to 10% between FR4 and 5 W Al packages and from 1% to 2% between 2 W and 5 W Al packages, respectively. Apparently, the LED attached to the 5 W Al substrate package shows the highest luminous and optical efficiency, due to its higher thermal conductivity of the dielectric layer, which allows effective dissipation of heat generated and subsequently improves the optical performance of the LED device.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] | |

| [42] | |

| [43] | |

| [44] | |

| [45] | |

| [46] | |

| [47] | |

| [48] | |

| [49] |