† Corresponding author. E-mail:

Project supported by the Science and Technology Major Project of Fujian Province, China (Grant No. 2013HZ0003-2).

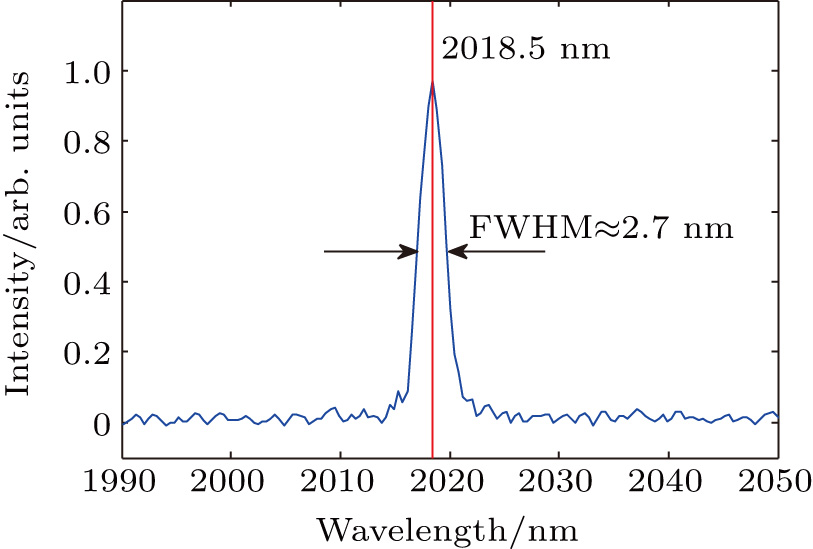

A 2-μm composite Tm:YAG laser pumped with a narrow-band laser diode was presented. The temperature distribution and thermal lens in the Tm:YAG were numerically simulated by a finite element method and the results were used to design the special cavity, in order to achieve a high efficiency and stable output. With a 25-W incident pump power, we obtained a maximum output power of 11 W at 2018.5 nm, corresponding to a slope efficiency of 51.3% and an optical-to-optical efficiency of 44.5%, respectively. The beam quality was measured to be

Diode-end-pumped solid-state eye-safe 2-μm lasers are of great interest due to their potential applications in coherent Doppler wind lidar and remote sensing,[1–3] and 2-μm lasers are also an ideal pumping laser source for optical parametric oscillators (OPO) and optical parametric amplifiers (OPA) in the mid-infrared wavelength region.[4,5]

Among the laser materials used to generate 2-μm laser emissions, Tm-doped lasers have the ability to use AlGaAs diodes around 800 nm as the pump source while maintaining a high efficiency and low thermal loading.[6] Thus, substantial studies have been dedicated to these laser systems in recent years.[7–10]

However, the characteristics of the small stimulated emission cross sections (

In 2008, Wu et al. reported a 6.97 W diode-end-pumped composite Tm:YAG laser at room temperature with a slope efficiency of 41.45%.[12] In 2009, Cheng et al. introduced the Tm:YAG ceramic as a gain medium.[13] They obtained a 4.5 W output power with a sloping efficiency of 20.5%. In addition, in 2012, Gao et al. increased the slope efficiency to 65% with a maximum output power of 6.05 W.[14] However, the operating temperature was maintained at 281 K, and we could see an obvious saturation at the maximum output. In 2015, Li et al. investigated the output characteristics of the Tm:YAG laser in the wide temperature range of 25–300 K.[15] The laser crystal was cooled with a liquid helium cooling system. At the temperature of 88 K, a maximum output power of 4.68 W was achieved with a slope efficiency of 56.1%. However, at the room temperature of 300 K, the output power was decreased to 1.2 W.

In this letter, we developed a high efficiency laser diode (LD) end-pumped composite Tm:YAG laser at room temperature. The LD was wavelength-locked by VBGs at 784.9 nm with a 0.1 nm linewidth. First, the temperature distribution in the laser crystal was numerically simulated using a finite element method. Then we obtained the thermal focal length by calculating the optical path difference of the crystal. Based on the above theoretical calculations, a simple two-mirror compact thermal stability cavity was designed and experimentally tested. Finally, we obtained a maximum output power of 11 W at 2018 nm under the incident pump power of 25 W corresponding to a slope efficiency of 51.3% and an optical-to-optical efficiency of 44.5%, respectively. In addition, the output power is scalable to a considerably higher value with a higher pumping power.

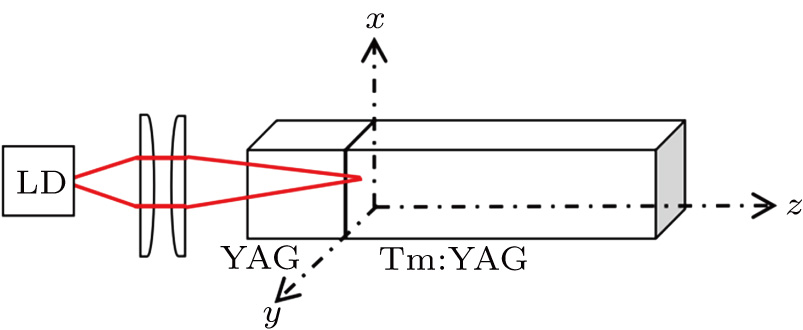

The geometry of the composite crystal is shown in Fig.

The thermal effect of the laser medium depends mainly on the heat flux induced by the pump power. In this case, the heat conduction equation describing the temperature distribution in the laser crystal is shown as follows:[16,17]

|

|

Considering that the thermal conductivity of the heat sink is much greater than that of the laser crystal, the temperature at the surrounding surfaces of the laser crystal is supposed to be the same as cooling water temperature at 288 K, and the end surfaces are supposed to be adiabatic.

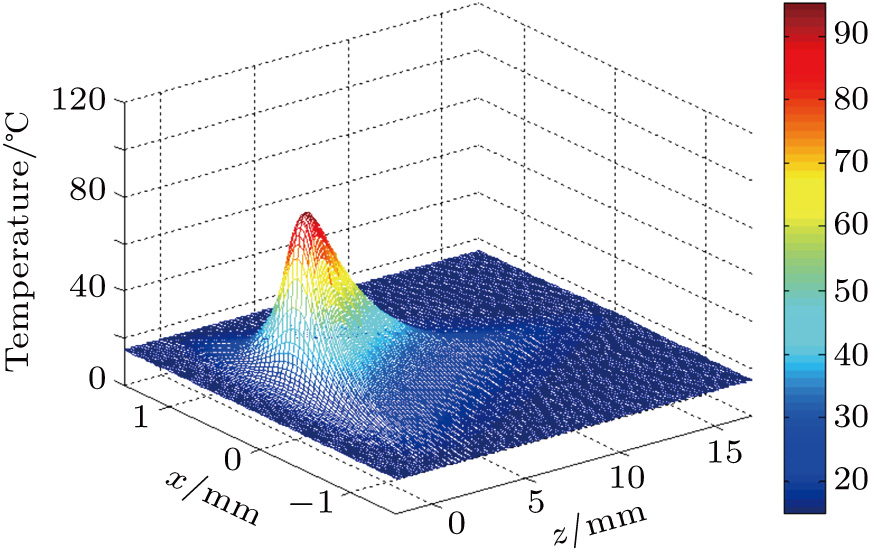

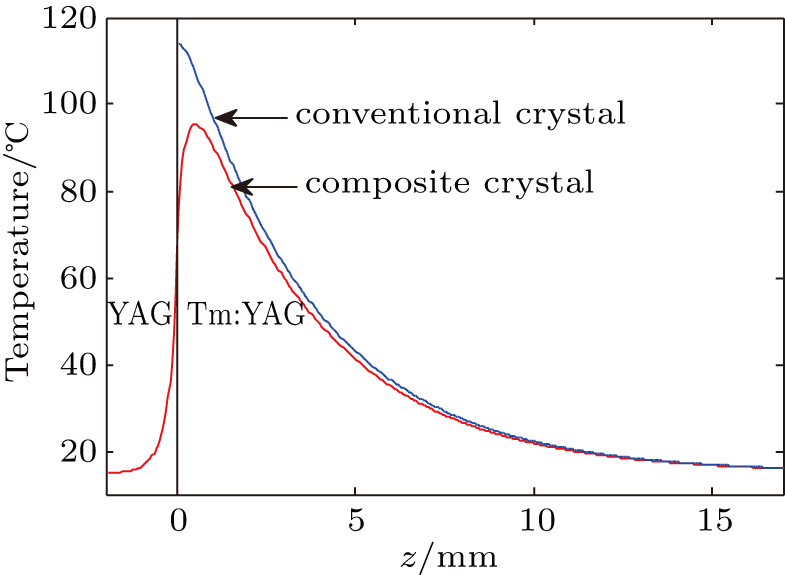

Then, we numerically solve Eq. (

The gradient distribution of the temperature in crystal results in the temperature-dependent variation of the refractive index and the stress-dependent variation of the refractive index.[18] Therefore, the optical path difference (OPD) for one pass can be expressed as

|

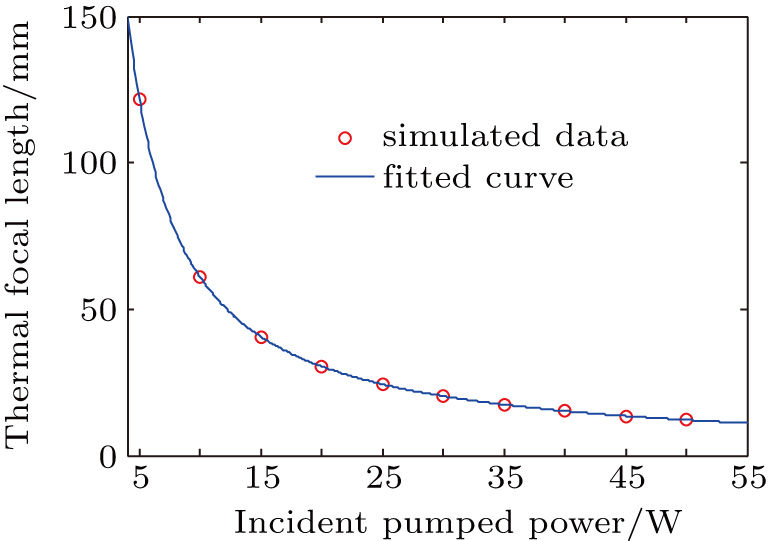

Figure

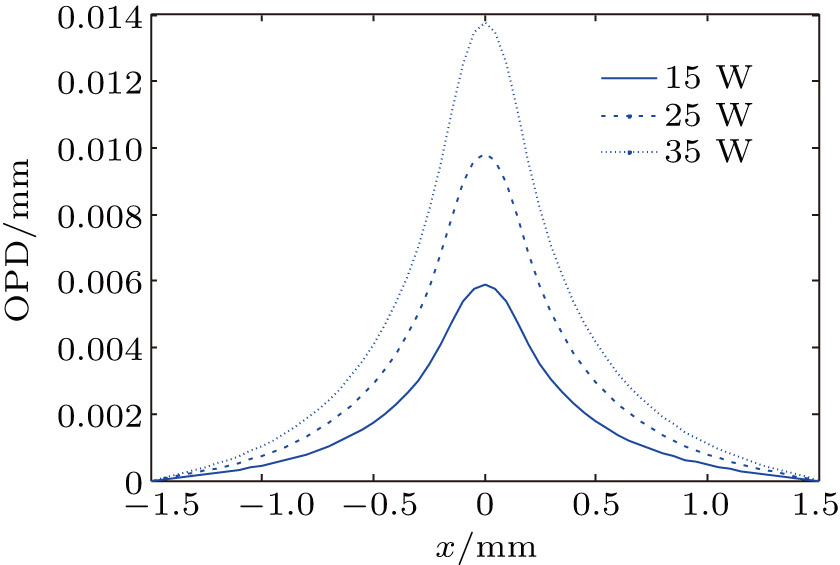

In the pumped region, it is common to consider the laser crystal to be a thermally induced thin lens. Then, the OPD can be approximated by a quadratic polynomial, and the focal length of the thermally induced lens can be derived by fitting the OPD distribution curve. Figure

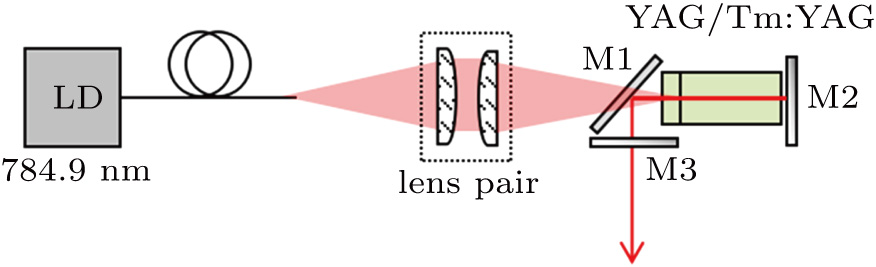

The experiment setup was shown in Fig.

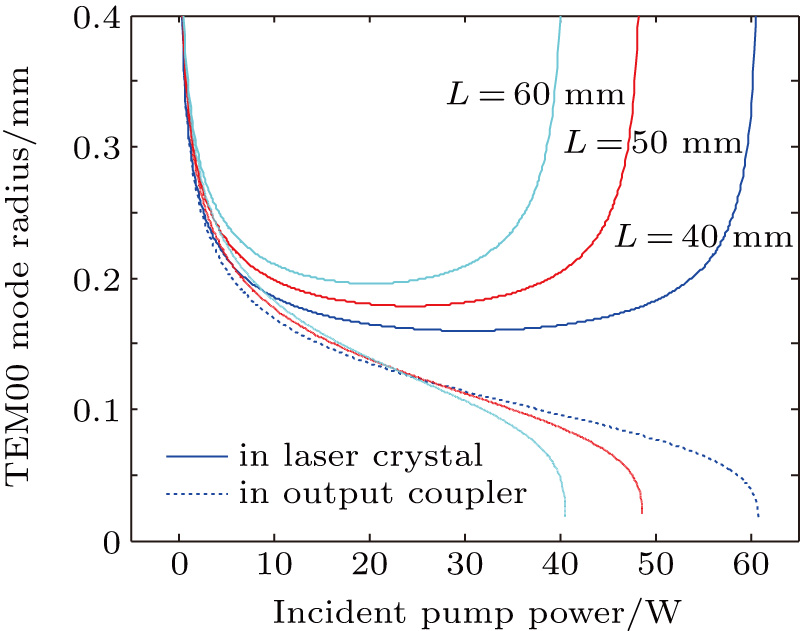

Considering the thermal lens effect, we calculate the TEM

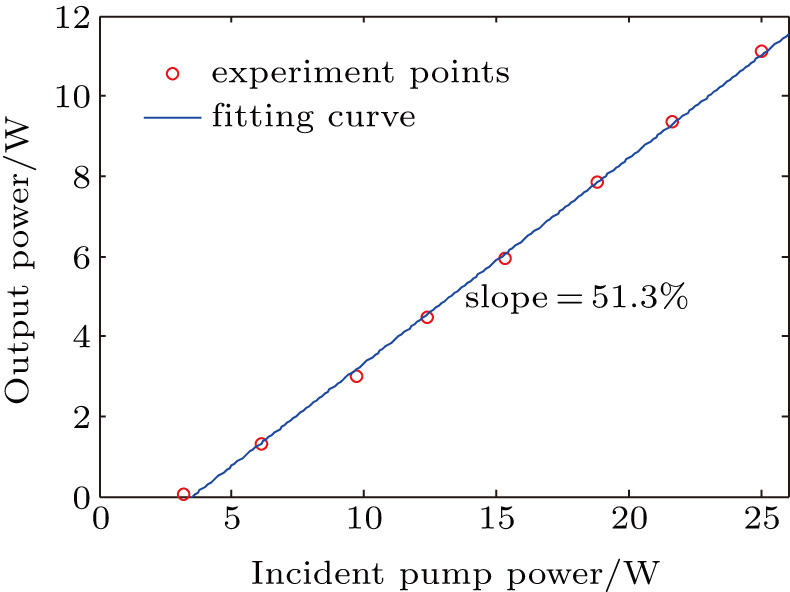

The average 2 μm output power versus the total incident pump power is shown in Fig.

As with the results shown in Fig.

The absorbed power was 98.4% of the total incident pump power corresponding to the absorption coefficient of 2.43 cm

At an output power of 11 W, the beam quality factors measured by the beam analyser (NanoModeScan) were

In summary, we have demonstrated a high-efficiency end-pumped 2-μm Tm:YAG laser. The thermal effects in the Tm:YAG/YAG composite crystal are comprehensively investigated, and the analysed results are used to design the cavity of the laser. Finally, a maximum output power of 11.1 W was obtained with an incident pump power of 25 W. The slope efficiency and optical-to-optical efficiency were 52.2% and 45.1%, respectively, relative to the absorbed pump power, and were 51.3% and 44.5%, respectively, relative to incident pump power. The conversion efficiency, when pumped with a VBG-stabilized narrow-band LD, was significantly higher than when pumped with a conventional broad-band LD. The beam quality factors were

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] |