† Corresponding author. E-mail:

A method of fabricating selenium (Se) microwire is demonstrated. A multimaterial fiber with amorphous selenium (a-Se) core and multicomponent phosphate glass cladding is drawn by using a conventional optical fiber drawing technique. Then the a-Se core of the fiber is crystallized by a post thermal process at 150 °C. After the multicomponent phosphate glass cladding is stripped from the multimaterial fiber by marinating the fiber in HF acid solution, a crystalline selenium (c-Se) microwire with high uniformity and smooth surface is obtained. Based on microstructure measurements, the c-Se microwire is identified to consist of most hexagonal state particles and very few trigonal state whiskers. The good photoconduction property of c-Se microwire with high quality and longer continuous length makes it possible to apply to functional devices and arrays.

In recent years, crystalline semiconductor filaments have received increasing attention due to their unique physical properties and potential for a wide range of applications such as future electronic and optoelectronic devices.[1–4] Several methods have been employed to fabricate microwires and nanowires including vapor–liquid–solid (VLS) growth,[5] high pressure chemical vapor deposition (HPCVD),[6] solution–liquid–solid approach,[7] and solid–solution–solid growth process.[8] The conventional VLS has been an important approach to the fabrication of high-quality microwires and nanowires. Nevertheless, filaments produced by this approach are limited to the mechanical fragility and lack of global orientation.[9] For the HPCVD method, currently it is impossible to achieve long lengths of microwires because of its slow deposition rate.[10] The other methods described above are inconvenient to produce crystalline structure microwires.

Selenium is an important semiconductor with unique properties, such as high photoconductivity, large piezoelectric, thermoelectric effect and nonlinear optical response.[11] Therefore, Se microwires show great potential applications in electronic, optical electronic devices and starting materials for fabricating the other functional materials.[12,13] Here a method to fabricate crystalline Se microwire by using a conventional optical fiber drawing technique is provided. This process has unique advantages: it takes full advantage of the fundamental simplicity of the traditional fiber drawing process and allows longer continuous lengths of c-Se microwires with high uniformity and smooth surface to be readily realized.

Commercial Se powder of 99.9% purity was prepared to fill in an 8-cm-long self-developed multicomponent phosphate glass (55P

The cross section and section of the obtained multimaterial fiber with Se core and multicomponent phosphate glass cladding were observed by optical microscope (OM, Olympus). Then the fiber samples were etched in HF acid (50% in deionized water) for two hours to dissolve glass cladding and obtain Se microwires. Microstructural analysis and the distribution of elements were investigated by using a Nova Nano SEM1530 scanning electron microscope with an energy dispersive x-ray spectrometer (EDS). The surface of the c-Se microwire was observed by using a Bruker Multimode 8 Atomic force microscopy (AFM). To determine the structure and crystal phase of the microwire, high-resolution transmission electron microscopy (HR-TEM) images and selected area electron diffraction (SAED) patterns were obtained by transmission electron microscope (TEM, JEM-2100F). The photosensitive current of the fibers between dark and illuminated states (under illumination from 532-nm DPSS laser, 632-nm HeNe laser and 808-nm HeNe laser) were recorded by using Keithley series 2450 source meter. All measurements were made at room temperature.

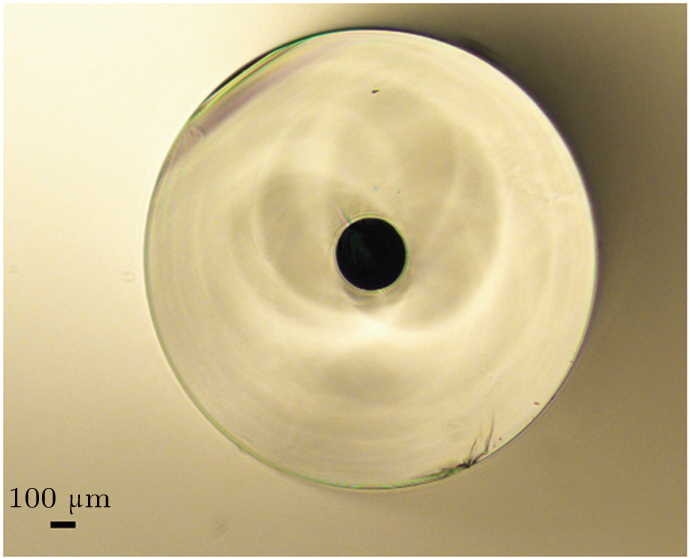

The topography of the as-drawn multimaterial fiber is shown in Fig.

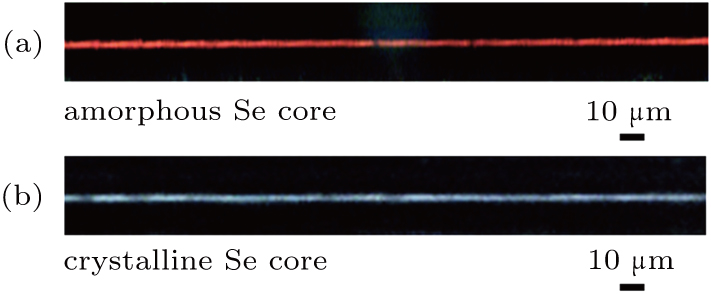

| Fig. 2. (color online) (a) Optical micrograph image of a-Se core fiber. (b) Optical micrograph image of c-Se core fiber annealing at 150 °C for 1 h. |

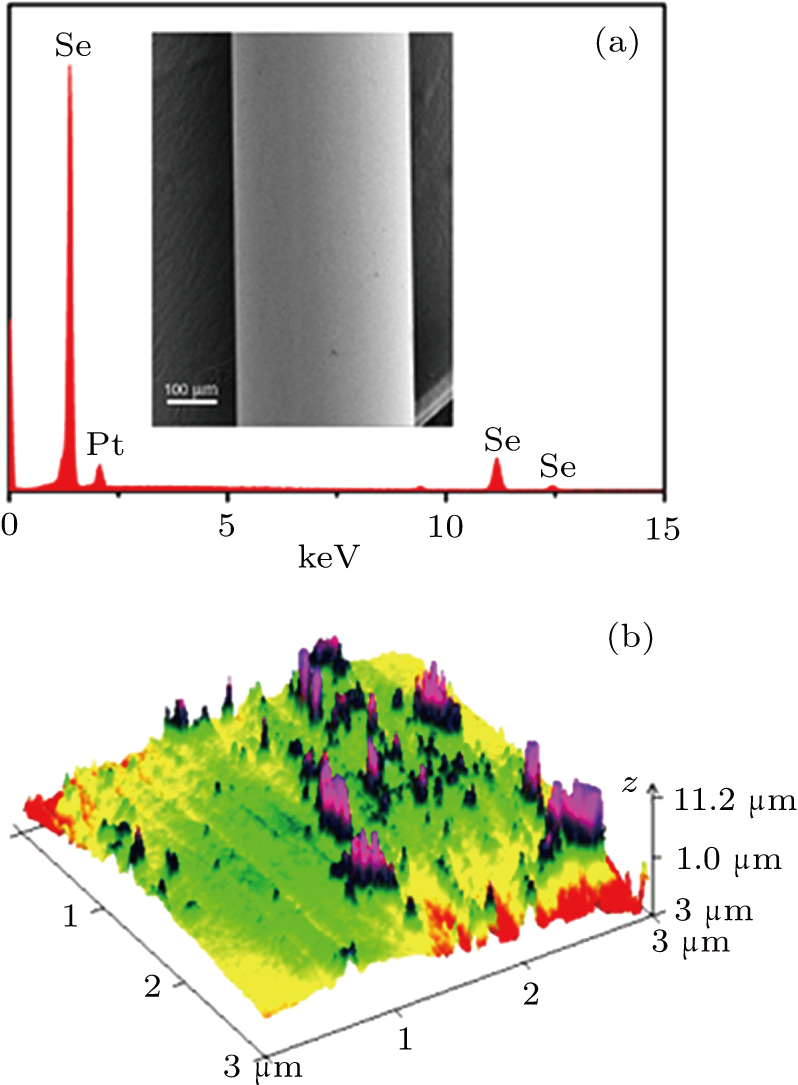

To obtain net c-Se microwire, it is necessary to strip the multicomponent phosphate glass cladding from the multimaterial fiber. Because this multicomponent phosphate glass is prone to dissolving in HF solution while selenium is not, c-Se microwires are obtained by marinating the fibers in HF acid (50% in deionized water) for two hours. The SEM image of the c-Se microwire in the inset of Fig.

| Fig. 3. (color online) (a) Elemental analysis image of c-Se microwire, the inset showing the SEM image of the microwire. (b) The AFM image of c-Se microwire. |

The surface roughness of microwire has a remarkable effect on combined microstructure of microwires and wave guide transmission loss due to surface scattering.[17,18] An AFM surface image of the c-Se microwire is observed with a Z direction resolution of 0.01-nm RMS as shown in Fig.

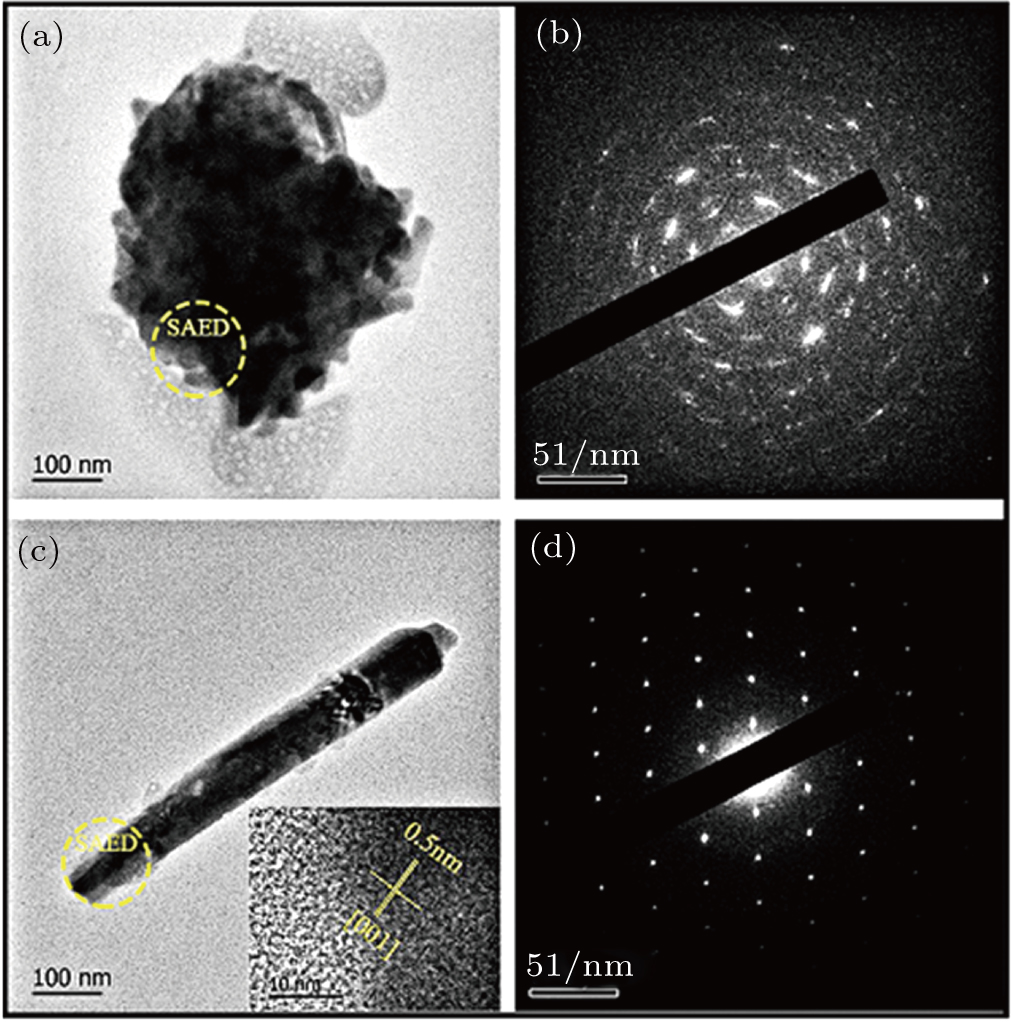

To further study the microstructure of the c-Se microwire, the c-Se microwire is crushed, then the TEM, SAED, and HR-TEM measurements are performed. Some Se particles can be observed from the TEM image in Fig.

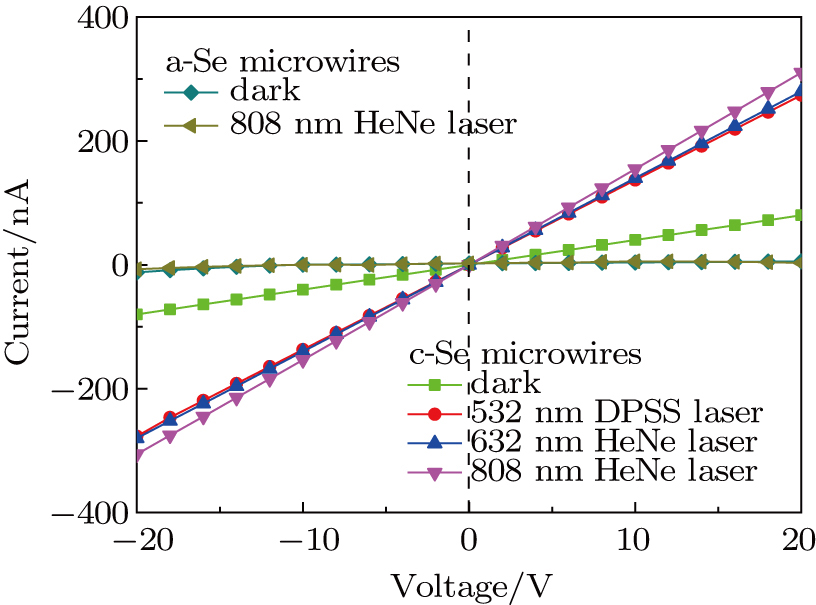

Photoconduction is an important characterization for a crystalline semiconductor microwire and it has been reported that there are some changes in conductivity between dark and illuminated states in semiconductor core fibers.[20,21] To study the photoelectric properties of Se microwire, 1cm-long a-Se and c-Se microwires are directly connected to external circuitry. Figure

In this work, a method of fabricating crystalline Se microwire is investigated. A multimaterial fiber with an a-Se core and multicomponent phosphate glass cladding is obtained through using a conventional optical fiber drawing method. After annealing the as-drawn multimaterial fiber at 150 °C, the a-Se core of the fiber is converted into crystalline Se. Subsequently, by stripping the multicomponent phosphate glass cladding in an aqueous HF solution, a longer continuous length of c-Se microwire with smooth surface is simply achieved, which is allowed to be used in arrays. The c-Se microwire consists of mostly hexagonal Se grains with a small quantity of trigonal phase whiskers. The largest difference with over three times the change in conductivity between dark (1.6 × 10

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] |