† Corresponding author. E-mail:

Project supported by the National Basic Research Program of China (Grant No. 2012CB932302), the National Natural Science Foundation of China (Grant Nos. 11634014, 51172271, 51372269, and 51472264), and the “Strategic Priority Research Program” of the Chinese Academy of Sciences (Grant No. XDA09040202).

Continuous CNT fibers have been directly fabricated in a speed of 50 m/h–400 m/h, based on an improved chemical vapor deposition method. As-prepared fibers are further post-treated by acid. According to the SEM images and Raman spectra, the acid treatment results in the compaction and surface modification of the CNTs in fibers, which are beneficial for the electron and load transfer. Compared to the HNO3 treatment, HClSO3 or H2SO4 treatment is more effective for the improvement of the fibers’ properties. After HClSO3 treatment for 2 h, the fibers’ strength and electrical conductivity reach up to ∼ 2 GPa and ∼ 4.3 MS/m, which are promoted by ∼ 200% and almost one order of magnitude than those without acid treatment, respectively. The load-bearing status of the CNT fibers are analyzed based on the downshifts of the G′ band and the strain transfer factor of the fibers under tension. The results reveal that acid treatment could greatly enhance the load transfer and inter-bundle strength. With the HClSO3 treatment, the strain transfer factor is enhanced from ∼ 3.9% to ∼ 53.6%.

Carbon nanotube (CNT), as a hollow nano-fiber, is particularly attractive because of its unique structure, low density, and remarkable mechanical, electrical, thermal and optical properties.[1] For practical applications, great effort has been made to assemble CNTs into macroscopic structures,[2] especially the continuous CNT fibers which is one of the most promising routes to exploit the outstanding axial properties of nanotubes.[3–5] CNT fibers are positioned for high-value applications, such as aerospace electronics, structural fibers, multi-functional fabrics, and composites.[6–8] Up till now, several methods have been established to fabricate CNT fibers, including wet-spinning fibers from a liquid suspension of CNTs, drawn from a vertically aligned CNT forest grown on a solid substrate or spun directly from the synthesis reaction zone in a chemical vapor deposition (CVD) system.[9–11] However, the performance of the CNT fibers is still far below that of individual CNTs.[1,4] Therefore, studies about the post-treatment of original CNT fibers for improvement of their mechanical and electrical properties are of great significance.[12–17]

In this work, we report the effects of various acid treatments on the properties of continuous CNT fibers which have been prepared through shrinking CNT films synthesized by an improved CVD method. The comparison and analysis of the experimental results reveal that the fibers’ mechanical properties and electrical conductivity can be increased effectively by appropriate acid post-treatment.

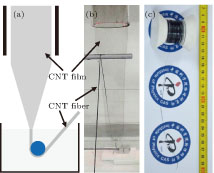

The continuous CNT fiber was directly prepared through in situ shrinking a CNT film with water and the corresponding procedure was illustrated in Fig.

Dry CNT fibers were immersed in acid (HNO3 (∼ 67%), H2SO4 (∼ 70%), and HClSO3 (∼ 99%)) for several hours and then twisted until the fiber was not shrinking to remove the extra acids and compact the fiber. The twisting process was carried out using a hand-held spindle or an automatic spinning machine in a fume hood. Finally, the fiber was washed by deionized water and dried under some tension at 120 °C for 12 h in a vacuum oven. As control experiments, the fibers with ethanol infiltration were twisted and dried.

The diameter, morphology, and microstructures of CNT fibers were characterized by scanning electron microscope (SEM, Hitachi 4800) and transmission electron microscope (TEM, Tecnai F20). Raman scattering spectra were recorded by LabRAM HR800 (HORIBA Jobin Yvon Inc.) with an excited wavelength of 633 nm. Resistances of fibers were measured by a Keithley-2400 sourcemeter with four-probe method under a current of 0.1 mA, using a sample with a gauge length of 50 mm. Mechanical property measurements were performed on a dynamic mechanical analyzer (DMA, Q800, TA Instruments) at a tensile speed of 0.05 mm/min, using a single CNT fiber pasted onto a hollow card with a gauge length of 15 mm. Raman spectra under continuous strain were obtained by combining the Raman spectra system and a homemade one-dimensional tensile platform. The one-dimensional tensile platform equipped with a micrometer can realize accurately continuous change of strain loaded along the long axis of the fibers.

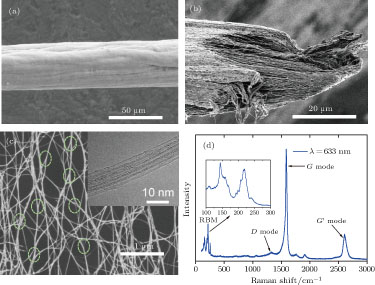

The performance, output and diameter of the continuous fiber can be controlled by adjustment of the synthesis conditions and collection speed. In general, the collection speed is 50 m/h–400 m/h and the fiber diameter is 10 μm–90 μm. Figure

The constituent of CNTs is mainly single-walled. The high resolution TEM (HRTEM) image, shown in inset of Fig.

The original fibers, directly fabricated at optimized synthesis conditions, were characterized and showed electrical conductivity of 0.3 MS/m–0.4 MS/m, strength of 0.5 GPa– 0.7 GPa and modulus of 10 GPa–20 GPa, respectively. Because of the high-purity, ultra-long CNTs and the unique hierarchical reticulate structure formed at high temperature, the performance of the continuous fibers remarkably precedes that of the most traditional materials such as Bucky paper, but is still far from that of an individual SWCNT.[3,14] The weak interaction between different CNTs and bundles is one of the most important reasons for this.[5] From a typical fracture morphology of a fiber, shown in Fig.

Because of the convenient operation and high efficiency, acidizing is widely used in treatment of CNTs through purification or introduction of functional groups.[24–27] Here, the idea of the CNT fiber’s properties improved by acid treatment, results from two aspects. First, most acids have the wettability of CNTs and can effectively remove the impurity in the fibers,[4] which are also beneficial for the fiber densification. Second, acid treatment can introduce the functional groups, which can enhance the interaction of CNTs and the fiber’s electrical conductivity by doping.[28] Concentrated nitric acid, concentrated sulfuric acid, and chlorosulfonic acid are the most common acids for treatment of CNTs and mainly used in purifying, mixing, dissolving, modification, etc.[3,4]

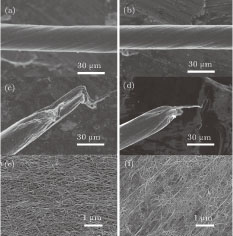

The effects of HNO3, H2SO4, and HClSO3 on the morphology and performance of the CNT fibers are shown in Figs.

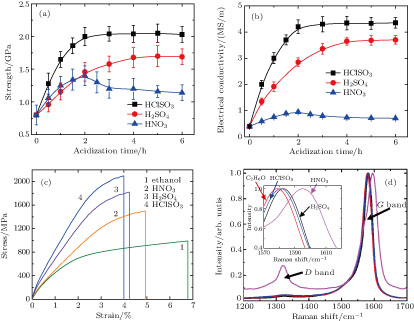

Besides the morphology changes, the acid treatments also remarkably improve the mechanical and electrical properties of fibers. The results of the tensile strengths and electrical conductivity at different acidizing time are shown in Figs.

Except the aforementioned compaction, the performance improvement of the fiber with acidizing also results from the surface modification.[12,27] Although the diameter decrease is similar (by 8%–12%), the performance of the fiber with H2SO4 and HClSO3 treatment is superior to that with HNO3 treatment. This result implies that the surface modification by acidizing also benefits the improvement of fibers’ properties.[26] For example, the load transfer between CNTs would be promoted by enhancements of the intertube interaction and interfacial shear property, due to the existence of dipole–dipole interaction and possible hydrogen bonding.[12] In addition, the functional groups might improve the conductivity by serving as excellent dopant and efficient electron pathways. The HNO3 treatment effectively modifies CNT surfaces by introducing abundant functional groups, such as –COOH and –OH, which has been reported many times.[24,26–28] For the fibers with H2SO4 treatment, the sulphate ion from the residual sulfuric acid in the fiber is also excellent dopant.[10] As for the HClSO3 treatment, it is similar to the H2SO4 treatment, due to the reaction between HClSO3 and the moisture generating H2SO4 and HCl.[4] The surface modification can be proved by the Raman spectra (Fig.

It has been reported that the conduction of CNT fibers is mainly controlled by electron hopping mechanism.[29,30] As the intertube spacing became smaller, the hopping is enhanced and the contact resistance is reduced significantly.[22,24,31] In addition, the smaller intertube spacing also improves the interfacial shear property.[14,31,32] The sliding is dominant for the fracture of a fiber because of the weak intertube interaction.[17,26] After the acidizing, the sliding distance decreases significantly from tens of μm (Fig.

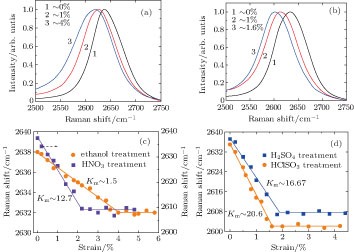

The in situ Raman measurements were employed to unveil the load-bearing status of the CNT fibers.[33] Figures

According to the variation of the Raman spectra, the micromechanical process in macroscale CNT fibers is analyzed.[17,33] The macroscale strain from the axial extension of CNTs can be estimated, based on the downshift rate of the G′ band (Km) at a low-strain stage. The downshifts of the G′ band are expected, which arise from the weakening of the carbon–carbon bonds when the inter-atomic distance elongated.[16] In the light of Corning’s work, the average Km is 37.5 cm−1/1% strain for strained individual SWNTs.[34] This value is much higher than that of the CNT fibers without or with acid treatment, which implies the macroscale strain of the fibers results from not only the axial extension of the CNT bundles but also the CNT network deformation at a low-strain stage. Furthermore, the macroscale strain from CNTs’ axial extension are quantitatively evaluated, based on the strain transfer factor (STF) which is defined as the ratio of Km for a CNT fiber to that for an individual CNT (37.5 cm−1/1% strain).[16] The STF is only ∼ 3.9% for the CNT fibers with ethanol infiltration, which implies that CNTs’ axial extension merely contributes several percent to the total macroscale strain. After acid treatment, the STF is improved by at least one order of magnitude (the fiber’s STF ∼ 33% with HNO3 treatment, ∼ 43% with H2SO4 treatment and ∼ 53.6% with HClSO3 treatment, respectively), which means the strain transfer in the fiber is more effective.[33] In addition, in Figs.

In summary, a CNT fiber, directly and continuously prepared at a collection speed of 50 m/h–400 m/h via an improved CVD method, consists of a continuous reticulate network with lots of Y-type junctions and shows electrical conductivity of 0.3 MS/m–0.4 MS/m, strength of 0.5 GPa–0.7 GPa and modulus of 10 GPa–20 GPa. Its performance markedly precedes that of the most traditional materials such as Bucky paper, but is still far worse than that of an individual SWCNT.[3,14] We treat the as-grown CNT fibers by acidizing to densify and modify the fibers and effectively reduce the barrier for the charge carrier and load transfer between CNTs. Compared to the HNO3 treatment, HClSO3 or H2SO4 treatment is more effective for the improvement of the fibers’ properties. After HClSO3 treatment, the fibers’ strength and electrical conductivity are promoted by ∼ 200% and almost one order of magnitude than those without acid treatment, respectively. The results of the G′ band downshifts and strain transfer factor of the fibers under tension reveal that acid treatment could greatly enhance the load transfer and inter-bundle strength. The modified CNT fibers have great potential applications in high-strength and conductivity composites, multifunctional fabrics and structural fibers.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] |