† Corresponding author. E-mail:

In this work, long-period waveguide grating-based tunable wavelength filters using organic–inorganic grafting poly(methyl methacrylate) (PMMA) materials are designed and fabricated by metal-cladding directly defined technique. The thermal stabilities and optical properties of the organic–inorganic grafting PMMA core materials are analyzed. Structures and performance parameters of the waveguide gratings and self-electrode heaters are designed and simulated. The contrast of the filter is about 15 dB and the resonant wavelength can be tuned by different electric powers applied to the metal-cladding self-electrode heaters. The temperature sensitivity is 3.5 nm/°C and the switching time is about 1 ms. The technique is very suitable for realizing the optoelectronic integrated wavelength-division-multiplexing systems.

Long-period waveguide gratings (LPWGs) are gratings in planar waveguide with grating period around 100 µm.[1–3] LPWGs-based devices have aroused considerable interest in recent years in the field of optical communication and sensor application because of the flexibility in waveguide structure and material as compared with the long-period fiber gratings.[4–8] Specially, LPWGs-based tunable wavelength filters are very suitable for realizing functional wavelength division multiplexing systems using optical planar integrated circuits. They can be compatible with other devices on silicon substrates, and can be produced in large quantities by using standard microelectronic processing techniques. Several material systems, including silicon-on-insulator (SOI), silicon, LiNbO3 and polymers have been used to achieve LPWGs chip.[9–12] As a multi-functional material system, polymers exhibit well-controlled refractive indices, highly flexible structures, and large thermo–optic (TO) and electro–optic (EO) coefficients which can be conductive to realizing the monolithic integration with LPWGs-based tunable wavelength filter module.[13,14] At present, some studies have reported polymer LPWGs produced by reactive ion etching (RIE),[15] soft lithography,[16] or induced refractive index modulation.[17] In this paper, we propose a metal-cladding confinement waveguide structure to directly produce polymer LPWGs-based thermo–optic tunable wavelength filter based on organic–inorganic grafting PMMA materials. The thermal stabilities and optical properties of the hybrid materials are analyzed. Structural characteristics of the waveguide gratings and self-electrode heaters are provided. Optical performance parameters of the tunable wavelength filter are simulated and measured. The contrast and temperature sensitivity of the filter are obtained. The technique is advantageous in realizing the photonic multi-functional integrated circuits (PICs) WDM communication systems.

The organic–inorganic grafting PMMA waveguide material is synthesized by hydrolysis and polycondensation of 3-methacryloxy-proyltrimethoxysilane (MAPTMS, KH570), (3-glycidoxypropyl)trimethoxy-silane (GPTMS, KH560), methylmethacrylate (MMA), and tetrabutyl titanate (Ti(OC2H5)4. The waveguide layer can form the grafting PMMA material with SiO2–TiO2 network. The molecular structure and synthesis process of the SiO2–TiO2 organic–inorganic grafting PMMA materials are given in Fig.

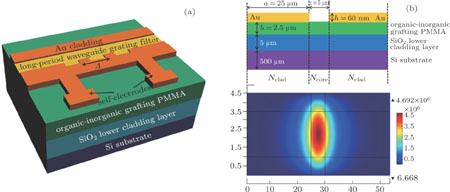

The schematic diagram of a metal-cladding LPWG filter with self-electrode heaters is shown in Fig.

The relative eigenvalue equations based on effective index method[18] for the TM modes of core and cladding layers are defined, respectively. The effective index of core layer denoted as N core is given as

The effective index of cladding layer denoted as N clad is described as

| (2) |

| (3) |

| (4) |

| (5) |

The relations between the core thickness b and TM mode effective refractive indices of the core and the cladding for the resonant wavelength are shown in Figs.

| Fig. 3. (color online) Relations between the core thickness b and TM mode effective refractive indices of (a) the core and (b) the cladding for the resonant wavelength. |

As the LPWG filter, significant power coupling between TM0 mode in the core waveguide and TMm mode in the cladding is expected to occur at the resonance wavelength λ0 = (N core - N clas) Λ, where Λ is the grating pitch. The LPWG filter is designed to operate at a grating pitch of 98 m with an off-resonance wavelength of 1550 nm. The width of the core waveguide is 5 µm. The width and the height of the metal strips are defined as 25 µm and 60 nm, respectively. The corrugation depth is 2 µm, and the duty cycle is 50%. The grating length L is 5.0 mm. The transmission spectrum of the LPWG filter is given by[19]

| (6) |

| (7) |

|

|

The dependence of the coupling coefficient on the cladding thickness is shown in Fig.

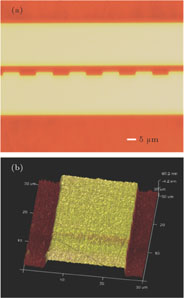

This LPWG filter is directly achieved by photolithography fabrication process forming Au-cladding defined structure. Figure

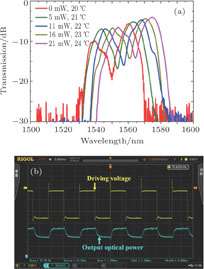

The fabricated metal-cladding LPWG filters are characterized by launching light at wavelengths of 1510 nm–1590 nm from an amplified spontaneous emission (ASE) source into the waveguide from a standard single-mode fiber, and by monitoring the output on an infrared camera, a photodetector and an optical spectrum analyzer. The transmission loss of the direct waveguide with 5-μm width is measured to be 1.2 dB/cm by a cut-back method. When electric power is applied to the self-electrode, heat is generated periodically along the waveguide, which generates a thermo–optic grating effect. Figure

Compared with the ideal simulated parameters of the filters, the actually measured values of temperature sensitivity, contrast and insertion loss are slightly lower, which may be due to the fact that heat dissipation in actually measured process affects the thermal efficiency of metal self-electrodes and thus temperature sensitivity is disturbed. The contrast might be influenced by machining accuracy in the fabricating process for the ridge height of the gratings. By taking into consideration the absorption loss of the actual waveguide material and the coupling loss between the fiber and the waveguide, the actual insertion loss of the device measured is larger than the calculated value. However, in contrast to other results reported, there are still certain advantages in the key parameters of our device. For the reported TO tunable polymer LPWG filter devices,[20–22] including our device, the contrast is obtained mainly in a range of 10 dB–30 dB. The switching rise and fall times and the sensitivity are put into perspective by comparing with the performances of the other devices published in the literature as given in Table

| Table 1.

Comparison of other published results for polymer LPWG filter device with our results. . |

In this study, we propose and demonstrate TO tunable LPWG filters based on organic–inorganic grafting PMMA materials by using the metal-cladding directly defined technique. The optical characteristics of the SiO2–TiO2 grafting PMMA material are analyzed. T g and T d of the hybrid material are measured to be 135 ºC and 230 ºC, respectively. Performance parameters of the device are designed and simulated. The contrast of the rejection band for the center wavelength is 15 dB, and 30 mW electric power applied to self-electrode heaters can achieve a maximum contrast change. The temperature sensitivity of the filter is about 3.5 nm/ºC. The switching rise and fall times are measured to be 1.1 ms and 1.2 ms, respectively. The chip could improve the flexibility for the optoelectronic integrated circuits.

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] |