† These two authors contributed equally to this work.

‡ Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant Nos. 51373082 and 11404181), the Taishan Scholars Program of Shandong Province, China (Grant No. ts20120528), and the Postdoctoral Scientific Research Foundation of Qingdao City, China.

Electrospun nanofibers with designed or controlled structures have drawn much attention. In this study, we report an interesting new closed-loop structure in individual cerium nitrate/polyvinyl alcohol (Ce(NO3)3/PVA) and NaCl/PVA fibers, which are fabricated by electrospinning with a nail collector. The electrospinning parameters such as voltage and Ce(NO3)3 (or NaCl) concentration are examined for the formation of the closed-loop structure. The results suggest that the increase of the spinning voltage or addition of Ce(NO3)3 (or NaCl) is favorable for the formation of the closed-loop structure, and the increase of loop numbers and the decrease of loop size. Further analyses indicate that the formation mechanism of the closed-loop fibers can be predominantly attributed to the Coulomb repulsion in the charged jets.

Over the past few decades, electrospinning, as a simple, versatile, and useful technique for fabricating nanofibers, has attracted much attention.[1–5] By electrospinning, a great variety of polymers have been electrospun into micro- and nano-fibers and the as-spun fibers have shown great potential applications in various fields.[5–9] Generally, the process of electrospinning is as follows. A charged polymer solution or melt jet is bending, branching, and whipping in a high electric field due to the interplay between the electric force and the solution surface tension.[10–13] With the solvent evaporating or melt cooling, the jet solidifies into fibers and deposits on the collector. Owing to the bending instability of the electrospinning jet, fibers with nonwoven and randomly arranged structures are the most typical macroscopic organization obtained.[12] However, the microstructures of the electrospun mats and even individual fiber can be designed and controlled by modifying the electrospinning devices and controlling the electrospinning process.[1–5,12,13]

It has been reported that ultrathin fibers with different structures (e.g., highly aligned arrays,[14–18] patterned mats,[19,20] crossed arrays,[21,22] and twisted fiber ropes[22,23]) can be electrospun by using special collectors such as rotating disk collectors,[14] parallel electrodes,[15] dielectric collector,[16] conductive pattern template,[19] frame collector,[23] or by centrifugal electrospinning[22] and near-field electrospinning.[24] Meanwhile for individual fibers with helical,[25,26] core–shell,[27] and hollow[28,29] structures, they could be obtained through modified electrospinning devices including reciprocating-type electrospinning,[25] electrospinning with tip collector,[26] and coaxial spinneret,[27–29] respectively. Moreover, by changing the electrospinning processing parameters (such as polymer materials, solution concentration, spinning voltage, working distance, and solution feeding rate), fibers with bead,[30,31] porous,[31,32] and ribbonlike[33,34] structures have also been successfully obtained.

Joachim in 1998 first obtained fibers with a closed-loop structure by drawing a single nanofiber.[35] It was reported that a closed-loop with a radius of 60 nm was formed by joining side-by-side two parts of open loops. Koombhongse et al. found loops formed in a single jet of polyhydroxyethyl methacrylate due to the bending and branching of the electrospinning process.[33] Moreover, by electrospinning, Reneker et al. have obtained a fluffy, columnar network of polycaprolactone (PCL) fibers named “garland”.[36] The garland structure is formed by the constrained motion of some closed-loop fibers. It was pointed out that the closed-loop is formed by the contact of open loops in flight when the mechanical forces overcome the repulsive forces in the charged jets.[36] However, the preparation and formation mechanism of electrospun fibers with new closed-loop structure remains a challenge.

In this article, we report on a new closed-loop structure in individual cerium nitrate/polyvinyl alcohol (Ce(NO3)3/PVA) or NaCl/PVA fibers, which are fabricated by a modified electrospinning device with a tip collector. The electrospinning parameters such as voltage and solution concentration are controlled to examine the formation of the closed-loop structure. Additionally, the formation mechanism of the loop-like structure is also discussed.

As mentioned above, to fabricate fibers with controlled structures, modification of the electrospinning device is a common and effective method, and most of the modifications focus on the collector. Consequently, in this work, the modified electrospinning setup used is also a collector-modified one as displayed in Fig.

| Fig. 1. (a) Schematic illustration of the modified electrospinning setup, where a metal nail is used as the collector. (b) The corresponding schematic electric field distribution. |

The polymer solution was prepared by dissolving PVA (MW 60000, Sinopharm Chemical Reagent Co., Ltd., CHN) in deionized water at 10 wt.% and then stirring thoroughly for 2 h at room temperature. Subsequently, cerium (III) nitrate (Ce(NO3)3·6H2O, MW 434.22, Aladdin Industrial Inc., CHN) was dissolved in the prepared PVA solution at 1.5 wt.% for 2 h, then the Ce(NO3)3/PVA precursor solution with 1.5 wt.% Ce(NO3)3 was obtained. Similarly, Ce(NO3)3/PVA and NaCl/PVA solutions with different concentrations of the salt were prepared. All the solutions were agitated at room temperature under constant stirring for at least 24 h prior to electrospinning. The electrospinning was carried out under a high voltage of about 15–30 kV and the distance between the needle and the nail was about 10 cm at room temperature. The morphologies of the electrospun fibers were characterized by an optical microscope (BX-51, Olympus) and a zoom-stereo microscope (SMZ-168, Motic).

It was suggested in our previous study that the tip collector electrospinning can produce fibers with curled structure.[26] As shown in Fig.

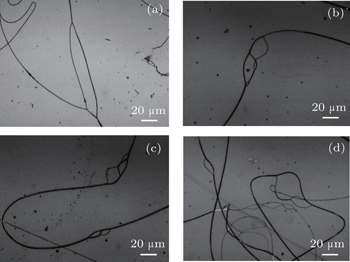

To investigate the formation of the closed-loop fiber, we first examine the effect of the applied voltage in the electrospinning process. Figures

| Table 1. Average diameters and loop structures of the electrospun Ce(NO3)3/PVA fibers obtained with different voltages. . |

It is mentioned above that a higher spinning voltage may induce the formation of closed-loop Ce(NO3)3/PVA fibers. For a further investigation, the PVA solutions with different concentrations of Ce(NO3)3 were prepared and the as-spun fibers were examined with an optic microscope as shown in Fig.

| Table 2. Average diameters and loop structures of the electrospun Ce(NO3)3/PVA fibers obtained with different concentrations of Ce(NO3)3/PVA. . |

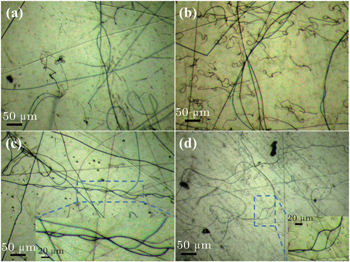

Addition of Ce(NO3)3 to the PLA solution is beneficial for the formation of closed-loop structures and then a question is raised: whether the addition of other salts could also give a similar effect on the formation of close loops. Accordingly, an NaCl/PVA solution was prepared and then electrospun into fibers. The as-spun fibers are shown in Fig.

As mentioned in the introduction, electrospun fibers with closed-loop structure have been previously reported by Joachim[35] and Reneker et al.[33,36] Those closed-loop structures were usually formed by the side-by-side joining of two parts of open loops,[35] bending and branching of the electrospinning process,[33] or the contact of open loops in flight when the mechanical forces overcome the repulsive forces in the charged jet.[35] However, in this study, different closed-loop structures in a single fiber are observed, which is obtained from the salt doping PVA solutions by a tip electrospinning. As the experimental results suggest, the increases of the high voltage and the concentration of the salt are favorable for the formation of closed-loop structures. This suggests another possible mechanism to explain the formation of closed-loop fibers. As shown in Fig.

We prepare Ce(NO3)3/PVA and NaCl/PVA composite fibers with closed-loop structure under high voltages and different concentrations of Ce(NO3)3 and NaCl by a tip electrospinning device. It is found that the increases of the voltage and the salt concentration will lead to the increase of representative number of closed loops and the decrease of the average scale of the closed loops. To understand the formation mechanism of the closed loop, a schematic model is proposed, in which the formation of the closed loop is ascribed to the Coulomb repulsion inside the single jet. The charge density of the electrospinning jet and thus the Coulomb repulsion can be enhanced by the intensive electric field from the designed tip electrospinning setup and the increase of the spinning voltage and the addition of salts.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 | |

| 30 | |

| 31 | |

| 32 | |

| 33 | |

| 34 | |

| 35 | |

| 36 |