† Corresponding author. E-mail:

High quality, concentrated sugar syrup crystal is produced in a critical step in cane sugar production: the clarification process. It is characterized by two variables: the color of the produced sugar and its clarity degree. We show that the temporal variations of these variables follow power-law distributions and can be well modeled by multiplicative cascade multifractal processes. These interesting properties suggest that the degradation in color and clarity degree has a system-wide cause. In particular, the cascade multifractal model suggests that the degradation in color and clarity degree can be equivalently accounted for by the initial “impurities” in the sugarcane. Hence, more effective cleaning of the sugarcane before the clarification stage may lead to substantial improvement in the effect of clarification.

Cane sugar (sucrose) is a basic livelihood commodity produced from sugarcane. Among the major cane sugar producers and consumers, China ranks the 3rd, accounting for 7% of the world total. Within China, the Guangxi Autonomous Region in southwest China is the biggest producer of cane sugar in the country, accounting for more than 60% of the market. Unlike in developed countries such as USA and Australia, cane sugar production in most factories in Guangxi and many other regions in China has not been made automatic, partly due to a lack of understanding of the fundamental physics and chemistry involved in the production process.

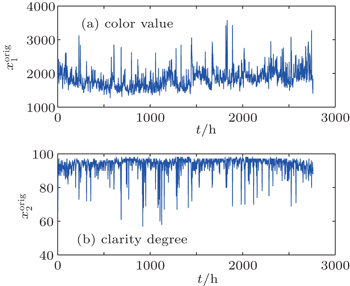

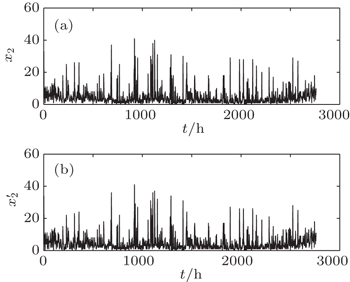

In general, cane sugar processing consists of six phases: milling, clarification, evaporation, crystallization, centrifuging, and drying so as to obtain white sugar, brown sugar, and other products.[1] In particular, the juice from the milling workshop is called the mixed juice, which contains water, sucrose, bagasse, soil, sand, reduced sugar, and many organic and inorganic non-sugar components. The latter are residual nutrients in the sugarcane, including colloidal substances, inorganic salts (iron, magnesium, aluminum, calcium, and so on), and pigments. Affecting the appearance, color, and concentration of the sugar, the non-sugar components are detrimental to the sugar production, and thus should be carefully removed. This is the aim of the next stage, the clarification stage. It is characterized by two target variables: the color of the produced sugar and its clarity degree. A typical example of the temporal variation of these variables is shown in Fig.

There has been a great deal of effort expended to improve the clarification of the mixed juice by using physical and chemical means, including using enzymes to reduce viscosity,[2] improving the flocculants,[3] employing electrocoagulation,[4] and enhancing decolorization by hydrodynamic cavitation.[5] These approaches are hoped to directly or indirectly enhance the absorption of impurities by flocs and sediments in the settler. Unfortunately, the effectiveness of the methods has not been thoroughly validated. As a result, these methods have not been adopted in practice yet.

There also has been effort to use neural network based prediction schemes[6,7] to improve cane sugar production. Being black or gray box-based approaches, however, they have not yielded much understanding of the basic physics and chemistry involved in the clarification process, and thus have not helped much with cane sugar production. Observing Fig.

The multifractal is one of the most important models contributed by complexity science. It is worth noting with the excitement that there has been a great deal of research on complexity science by the Chinese physical community, including works on stochastic resonance, bifurcations, and chaos.[8–22]

Mathematically, multifractals are characterized by many or infinitely many power-law relations. In this paper, we work with a specific type of multifractal, called the random multiplicative process model, to analyze the color value and the clarity degree. This type of multifractal was initially developed to understand the intermittent features of turbulence.[23–25] Mandelbrot was among the first to introduce this concept. Parisi and Frisch's work[26] on turbulence has made it widely known. It has been applied to the study of various phenomena, such as rainfall,[27] liquid water distributions inside marine stratocumuli,[28,29] finance,[30] tropical deep convective variability,[31] and network traffic.[32,33]

The remainder of the paper is organized as follows. In Section 2, we perform a distribution analysis of the clarification process, to infer whether the variations in the color value and the clarity degree may have system-wide causes. In Section 3, we employ the cascade multiplicative multifractal process to model the variations in the color and clarity degree. We show that those variations can be characterized by multifractal processes. The concluding discussion is presented in Section 4.

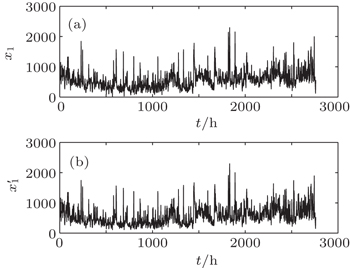

As we have pointed out, in order to infer whether the variations in the color value and the clarity degree may have system-wide causes, we may focus on the variations in the color value and clarity degree around the minimal and the maximal values, respectively. Denote the raw data of the color value and clarity degree by

| Fig. 3. Modeling of the variation of clarity degree: (a) measured and (b) simulated with σ = 0.1385. |

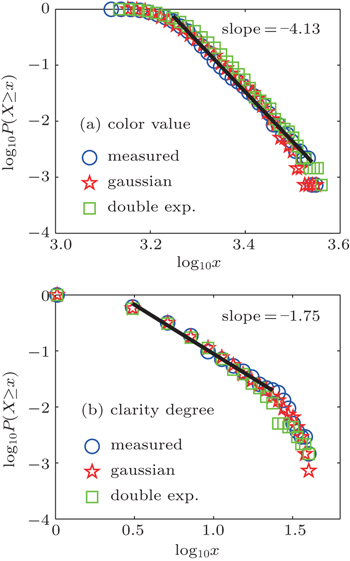

Let us perform a distribution analysis of these variables. Concretely, we will check whether they may follow two specific distributions. One is an exponential distribution, which may be expressed by its probability density function (PDF)

We hypothesize that if the distribution is close to exponential, or other thin-tailed distributions, then the variations in the color value and the clarity degree are simply random and do not have system-wide causes. However, if the distribution is heavy-tailed, then the variations in the color value and the clarity degree may have system-wide causes.

We have estimated the distributions for the time series data of x1 and x2. The results are shown in Fig.

To gain deeper insights into the clarification of sugarcanes, in this section we perform a multifractal analysis of x1 and x2.

With the framework of the cascade multiplicative model, one considers the moments

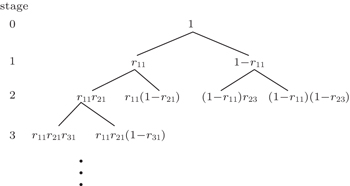

To better understand multifractal formalism, we consider below the random multiplicative cascade model. The conservative model, which is most pertinent here, is specified as follows. Consider a unit interval. Associate it with a unit mass. Divide the unit interval into two, say, left and right segments of equal length. Also, partition the associated mass into two fractions, r and 1 – r, and assign them to the left and right segments, respectively. The parameter r is in general a random variable, governed by a PDF P(r), 0 ≤ r ≤ 1. The fraction r is called the multiplier. Each new subinterval and its associated weight are further divided into two parts following the same rule. This procedure is schematically shown in Fig.

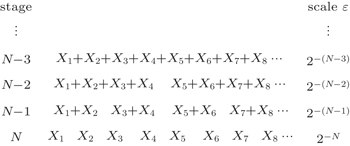

Let us now explain how to obtain the weights wi from a positive time series. The basic idea in analyzing a generic time series {Xi} is to view {Xi, i = 1,…, 2N} as the weight series of a certain multiplicative process at stage N. Under this scenario, the total weight

Given the weight sequence at stage N, the weights at stage

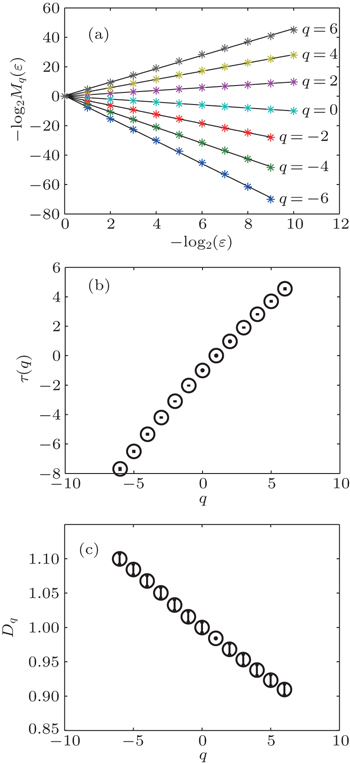

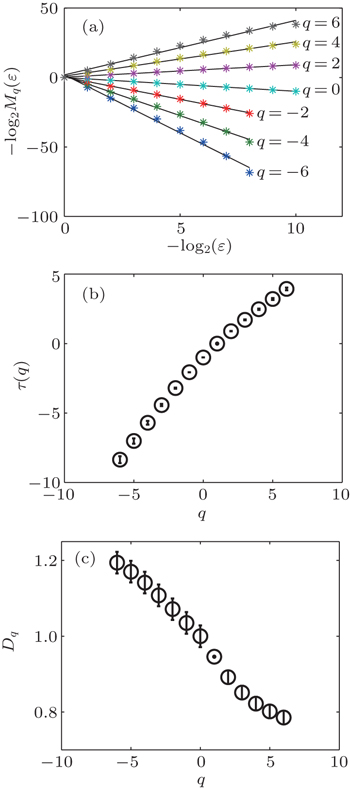

Following the above procedure, we have analyzed the multifractal properties of x1 and x2. The results are shown in Figs.

| Fig. 7. Multifractal analysis of the time series data of color value. Fitted lines for (a) Eq. ( |

| Fig. 8. Multifractal analysis of the time series data of clarity degree. Fitted lines for (a) Eq. ( |

The relevance of the cascade multifractal model to the variations in the color and the clarity degree can be made stronger by actually simulating these variables using the cascade model schematized in Fig.

The range in the unit interval means that it is a truncated Guassian distribution, therefore, given σ, c is determined by the condition

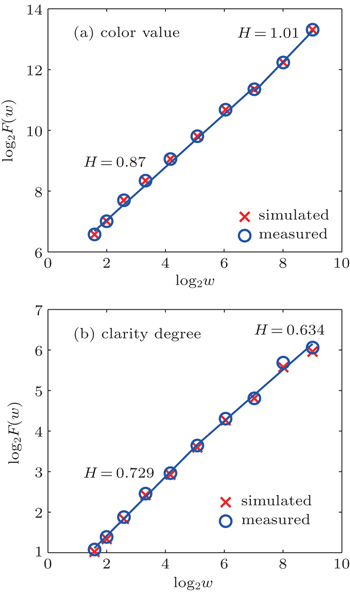

The similarity between the observed and the simulated color and clarity degree data can be further analyzed by examining the long-range correlation property of the data, quantified by the Hurst parameter 0 < H < 1. It is well-known that depending on whether H < 1/2, = 1/2, or > 1/2, a time series is said to have anti-persistent correlation, short-range correlation or is memoryless, or long-range correlations. In Ref. [1], we have analyzed the color and the clarity degree data, as well as other variables pertaining to the clarification process using detrended fluctuation analysis (DFA)[34] and adaptive fractal analysis (AFA).[35–38] Here, we only present the results in Fig.

| Fig. 9. Long-range correlation analysis of the measured and simulated data. (a) Color value and (b) clarity degree. |

In summary, we have shown that the measured color value and clarity degree data possess multifractal properties, and can be well-modeled by the cascade process, in the sense that the distributions and the correlations of the simulated data are almost identical to those of the real data. Interestingly, these features are largely preserved when different functionals are used for the multiplier distribution, including a double-exponential

Cane sugar production is an important industrial process. One of the most important steps in cane sugar production is the clarification process, which produces high quality, concentrated sugar syrup crystal for further processing. To gain fundamental understanding of the physical and chemical processes associated with the clarification process, and help design better approaches to improve the clarification of the mixed juice, in this paper, we have examined whether the degradation in the color and the clarity degree may have system-wide causes. We have found that the answer is positive. This has further motivated us to employ the cascade multiplicative multifractal model to analyze the variations in the color and the clarity degree. We have shown that those variations can be characterized by multifractal processes. Moreover, they can be conveniently modeled by the cascade model, with the simulated and the observed data having very similar distributions as well as long-range correlation properties.

Broadly speaking, the degradation in the color and the clarity degree may be thought to be caused by the “impurities” in the sugarcane. The cascade model adopted here is essentially a conservative model. This suggests that the “impurities” in the sugarcane may be associated with the “remnants” of the “dirts” of all kinds that remain during the initial cleaning of the sugarcane. Referring to the construction rule of the cascade model shown in Fig.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 | |

| 30 | |

| 31 | |

| 32 | |

| 33 | |

| 34 | |

| 35 | |

| 36 | |

| 37 | |

| 38 |