† Corresponding author. E-mail:

Project supported by the Open Foundation of State Key Laboratory of Electronic Thin Films and Integrated Devices (Grant No. KFJJ201506), the Scientific Research Starting Foundation of Hainan University (Grant No. kyqd1539), and the Natural Science Foundation of Hainan Province (Grant No. 20165187).

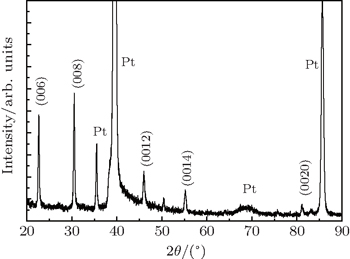

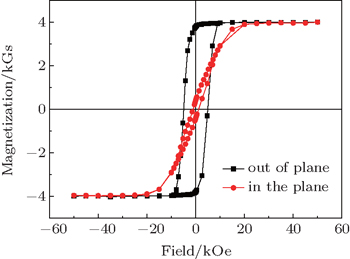

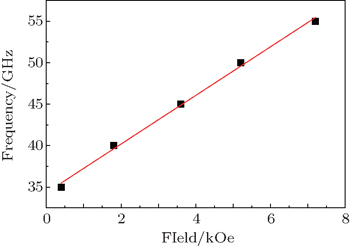

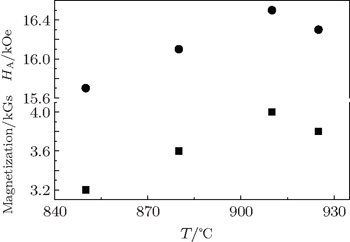

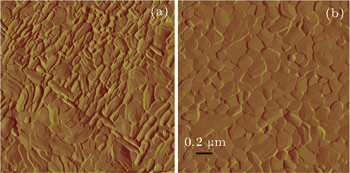

Barium ferrite (BaM) thin films are deposited on platinum coated silicon wafers by pulsed laser deposition (PLD). The effects of deposition substrate temperature on the microstructure, magnetic and microwave properties of BaM thin films are investigated in detail. It is found that microstructure, magnetic and microwave properties of BaM thin film are very sensitive to deposition substrate temperature, and excellent BaM thin film is obtained when deposition temperature is 910 °C and oxygen pressure is 300 mTorr (1 Torr = 1.3332 × 102 Pa). X-ray diffraction patterns and atomic force microscopy images show that the best thin film has perpendicular orientation and hexagonal morphology, and the crystallographic alignment degree can be calculated to be 0.94. Hysteresis loops reveal that the squareness ratio (Mr/Ms) is as high as 0.93, the saturated magnetization is 4004 Gs (1 Gs = 104 T), and the anisotropy field is 16.5 kOe (1 Oe = 79.5775 A·m−1). Ferromagnetic resonance measurements reveal that the gyromagnetic ratio is 2.8 GHz/kOe, and the ferromagnetic resonance linewith is 108 Oe at 50 GHz, which means that this thin film has low microwave loss. These properties make the BaM thin films have potential applications in microwave devices.

With the rapid developments of satellite communication, radar and global positioning systems, it is required that the next-generation microwave ferrite devices will be smaller, self-biased and low loss.[1,2] In the centimeter wave range, yttrium iron garnet is an ideal candidate material for microwave ferrite devices due to its low microwave loss.[3] However, it needs a larger external magnetic field to obtain resonance in the millimeter wave region, which is a disadvantage for minimizing the size of the device. Barium ferrites (BaFe12O19, BaM) with excellent c-axis orientation each have a large uniaxial magnetocrystalline anisotropy field (∼17 kOe) and low microwave loss, so it is possible to provide enough biased magnetic field to produce resonance and eliminate the requirement for an external magnetic field, thus reducing the size of the device.[4] Hence, excellent c-axis orientation BaM thin film is a very attractive material for microwave ferrite devices in the millimeter wave region.

The structure of BaM can be described as RSR*S*, where R is the rhombohedral block including two O4-layers and one BaO3 layer with the composition

So far, many methods have been tried to grow c-axis oriented BaM thin films, such as sputtering,[6] sol-gel,[7] metalloraganic decomposition,[8] liquid phase epitaxy,[9] etc. Besides these methods, pulsed laser deposition is another popular way to deposit BaM thin films.[10–12] In previous work, BaM thin films with high orientation and low microwave loss were deposited on sapphire substrate by pulsed laser deposition (PLD).[10,11] Our goal is to grow c-axis oriented BaM thin film with low microwave loss on silicon substrate for millimeter wave applications. Owing to the fact that the lattice mismatch between BaM and platinum (Pt) is small (about 5.8%),[13] we introduce Pt as the buffer layer in this research, and hopefully it can prevent Si from diffusing into BaM. In this paper, we discuss the effects of deposition substrate temperature on the microstructure, magnetic and microwave properties of BaM thin film.

BaM thin films were deposited on Pt-coated silicon substrates. The target was of a conventionally sintered BaFe12O19 polycrystalline material. The target was ablated using a KrF (λ = 248 nm) excimer laser working at 10 Hz. The distance between target and substrate was 5 cm. The substrate temperature ranged from 850 °C to 925 °C, the oxygen pressure was in a range of 300 mTorr. After deposition, thin films were sintered in flowing oxygen for 2 h at a temperature of 1000 °C.

The ferromagnetic resonance (FMR) experiments were measured using short waveguide. In measurement, an external magnetic field which was perpendicular to the film plane was swept at a fixed frequency in a range from 30 GHz to 55 GHz. The microwave magnetic field was applied in the BaM thin film plane. Crystal structures of BaM films were measured by x-ray diffractometer (XRD, Bede TM 2000) with a Cu Kα radiation. Morphologies of films were carried out by atomic force microscopy (AFM). The M–H loops were measured by a vibration sample magnetometer (VSM) with an applied field in a range from −50 kOe to +50 kOe.

Figure

Since the degree of grain orientation (f) for thin film is very important for microwave loss, it needs to be calculated by the Lotgering way,[14] and it is expressed as

The atomic force microscopy images (2 μm×2 μm) of BaM films deposited at 850 °C and 910 °C are shown in Figs.

| Fig. 2. The atomic force microscopy images (2 μm×2 μm) of BaM for samples deposited at 850 °C (a) and 910 °C (b), respectively. |

Figure

However, HA could be measured by FMR system. The relation between FMR frequency and external magnetic field is plotted in Fig.

The values of Ms and HA of the samples deposited in different substrate temperatures can also be obtained in the same way as that shown in Fig.

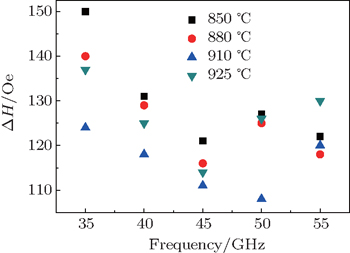

The plot of FMR line width (ΔH) versus frequency for the excellent thin film in a frequency range from 30 GHz to 55 GHz is shown in Fig.

| Fig. 6. Plots of FMR line width (ΔH) versus frequency for the excellent thin film in a frequency range from 30 GHz to 55 GHz. |

Highly oriented BaM thin films are successfully deposited by PLD on Pt-coated Si wafer. It is found that the magnetic and microwave properties of BaM thin films are dependent on the substrate temperature: when the substrate temperature is 910 °C an excellent BaM film can be obtained which has a high c-axis orientation, high anisotropic field, and low microwave loss. A saturated magnetization of 4004 Gs, squareness ratio (Mr/Ms) of 0.93, and an anisotropy field of 16.5 kOe can be obtained for the excellent thin film, and the FMR line width is 108 Oe at 50 GHz. These properties indicate that this BaM thin film is suitable for applications in microwave/millimeter wave devices such as circulators, isolators, filters, etc.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 |