† Corresponding author. E-mail:

We studied the influence of heat treatment time on the optical, thermal, electrical, and mechanical properties of strontium barium niobate (Sr1−xBaxNb2O6; hereafter SBN) piezoelectric glass-ceramics with tungsten bronze-type structure, which have good piezoelectric properties and are important lead-free piezoelectric materials. We found that the best heat treatment time is 4 h. The properties of the prepared materials are better than that of SBN ceramics and the glass-ceramic growth is faster than the SBN crystal when the heat treatment time of the SBN piezoelectric glass-ceramic is controlled, reducing the preparation costs greatly.

Piezoelectric materials have been widely used in the transformation between mechanical energy and electric energy. Ceramic materials possess a high dielectric constant but a low dielectric strength. Polymer materials possess a high dielectric strength but a small dielectric constant (typically < 5). Glass-ceramics are a kind of special polymeric material which has the advantage of high dielectric constant and high dielectric strength. Sr0.5Ba0.5Nb2O6 piezoelectric glass-ceramic is generally prepared by sintering methods.[1,2] However, it is difficult to eliminate porosity via those methods, leading to low breakage strength. Niobate-based piezoelectric ceramic systems often contain lead which may cause environmental pollution,[3,4] so a variety of methods have been used to research piezoelectric ceramic glass,[5,6] which shows that lead-free piezoelectric ceramic glass has excellent development prospects.

Compared with other energy storage materials, the tungsten bronze-type structure and perovskite-type structure of glass-ceramics have attracted more attention. The perovskite-type structure of glass-ceramics has been studied in our previous work.[7] Hence, we focus on tungsten bronze-type structure of glass-ceramics in this paper. Glass-ceramics with tungsten bronze-type structure is a kind of most relevant material currently. The ion at each position leads to a strong spontaneous displacement polarization below the temperature of Curie point, which makes the crystals exhibit a high dielectric constant in the macro. At present, the study of glass-ceramics with tungsten bronze-type structure is mostly concentrated in the glass system whose main crystal phase is the niobium acid.

Du et al.[8] found that tungsten bronze-type structure PbNb2O6 appears in the heating temperature range of 850–900 °C in the Na2O–PbO–Nb2O5–SiO2 system, and the content of PbNb2O6 increases with the increase of the crystallization temperature. Reece et al.[9] found that (Sr, Ba, Pb) Nb2O6 glass-ceramics can be obtained in the PbO–BaO–SrO–Nb2O5–B2O3–Al2O3–SiO2 system by sintering process, they also found that the content of Pb plays an important role in the dielectric constant of the sample and the dielectric constant increases with the increase of the content of Pb. Cheng et al.[10] found that in the PbO–BaO–SrO–Nb2O5–B2O3–SiO2 system, only the (Pb, Sr, Ba) Nb2O6 (PSBN) crystal phase appears in the sample in the heating temperature range of 700–1000 °C and the content of PSBN phase increases with the increase of heating temperature in the crystallization temperature range.

However, all these materials used in the past contain Pb, which pollutes the environment, which is not conducive to long-term development. Therefore, niobate lead-free piezoelectric glass-ceramics was studied in this paper. The strontium barium niobate (Sr1−xBaxNb2O6; hereafter SBN) with tungsten bronze-type structure was prepared by the high-temperature melting method. The effect of heat treatment time on the performance of the glass-ceramics was studied by experimental comparisons. We found that SBN lead-free piezoelectric glass-ceramics can also have a high dielectric constant and a high piezoelectric coefficient.

Using analytically pure SiO2, SrCO3, Ba(NO3)2, Nb2O5, and H3BO3 as starting materials, we prepared glass-ceramics with different proportions. When the content of SiO2 exceeded 60% (molar ratio), the melt temperature of the glass rose and the viscosity increased. It was difficult to remove small bubbles in the glass. When the content of the SiO2 was less than 35%, the SBN glass crystallized easily. Therefore, the content of SiO2 was maintained between 35% and 60%. The molar ratio of Sr+ and Ba+ was maintained at 1:1 and that of (Sr2++Ba2+): Nb5+ between 1:2 and 1.5:2. To reduce the viscosity of the glass, we added an appropriate amount of boric acid. The starting materials were placed into a ball mill for mixing. The mixture was then transferred to a silicon carbide resistance furnace and melted for 20 min at the temperature of 1470 °C. It was then placed in a blender for 1.5 h. The SBN glass liquid was placed on a pre-heated iron to mold in order to obtain SBN glass samples. The glass was annealed in a muffle furnace at 550 °C for 10 h to obtain the SBN glass. Finally, the SBN glass was placed in a muffle furnace at 680 °C and fired for 2 h, 4 h, 6 h, 8 h, and 10 h to produce five SBN glass-ceramic samples. In this way, the prepared glass has a short production cycle and the glass-ceramic grain growth may be easily controlled, which is an advantage for large-scale industrial production.

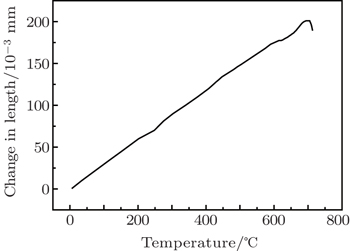

The SBN glass was placed in the thermal expansion coefficient tester. The transition temperature of the SBN glass was about 655 °C and the softening temperature of the SBN glass was about 701 °C as shown in Fig.

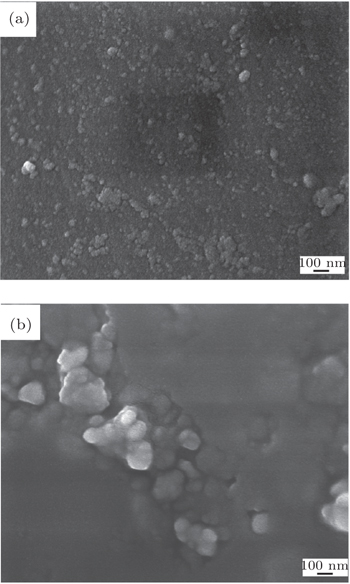

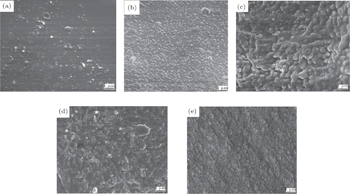

Figures

| Fig. 2. SEM micrographs of SBN glass by heat treatment for 2 h (a), 4 h (b), 6 h (c), 8 h (d), 10 h (e) magnified 10000 times respectively. |

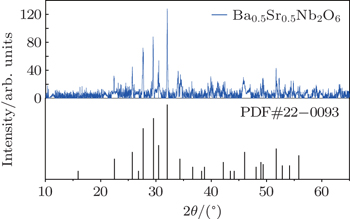

Figure

Figure

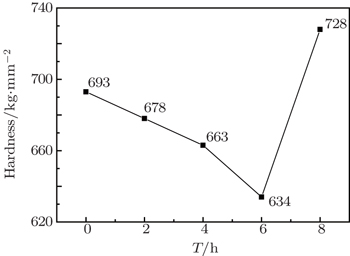

A hardness tester was used to investigate the hardness of the SBN glass-ceramics. The hardness was calculated using the following equation:

The hardness of the same samples was measured 5 times and the mean value was calculated. Figure

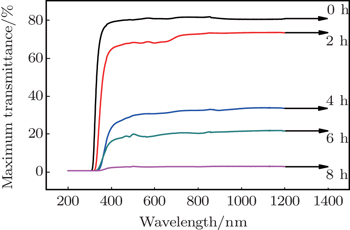

Transmittance is a mainly-used quantity to describe the transparency of substance. When the transmittance of a substance is greater than 10%, the substance is defined as a transparent body, but when it is less than 10%, the substance is defined as a non-transparent body.[12] We measured the transmittance of the SBN glass-ceramics after 0 h, 2 h, 4 h, 6 h, and 8 h heat treatment time using a spectrophotometer and the results are shown in Fig.

Figure

An Agilent-16451B was used to measure the dielectric constant of the SBN piezoelectric ceramic glass following the equation:

The sample was heated for 20 min and then placed in a ZJ-3AN quasi-static d33 meter to obtain piezoelectric coefficient d33 (pC·N−1).

Table

| Table 1. Permittivity and piezoelectric coefficient of the glass. . |

A novel glass-ceramic has been successfully prepared by heat treating SBN glass at 680 °C with various durations (2 h, 4 h, 6 h, 8 h, or 10 h). The analysis of the resulting samples leads to the following conclusions.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 |