† Corresponding author. E-mail:

Project supported by the Programme of Introducing Talents of Discipline to Universities (Grant No. B07018).

A multi-layer damper with waved plates under one-axial load is considered. A method of theoretical calculation of its energy dissipation coefficient is proposed. An experimental research of own frequencies and vibration transfer ratios for different parameters of damper structure, harmonic vibration load and random load is performed. Results of this research are approximated by functions; it is possible to use these functions for the calculation of the damper too.

All-metal vibration insulators have high strengths, high life-times, high energy dissipation coefficients, ability to work in aggressive media and vacuum. One of the widely used types of all-metal vibration insulators is the plate damper. Energy dissipation in this damper is provided by dry friction between plates (usually these plates are made of steel and have waves).[1–4] Some calculation methods of plate dampers were presented.[5–8] However usually they need some experimentally obtained constants or functions. Most of the research is devoted to the round damper of a shaft. In this case the damper is loaded by a revolving force. The hysteretic loop for this case is elliptic.[9–13] It is near the hysteretic loop of the linear system and simplifies a solution of differential equations. However some plate dampers are not round, their waves are placed on a plane, and they work under one-axial load. The hysteretic loop in this case is nearer to a parallelogram or triangle than to an ellipsis. Therefore it is necessary to use other methods of calculating these “plane” plate dampers.

Let us consider first a one-wave plate damper with two layers. The thickness of a layer is δ. Plates are rectangle, its size across the waves is B, along the waves it is L. The upper layer is loaded by vibration force with amplitude F. Under the assumption of uniform pressure distribution in a contact between the first and second layers, the value of amplitude of this pressure is p = F/(BL).

The wave of the damper is a segment of a circle with radius R and angle 2φ1. Take an infinitely small area with angle φ and angle difference dφ (Fig.

Infinitely small force on this area is dF = pRLdφ. Thus amplitude of normal force to a surface of a layer is dFn = pRL cos φ dφ, and the amplitude of tangent force is dFt = pRL sin φdφ. Normal force provides a friction force with amplitude dH = f dFn = pRL f cos φ dφ, where f is the friction coefficient. This force is in the direction opposite to dFt. Thus the amplitude of total tangential force is dH − dFt = pRL(f cos φ − sin φ)dφ.

If A is the amplitude of damper displacement under load F, the amplitude of tangential displacement is A sin φ. The hysteretic loop of tangential force for a load from 0 to A has the shape of a triangle. The area of this loop W is the energy dissipated during one cycle of the load.

The full dissipated energy for two halves of the wave is

If the angle is large, it is possible that after any value of φ = φb the inequality f cos φ < sin φ holds true. It means that this angle tangential displacement has the opposite direction. However energy dissipation takes place in this case too, it is only necessary to calculate an integral (

Potential energy of a deformed damper is

Thus it is possible to calculate an energy dissipation coefficient of the system as follows:

If the damper has N waves, it is possible to assume that the displacements in the inner waves are all near to zero, because displacements from forces applied to the highest points of the wave take place in opposite directions. Thus only two side parts of the damper have considerable relative displacements, and the problem is similar to the previous one.

Real contact between layers of the damper does not take place on all points of the surface, because the shapes of the layers have little difference between them. However because total force F is the same, if in some places contact is randomly absent, the pressure (and, respectively, friction force) proportionally increases in other places and total consequence is the same.

If a damper has n layers, it has (n − 1) contact pairs. Some of these layers, perhaps, have no slip, thus they do not take part in the process of energy dissipation. As a first approximation it is possible to assume that all contact pairs slip, thus it is necessary to multiply (

If the calculation of k is difficult, it is possible to assume k ≈ F/A for a linear system. In this case

For a plate damper with R = 192 mm, B = 78 mm, N = 1, φ1 = 0.204 rad, f = 0.1, and φb = 0.0997 rad. Calculated values are presented in Table

| Table 1. Calculated values of energy dissipation coefficient (N = 1, δ = 0.28 mm). . |

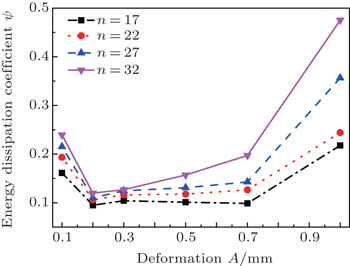

| Fig. 2. Energy dissipation coefficients versus deformation of plate damper for (a) N = 1 and δ = 0.28 mm, and (b) N = 3 and δ = 0.28 mm for different values of n. |

The disadvantage of Eq. (

For N = 3, the average value of energy dissipation coefficient for large deformation amplitudes in Fig.

For φ < 0.2, equation (

Its average value in the studied range is 0.17. Thus for φ > 0.2 it is possible to use Eq. (

For φ < 0.2 it is possible to estimate 0.17 < ψ < 0.34, and this question needs future research.

The calculated value of ψ allows the calculation of dynamic characteristics of the plate damper. For example, it is possible to use software ANSYS and harmonic analysis in this software. It is necessary to insert the value of ψ/(4π) as a coefficient of frequency independent damping DMPR. An example of this calculation is presented in Fig.

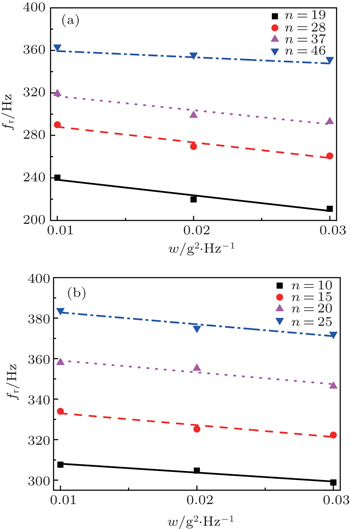

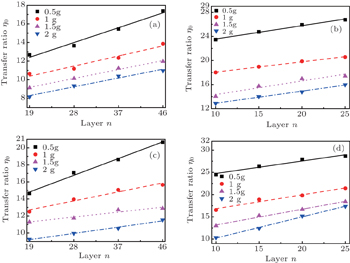

Another way of calculating the plate damper is approximation of experimental results. By using this method, we obtain not only the harmonic vibration, but also the random load. For harmonic vibration, the own frequency f0 and vibration transfer ratio on resonance η0 are obtained. Some experimental results are presented in Figs.

| Fig. 5. Dependences of f0 on ain and n for (a) δ = 0.28 mm and N = 1, (b) δ = 0.52 mm and N = 1, (c) δ = 0.28 mm and N = 3, and (d) δ = 0.52 mm and N = 3. |

| Fig. 6. Dependences of η0 on ain and n for (a) δ = 0.28 mm and N = 1, (b) δ = 0.52 mm and N = 1, (c) δ = 0.28 mm and N = 3, and (d) δ = 0.52 mm and N = 3. |

For calculating the characteristics of the damper, the experimental results are approximated by linear functions. As regards frequency:

for δ = 0.28 mm and N = 1: f0 = (265.21 + 1.55n) − (4.95 + 0.186n)a Hz (error is to 2.3%);

for δ = 0.52 mm and N = 1: f0 = (249.42 + 4.54n) − (1.32 + 0.53n)a Hz (error is to 2.0%);

for δ = 0.28 mm and N = 3: f0 = (152.9 + 5.2n) − (11.59 − 0.009n)a Hz (error is to 3.0%);

for δ = 0.52 mm and N = 3: f0 = (262.1 + 5.47n) − (3.087 + 0.21n)a Hz (error is to 2.1%).

As regards vibration transfer ratio on resonance:

for δ = 0.28 mm and N = 1: η0 = (9.94 − 1.838a) + (0.18 − 0.046a)n (error is to 7.1%);

for δ = 0.52 mm and N = 1: η0 = (24.075 − 7.128a) + (0.205 − 0.0006a)n (error is to 9.8%);

for δ = 0.28 mm and N = 3: η0 = (12.075 − 1.89a) + (0.235 − 0.092a)n (error is to 7.8%);

for δ = 0.52 mm and N = 3: η0 = (26.075 − 10.71a) + (0.195 + 0.128a)n (error is to 12.4%).

For random load with different values of load power spectral density w = 0.01 g2/Hz, …, 0.03 g2/Hz, the value of root mean square acceleration is equal to the square root of the total area below the power spectral density curves, transfer ratio ηr = s2/s1, where s1 is the input root mean square acceleration, s2 is the root mean square acceleration on the protected object on resonance, and frequency of maximal output spectral density fr are obtained. Some experimental results are presented in Figs.

Approximation functions for frequency are as follows.

For δ = 0.28 mm and N = 3: fr = (181.2 + 4.05n) − (2213 − 30.9n)w (error is to 3.0%);

for δ = 0.52 mm and N = 3: fr = (262.145 + 5.09n) − (395.67 + 8.72n)w (error is to 0.9%).

Approximation functions for transfer ratio are as follows.

For δ = 0.28 mm and N = 3: ηr = (499 + 2.57n)w2 − (34.4 + 0.15n)w + (1.23 − 0.0007n) (error is to 3.0%);

for δ = 0.52 mm and N = 3: ηr = (829 − 5.55n)w2 − (52.5 −0.27n)w + (1.41 −0.0048n) (error is to 0.74%).

It is possible to draw some conclusions from the comparison of experimental results. Own frequency of the studied plate damper depends on total thickness of the damper, but not on the number or thickness values of the layers (for example, dampers with the same values of total thickness nδ = 46 × 0.28 = 12.88 mm and nδ = 25 × 0.52 = 13 mm have similar own frequencies seen from Fig.

The own frequency is little dependent on input acceleration ain: if ain increases 4 times (from 0.5 g to 2 g), maximal changing of f0 is 5%, usually it is less (it is the same as that for damper with N = 3). Frequency fr is also little dependent on load power spectral density: if w increases 3 times from 0.01 g2/Hz, …, 0.03 g2/Hz, the maximal change of fr is 10%. It is a useful property to allow an application of studied plate damper in wide ranges of vibration and random load.

Vibration transfer ratio on resonance increases if the number of layers increases, because η0 ≈ 2π/ψ, and energy dissipation coefficient ψ increases when friction in the system increases, and it decreases when stiffness of system increases. Thus it means that if the number of layers increases, the stiffness of the studied damper increases more than friction, though the friction surface increases in this case. Therefore for a small vibration transfer ratio on resonance it is better to use the small number of layers. If the thickness value of each layer is bigger, the dependence of η0 on n is significantly weak (Fig.

Plate damper is a dry friction system. For a dry friction system if deformation amplitude is equal to zero, there is no slip in the system and ψ = 0. For non-zero deformation amplitude the value of ψ increases to any maximum and then decreases. This maximum usually lies in a range of little amplitude.

Because the studied damper has a high own frequency, its deformation amplitude on resonance is small. The whole range of vibration amplitudes obtained in dynamic experiment (from 0.01 mm to 0.1 mm) is before the maximum of ψ. Thus if input acceleration increases, the value of ψ increases too, and acceleration of the protected object increases not so much. If the input acceleration increases 4 times (from 0.5 g to 2 g), the transfer ratio on resonance significantly decreases (because η0 ≈ 2π/ψ, Fig.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 |