† Corresponding author. E-mail:

Project supported by the National Key Basic Research Program of China (Grant Nos. 2014CB643903 and 2013CB932904), the National Special Funds for the Development of Major Research Equipment and Instruments, China (Grant No. 2012YQ140005), the National Natural Science Foundation of China (Grant Nos. 61435012, 61274013, 61306088, and 61290303), and the Strategic Priority Research Program (B) of the Chinese Academy of Sciences (Grant No. XDB01010200).

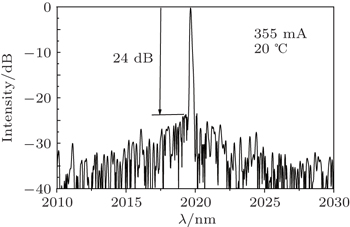

We report a type-I GaSb-based laterally coupled distributed-feedback (LC-DFB) laser with shallow-etched gratings operating a continuous wave at room temperature without re-growth process. Second-order Bragg gratings are fabricated alongside the ridge waveguide by interference lithography. Index-coupled LC-DFB laser with a cavity of 1500 μm achieves single longitudinal mode continuous-wave operation at 20 °C with side mode suppression ratio (SMSR) as high as 24 dB. The maximum single mode continuous-wave output power is about 10 mW at room temperature (uncoated facet). A low threshold current density of 230 A/cm2 is achieved with differential quantum efficiency estimated to be 93 mW/A. The laser shows a good wavelength stability against drive current and working temperature.

The semiconductor laser diode based on AlGaAsSb/InGaAsSb alloys grown on GaSb substrates is attracting more and more attention in mid-infrared applications such as remote gas sensing,[1] molecular spectroscopy,[2] medical and defense applications[3] for its small size and excellent laser property. Many industrial and harmful gaseous byproducts such as CO, HF, CO2 and H2O have strong absorption features in the wavelength range between 1.9 μm and 5 μm which is fully covered by GaSb-based laser diode.[4–6] For designing a lidar system for gas sensing, a tunable diode laser absorption spectroscopy (TD-LAS) laser with narrow linewidth is particularly important, which has been reported in previous literature.[1,7,8] GaSb-based Fabry–Perot (FP) laser exhibits mode hops and is inapplicable for this kind of application.[9] Lasers with a mode selecting function such as distributed feedback lasers show excellent characteristics in narrow linewidth and single longitudinal mode emission, thus they are the ideal candidates for gas sensing applications.[10,11]

The conventional fabrication of InP-based DFB lasers emitting around 2 μm requires two to three high-quality epitaxial growths, the first epitaxial process stops after the growth of the waveguide layer, then a Bragg grating structure is fabricated on the wafer, after that, an epitaxial re-growth step is necessary to complete the growth of the laser epitaxy.[12,13] Although the re-growth technique is common and mature in InP-based DFB lasers, it is particularly difficult in the case of GaSb-based laser due to the oxidation of the high Al content in the epitaxy.[14] Miller et al. proposed a regrowth-free DFB structure in which the gratings were located alongside the ridge-waveguide. The laser structure was completed in a single epitaxy layer growth step and avoided the difficulty in the re-growth process. This kind of laser was later named ‘laterally coupled’ DFB (LC-DFB) laser.[15] LC-DFB is aimed at avoiding the oxidation of Al content in the epitaxy after the defining of grating, and it can also be used in GaAs and InP material to avert the re-growth step.[15–17] The GaAs- and InP-based LC-DFB lasers showed a good laser property which was very competitive compared with the traditional DFB laser and attracted a lot of attention.[15–17] So far, the continuous wave operation of GaSb-based LC-DFB laser diodes were reported to emit light beams at wavelengths of 2 μm, 2.3 μm, 2.6 μm, 2.8 μm, 3.4 μm.[5,18–20] Owing to the mode selecting mechanism of LC-DFB lasers, the defining of subsize grating is the most important and difficult part. Among the reports of LC-DFB lasers, Bragg grating has been fabricated using e-beam lithography (EBL),[15,16,21] nanoimprint lithography,[22] and interference lithography.[23] EBL is good at assuring the grating quality but it is expensive and fabrication-inefficient, which is costly and time consuming.[7] Interference lithography and nanoimprint lithography are good at defining Bragg grating on a planar epitaxy surface but they present a big problem in transferring the surface grating deep into the waveguide layer as a high aspect ratio is needed in dry etching. To be specific, the traditional fabrication schedule is first patterning grating on the top of the epitaxy, followed by the defining of the ridge waveguide with photolithography. To form a good coupling coefficient, the ridge waveguide and grating are then etched deep to the waveguide layer in one etching process, which brings problems to the deep dry etching as a high aspect ratio (normally 20:1) is required to transfer the surface grating deep into the waveguide layer.[23]

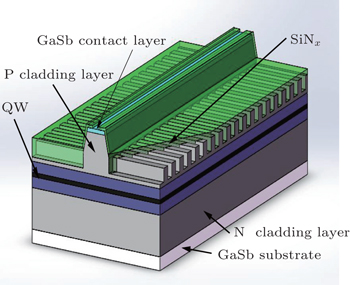

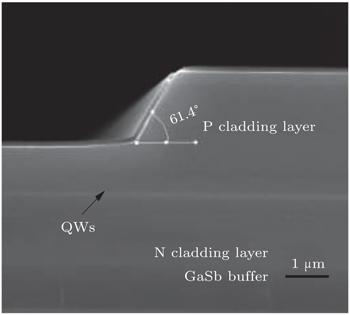

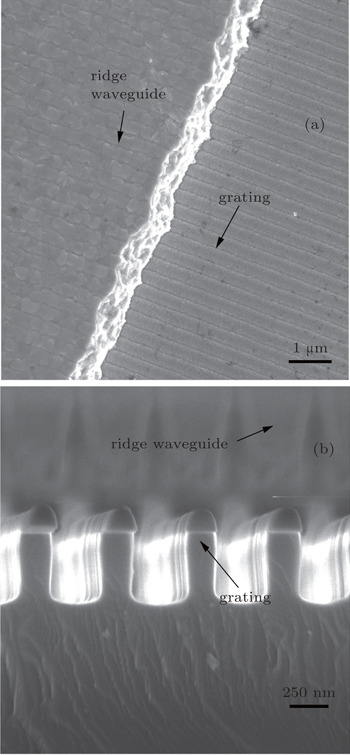

To solve the aforementioned problems and reduce the aspect ratio in dry etching, we report an improved new approach to fabricating an index coupled LC-DFB laser with second-order grating by interference lithography. Figure

The GaSb-based laser structure is grown on an n-type GaSb (100) substrate by using solid–source molecular beam epitaxy (MBE). The epilayer structure contains an n-doped Gasb buffer layer followed by a 1.5-μm n-doped Al0.9Ga0.1As0.02Sb0.98 cladding layer. The undoped active layer consists of 20 nm/10 nm three pairs of In0.2Ga0.8Sb/Al0.4Ga0.6As0.02Sb0.98 quantum wells (QWs) with a compressive strain of 1.0% located in the central part of an undoped 400-nm Al0.4Ga0.6As0.02Sb0.98 waveguide layer.[4] The upper cladding layer is composed of p-doped Al0.9Ga0.1As0.02Sb0.98 layer with a thickness of 1.5 μm followed by a 250-nm highly doped GaSb contact layer for achieving a good Ohm contact with the p-side electrode mental.

The design of our LC-DFB lasers is based on the effective coupling coefficient, the modal effective refractive index of the unperturbed ridge laser is numerically calculated by using a full-vector finite-difference calculation.[21] Assuming an effective-medium index for the grating region, the neff is calculated to be 3.45 while the electric-field overlap factor Γgrating, which describes the extent to which the electric field overlaps with the grating is calculated to be 0.46%, thus the second-order grating width is calculated to be 580 nm for a wave range of 2 μm. Using the approximation employed in Ref. [24], the feedback effect of the lateral gratings can be quantified by estimating the grating coupling coefficient,

Figure

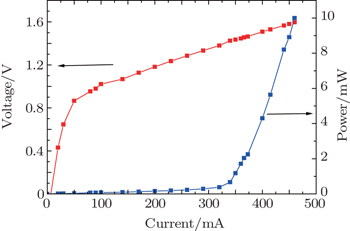

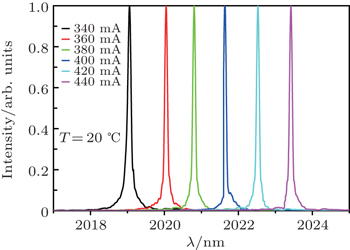

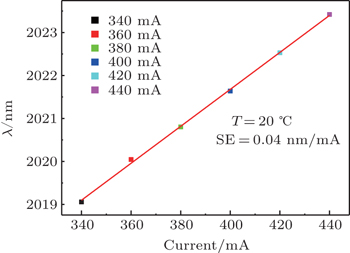

All devices are mounted epi-side down onto a copper heatsink. The output characteristics of these devices are measured using a calibrated thermopile detector at room temperature. Emission spectra are measured by a Fourier-transform infrared (FTIR) method. All the devices are tested without facet coating. Figure

| Fig. 5. Representative output spectrum of an LC-DFB laser with an injecting current of 355 mA. The laser shows a single longitudinal mode operation with an SMSR of 24 dB. |

The light against current (L–I) characteristics at room temperature are shown in Figs.

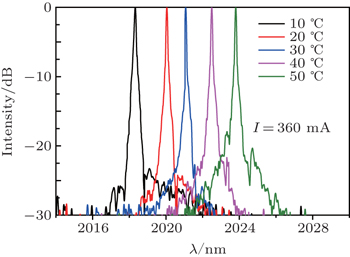

The light against temperature characteristics are shown in Fig.

We successfully present an improved fabrication of LC-DFB laser which is low cost and productive. The second-order etched grating is patterned by interference lithography on a nonplanar epitaxy. Our improved fabrication sharply reduces the aspect ratio of the conventional process without loss of laser property. The epitaxy is completed in a single growth step and avoids the regrowth of oxidated Al content in epitaxy layer. The CW laser operates in a single longitudinal mode at room temperature with an SMSR of more than 24 dB. The wavelength stability against current and temperature shows a typical characteristic of laterally coupled distributed feedback laser. The device emits up to 10 mW at room temperature which is high enough for gas sensing application in mid-infrared wavelength.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 |