†Corresponding author. E-mail: songhuihui@mail.nwpu.edu.cn

*Project supported by the National Natural Science Foundation of China (Grant No. 51072165) and the Fund of the State Key Laboratory of Solidification Processing in Northwestern Polytechnical University, China (Grant Nos. KP201307 and SKLSP201313).

Pyrolytic carbon (PyC) coatings are deposited on the Nextel-440 fiber fabrics by chemical vapor deposition (CVD). The dielectric properties of the Nextel-440 fiber fabrics with PyC coatings (Nextel-440/PyC) are investigated in a temperature range from room temperature to 700 °C in X-band. Compared with the permittivity of the original Nextel-440 received, the complex permittivity of the Nextel-440/PyC (the real part ε′ and the imaginary part ε″), is significantly improved: ε′ of the Nextel-440/PyC has a positive temperature coefficient, in contrast, ε″ of the Nextel-440/PyC exhibits a negative temperature coefficient. Moreover, the reflection loss in units of dB is calculated. The results indicate that the microwave absorbing properties of the Nextel-440/PyC coatings is enhanced at 700 °C compared with that at lower temperatures.

Microwave absorbing materials have attracted much attention because of their civil and military applications.[1– 6] These materials ideally possess low density, favorable mechanical properties, and appropriate dielectric properties for strong microwave absorption over a wide frequency range. Sometimes, they are used in high temperature environments.[7] For this, the high temperature dielectric property of a material of this kind is one of the most important parameters, and many studies has been carried out to determine this.[8– 13] Wen et al.[9]and Song et al.[10] reported the dielectric properties of short carbon fiber/silica composites in a temperature range from 30 ° C to 600 ° C and those of carbon-nanotube/silica composites in a temperature range between 100 ° C and 500 ° C. Tian et al.[12] and Liu et al.[13] investigated the dielectric properties of SiC fiber-reinforced SiC matrix composites in a temperature range from 25 ° C to 700 ° C.

Ceramic matrix composites (CMCs) have been recognized as candidate materials for high-temperature structural applications because they are lightweight and exhibit a much greater resistance to high temperature and aggressive environments than metals or other conventional engineering materials.[14] As is well known, continuous fiber reinforced ceramic composites (CFCCs) can provide a significant amount of toughness and avoid catastrophic failure. Because of this, CFCCs have been investigated intensively as structure microwave absorbing materials at high temperature. The continuous fibers in CFCCs are mostly ceramic. These ceramic fibers and their fabrics can be used as reinforcement in CFCCs, which is attracting increasing levels of attention.[15] Among the different kinds of ceramic fibers, the commercial available Nextel series of Al2O3 fibers produced by Minnesota Mining and Manufacturing Corporation (3M) have aroused much interest.[16] Pyrolytic carbon (PyC) coating has become well known as one of the best interphase materials between fiber and ceramic matrix for CFCCs, providing excellent mechanical properties.[17, 18] At the same time, the PyC interphase coating also affects other physical properties of the ceramic fibers and the CFCCs, such as dielectric properties. Ding et al.[19] investigated the effect of PyC coatings on the dielectric properties of the Nextel-440 fiber fabrics at room temperature. However, results about the effect of PyC coatings on the dielectric properties of the Nextel-440 fiber fabrics at high temperature have never been reported.

In this paper, PyC coatings are deposited on the Nextel-440 fiber fabrics by chemical vapor deposition (CVD). The dielectric properties of the Nextel-440 fiber fabrics with PyC coatings-Nextel-440/PyC, are investigated in a temperature range from room temperature (RT) to 700 ° C in X-band. Moreover, the reflection loss in units of dB indicating the absorbing property of the Nextel-440/PyC is calculated.

The continuous Nextel-440 fibers were produced by 3M corporation and brained by Nanjing Class Fiber Institute (China). The parameters of the Nextel-440 fibers fabrics could be found in Ref. [19].

The PyC coatings were deposited on the Nextel-440 fibers by decomposition of C3H6 at 800 ° C for 1.5 h at a pressure of 5 kPa, arriving at a thickness of about 0.15 μ m. C3H6 was the gas precursor, and H2 was chosen as the diluent gas. The flow rates of C3H6 and H2 were 1500 ml/min and 1000 ml/min, respectively.

The morphologies of the original Nextel-440 fibers and the Nextel-440/PyC were observed by scanning electron microscopy (SEM) (Model SUPRA-55, Zeiss, Germany and S-4700, Hitachi, Japan). The dielectric property was, respectively, measured at room temperature, 300 ° C, 500 ° C, and 700 ° C in X-band, by the rectangular wave-guide method through using a vector network analyzer VNA (Agilent technologies E8362B). The size of the tested samples was 22.86 mm (length) × 10.16 mm (width) × 2 mm (thickness). The measurement details were reported elsewhere.[20] The tested samples were treated as shown in Fig. 1. The final product was a transparent glassy material, which densified the fiber fabrics, avoiding the dispersing of fiber bundles in fabrics and preventing the oxidization of the PyC coatings in the samples. The parameters of the tested samples after this treatment are listed in Table 1.

| Table 1. Parameters of the samples after treatment at room temperature. |

Figure 2 shows the morphologies of the Nextel-440 fibers before and after PyC deposition. Before PyC deposition, the surfaces of the original Nextel-440 fibers are rough, and there are some pimples and defects (Fig. 2(a)). After the PyC deposition, the surfaces become relatively smooth and no bridging is detected (Fig. 2(c)). Figures 2(b) and 2(d) present the cross sections of the Nextel-440 fibers before and after PyC deposition, indicating that the PyC coating has been deposited uniformly. The thickness of the PyC coating is about 0.15 μ m.

The dielectric property is characterized in terms of the relative complex permittivity, with the real part ε ′ and the imaginary part ε ″ . Figure 3 shows the values of complex permittivity of the samples at different temperatures. As can be seen, the values of relative complex permittivity of the Nextel-440/PyC is bigger than that of the Nextel-440 fiber fabrics at each temperature, which results from more polarizations and conduction loss caused by the as-deposited PyC coatings.[19] In addition, it can be found that the complex permittivity (both ε ′ and ε ″ ) of the original Nextel-440 fiber fabrics slightly increases as the temperature rises. It is also observed that ε ′ of the Nextel-440/PyC increases with increasing temperature, indicating a positive temperature coefficient; while ε ″ of the Nextel-440/PyC decreases with increasing temperature, indicating a negative temperature coefficient.

According to the Debye theory, the complex permittivity of the composites could be expressed as

where ε ∞ is the high frequency limiting value of permittivity, ε s is the static value of permittivity, ε 0 is the dielectric constant in vacuum, ω = 2π f is the angular frequency, f is the frequency of the incident wave in Hz, τ (T) is the relaxation time at a specific temperature T, and σ (T) is the electrical conductivity at a specific temperature T. According to the Arrhenius formula, [18] the relaxation time τ (T) can be described as

Based on Eqs. (1) and (3), the positive temperature coefficient of the real part ε ′ of the Nextel-440/PyC as shown in Fig. 3(a), results from the shortened relaxation time at the elevated temperature.[21] For the Nextel-440/PyC, the original Nextel-440 fiber is composed of 70% Al2O3, 28% SO2, and 2% B2O3 by weight and formed in the main of small γ -alumina in amorphous silica; [22] the as-deposited PyC coating has been confirmed to consist of micro-crystallite graphite and disordered carbon.[19, 23] There are free electrons in graphite plane and weak bond electrons among graphite planes in the PyC coating. The weak bound electrons in the PyC coating introduce the relaxation polarization. The shortened relaxation time at the elevated temperature can cause more polarizations.

Compared with the slightly increasing trend of the imaginary part ε ″ of the original Nextel-440 fiber fabrics in the temperature range studied, the imaginary part ε ″ of the Nextel-440/PyC presents a decreasing trend, as shown in Fig. 3(b), indicating a negative temperature coefficient. It can be noted that the as-deposited PyC coating contributes to this phenomenon of the imaginary part ε ″ of the Nextel-440/PyC.

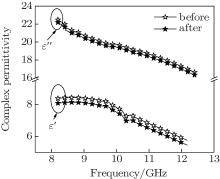

| Fig. 3. Variations of complex permittivity ((a) real part ε ′ and (b) imaginary part ε ″ ) with frequency for samples at different temperatures. |

Equation (2) shows that ε ″ is determined by the relaxation time and electrical conductivity of the composites. For most of dielectric materials, conduction loss is the most important factor that affects the permittivity ε ″ . In the case of the Nextel-440/PyC, the electrical conductivity at room temperature of original Nextel-440 fiber is about 5 × 10− 3 S· cm− 1 and that of the Nextel-440 fiber with around 0.15-μ m thick PyC coatings is about 334 S· cm− 1. The as-deposited PyC coating has a significantly higher conductivity because of the existence of π -bonding, [19] so the electrical conductivity would play a dominant role in the imaginary ε ″ . Thus, ε ″ of the Nextel-440/PyC can be expressed as

where σ (T) is the electrical conductivity at a specific temperature.

Precisely, how the temperature dependence of ε ″ of the Nextel-440/PyC declines is not yet well understood. Figure 4 shows the variations of complex permittivity with frequency for the Nextel-440/PyC sample, measured at room temperature before and after the high temperature measurement. As can be seen, the complex permittivity of the Nextel-440/PyC before and after the high temperature measurement has changed slightly, which could be ignored, indicating that most of the PyC coatings are not oxidized during the high temperature measurement process.

The high temperature microwave absorbing properties is evaluated by calculating the reflection loss (RL) according to the transmission line theory mentioned in Ref. [21]. For this case, d is taken to be 2 mm, and μ r can be taken to be 1 due to the weak magnetisms of the samples. Figure 5 shows the curves of calculated RL (in units of dB ) versus frequency of the samples at different temperatures. Figure 5(a) shows that the values of RL increase with temperature rising, indicating that the microwave absorbing property of the original Nextel-440 fiber fabrics at 700 ° C is poorer than at lower temperature. As presented in Fig. 5(b), the values of RL of the

| Fig. 5. Curves of calculated RL versus frequency for (a) the original Nextel-440 fiber fabrics and (b) the Nextel-440/PyC at different temperatures. |

Nextel-440/PyC decrease with increasing temperature, which implies that the microwave absorbing properties at 700 ° C is stronger than at lower temperatures.

In this paper, for the first time, the microwave dielectric properties of the Nextel-440 fiber fabrics with PyC coatings are reported in a temperature range from room temperature to 700 ° C in X-band. The results show that the real part ε ′ of complex permittivity of the Nextel-440/PyC has a positive temperature coefficient; in contrast, the imaginary part ε ″ exhibits a novel negative temperature coefficient. Moreover, the microwave absorbing property of the Nextel-440/PyC is calculated, which is stronger at 700 ° C than at the lower temperature in the temperature range studied. This report provides a reference for future studies of fiber/matrix composites with pyrolytic carbon interphase coatings used in high temperature environments.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

|

| 21 |

|

| 22 |

|

| 23 |

|

| 24 |

|