†Corresponding author. E-mail: daishixun@nbu.edu.cn

‡Corresponding author. E-mail: wuyuehao@nbu.edu.cn

*Project supported by the National Natural Science Foundation of China (Grant Nos. 61177087 and 61435009), the National Key Basic Research Program of China (Grant No. 2012CB722703), the Program for Innovative Research Team of Ningbo City, China (Grant No. 2009B21007) , the K. C. Wong Magna Fund in Ningbo University, the Open Fund of the State Key Laboratory of Luminescent Materials and Devices (South China University of Technology), China (Grant No. 2014-skllmd-01), and the Natural Science Foundation of Ningbo City, China (Grant No. 2014A610125).

We report the applications of a low-cost and environmentally friendly chalcogenide glass, 75GeS2-15Ga2S3-10CsI, in building active microsphere laser oscillators. A silica fiber taper is used as the coupling mechanism. With an 808-nm laser diode as a pump source, we show that a high- Q (∼ 6×104) laser mode could be obtained from a 75-μm diameter microsphere that is coupled with a 1.77-μm waist-diameter fiber taper. The threshold of the incident pump power is 1.39 mW, which is considerably lower than those of previously reported free-space coupled chalcogenide microsphere lasers. We also note an apparent enhancement in laser power generated from this chalcogenide microsphere laser.

Glass microspheres have become attractive choices in the fields of nonlinear optics, luminescence, quantum optics, and optical sensing.[1, 2, 3, 4, 5] They trap light by continuous total internal reflections (TIRs) at the glass/air boundary and confine optical energy in the form of Whispering Gallery (WG) modes.[6] Due to their superior optical properties, such as high Q-values and low mode volumes, active microsphere laser oscillators made of rare earth ion (REI)-doped glass materials are well-known to have low lasing thresholds, high pump efficiencies, and narrow emission linewidths.[7]

Various glass materials have been used as base materials for building active or passive microsphere laser oscillators, such as silica, borosilicate, phosphate, tellurite, fluoride, barium– titanium– silicate, and chalcogenide glasses (ChGs).[7– 14] Among them, ChGs are particularly interesting because of their good transparencies in the IR spectrum, good solubilities of REIs, high refractive indices, and low phonon energies.[15] Microsphere laser oscillators have been built with conventional ChG materials such as 70Ga2S3-30La2S3 (in mol% ) (GLS) and As2S3.[12, 13] However, these two ChGs have inherent short-comings that restrict their further/wider applications: GLS glass utilizes the expensive rare earth element of lanthanum and As2S3 poses safety concerns in the manufacturing/handling process.

In the present paper, we propose the use of a novel ChG to build active microsphere laser oscillator, whose composition can be expressed as 75GeS2-15Ga2S3-10CsI (in mol% ) (doped with 0.5-wt% Nd2S3). In short, we call it GGSI in the rest of this paper. While sharing similar advantageous optical properties with other ChGs in the IR spectrum, the GGSI only costs approximately a quarter that of GLS and it does not contain the hazardous element of arsenic. Moreover, GGSI has a low melting temperature (∼ 900 ° C) and a good thermal stability (Δ T > 150 ° C, Δ T = Tx – Tg), which makes the fabrication process relatively convenient.[16] Moreover, we use a tapered fiber to couple the pump light in and the excited laser modes out of the microsphere. This fiber taper coupling mechanism was previously used in microsphere lasers fabricated with other materials.[9, 10] It was also used for generating Raman lasing in microspheres made of As2S3.[13] In this work, we report its first application with an active microsphere laser oscillator made of ChG materials. We show that high-Q (∼ 6× 104) laser modes can be generated from a 75-μ m diameter GGSI microsphere that is coupled with a 1.77-μ m waist diameter silica fiber taper. We also demonstrate that the performances in pump threshold and the emitted laser power of our fabricated laser are much better than those of free-space coupled active ChG microsphere laser oscillator.

We first fabricated bulk GGSI glasses with the facilities of our laboratory.[16] The refractive index of the GGSI glass was 1.99 at 1310 nm and a typical attenuation value of this material was 0.0298 mm− 1. The bulk material was then crushed into powders of appropriate sizes and dropped through a home-made vertical furnace, which was filled with the inert gas of argon. In the hyperthermal environment of the furnace the surface tension pulled the molten glass powders into spherical droplets, which were then cooled into solid microspheres when dropped out from the bottom outlet of the furnace.[17] Most of the ChG microspheres fabricated with the facilities of our lab have diameters ranging from 50 μ m to 150 μ m. To prepare the fiber taper, we attached both ends of a piece of standard communication fiber (∼ 1 meter long) to a pair of high-precision motion stages (ZOLIX, model number: TSA 50-C), melted the fiber in its central region using an oxyhydrogen micro-torch, and controlled the stages to move in opposite directions with appropriate speeds. The molten region of the fiber was elongated in this pulling process and its diameter was reduced accordingly. The molten region of the fiber was approximately 3 mm in length and the resulting fiber taper was approximately 2.5 cm in length. A typical loss caused by the fiber drawing process was about 0.5 dB. By carefully adjusting the size of the molten region and the drawing speed/distance, we could fabricate fiber tapers with waist diameters ranging from 1 μ m to 3 μ m.

With the aid of a high power optical microscope (KEYENCE, model number: VHX-1000E), we selected a 75-μ m diameter microsphere for a demonstration experiment. This microsphere was glued onto the tip of a fiber stem, which was then mounted on a 3-axis nano-positioning stage (THORLABS, model number: NanoMax-TS). We fabricated a fiber taper of 1.77-μ m waist diameter for coupling with the microsphere. By careful adjustments, we positioned the fiber taper in direct contact with the microsphere in its equator region. Noting that Nd3+ ions absorb photon energy strongly around 800 nm, due to the absorption band of 4I9/2→ 4F5/2+ 2H9/2, we chose a fiber-coupled 808-nm laser diode (LEO, model number: LE-LS-808-80TFCS) as a pump source. Since the pump light was launched into the single mode fiber, the evanescent tail of the light in the taper was coupled into the ChG microsphere. The output port of the single mode fiber was connected to an optical spectrum analyzer (OSA) (ANDO, model number: AQ6317B), so that the spectral characteristics of the pump light and the WG modes produced by the ChG microsphere could be accurately evaluated.

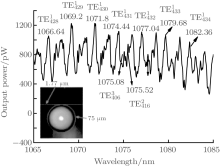

Figure 1 shows a typical fluorescence spectrum obtained from the ChG microsphere when the pump power is below the laser threshold. The WG mode numbers are marked near the corresponding resonant peaks. The inset shows a microscopic image of the ChG microsphere and the coupled fiber taper. The diameter of the sphere is 75 μ m and the waist diameter of the fiber taper is 1.77 μ m. Due to the mismatch of refractive indices between the ChG microsphere (1.99 at 1310 nm) and the silica fiber taper (1.46 at 1310 nm), only WG modes with high radial mode numbers (n > 1) can be phase-matched with the fundamental or low-order propagation modes of the silica fiber taper.[18] As such, a significant portion of the pump power and the laser power emitted from the microsphere are lost in the coupling process. The coupling efficiency of our setup can be enhanced by developing a suitable drawing technology for fiber tapers made of the same GGSI material. As such, the refractive index mismatch between the fiber taper and the microsphere can be eliminated and the coupling efficiency can be enhanced.

We numerically study the locations of WG mode resonance peaks using the classic Mie scattering theory. The average spacing between adjacent resonance peaks in the simulation results is 2.42 nm, which is deviated from the experimental result by 0.2 nm. This deviation is caused mainly by the departure of the fabricated microsphere from ideal spheres. The free spectral range (FSR) of the WG mode in different values of index m is about 0.15 nm, indicating an eccentricity of 3.2% for the fabricated ChG microspheres.[19]

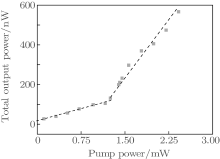

In Fig. 2, we show the total radiation power obtained from the ChG microsphere as a function of the incident pump power. It is apparent that before the incident pump power reaches a critical value of 1.39 mW, the optical radiation generated from the microsphere increases slowly with the pump power at a rate of 1.35× 10− 4. In this process, no laser oscillations are observed. The increasing rate of the radiation power immediately rises to 3.40× 10− 4 once the pump power has increased beyond that critical point. In addition, single-mode laser oscillation starts to appear. According to this observation, we consider the input pump power of 1.39 mW to be the threshold for producing effective laser oscillation in the selected ChG microsphere. This is much lower than the reported 82-mW threshold of the free space coupled active ChG microsphere laser oscillator that has a similar diameter of ∼ 90 μ m.[12] We also note that at the threshold pump power, the emitted laser power is approximately 10 nW. From the emitted laser power of 1 nW at the threshold for the free-space coupled ChG microsphere laser, we find that the efficiency of the fiber taper coupling method is apparently enhanced.

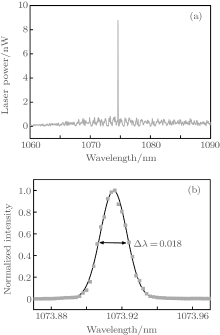

In Fig. 3(a), we show a typical single mode lasing peak obtained from our experimental setup. The pump power is set at a threshold of 1.39 mW. In Fig. 3(b), we show an expanded view of the single mode lasing peak (red dots) and its Gaussian fit (black curve). From the Gaussian fitting, we can estimate the linewidth of this lasing peak to be 0.018 nm and thus one can calculate the total Q-factor of this lasing mode to be ∼ 6× 104. The resolution limit of our OSA is 0.015 nm, which is very close to the linewidth of the laser profile. Therefore, it is likely that the actual profile of this lasing peak is narrower than the experimentally obtained profile. This implies the possibility of a Q-factor higher than the experimentally measured value of 6× 104. To improve the Q-factor of the GGSI microsphere laser, it is important to lower the attenuation of the base material. In our case, we measure an attenuation value of α ≈ 0.0298 mm− 1 with a 2.1-mm thick GGSI slice. This attenuation value determines an intrinsic Q-factor of ∼ 4× 105, which places an upper bound for the total Q-factor of the microsphere.

The output power of the ChG microsphere laser can be further enhanced by increasing the pump power beyond the laser threshold as demonstrated in Fig. 2. However, in this process, the single-mode operation of the microsphere laser becomes multi-mode. Figure 4 shows a typical multi-mode laser profile obtained from our experimental setup. This set of data is collected at a pump power of 1.56 mW. Transitions from single-mode laser oscillations to multi-mode ones are also noticed in microsphere lasers fabricated with other materials and its causes are ascribed to factors such as thermal expansions of the sphere under high pump powers and third order nonlinear effects of the material.[20] In our case, multi-mode laser oscillation is produced by increasing the pump power by approximately 0.2 mW above the pump threshold. We attribute this convenient transition between the single-mode and multi-mode laser oscillations to the index mismatch between the microsphere and the silica fiber taper. The mismatch of refractive indices results in the excitation of WG modes of high radial modes, which starts to lase when the pump power exceeds their thresholds.[21] This index mismatch can be eliminated by using a fiber taper made of the same GGSI material to probe the microsphere. Also, the 808-nm laser diode pump source does not maintain a single mode operation in the experimental process. It is possible that the laser diode excites multiple WG modes with different l indices (angular mode number) in the ChG microsphere, which starts to lase when the pump power reaches its threshold

In this paper we use a novel ChG glass, named GGSI in this work, to fabricate an active microsphere laser oscillator that is operative in the near infrared spectrum. The usage of the GGSI glass can considerably lower the cost and difficulty in producing a ChG microsphere laser oscillator. By using a 1.77-μ m waist diameter silica fiber taper as the coupling mechanism, we demonstrate that high Q-factor laser mode (∼ 6× 104) can be generated from a 75-μ m diameter GGSI microsphere. The threshold pump power is 1.39 mW, which is considerably lower than the threshold of the previously reported free-space coupled ChG microsphere laser.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

|

| 21 |

|