Corresponding author. E-mail: mayq@staff.shu.edu.cn

Project supported by the Natural Science Foundation of Shanghai, China (Grant No.13ZR1415900).

A hybrid natural element method (HNEM) for two-dimensional viscoelasticity problems under the creep condition is proposed. The natural neighbor interpolation is used as the test function, and the discrete equation system of the HNEM for viscoelasticity problems is obtained using the Hellinger–Reissner variational principle. In contrast to the natural element method (NEM), the HNEM can directly obtain the nodal stresses, which have higher precisions than those obtained using the moving least-square (MLS) approximation. Some numerical examples are given to demonstrate the validity and superiority of this HNEM.

The meshless method is a numerical method that is an alternative to the finite element method (FEM). The trial function of the meshless method is constructed from a set of nodes, which allows the meshless method not to generate a mesh, so it will save more preliminary workload than the FEM. It has been given great attention by many researchers since the element-free Galerkin (EFG) method was presented by Belytschko.[1] In addition to the EFG method, [2, 3] there are many other meshless methods, such as the improved element-free Galerkin method, [4– 7] the complex variable meshless method, [8– 10] the complex variable element-free Galerkin (CVEFG) method, [11– 17] the interpolating element-free Galerkin (IEFG) method, [18, 19] the radial basis function (RBF) method, [20] the finite point method (FPM), [21, 22] the meshless local Petrov– Galerkin (MLPG) method, [23] the reproducing kernel particle method (RKPM), [24– 28] the meshless manifold method, [29, 30] the boundary element-free method (BEFM), [31– 40] and the improved boundary element-free method (IBEFM).[41– 44]

The natural element method (NEM) is a meshless method, first presented by Braun and Sambridge; [45] this method has been successfully applied in solid mechanics and fluid mechanics. Sukumar et al.[46] successfully solved partial differential equations of the elliptic type in solid mechanics by using this method. Bueche et al.[47] researched the NEM for elastokinetics problems. Cueto et al.[48] extended the NEM based on the concept of an a -shape and realized a three-dimensional analysis. Matinez et al.[49] applied the NEM in the analysis of fluids. Calvo et al.[50] studied the NEM for large deformation problems. Daneshmand and Niroomandi discussed the vibration modes of fluid-structure systems using the NEM.[51] Daneshmand et al.[52] used the NEM to calculate the two-dimensional flow under sluice gates. Shahrokhabadi et al.[53] used the NEM to analyze seepage problems of underground water. The natural element approximation of the Reissner– Mindlin plate for locking-free numerical analysis of plate-like thin elastic structures was established by Cho et al.[54]

Because the test functions of the NEM are smooth (C∞ )except at the nodes where they are C0, [55– 57] we cannot obtain the nodal stresses. To overcome this disadvantage, we can use the MLS approximation to calculate the nodal stresses by the nodal displacements obtained using the NEM. This method was first used in the FEM by Tabbara et al.[58] Except for this method, the hybrid natural element method (HNEM) can also obtain the nodal stresses, which has been successfully applied in elasticity problems and elastoplasticity problems.[59, 60] The HNEM adopts displacement interpolation and stress interpolation respectively using natural neighbor interpolation, [61, 62] and the corresponding formulae are obtained according to the Hellinger– Reissner variational principle.[63, 64]

Viscoelasticity problems are important nonlinearity problems in material engineering. Viscoelastic materials have the characteristics of both an elastic solid and a viscous fluid, so the stress– strain relationship is difficult to model. Peng and Xu studied the constitutive relationship of permanent deformation in asphalt pavements.[65] The constitutive relationship of viscoelastic materials correlates with time. Thus the effect of time on the material should be considered in the calculation. That the time parameter is important in the process of calculation brings great difficulty in solving the viscoelasticity mechanics problems, so analytical solutions can be obtained for only a few simple viscoelastic problems.[66] The solutions of complex viscoelastic problems in engineering mainly rely on numerical calculations, for which the meshless methods have been widely used. Yang and Liu combined the element-free Galerkin method and a precise algorithm in the time domain to study two-dimensional viscoelasticity problems.[67] Using the meshless local Petrov– Galerkin method, Sladek et al.[68, 69] analyzed anisotropic and linear viscoelastic solids, and discussed quasistatic and transient dynamic problems in two-dimensional linear viscoelastic media. Based on the rigid/viscoplastic element-free Galerkin method, the massive metal forming process was discussed by Guan et al.[70] Canelas and Sensale studied a boundary knot method for harmonic elastic and viscoelastic problems.[71] A complex variable element-free Galerkin method for linear viscoelasticity problems under the creep condition was analyzed by Cheng et al.[72] Three-dimensional viscoelasticity problems were analyzed via the improved element-free Galerkin method by Peng et al.[73]

Based on the natural neighbor interpolation, the HNEM for two-dimensional viscoelasticity problems under the creep condition is presented in this paper. According to the linear viscoelastic Hellinger– Reissner variational principle, the equation system of the viscoelastic hybrid natural element method under the creep condition is established. Finally, the effectiveness and superiority of this method are proved through numerical examples in this paper.

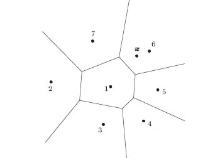

The natural neighbor interpolation (NNI)[61, 62] in the NEM is adopted to construct the shape functions for the HNEM. Consider a bounded domain Ω in two dimensions that is described by a set N of m scattered nodes: N = {N1, N2, . . . , Nm}, m ≥ 3; their coordinates are xi, i = 1, 2, . . . , m. The Voronoi diagram V ( N) of the set N is a subdivision of the domain into regions V ( Ni) , where each region V ( Ni) is associated with a node Ni, such that any point in V ( Ni) is closer to Ni than to any other node Nj ( j ≠ i) . The Voronoi diagram in essence partitions space into closest-point regions. The region V ( Ni) (Voronoi cell) for a node Ni is a polygon

|

where d( xi, xj) is the Euclidean distance between xi and xj.

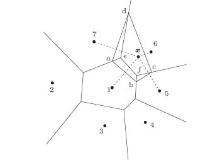

A part of the Voronoi diagram V ( N) is shown in Fig. 1. Suppose x to be any point within the region, the natural neighbor nodes around x are found according to the empty circumcircle criterion of Delaunay.[74] The natural neighbor nodes of x are 1, 5, 6, and 7, as shown in Fig. 2.

After the natural neighbor nodes of x are determined, we can build a local interpolation format as follows:

|

where f( x) is the interpolation physical quantity for node x; i is the serial number of natural neighbor nodes around x; n is the total number of natural neighbor nodes around x; fi is the physical quantity value of node i; and ϕ i( x) is the shape function of node xi. The shape function can be chosen between Sibsonian and non-Sibsonian interpolations.[62]

The Sibsonian interpolation can be written as

|

|

where Aj( x) is the area of overlap of Voronoi cells between node j and x, and A( x) is the area of the Voronoi cell of x. The four regions shown in Fig.2 are the second-order cells, while their union (closed polygon abcd) is the first-order Voronoi cell, and the shape function ϕ 1( x) is given by

|

The derivatives of ϕ i( x) can be obtained by differentiating Eq. (3)

(6) (6) |

For the traditional mechanical problems, we can take Eq. (3) as the displacement interpolation function

|

where ϕ i( x) is the shape function associated with node i, and ui is the displacement of node i.

By definition of the shape function given in Eq. (3), we have the following relations:

|

|

Referring to Fig. 2, if x is to coincide with any node, for instance node 1, then it is readily seen that ϕ 1( x) = 1 and ϕ i( x) = 0, i ≠ 1, i.e.,

|

which implies that the natural neighbor interpolation passes through the node values, and the node unknowns ui are the nodal displacements, which is in contrast to most meshless approximations, where the nodal parameters ui are not the nodal displacements. Thus the essential boundary conditions can be imposed easily by using the natural neighbor interpolation, as in the FEM.

Under the condition of small deformation, the stress tensor

|

where

|

|

The strain tensor

|

where

|

|

The constitutive relationship of linear viscoelastic materials can be written as

|

where J1 ( t) and J2 ( t) are two creep compliances. The J1 ( t) varies for different models. For the case of the Maxwell model,

|

for the case of the Kelvin model,

|

and for the case of the three-parameter model,

|

where G, G1, and G2 are the shear elastic moduli, and η is the viscosity constant of each model. The J2 ( t) is

|

where K is the volumetric modulus of elasticity, and

|

with E being the elasticity modulus, and ν being the Poisson ratio.

Under the creep condition, the stress σ is constant, while the strain ε ( t) and the displacement u ( t) depend on time, as shown in Eq. (17). For the two-dimensional problems, by assuming that the body force

The equilibrium equation can be written as

|

where

|

|

|

The strain– displacement relationship can be written as

|

where

|

|

The stress– strain relationship can be written as

|

and the constitutive matrix C is

|

|

where J1 and K can be obtained from Eqs. (18)– (20) and (22).

The boundary conditions can be written as

|

|

where

|

|

|

and n1 and n2 are the units outward normal to boundary Γ σ , respectively.

Suppose that there are N nodes in problem domain Ω , the displacement and the stress at an arbitrary point x can be expressed as

|

|

where n is the total number of natural neighbor nodes around x, and ϕ i is the interpolation function of displacement u and stress σ , which can be constructed by Eq. (3).

Equations (38) and (39) can be written in matrix form as

|

|

where Φ ( x) and P( x) are matrices of shape functions, q and β are the nodal displacement vector and the nodal stress vector, respectively,

|

|

|

|

|

|

|

|

The properties of linear viscoelastic materials are related to time only and have nothing to do with the loading history. So the stress and the displacement at each point in time can be calculated directly by the Hellinger– Reissner variational principle. At each point in time, the Hellinger– Reissner variational principle can be expressed as

|

where

|

and B is the surplus energy density function

|

where C can be obtained from Eqs. (31) and (32).

Supposing that the displacement boundary condition Eq. (33) is satisfied, and substituting Eqs. (40), (41), and (52) into Eq. (50), we can obtain

|

|

where

|

|

|

|

According to the stationary value condition of the multi-variation variational principle

|

we have

|

Substituting Eq. (60) into Eq. (54) yields

|

where

|

Based on the stationary condition of the variation principle, i.e.,

|

the equations of the HNEM for solving the generalized displacement can be found as follows:

|

We can obtain the nodal displacements at any time by solving Eq. (64), and the nodal stresses can be obtained by substituting the nodal displacements in Eq. (60). Then the displacement and the stress at any point in the domain can be gained using Eqs. (40) and (41). Thus the HNEM for two-dimensional viscoelasticity problems under the creep condition is established.

Four examples are discussed to demonstrate the applicability of the HNEM for two-dimensional linear viscoelasticity problems. The results obtained using the HNEM are compared with the analytical solutions and the ones of the NEM and the FEM. The nodal stresses obtained from the NEM are calculated with the MLS approximation.

The Sibson interpolation is used as the shape function in the numerical examples presented in this section. Delaunay triangles are used as the integration cells, and in each integration cell, three Gauss points are used for the Gaussian quadrature.

A cylinder with uniform pressure p on the inner surface is shown in Fig.3, the outer radius of the cylinder is b = 5 m, and the inner radius is a = 1 m. The inner pressure is p = 30 kPa and the volume deformation is elastic, elasticity modulus E = 1.0 × 106 Pa, Poisson ratio ν = 0.25. For the rheological properties of shear deformation, we respectively adopt the Maxwell model and the Kelvin model, and the parameters are

Regardless of the body force, the cylinder can be studied as a plane strain problem.

In the polar coordinates, the analytical solution of the radial displacement of a Maxwell material is given by[66]

|

where

|

Equation (65) shows that there is a flow phenomenon in the radial displacement of the Maxwell material, so it can be applied only in a short time; otherwise, the deformation is too large, and the solution of elastic displacement based on the small strain is not correct.

In the polar coordinates, the analytical solution of the radial displacement of a Kelvin material is given by[66]

|

where

|

Equation (67) shows that the displacement of the Kelvin material is zero at the loading instant, and it tends to be steady when the time is long enough.

Because of the symmetry, only one quarter of the cylinder needs to be considered in the analysis, as shown in Fig. 4. A total of 11 × 11 nodes are arranged in the domain as shown in Fig. 5.

The radial displacements of nodes at x2 = 0 when t = 30 s using the two models are given in Figs. 6 and 8. The displacements of node (1, 0) depending on time using the two models are shown in Figs. 7 and 9. From Figs. 6– 9, we can see that the results obtained by the HNEM have precision similar with that of the NEM and are in accord with the analytical solution.

A cantilever beam with a distributed load is shown in Figs. 10. The length of the beam is L = 8 m and the width is H = 2 m. The distributed load is q = 30 kPa, and the volume deformation is elastic with E = 1.0× 108 Pa, ν = 0.25. The rheological property of shear deformation satisfies the Kelvin model, and the corresponding parameters are G = 2× 108 Pa and η = 6 × 108 Pa · s. Regardless of the body force, the cantilever beam can be discussed in terms of a plane stress problem.

| Fig. 10. Cantilever beam with a distributed load. |

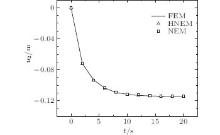

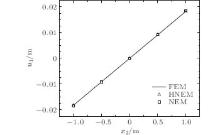

An array of 13 × 5 nodes is distributed on the beam, as shown in Figs. 11. The vertical and the horizontal displacements of the nodes at the left side of the cantilever beam are set as zero when calculated. Under the same nodal distribution, the numerical results obtained using the HNEM and the NEM are shown in Figs. 12– 15.From Figs. 12– 14, we can see that the nodal displacements obtained using the HNEM are in good agreement with those obtained using the NEM and the FEM; while the nodal stresses obtained using the HNEM are more precise than those from the NEM, as shown in Figs. 15.

| Fig. 11. Nodal distribution and Delaunay triangles of the beam. |

| Fig. 12. Vertical displacements of nodes on the neutral axis of the beam when t = 20 s. |

| Fig. 13. Time variation of vertical displacement of point (8, 0). |

| Fig. 14. Horizontal displacements of nodes on the right edge of the beam when t = 20 s. |

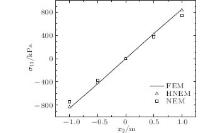

| Fig. 15. Horizontal normal stress at x1 = 2 m when t = 20 s. |

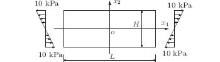

Consider a beam subjected to simple bending, as shown in Figs. 16. The length is L = 10 m and the width is H = 4 m. The volume deformation is elastic and E = 1.0 × 106 Pa, ν = 0.3. The three-parameter model is adopted to describe the rheological property of the shear deformation, and the parameters are G1 = 5.0 × 105 Pa, G2 = 1.0 × 106 Pa, and η = 2.0 × 106 Pa · s. This example is discussed as a plane stress problem without considering the body force.

| Fig. 16. Beam subjected to simple bending. |

By taking advantage of the symmetry of the model, only a quarter of the model is considered in this analysis. At axes of x1 and x2, the horizontal displacements of the nodes are zero, and the vertical displacements of the nodes at the origin are set to zero for the restriction of rigid body displacements. As shown in Figs. 17, 13 × 7 nodes are arranged on a quarter of the model.

| Fig. 17. Nodal distribution and Delaunay triangles in a quarter of the beam. |

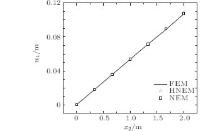

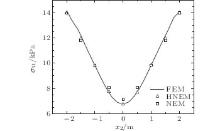

Under the same nodal distribution, the nodal displacements obtained using the HNEM and the NEM are described in Figs. 18– 20, and the nodal stresses are shown in Figs. 21. From Figs. 18– 20, we can see that the nodal displacements obtained using the HNEM are in good agreement with those obtained using the NEM and the FEM. The nodal stresses from the HNEM agree well with those from the FEM, while the precision of the nodal stresses is higher than that from the NEM, as shown in Figs. 21.

| Fig. 18. Vertical displacements of nodes at x2 = 0 when t = 30 s. |

| Fig. 19. Time variation of vertical displacement of node (5, 0). |

| Fig. 20. Horizontal displacements of nodes at x1 = 5 m when t = 30 s. |

| Fig. 21. Horizontal normal stress at x1 = 2.5 m when t = 30 s. |

A plate with a central hole subjected to an axial uniform tension is shown in Figs. 22. The length of the plate is L = 10 m, the width is H = 4 m, and the radius of the hole is R = 1 m. The tensile load is q = 1 kPa, and the volume deformation is elastic with elasticity modulus E = 1.0× 108 Pa, and Poisson ratio ν = 0.25. Using the three-parameter viscoelastic model, the corresponding parameters are G1 = 8.0 × 107 Pa, G2 = 1.0 × 108 Pa, and η = 2.0 × 108 Pa · s. Regardless of the body force, the plate can be discussed as a plane stress problem.

| Fig. 22. Plate with a central hole under an axial uniform tension. |

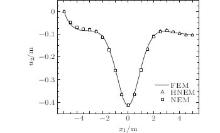

There are 200 nodes distributed on the plate, as shown in Figs. 23. The vertical and the horizontal movements of the nodes at the left side of the plate are restricted in the procedure. The nodes near the hole are numerous so as to improve the calculation precision. The numerical results obtained by the HNEM and the NEM are shown in Figs. 24– 26. From Figs. 24 and 25, we can see that the nodal displacements solved by the HNEM fit well with those from the NEM and the FEM. In Figs. 26, it is shown that the nodal stresses gained by the HNEM are close to those by the FEM and have higher precision than those by the NEM.

| Fig. 23. Nodal distribution and Delaunay triangles of the plate. |

| Fig. 24. Horizontal displacements of the nodes at x2 = 2 m when t = 30 s. |

| Fig. 25. Vertical displacements of nodes at x2 = 2 m when t = 30 s. |

| Fig. 26. Horizontal normal stresses of nodes at x1 = − 2.5 m when t = 30 s. |

In this paper, according to the properties of linear viscoelastic materials, the HNEM for linear viscoelastic materials under the creep condition is presented. The HNEM solves the problem that the nodal stresses cannot be obtained directly by the NEM.

Numerical examples show that the HNEM can obtain precise nodal displacements of linear viscoelastic materials, which illustrates the effectiveness of the method proposed in this paper. Under the same nodal distribution, the HNEM has a precision of nodal displacements similar to that of the NEM, while the precision of nodal stresses using the HNEM is higher than that using the NEM by the MLS approximation, which shows the superiority of this method.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

|

| 21 |

|

| 22 |

|

| 23 |

|

| 24 |

|

| 25 |

|

| 26 |

|

| 27 |

|

| 28 |

|

| 29 |

|

| 30 |

|

| 31 |

|

| 32 |

|

| 33 |

|

| 34 |

|

| 35 |

|

| 36 |

|

| 37 |

|

| 38 |

|

| 39 |

|

| 40 |

|

| 41 |

|

| 42 |

|

| 43 |

|

| 44 |

|

| 45 |

|

| 46 |

|

| 47 |

|

| 48 |

|

| 49 |

|

| 50 |

|

| 51 |

|

| 52 |

|

| 53 |

|

| 54 |

|

| 55 |

|

| 56 |

|

| 57 |

|

| 58 |

|

| 59 |

|

| 60 |

|

| 61 |

|

| 62 |

|

| 63 |

|

| 64 |

|

| 65 |

|

| 66 |

|

| 67 |

|

| 68 |

|

| 69 |

|

| 70 |

|

| 71 |

|

| 72 |

|

| 73 |

|

| 74 |

|