中国物理B ›› 2020, Vol. 29 ›› Issue (11): 116201-.doi: 10.1088/1674-1056/aba2e5

Meng-Jia Su(宿梦嘉)1,2, Qiong Deng(邓琼)1,2,†( ), Min-Rong An(安敏荣)3,‡(

), Min-Rong An(安敏荣)3,‡( ), Lan-Ting Liu(刘兰亭)1,2

), Lan-Ting Liu(刘兰亭)1,2

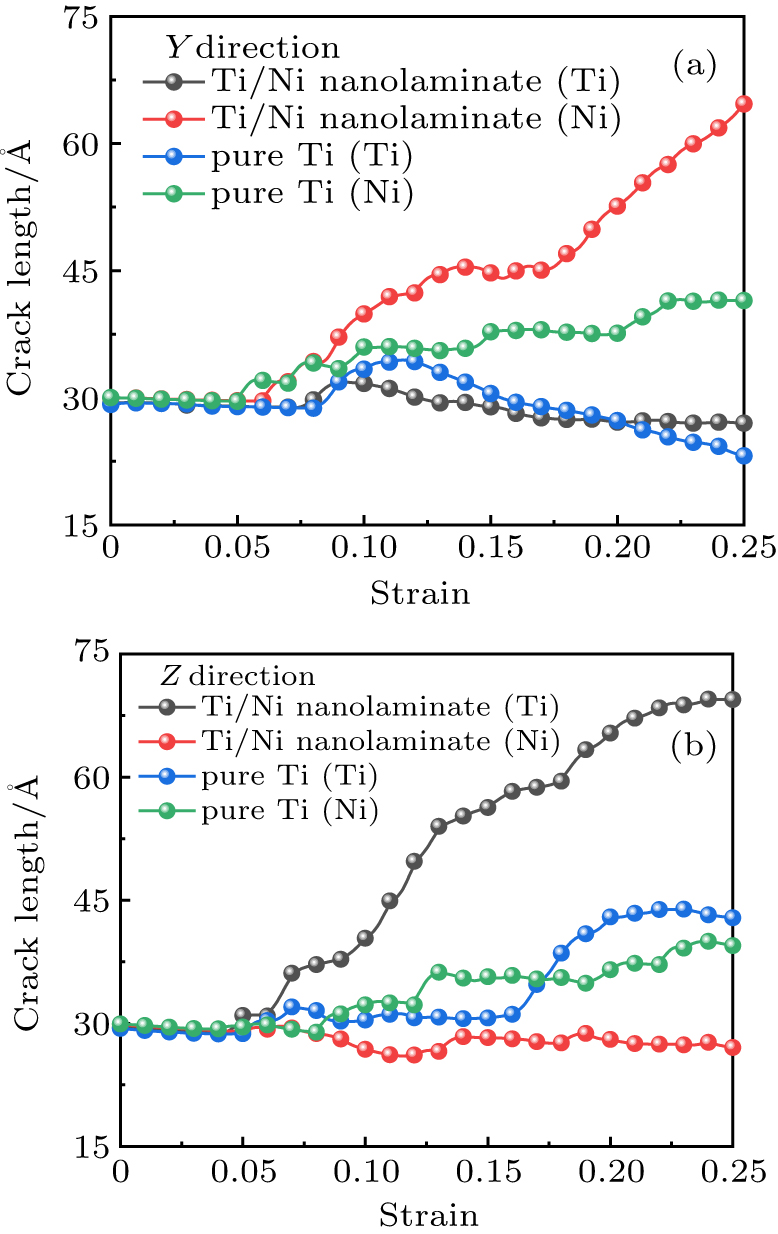

Plastic deformation mechanism transition of Ti/Ni nanolaminate with pre-existing crack: Molecular dynamics study

Meng-Jia Su(宿梦嘉)1, 2, Qiong Deng(邓琼)1, 2, †, Min-Rong An(安敏荣)3,, ‡, and Lan-Ting Liu(刘兰亭)1, 2

- 1 Fundamental Science on Aircraft Structural Mechanics and Strength Laboratory, Northwestern Polytechnical University, Xi’an 710072, China

2 School of Aeronautics, Northwestern Polytechnical University, Xi’an 710072, China

3 College of Materials Science and Engineering, Xi’an Shiyou University, Xi’an 710065, China